RT/duroid 6002 High Frequency PCB

Overview

In this article, we will discuss the high frequency PCB created using RT/duroid 6002 material.

Rogers RT/duroid 6002 material is a preferred choice for PTFE-based ceramic composites. It is a low loss and low dielectric constant laminate that meets the rigorous requirements for mechanical reliability and electrical stability in complex microwave structural designs.

The dielectric constant of RT/duroid 6002 remains stable across temperatures ranging from -55 ℃ to 150 ℃, making it suitable for filters, oscillators, and delay lines that require electrical stability.

Properties of RT/duroid 6002

RT/duroid 6002 showcases impressive characteristics that make it ideal for demanding applications. Let's explore some key features.

Let's begin by discussing the Dielectric Constant of RT/duroid 6002 substrate. It maintains a reliable signal transmission with a process value of 2.94±0.04 at 10 GHz and 23°C. The Dielectric Constant remains consistent at 2.94 throughout the design phase, covering a frequency range of 8 GHz to 40 GHz, as determined by the Differential Phase Length Method.

The Dissipation Factor, or tan delta, is remarkably low at 0.0012 at 10 GHz and 23°C, indicating minimal signal loss and excellent performance.

RT/duroid 6002 also exhibits a positive thermal coefficient of dielectric constant, measuring +12 ppm/°C at 10 GHz over a temperature range of 0°C to 100°C. This ensures stability and reliable performance even in varying thermal conditions.

In terms of electrical properties, RT/duroid 6002 demonstrates excellent electrical insulation capabilities with a volume resistivity of 10^6 Mohm.cm. Additionally, the surface resistivity measures 10^7 Mohm, further enhancing the material's electrical performance.

When it comes to mechanical properties, RT/duroid 6002 showcases impressive tensile modulus values of 828 MPa (120 kpsi) in both the X and Y directions at 23°C, indicating its high strength and rigidity. The material also exhibits an ultimate stress of 6.9 MPa (1.0 kpsi) and an ultimate strain of 7.3%, highlighting its ability to withstand demanding conditions.

To ensure structural integrity under pressure, RT/duroid 6002 boasts a compressive modulus of 2482 MPa (360 kpsi) in the Z direction.

Rogers 6002 PCB has excellent resistance to moisture absorption, with only 0.02% absorption according to the D48/50 test method specified by IPC-TM-650 2.6.2.1 and ASTM D570.

The material also exhibits a thermal conductivity of 0.6 W/m/K at 80°C, allowing for efficient heat dissipation in electronic systems.

In terms of thermal expansion, RT/duroid 6002 has a coefficient of thermal expansion of 16 ppm/°C along the X and Y axes, and 24 ppm/°C along the Z axis, at 23°C and 50% relative humidity.

Other notable properties include a decomposition temperature (Td) of 500°C, ensuring the material's stability and reliability even at high temperatures. The density of RT/duroid 6002 is 2.1 gm/cm³, and its specific heat measures 0.93 J/g/K (0.22 BTU/ib/°F), contributing to efficient thermal management.

RT/duroid 6002 also exhibits excellent copper peel strength, with a value of 8.9 lbs/in (1.6 N/mm), as tested according to IPC-TM-650 2.4.8.

Additionally, RT/duroid 6002 is classified as V-0 for flammability according to UL 94 standards, ensuring its resistance to ignition and flame propagation.

Furthermore, RT/duroid 6002 is compatible with lead-free processes, aligning with industry standards and environmental regulations.

|

Property

|

RT/duroid 6002

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

2.94±0.04

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Dielectric Constant,εDesign

|

2.94

|

|

|

8GHz to 40 GHz

|

Differential Phase Length Method

|

|

Dissipation Factor,tanδ

|

0.0012

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal Coefficient of ε

|

+12

|

Z

|

ppm/℃

|

10 GHz 0℃-100℃

|

IPC-TM-650 2.5.5.5

|

|

Volume Resistivity

|

106

|

Z

|

Mohm.cm

|

A

|

ASTM D 257

|

|

Surface Resistivity

|

107

|

Z

|

Mohm

|

A

|

ASTM D 257

|

|

Tensile Modulus

|

828(120)

|

X,Y

|

MPa(kpsi)

|

23℃

|

ASTM D 638

|

|

Ultimate Stress

|

6.9(1.0)

|

X,Y

|

MPa(kpsi)

|

|

Ultimate Strain

|

7.3

|

X,Y

|

%

|

|

Compressive Modulus

|

2482(360)

|

Z

|

MPa(kpsi)

|

|

ASTM D 638

|

|

Moisture Absorption

|

0.02

|

|

%

|

D48/50

|

IPC-TM-650 2.6.2.1

ASTM D 570

|

|

Thermal Conductivity

|

0.6

|

|

W/m/k

|

80℃

|

ASTM C518

|

|

Coefficient of Thermal Expansion

(-55 to 288℃)

|

16

16

24

|

X

Y

Z

|

ppm/℃

|

23℃/50% RH

|

IPC-TM-650 2.4.41

|

|

Td

|

500

|

|

℃ TGA

|

|

ASTM D 3850

|

|

Density

|

2.1

|

|

gm/cm3

|

|

ASTM D 792

|

|

Specific Heat

|

0.93(0.22)

|

|

j/g/k

(BTU/ib/OF)

|

|

Calculated

|

|

Copper Peel

|

8.9(1.6)

|

|

Ibs/in.(N/mm)

|

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-free Process Compatible

|

Yes

|

|

|

|

|

RT/duroid 6002 PCB Capability

For RT/duroid 6002 PCBs, we offer single layer, double layer, multi-layer, and hybrid board options.

RT/duroid 6002 PCBs are available in various thicknesses, including standard thicknesses such as 10 mils, 20 mils, 30 mils, and 60 mils, as well as non-standard thicknesses like 15 mils, 25 mils, 35 mils, and 40 mils. Our designers can create boards as thin as 5 mils and as thick as 125 mils.

The finished PCB copper options include 1oz and 2oz. Our high frequency material can accommodate a maximum PCB size of 400mm by 500mm, allowing for single boards or different designs within a panel.

We offer solder mask options in green, black, blue, yellow, and more. Pads plating options include immersion gold, HASL, immersion silver, immersion tin, and bare copper.

|

PCB material:

|

Ceramic-filled PTFE composite

|

|

Designation:

|

RT/duroid 6002

|

|

Dielectric constant:

|

2.94 ±0.04 (process), 2.94 (design)

|

|

Layer count:

|

1-layer, 2-layer, multi-layer, hybrid designs.

|

|

Laminate thickness:

|

5mil (0.127mm), 10mil (0.254mm), 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil (0.762mm), 35mil (0.889mm), 40mil (1.016mm), 50mil (1.270mm), 60mil (1.524mm), 90mil (2.286mm), 100mil (2.540mm), 120mil (3.048mm), 125mil (3.175mm)

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red, etc.

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP etc..

|

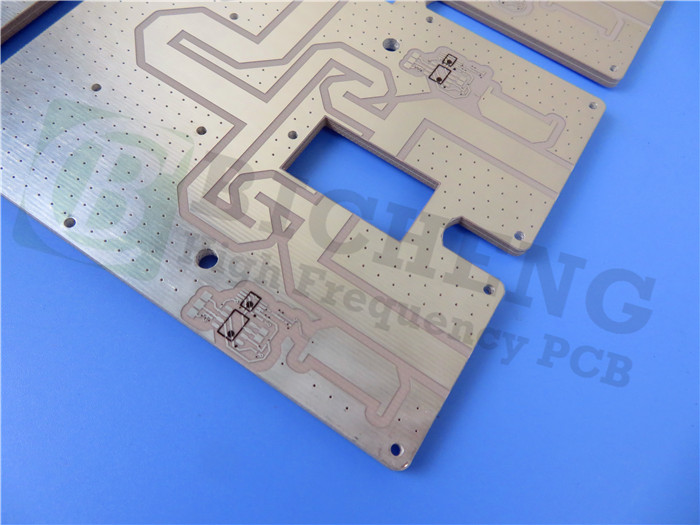

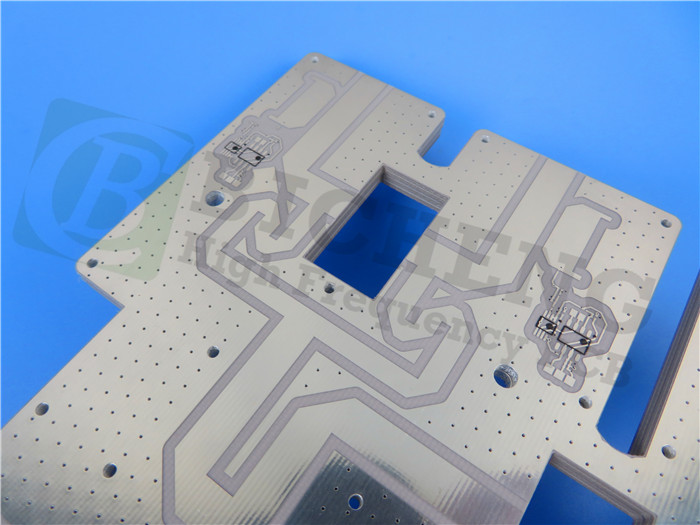

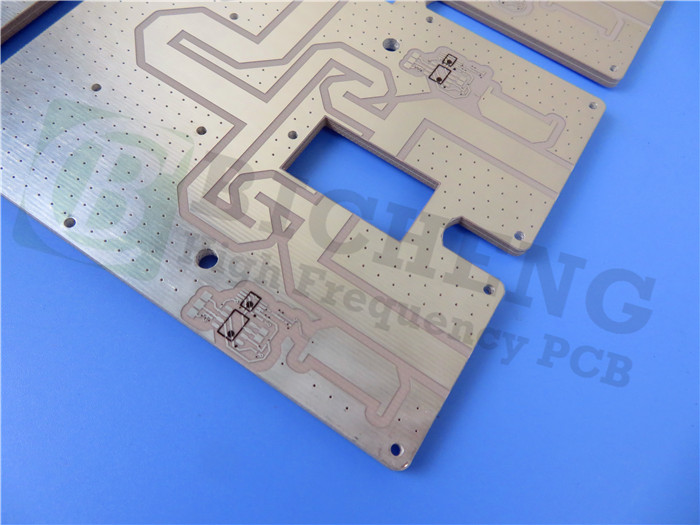

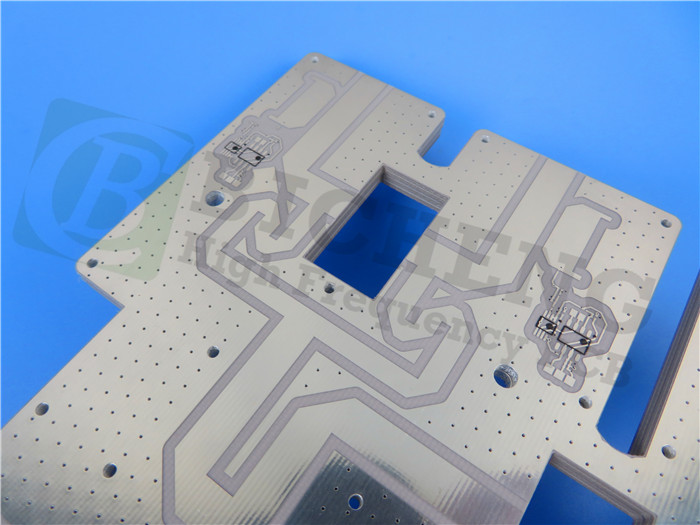

An Example of RT/duroid 6002 PCB

RT/duroid 6002 PCBs are typically white in color. The image presented showcases a double-sided PCB with immersion silver, designed specifically for phased array antennas.

RT/duroid 6002 PCB Applications

RT/duroid 6002 PCBs find their applications in various fields such as GPS antennas, ground-based and airborne radar systems, power backplanes, and commercial airline collision avoidance systems.

In Conclusion

RT/duroid 6002 high frequency PCBs offer tight thickness control and low out-gassing. They are highly suitable for flat and non-planar structures, including antennas, complex multi-layer PCBs with inner-layer connections, and microwave PCBs for aerospace designs in challenging environments.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com