How Does Megtron 6 M6 Material Solve Signal Loss Challenges in High-Frequency PCBs?

In the race for higher data speeds and greater bandwidth, signal loss is the ultimate enemy. As frequencies climb into the gigahertz range—common in 5G, radar, and high-speed computing—traditional PCB materials like FR-4 become a significant bottleneck. They absorb and degrade signals, leading to data errors, reduced range, and compromised system performance.

Panasonic Megtron 6 M6 laminate is engineered specifically to combat this enemy. It solves signal loss challenges through a fundamental improvement in its core material properties, primarily by minimizing Dielectric Loss and ensuring Impedance Stability. Let's break down the science behind it.

1. Taming the Primary Culprit: Ultra-Low Dielectric Loss (Df)

The most significant source of signal loss at high frequencies is not the conductor but the insulating substrate itself, a phenomenon known as Dielectric Loss.

The Problem with FR-4: Standard FR-4 has a Dissipation Factor (Df) in the range of 0.020 at 1 GHz. Think of Df as a measure of how much electrical energy the substrate converts into wasted heat. A higher Df means the material "absorbs" more of your signal, attenuating it as it travels along the trace.

The Megtron 6 Solution:Megtron 6 M6 boasts an exceptionally low Df of 0.002 at 1GHz and a still-impressive 0.0037 at 13GHz. This is an order-of-magnitude improvement.

Analogy: If FR-4 is a rough, muddy path that saps a runner's energy, Megtron 6 is a smooth, high-tech track. The signal experiences far less resistance from the substrate, allowing it to travel farther and with greater integrity.

Result: This directly translates to lower insertion loss, enabling longer trace lengths, higher data rates (crucial for 400G/800G optics), and more powerful signals in applications like 77GHz automotive radar.

2. Ensuring Predictable Performance: Stable Dielectric Constant (Dk)

The Dielectric Constant (Dk) is a measure of how much the insulating material slows down the electrical signal and affects its impedance. An unstable Dk is a silent killer of signal integrity.

The Problem with Inconsistent Materials: In many materials, the Dk can vary with frequency, temperature, or even the manufacturing lot. This variability makes it incredibly difficult for engineers to design precise impedance-controlled lines (like the 50-ohm traces in our 12-layer PCB). An unexpected shift in Dk during operation can detune your circuit, cause impedance mismatches, and lead to signal reflections.

The Megtron 6 Solution: Megtron 6 high speed PCB offers a stable and predictable Dk of ~3.34 at 13GHz, with minimal change over a wide frequency range. This stability is engineered into the material's composition.

Result: Design engineers can model their high-speed circuits with extreme confidence. The impedance calculated in the simulation (e.g., the 4.31mil trace for a 50-ohm line on L3) will be the impedance fabricated on the actual board. This eliminates guesswork, reduces design iterations, and guarantees that eye diagrams remain open and well-defined.

3. The Combined Effect: Enhanced Signal Integrity and System Bandwidth

The combination of a low Df and a stable Dk is what truly sets Megtron 6 apart. It's not just about losing less signal; it's about preserving the signal's quality.

Lower Attenuation: The low Df directly reduces the amount of signal amplitude lost per unit length.

Minimized Dispersion: The stable Dk ensures that different frequency components of a complex digital signal travel at the same speed. This prevents the "smearing" or spreading out of the signal pulse, which is critical for maintaining the shape of high-speed digital waveforms.

4. Supporting Factors: Thermal and Dimensional Stability

While not directly electrical, Megtron 6's thermal properties play a crucial supporting role in combating long-term performance degradation.

High Tg and Td: With a Glass Transition Temperature (Tg) >185°C and a Thermal Decomposition Temperature (Td) of 410°C, Megtron 6 can withstand the high temperatures of multiple lead-free soldering cycles without breaking down.

Why this matters: If a material degrades thermally during assembly, its Dk and Df can permanently change, altering the performance of the finished PCB from the design intent. Megtron 6's robustness ensures the electrical properties you designed for are the ones you get after manufacturing.

Low CTE: Its controlled Coefficient of Thermal Expansion (16/16/45 ppm/°C) prevents excessive warping or delamination under thermal stress. This maintains the physical geometry of the impedance-controlled traces, which is essential for their consistent electrical performance.

Conclusion: A Material Engineered for the Gigahertz Era

In summary, Megtron 6 M6 solves high-frequency signal loss challenges by providing an ultra-low-loss dielectric "foundation" that is both stable and predictable. It directly attacks the primary sources of loss—dielectric absorption and impedance variation—that plague conventional materials.

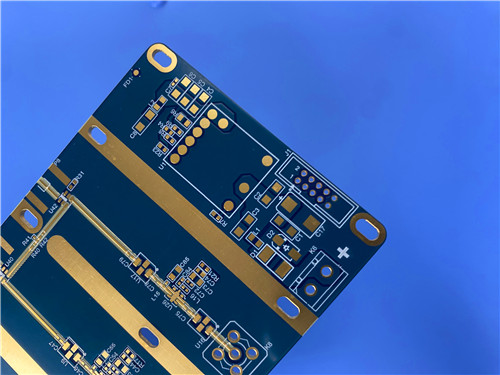

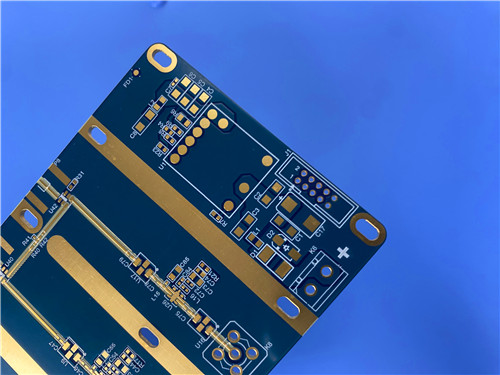

By choosing a PCB built with Megtron 6, like the 12-Layer Megtron6-M6 High Speed 2.0mm Thick PCB, you are not just selecting a component; you are choosing a guaranteed level of signal fidelity. This allows your designs to achieve the performance boundaries required for the next generation of 5G infrastructure, autonomous vehicles, and high-performance computing systems.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com