What Are the Advantages and Benefits of Using RO4350B PCB?

Introduction

In the dynamic world of modern electronics, the demand for high-performance materials continues to rise. Addressing this need, Rogers introduces the RO4350B PCB, a revolutionary solution that combines the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. RO4350B laminates offer excellent control over dielectric constant (Dk) and low loss characteristics, all while maintaining affordability. With no special through-hole treatments required, this innovative PCB material sets a new benchmark in high-frequency circuit design. In this blog, we will explore the features, benefits, and applications of the RO4350B PCB in depth.

Features of RO4350B

The Rogers 4350B possesses an array of exceptional features that make it a preferred choice for advanced PCB designs:

1)Dielectric Constant:

With a precisely controlled Dk of 3.48 +/-0.05 at 10GHz/23°C,Rogers 4350B dielectric constant ensures consistent and reliable signal propagation.

2)Dissipation Factor:

The low dissipation factor of 0.0037 at 10GHz/23°C guarantees efficient power transmission and minimizes signal loss.

3)Thermal Conductivity:

RO4350B exhibits an impressive thermal conductivity of 0.69 W/m/°K, aiding in effective heat dissipation and enhancing the overall reliability of the system.

4)Coefficient of Thermal Expansion (CTE):

The PCB's CTE consists of an X-axis CTE of 10 ppm/°C, a Y-axis CTE of 12 ppm/°C, and a Z-axis CTE of 32 ppm/°C. This ensures excellent dimensional stability, even in harsh thermal shock environments.

5)High Tg Value:

With a high glass transition temperature (Tg) exceeding 280°C, RO4350B maintains its stability throughout various processing and operating temperature ranges.

6)Low Water Absorption:

The PCB exhibits a low water absorption rate of 0.06%, guaranteeing its reliability and performance in humid conditions.

Benefits of RO4350B

The Rogers 4350B PCB offers a range of benefits that set it apart as an exceptional choice in the industry:

1)Ideal for Multi-Layer Board (MLB) Constructions:

The unique properties of RO4350B make it an excellent choice for complex multi-layer board constructions. It ensures superior dimensional stability, facilitating precise alignment of circuit layers.

2)Cost-Effective Processing:

Unlike traditional microwave laminates, RO4350B can be processed using standard FR-4 fabrication techniques. This significantly reduces manufacturing costs while delivering high-performance results.

3)Excellent Dimensional Stability:

The compatibility of RO4350B's expansion coefficient with copper enables outstanding dimensional stability, critical for reliable operation in mixed dielectric MLB constructions.

4)Competitive Pricing:

Rogers understands the importance of affordability, and RO4350B reflects their commitment to providing high-quality materials at a competitive price point.

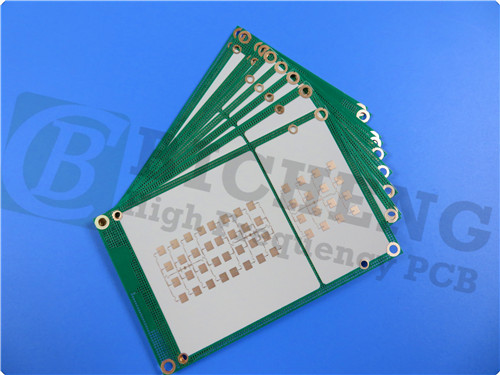

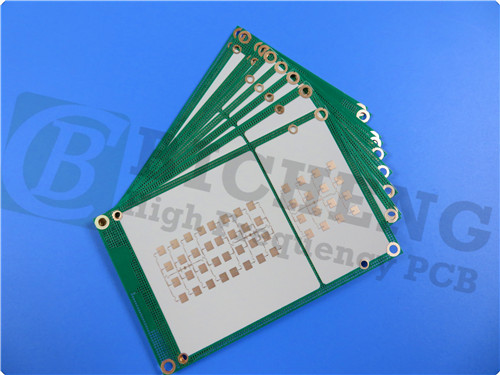

Diving into PCB Details

The Rogers RO4350B PCB boasts a 2-layer rigid construction, featuring the following specifications:

Copper Layer 1: 35μm

Rogers RO4350B Core: 0.338 mm (13.3 mils)

Copper Layer 2: 35μm

The PCB construction details further enhance its usability:

Board Dimensions: Each PCB measures 40 mm x 40 mm with a tolerance of +/- 0.15mm, ensuring precise fit and compatibility.

Minimum Trace/Space: The minimum trace and space width are set at 5/6 mils, enabling intricate and compact designs without compromising signal integrity.

Minimum Hole Size: The RO4350B PCB supports a minimum hole size of 0.2mm, ensuring compatibility with a wide range of components and assembly processes.

No Blind Vias: The absence of blind vias simplifies fabrication and ensures ease of assembly.

Finished Board Thickness: Each PCB is finished at 0.5mm, striking a balance between flexibility and stability.

Finished Cu Weight: The outer layers of the RO4350B PCB feature a finished copper weight of 1 oz (1.4 mils), providing excellent conductivity and current-carrying capacity.

Via Plating Thickness: The via plating thickness is 20μm, ensuring durable and reliable interconnection between layers.

Surface Finish: The PCB employs an immersion gold finish, offering excellent solderability and facilitating a reliable connection with electronic components.

Top Silkscreen: The top silkscreen is in white, providing clear and visible markings for component placement and identification.

Bottom Silkscreen: The bottom silkscreen is absent, allowing for a clean and sleek appearance.

Top and Bottom Solder Mask: The RO4350B PCB does not feature top and bottom solder masks, providing an unobstructed view of the copper traces.

100% Electrical Test: Each PCB undergoes a thorough 100% electrical test before shipment, ensuring high-quality standards are met.

PCB Statistics

The statistics of the RO4350B material PCB 13.3mil further illustrate its versatility and capabilities:

Components: The PCB supports up to 10 components, enabling various circuit configurations and functionalities.

Total Pads: A total of 29 pads are available for component connections.

Thru-Hole Pads: Out of the 29 pads, 19 are specifically designed for mounting components using thru-hole technology.

Top SMT Pads: The PCB accommodates 10 top surface-mounted (SMT) pads for compact and efficient component placement.

Bottom SMT Pads: The RO4350B PCB does not offer bottom SMT pads.

Vias: The PCB incorporates a total of 21 vias, providing essential interconnections between layers and promoting efficient signal flow.

Nets: With 1 net, the RO4350B PCB supports a focused and precise signal routing.

Applications of RO4350B

The versatility of the RO4350B PCB Immersion Gold makes it an ideal choice for various high-frequency applications, including:

1)Cellular Base Station Antennas and Power Amplifiers:

The exceptional electrical performance of RO4350B empowers seamless communication and signal transmission in cellular networks.

2)RF Identification Tags:

RO4350B enables high-quality, reliable RF identification tags, ensuring efficient data transfer and detection.

3)Automotive Radar and Sensors:

With the ability to withstand demanding automotive environments, RO4350B PCBs provide the stability and performance required for automotive radar and sensor applications.

4)LNBs for Direct Broadcast Satellites:

The superior electrical characteristics of RO4350B support the efficient reception and transmission of satellite signals, enhancing the performance of LNBs.

Conclusion

The RO4350B Frequency PCB represents a significant breakthrough in high-performance electronic materials. Offering the perfect fusion of electrical performance, manufacturability, and cost-effectiveness, this innovative material caters to the evolving needs of the industry. Whether it's cellular base stations, automotive radar, or satellite communication, the RO4350B PCB excels in a variety of high-frequency applications. Experience the power of advanced PCB design with the RO4350B and unlock a new realm of possibilities for your electronic projects.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com