Introduction:

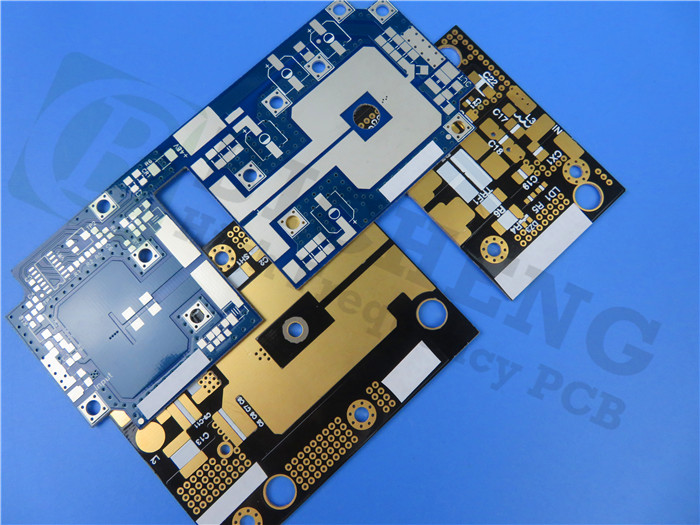

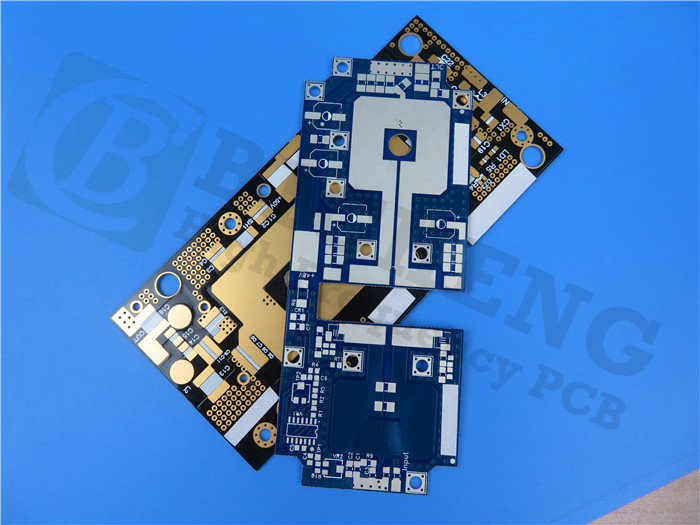

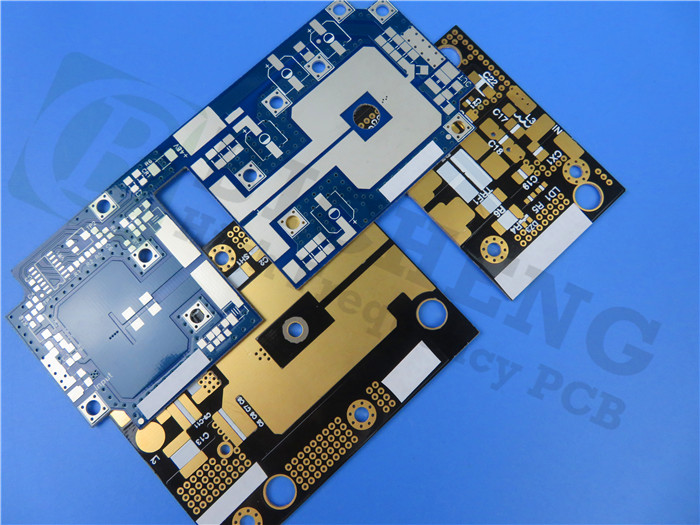

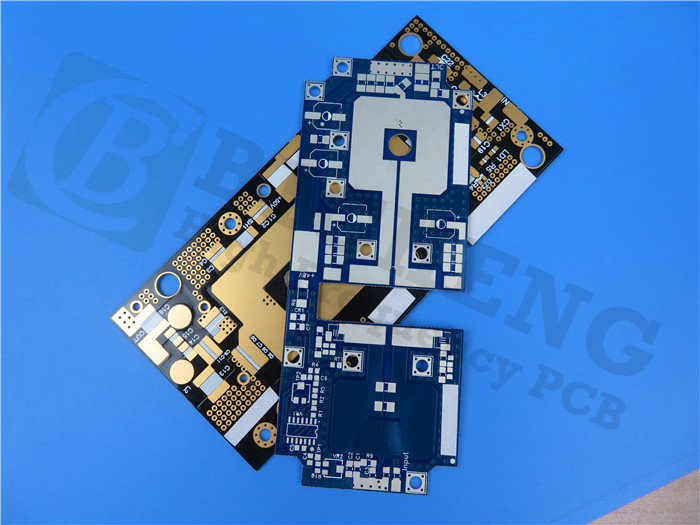

The RF-35 PCB has established itself as a leading solution for high-performance radio frequency (RF) applications. With its exceptional electrical properties and robust construction, the RF-35 high frequency PCB offers a reliable and cost-effective option for various industries. In this article, we will explore the key features, specifications, and advantages of the RF-35 PCB, while also examining its applications and availability.

The Properties of RF-35 Substrate:

The RF-35 3.28mm substrate boasts impressive properties that make it an ideal choice for RF applications. With a dielectric constant of 3.50 at 1.9 GHz and a dissipation factor of 0.0018 at the same frequency, the RF-35 PCB efficiently stores and transmits electrical energy. Its low moisture absorption rate of only 0.02% at .060 inch ensures excellent stability and performance in various environmental conditions.

Stackup:

The PCB has a 2-layer stackup configuration consisting of the following layers:

Copper Layer 1: 70 μm, the first copper layer on the top side.

RF-35 Core: 60mil (1.524 mm), the Taconic RF-35 core material layer.

Prepreg (Bonding ply): FastRise 28, used for bonding the core and the top copper layer.

RF-35 Core: 60mil (1.524 mm), the second layer of the Taconic RF-35 core material.

Copper Layer 2: 70 μm, the second copper layer on the bottom side.

Construction Details:

Board dimensions: 228mm x 189mm with a tolerance of +/- 0.15mm.

Minimum Trace/Space: 4/4 mils, specifying the minimum width and spacing of copper traces.

Minimum Hole Size: 0.5mm, denotes the smallest diameter for drilled holes on the PCB.

No Blind vias: Indicates that all vias are through-hole vias, extending through the entire PCB.

Finished board thickness: 3.3mm, the overall thickness of the completed PCB.

Finished Cu weight: 2oz (2.8 mils) outer layers, specifies the copper weight on the outer layers.

Via plating thickness: 25 μm, the thickness of the copper plating inside the vias.

Surface finish: Immersion Tin, the coating applied to protect the copper surfaces.

Top Silkscreen: White, the color of the silkscreen printing on the top layer.

Bottom Silkscreen: No, indicating no silkscreen printing on the bottom layer.

Top Solder Mask: No, specifying the absence of a solder mask on the top layer.

Bottom Solder Mask: No, indicating the absence of a solder mask on the bottom layer.

100% Electrical test used prior to shipment, ensuring the functionality of the PCB.

PCB Statistics:

Components: 27, the number of individual components mounted on the PCB.

Total Pads: 137, the total number of connection points on the PCB.

Thru Hole Pads: 92, the number of pads for through-hole components.

Top SMT Pads: 45, the number of pads for surface-mount components on the top layer.

Bottom SMT Pads: 0, indicating no surface-mount components on the bottom layer.

Vias: 102, the total number of vias present on the PCB.

Nets: 8, the number of interconnected nets or electrical connections on the PCB.

Type of artwork supplied: Gerber RS-274-X, the industry-standard file format for PCB manufacturing.

Quality standard: IPC-Class-2, indicating the adherence to the IPC (Institute of Printed Circuits) quality standard at Class 2 level. This standard defines the acceptability criteria for PCB manufacturing and assembly.

Availability: The PCB is available worldwide, allowing for global distribution and procurement.

Benefits:

Low Cost: The PCB offers cost-effective solutions for RF applications.

Excellent Peel Strength: The PCB exhibits strong bonding between layers.

Exceptionally Low Dissipation Factor: The material has low energy loss, ideal for RF signals.

Low Moisture Absorption: The PCB material has low moisture absorption properties.

Enhanced Surface Smoothness: The surface of the PCB is smooth, promoting signal integrity.

Indispensable Strength and Reliability:

The RF-35 PCB exhibits remarkable peel strength, surpassing 8.0 lbs./linear inch for 1/2 oz. copper and exceeding 10.0 lbs./linear inch for 1 oz. copper, as measured by IPC-TM 650 2.4.8. This exceptional peel strength guarantees the reliability and durability of the PCB during operation. Furthermore, the material possesses a dielectric breakdown of 41 kV, ensuring its resilience under high-voltage conditions.

Mechanical and Thermal Stability:

The RF-35 PCB demonstrates impressive mechanical and thermal stability. With a flexural strength of over 22,000 psi lengthwise and over 18,000 psi crosswise, as measured by ASTM D 790, it can withstand demanding operating conditions. Tensile strength measurements of 27,000 psi (or 187 N/mm²) lengthwise and 21,000 psi (or 145 N/mm²) crosswise, as per ASTM D 638, further prove its robustness. The dimensional stability of the RF-35 PCB is exceptional, with a lengthwise dimensional stability of 0.00004 in/in and a crosswise dimensional stability of -0.00010 in/in, as measured by IPC-TM 650 2.4.39. These characteristics ensure consistent performance and reliability over time.

Thermal Conductivity and Flame Resistance:

The RF-35 material PCB exhibits a thermal conductivity of 0.24 W/m/K, as measured by ASTM F 433, allowing for efficient dissipation of heat generated during operation. Additionally, the material's high glass transition temperature (Tg) of over 315°C ensures stability and reliability even at elevated temperatures. The RF-35 PCB is rated V-0 for flammability, meeting the stringent UL-94 standard, thus providing added safety and peace of mind.

Dependable Electrical and Physical Performance:

With an X-Y coefficient of thermal expansion (CTE) ranging between 19-24 ppm/°C and a Z CTE of 64 ppm/°C, as measured by ASTM D 3386 (TMA), the RF-35 PCB maintains its electrical and physical integrity under varying temperature conditions. The material's hardness of 34% on the Rockwell M scale further enhances its durability and resistance to wear and tear.

Applications and Availability:

The RF-35 PCB finds applications in a wide range of industries, including telecommunications, aerospace, automotive, and consumer electronics. It is particularly suited for power amplifiers, filters, and circuits requiring customized RF designs. With its exceptional performance and cost-effectiveness, the RF-35 PCB is readily available worldwide, ensuring easy access and procurement for companies and individuals seeking high-quality PCB solutions.

Conclusion:

The RF-35 PCB, characterized by its exceptional electrical properties, mechanical strength, and thermal stability, represents a reliable and cost-effective choice for RF applications. Its exceptional peel strength, low moisture absorption, and high thermal conductivity contribute to its reliability and longevity. With its wide range of applications and global availability, the RF-35 circuit board is poised to unlock new possibilities in the realm of high-performance RF designs. For more information or inquiries, contact our sales team at sales20@bichengpcb.com and embark on a journey of innovation with the RF-35 PCB.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com