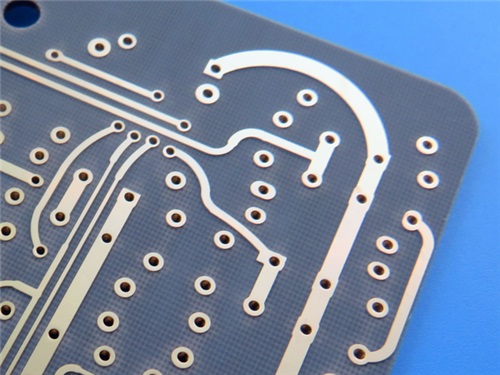

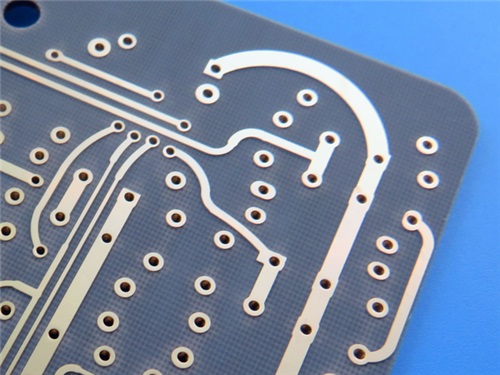

What Are the Key Advantages of Using F4BM220 Laminate for High-Frequency 2-Layer PCBs?

For engineers designing high-frequency circuits, selecting the right PCB substrate is a critical decision that directly impacts performance, reliability, and cost. When it comes to 2-layer boards for RF, microwave, and fast digital applications, F4BM220 laminate emerges as a superior choice over standard FR-4 and even other PTFE-based materials. Its advantages are rooted in a unique formulation that balances electrical performance, mechanical stability, and manufacturability.

Here are the key advantages of using F4BM220 substrate for yourhigh-frequency 2-layer PCBs:

1. Exceptionally Low Signal Loss at High Frequencies

The primary advantage of Wangling F4BM220 is its outstanding electrical performance in the GHz range.

Ultra-Low Dissipation Factor (Df): At 10 GHz, its Df is a mere 0.001. This is an order of magnitude lower than standard FR-4, resulting in significantly reduced dielectric signal loss. For 2-layer PCBs, where trace lengths are direct and signal integrity is paramount, this minimizes attenuation, preserves signal strength, and improves the overall efficiency of power amplifiers, filters, and transmission lines.

Stable, Low Dielectric Constant (Dk): With a Dk of 2.2±0.04 at 10 GHz, F4B DK2.2 allows for precise and predictable impedance control (e.g., 50Ωtransmission lines). Its remarkably low thermal coefficient of Dk (-142 ppm/°C) ensures this impedance remains stable across a wide operational temperature range (-55°C to 150°C), preventing performance drift in varying environments.

2. Enhanced Mechanical and Dimensional Stability

High-frequency circuits are often sensitive to physical deformation, which can alter electrical lengths and performance.

Matched, Low CTE: F4BM220 offers a low and well-matched Coefficient of Thermal Expansion in the X and Y axes (25 and 34 ppm/°C). This closely matches the CTE of copper, reducing stress on plated through-holes (vias) and solder joints during thermal cycling. For a 2-layer board, this translates to exceptional long-term reliability, especially in applications subject to temperature fluctuations like outdoor antennas or automotive radar.

Minimal Moisture Absorption: With water absorption of≤0.08%, F4BM220 is highly resistant to humidity. This prevents the common issue of Dk and Df values shifting in humid environments, ensuring consistent performance from factory to field deployment.

3. Optimal Balance for Thin-Core, High-Performance Builds

The 0.5mm core thickness specification is particularly well-suited to F4BM220.

Stiffness in Thin Profiles: The material's composition provides excellent rigidity even in thin cores, preventing board flex that could damage components or affect performance. This makes it ideal for compact, lightweight modules common in modern aerospace, portable communications, and phased array systems.

Controlled Impedance in Simple Stackups: For 2-layer designs, achieving precise controlled impedance can be challenging. The stable Dk of F4BM220, combined with a well-defined thin core, allows designers to calculate and achieve target impedance (e.g., microstrip lines) with high confidence and reproducibility.

4. Superior Thermal Performance and Reliability

High Decomposition Temperature: The PTFE-based material can withstand temperatures up to 288°C, ensuring it remains stable during assembly processes like soldering and rework.

V0 Flammability Rating: It meets the UL-94 V0 standard, a critical requirement for many commercial and aerospace applications, enhancing the safety and compliance of the final product.

5. Cost-Effective Performance for Non-Critical PIM Applications

Within the family of high-performance PTFE laminates, F4BM220 offers a strategic advantage:

It uses Electrodeposited (ED) copper foil, which is more cost-effective than specialized foils. While its companion material F4BME220 (with RTF foil) is necessary for ultra-low Passive Intermodulation (PIM) applications like sensitive receiver front-ends, F4BM220 is the optimal, cost-efficient choice for the vast majority of high-frequency applications where PIM is not the primary concern, such as power amplifiers, filters, and many antenna elements.

Conclusion: The Ideal Foundation for Demanding 2-Layer Designs

In summary, choosing F4BM220 high frequency laminate for a 2-layer PCB provides a compelling trifecta of low electrical loss, outstanding mechanical stability, and practical manufacturability. It elevates the performance ceiling of double-sided boards, enabling them to function reliably in demanding high-frequency scenarios where FR-4 would fail. By ensuring signal integrity, impedance stability, and rugged reliability in a thin-profile format, F4BM220 DK2.2 F4B PTFE PCB allows engineers to push the boundaries of RF and microwave design without moving to more complex and costly multilayer architectures. For applications ranging from satellite communications and radar to base station antennas and test equipment, it represents a foundational material choice that guarantees performance from the substrate up.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com