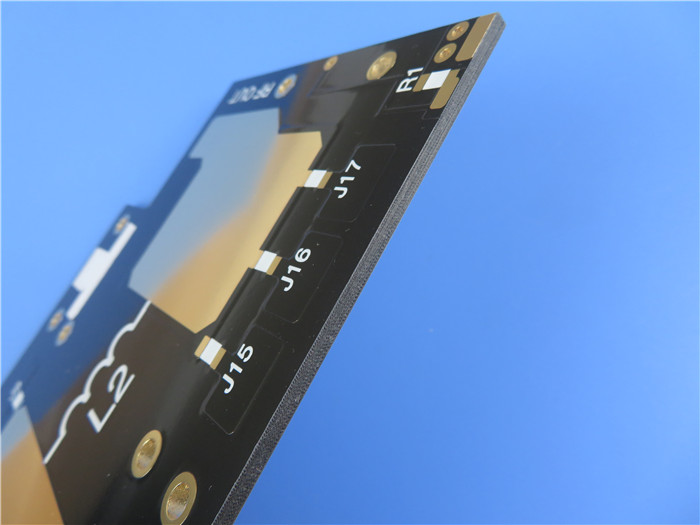

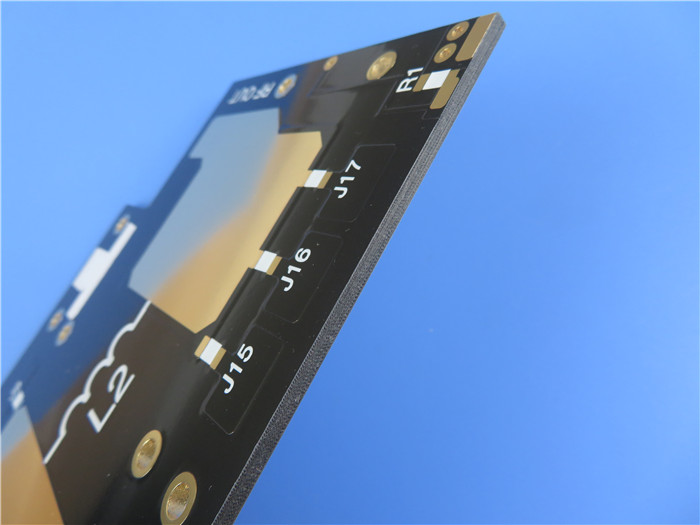

Teflon PTFE PCB

High-frequency PCBs using polytetrafluoroethylene (PTFE) as their PCB substrate are known as

Teflon PCBs or

PTFE PCBs. Teflon PCBs transmit signals at frequencies up to 5 GHz. Dupont Corporation markets its

PTFE materials under the Teflon brand name, which is so well-known that people often refer to PTFE substrate PCBs used in microwave and RF applications as Teflon PCBs.

Properties of Teflon PCB

|

Name

|

Test condition

|

Unit

|

Value

|

|

Density

|

Normal state

|

g/ cm3

|

2.1~2.35

|

|

Moisture

Absorption

|

Dip in the distilled

water of 20±2℃ for 24

hours

|

%

|

≤0.02

|

|

Operating

Temperature

|

High-low temperature

chamber

|

℃

|

-50℃~+260℃

|

|

Thermal

Conductivity

|

|

W/m/k

|

0.8

|

|

CTE (typical)

|

0~100℃ (εr :2.1~2.3)

|

ppm/℃

|

25(x)

|

|

34(y)

|

|

252(z)

|

|

CTE (typical)

|

0~100℃ (εr :2.3~2.9)

|

ppm/℃

|

14(x)

|

|

21(y)

|

|

173(z)

|

|

CTE (typical)

|

0~100℃ (εr :2.9~3.5)

|

ppm/℃

|

12(x)

|

|

15(y)

|

|

95(z)

|

|

Shrinkage

Factor

|

2 hours in boiling

water

|

%

|

0.0002

|

|

Surface Resistivity

|

500V DC

|

Normal state

|

M·Ω

|

≥1×104

|

|

Constant

humidity and temperature

|

≥1×103

|

|

Volume Resistivity

|

Normal state

|

MΩ.cm

|

≥1×106

|

|

Constant

humidity and temperature

|

≥1×105

|

|

Pin Resistance

|

500V DC

|

Normal state

|

MΩ

|

≥1×105

|

|

Constant humidity and temperature

|

≥1×103

|

|

Surface dielectric strength

|

Normal state

|

d=1mm(Kv/mm)

|

≥1.2

|

|

Constant

humidity and temperature

|

≥1.1

|

|

Dielectric Constant

|

10GHZ

|

εr

|

2.20,2.55,2.65,3.0,3.5 (±2%)

|

|

Dissipation Factor

|

10GHZ

|

tgδ

|

2.2

|

≤7×10-4

|

|

2.55~2.65

|

≤1×10-3

|

|

3.0~3.5

|

≤1.5×10-3

|

Excellent mechanical, thermal, and electrical qualities can be found in Teflon PCB boards. Applications requiring high frequency and high temperature use this board. The characteristics of this printed circuit board are listed below:

Great chemical resistance: This substance can survive chemical exposure. Its original qualities are unaffected by exposure to chemicals, oils, and grease. PTFE boards can be used in a setting with chemical reagents.

Low temperature resistance: Teflon PCB material has excellent mechanical durability. It can sustain a 5 percent elongation even when the temperature drops to -196 degrees Celsius.

Weather resistance: One of this material's best qualities is this. Any weather may be handled by Teflon PCB. They are strong and dependable as a result.

Low dissipation factor: Teflon PCB board has a low dissipation factor, which contributes to its effectiveness as an insulator. High-quality and effective electronic systems are best suited for this material. For uses like radar and radio frequency, it is perfect.

Non-stick: This substance is both non-stick and non-adhesive. Every carbon atom has a fluorine atom bonded, making up the compound known as PTFE. This substance is inert due to its tight bonding.

Low water absorption: PTFE PCBs can be used in humid environments since they feature low water absorption. This means that this board can withstand moisture.

Exceptional electrical properties: Low dielectric loss and high frequency dielectric constant are two properties of PCB Teflon. High breakdown voltage and volume resistivity are features of this material. It has a dielectric constant of 2.0.

The cost of Teflon PCBs

Teflon PCBs are the most expensive when compared to FR4 and metal substrate PCBs, and PTFE laminates account for the majority of the cost of Teflon PCBs. Additionally, commercial Teflon PCBs are more expensive than Teflon PCBs of military grade (so RT5000 and RT6000 series Teflon PCBs are more expensive than RO3000 series Teflon PCBs).

There are no set market prices for Teflon PCBs. Because individual Teflon PCBs have varied specifications and because different PCB manufacturers provide different PTFE PCB pricing, among other factors, PTFE laminates do not have fixed prices from high-frequency laminate vendors. All PTFE laminates are pricey, and some laminates, like the Rogers RT7000 series used in military radar systems, are hard to find. And Teflon PCB manufacturers in North America and Western Europe are much higher than those in China.

Concerning the laminate cost of FR4, PPO and Teflon, FR4 is the cheapest one, while Teflon is the most expensive one. In terms of DK, DF, water absorption and frequency feature, Teflon is the best. When product applications require frequency above 10GHz, only can we choose Teflon PCB substrate to manufacture. The performance of Teflon is far better than other substrates, However, the Teflon substrate has the disadvantage of high cost and large heat-resisting property. To improve PTFE stiffness and heat-resisting property function, a large number of SiO2 or fiber glass as the filling material. On the other hand, due to molecule inertia of PTFE material, which it is not easy to combine with copper foil, thus, it needs to do the special surface treatment on the combination side. Concerning combination surface treatment, normally use chemical etching on PTFE surface or plasma etching to plus surface roughness or add one adhesive film between PTFE and copper foil, but these may influence dielectric performance.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com