Do you know more about Rogers TMM Series PCB?

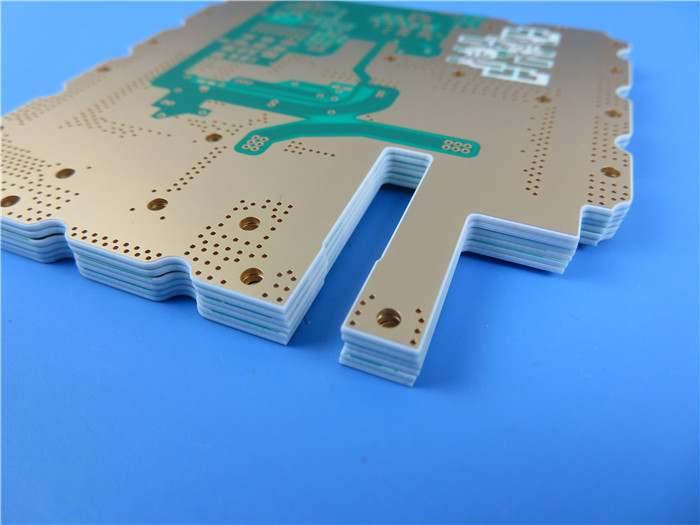

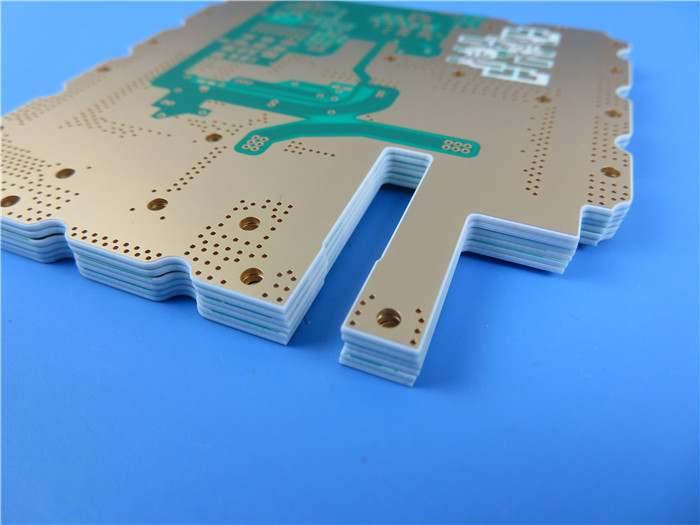

Rogers TMM thermoset microwave materials are hydrocarbon ceramics and thermoset polymers composites specifically designed for strip-line and microstrip applications. TMM comes in various claddings and dielectric constants. TMM laminates feature some mechanical and electrical properties that make them ideal for several applications.

TMM has an excellent thermal expansion coefficient, low dielectric constant (Dk) thermal change rate, and consistent dielectric constant. TMM can offer greater specifications of copper coating. These laminates feature the properties of both PTFE microwave circuit laminates and ceramic without needing the production techniques used for these materials.

Like other laminates that need sodium napthanate treatment before undergoing electroless plating, TMM is unique as it doesn’t require such treatment. One of the most amazing properties of TMM laminates is their extremely low thermal coefficient of Dk, which is usually lower than 30 ppm/°C.

Advantages of Rogers TMM

Rogers TMM laminates are high-grade microwave materials with great electrical and mechanical properties. These materials combine the benefits of both PTFE microwave circuits and ceramic laminates.

Exceptional mechanical properties: Rogers TMM laminates resist cold and creep flow which makes them mechanically reliable and stable.

Resistant to chemical reagent: Rogers TMM laminates resist chemical reagents which help to ensure that there is no damage during the placement and production process. These microwave materials maintain their original properties after they have been exposed to chemical reagents for a specific time.

Thermosetting resin: Rogers TMM laminates are thermosetting resin that ensures good wire bonding. These materials can withstand any type of temperature, even high heat.

Moisture absorption: These laminates can survive in a humid environment. Rogers TMM can absorb moisture from its environment; hence, it is a good material for an environment with high levels of humidity.

The electrical and mechanical properties of TMM10 laminates combine many of the benefits of both ceramic and traditional PTFE microwave circuit laminates, without requiring the specialized production techniques common to these materials.

TMM10 laminates have an exceptionally low thermal coefficient of dielectric constant, typically less than 30 ppm/°C. The material’s isotropic coefficients of thermal expansion, very closely matched to copper, allow for production of high reliability plated through holes, and low etch shrinkage values. Furthermore, the thermal conductivity of TMM10 laminates is approximately twice that of traditional PTFE/ceramic laminates, facilitating heat removal.

Bicheng devote to supplying PCBs over 18 years with stable and strict quality gurantee, which service cellular base station antenna, satellite, high frequency passive components, microstrip line and band line circuit, millimeter wave equipment, radar system, digital radio frequency antenna and other fields wordwide. We are mainly providing high frequency PCBs which built on 3 high frequency material brands: Rogers Corporation, Taconic and Wangling. Dielectric constant ranges from 2.2 to 10.2 etc.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com