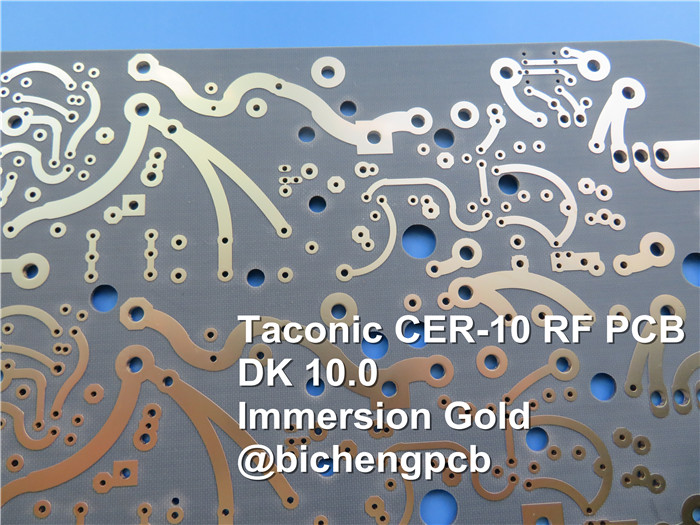

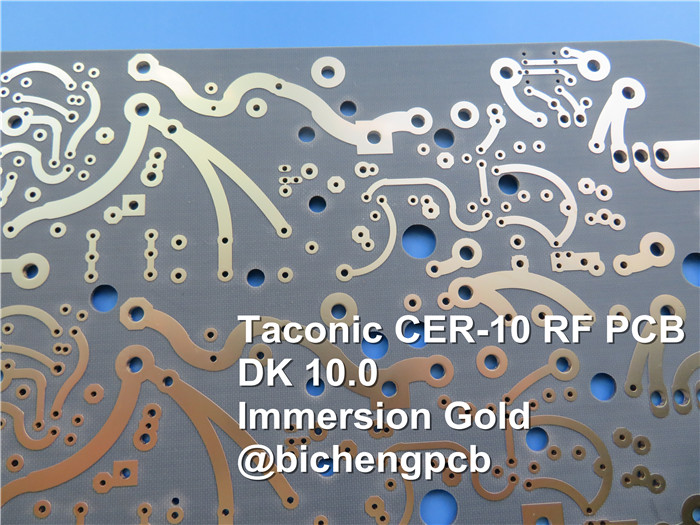

CER-10 PCB: Unleashing the Power of Ceramic Fill Technology

In the ever-evolving world of electronics, PCBs play a crucial role in enabling the functionality of countless electronic devices. To meet the demands of modern technology, Taconic has developed the CER-10 printed circuit board, a revolutionary laminate that showcases their expertise in ceramic fill technology and coated PTFE fiberglass. With exceptional interlaminar bond strength, solder resistance, and consistent electrical properties, the CER-10high frequencyPCB sets a new standard for reliability and performance. In this comprehensive product blog, we will delve into the features, benefits, construction details, statistics, and typical applications of the CER-10 PCB, empowering you with the knowledge to make informed decisions for your electronic projects.

Unraveling the Features of CER-10 PCB

The CER-10 PCB comes equipped with a range of exceptional features, ensuring optimal performance and reliability in various applications. Let's explore these features in detail:

1.1 Dielectric Constant and Dissipation Factor:

With a dielectric constant of 10 +/- 0.05 and a dissipation factor of 0.0035 at 10 GHz/23°C, the CER-10 PCB ensures stable signal propagation and minimal signal loss. This feature is particularly essential for high-frequency applications where maintaining signal integrity is paramount.

1.2 Thermal Conductivity:

The CER-10 PCB boasts a thermal conductivity of 0.63 W/mK, making it an ideal choice for applications that require efficient heat dissipation. By effectively managing thermal issues, the CER-10 PCB promotes the longevity and reliability of electronic devices, especially in demanding thermal environments.

1.3 Moisture Absorption:

With a moisture absorption rate of just 0.02%, the CER-10 PCB exhibits minimal moisture absorption properties. This characteristic ensures consistent electrical performance, even in humid conditions, thus enhancing the overall reliability and lifespan of the PCB.

1.4 Coefficient of Thermal Expansion (CTE):

The CER-10 PCB features a low CTE of 46 ppm/°C in the Z-axis direction (-55 to 288 °C). This means that the PCB experiences minimal expansion or contraction when subjected to extreme temperature changes, guaranteeing reliable plated-through-hole performance even in challenging thermal environments.

Unveiling the Benefits of CER-10 PCB

The CER-10 25mil material PCB offers a host of benefits that make it a standout choice for electronic designers and manufacturers. Let's explore these advantages:

2.1 Exceptional Interlaminar Bond:

Thanks to its proprietary composition and woven glass reinforcement, the CER-10 PCB exhibits outstanding interlaminar bond strength. This ensures the integrity and durability of the PCB, even under harsh operating conditions.

2.2 Low Moisture Absorption:

The minimal moisture absorption of the CER-10 PCB ensures consistent electrical properties and reliable performance over time. By reducing the impact of moisture, the PCB maintains its functionality and prevents degradation or failure due to environmental factors.

2.3 Enhanced Dimensional Stability:

The woven glass reinforcement in the CER-10 PCB contributes to excellent dimensional stability. This means that the PCB retains its shape and form, even when subjected to mechanical stress or fluctuations in temperature, ensuring reliable performance throughout its lifespan.

2.4 Low Z-Axis Expansion:

The CER-10 PCB exhibits low Z-axis expansion with a CTE of 46 ppm/°C. This characteristic is particularly crucial for applications that involve drastic temperature changes. By minimizing expansion or contraction, the CER-10 PCB maintains the integrity of the circuitry, preventing issues such as delamination or solder joint failure.

2.5 Stable DK over Frequency:

The CER-10 PCB offers stable dielectric constant (DK) over a wide frequency range. This feature is vital for applications that require consistent impedance matching and signal integrity across different frequencies, ensuring reliable and accurate data transmission.

2.6 Circuit Miniaturization:

The exceptional properties of the CER-10 PCB make it an excellent choice for circuit miniaturization. By providing reliable electrical performance in a compact form factor, the CER-10 PCB enables the creation of smaller and more efficient electronic devices.

2.7 Increased Flexural Strength:

The woven glass reinforcement in the CER-10 PCB contributes to enhanced flexural strength. This allows the PCB to withstand mechanical stresses and vibrations, making it suitable for applications that require durability and resilience.

Unmasking the PCB Construction Details

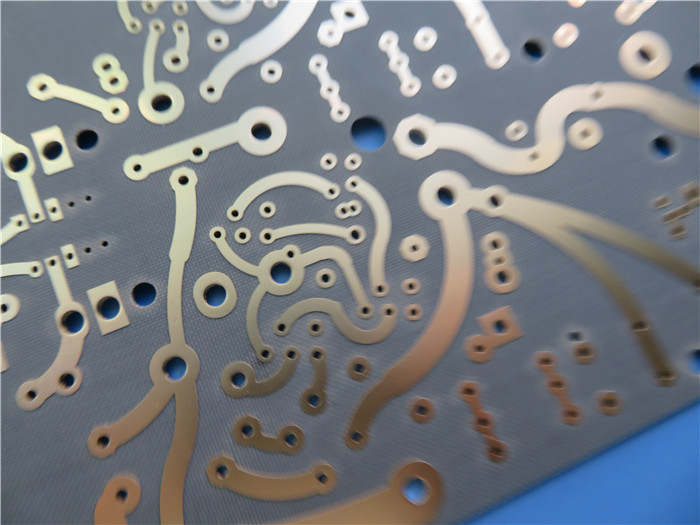

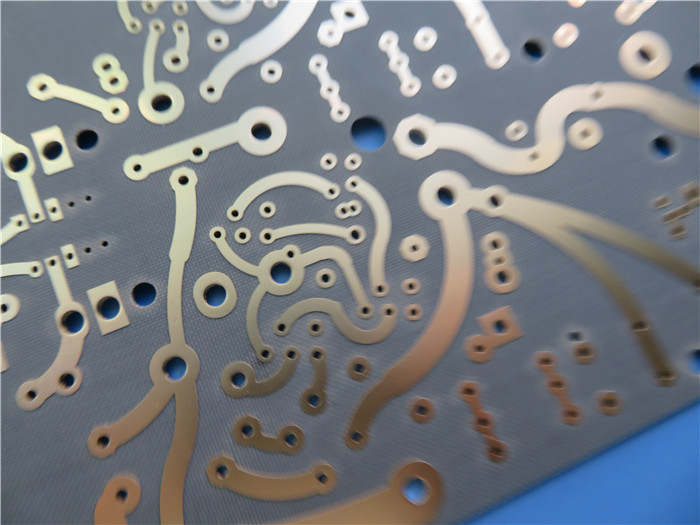

The CER-1025milPCB is a 2-layer rigid PCB constructed with precision and attention to detail. Let's explore the construction details of the CER-10 PCB:

3.1 Board Dimensions:

The CER-10 PCB is available in a standard size of 95mm x 89mm, providing ample space for designing and integrating electronic components.

3.2 Minimum Trace/Space and Hole Size:

The CER-10 PCB supports a minimum trace/space of 4/6 mils, enabling intricate and compact circuit designs. The minimum hole size supported is 0.3mm, allowing for precise placement of components and efficient routing.

Stackup:

The CER-10 PCB features a 2-layer stackup. It consists of a copper layer of 35 μm on the top and bottom, sandwiching the 25mil 0.635mm CER-10 substrate.

Finished Board Thickness and Copper Weight:

The finished board thickness of the CER-10 PCB is 0.8mm, providing a balance between durability and flexibility. The outer layers have a copper weight of 1 oz (1.4 mils), ensuring optimal conductivity and signal integrity.

Via Plating Thickness and Surface Finish:

The vias on the CER-10 PCB have a plating thickness of 20 μm, ensuring reliable electrical connections between layers. The surface finish of the PCB is Immersion Gold, which offers excellent solderability and corrosion resistance.

Silkscreen and Solder Mask:

The CER-10 PCB features a top silkscreen in black, allowing for clear labeling and component identification. It does not have a bottom silkscreen. The PCB does not have a top or bottom solder mask, which provides flexibility for specific applications or customization requirements.

Electrical Testing:

Before shipment, each CER-10 0.635mm laminate PCB undergoes a thorough 100% electrical test to ensure that all connections and circuits are functioning correctly. This stringent testing process guarantees the reliability and performance of the PCB.

Unveiling the Statistics of the CER-10 PCB

To provide a comprehensive overview, let's explore the statistics of the CER-10 PCB:

Components: The CER-10 PCB supports up to 24 components, allowing for complex and versatile circuit designs.

Total Pads: The PCB has a total of 70 pads, providing ample connectivity options for components and interconnections.

Thru Hole Pads: The CER-10 PCB features 42 thru-hole pads, enabling the use of traditional components or connectors.

Top SMT Pads: The PCB offers 28 top surface-mount technology (SMT) pads, facilitating the use of smaller and more compact surface-mount components.

Bottom SMT Pads: The CER-10 PCB does not have any bottom SMT pads, making it suitable for single-sided applications or designs that require components only on one side.

Vias: The PCB features 47 vias, allowing for efficient interconnection between different layers of the PCB.

Nets: The CER-10 PCB supports 3 nets, providing flexibility for various circuit design requirements.

The CER-10 PCB: A Worldwide Solution

The CER-10 PCB is readily available worldwide, catering to the needs of electronic designers and manufacturers across the globe. With its exceptional properties and reliable performance, the CER-10 PCB is an ideal choice for a wide range of applications.

Exploring Typical Applications

The Taconic CER-10 25mil substrate PCB finds its application in various electronic devices and systems. Here are some typical applications that leverage the capabilities of the CER-10 PCB:

Power Amplifiers: The CER-10 PCB's stable electrical properties and enhanced dimensional stability make it an excellent choice for power amplifiers, ensuring reliable and efficient amplification of signals.

Filters and Couplers: The CER-10 PCB's low Z-axis expansion and consistent electrical properties make it well-suited for filters and couplers, enabling precise signal filtering and coupling in communication systems.

Passive Components: The CER-10 PCB's exceptional interlaminar bond strength and increased flexural strength make it an ideal substrate for passive components such as resistors, capacitors, and inductors, ensuring their reliable integration and performance.

Conclusion

With its woven glass reinforcement, exceptional interlaminar bond strength, low moisture absorption, and enhanced dimensional stability, the CER-10 25mil PCB represents a significant advancement in PCB technology. Its outstanding electrical properties, low Z-axis expansion, and increased flexural strength make it a reliable and versatile choice for various applications. Whether it's power amplifiers, filters and couplers, or passive component integration, the Taconic CER-10 PCB delivers exceptional performance and reliability. With its availability worldwide, the CER-10 high frequency PCB empowers electronic designers and manufacturers to bring their innovative ideas to life. Experience the power of ceramic fill technology with the CER-10 PCB and unlock new possibilities in the world of electronics.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com