What Are the Benefits of Using RO4003C PCB?

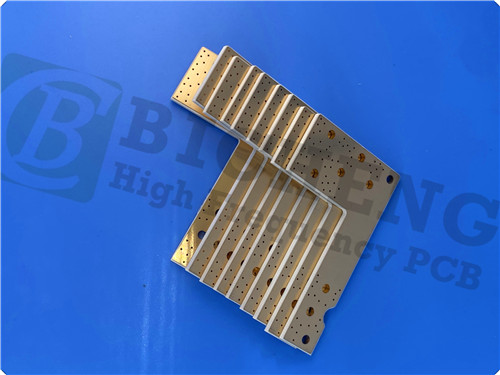

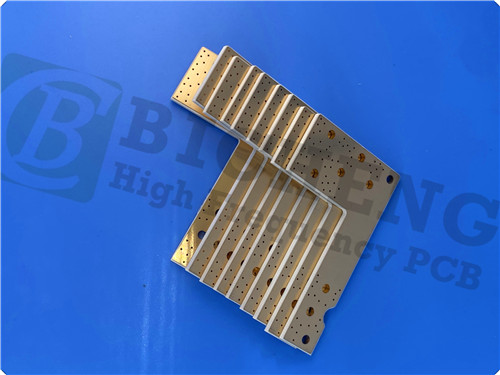

-RO4003C PCB 8mil

Introduction

The Rogers RO4003C PCB, a high-performance circuit board, has taken the electronics industry by storm with its exceptional electrical performance and remarkable manufacturability. This revolutionary PCB offers a cost-effective alternative to traditional microwave laminates without compromising on quality. With the Rogers RO4003C material at its core, this PCB delivers unparalleled performance, making it ideal for a wide range of applications. In this comprehensive productblog, we will delve deep into the features, benefits, construction details, statistics, and applications of the RO4003C PCB, highlighting its superiority in the market.

Introduction of RO4003C

The Rogers 4003C PCB is built using proprietary woven glass reinforced hydrocarbon/ceramic materials. It combines the electrical performance of PTFE (Polytetrafluoroethylene) with woven glass and the exceptional manufacturability of epoxy/glass. This breakthrough results in laminates that feature tight control of dielectric constant (Dk) and low loss.

What sets RO4003C laminates apart is their ability to achieve these impressive properties while utilizing the same processing method as standard epoxy/glass laminates, but at a fraction of the cost of conventional microwave laminates. Unlike PTFE-based microwave materials, no special through-hole treatments or handling procedures are required for the RO4003C PCB. It's important to note that RO4003C materials are non-brominated and not UL 94 V-0 rated.

One of the key advantages of RO4003C materials lies in their thermal coefficient of expansion (CTE), which offers several benefits to circuit designers. The expansion coefficient of RO4003C material closely aligns with that of copper, ensuring excellent dimensional stability. This stability is crucial for mixed dielectric multi-layer board constructions. Moreover, the low Z-axis CTE of RO4003C Substrate guarantees reliable plated through-hole quality, even in demanding thermal shock applications. With a glass transition temperature (Tg) exceeding 280°C (536°F), the expansion characteristics of Rogers RO4003C PCB materials remain stable throughout the entire range of circuit processing temperatures.

Features

The Rogers RO4003C High Frequency PCB boasts an array of impressive features that set it apart from other circuit boards in the market:

1)Dielectric Constant (Dk):

The RO4003C dielectric constant maintains a consistent Dk of 3.38 +/- 0.05 at 10GHz, ensuring reliable signal integrity.

2)Dissipation Factor:

With a dissipation factor of 0.0027 at 10GHz and 0.0021 at 2.5GHz, the PCB minimizes signal losses and delivers high-frequency performance.

3)Thermal Coefficient of Dielectric Constant:

The PCB exhibits a thermal coefficient of dielectric constant of +40 ppm/°C, enabling consistent performance across varying temperatures.

4)Thermal Conductivity:

With a thermal conductivity of 0.71 W/m/°K, the PCB effectively dissipates heat, enhancing overall reliability.

5)Coefficient of Thermal Expansion (CTE):

The RO4003C PCB showcases an X-axis CTE of 11ppm/°C, Y-axis CTE of 14ppm/°C, and Z-axis CTE of 46ppm/°C, ensuring stability and reducing the risk of failure due to thermal stress.

6)Low Moisture Absorption:

With a moisture absorption rate of only 0.06%, the PCB remains resilient in humid environments.

Benefits

The RO4003C PCB offers a host of benefits that make it an attractive choice for engineers and manufacturers alike:

1)Ideal for Multi-Layer Board (MLB) Constructions:

The exceptional dielectric control and tight manufacturing tolerances make the RO4003C PCB an excellent choice for multi-layer designs, enabling complex and high-density circuit layouts.

2)Processes like FR-4 at Lower Fabrication Cost:

The PCB can be processed using standard FR-4 processes, reducing fabrication costs and ensuring compatibility with existing manufacturing capabilities.

3)Designed for Performance-Sensitive, High-Volume Applications:

With its outstanding electrical properties and cost-effective nature, the RO4003C PCB is tailored for applications that demand high performance and large production volumes.

4)Competitively Priced:

The RO4003C PCB strikes the perfect balance between performance and cost, offering a cost-effective solution without compromising on quality.

PCB Stackup and Construction Details

The RO4003C 8mil PCB features a 2-layer rigid construction, consisting of copper layers on both sides. The stackup details are as follows:

Copper Layer 1: 35μm

Rogers 4003C Core: 0.203 mm (8mil)

Copper Layer 2: 35μm

The key construction details of the PCB are as follows:

Board Dimensions: The PCB measures 117.04mm x 67.11mm and is manufactured to a high precision of +/- 0.15mm.

Minimum Trace/Space: The PCB supports a minimum trace width and spacing of 4/4 mils, allowing for intricate circuit designs.

Minimum Hole Size: The PCB supports a minimum hole size of 0.3mm, facilitating the use of small and compact components.

No Blind Vias: The PCB does not incorporate blind vias, simplifying the manufacturing process.

Finished Board Thickness: The finished board thickness is 0.3mm, offering a low-profile solution for space-constrained applications.

Finished Copper Weight: The outer layers of the PCB feature a finished copper weight of 1oz (1.4 mils), ensuring excellent conductivity.

Via Plating Thickness: The vias of the PCB have a plating thickness of 20μm, offering robust connectivity.

Surface Finish: The PCB is finished with immersion silver, providing reliable solderability and excellent corrosion resistance.

Top Silkscreen: The top silkscreen is printed in black, allowing for clear component identification.

Bottom Silkscreen: The PCB does not have a bottom silkscreen.

Top and Bottom Solder Mask: The PCB does not have top and bottom solder masks.

100% Electrical Test: Each PCB undergoes a thorough electrical test prior to shipment, ensuring high quality and reliability.

PCB Statistics

The RO4003C PCB boasts the following statistics:

Components: The PCB accommodates 19 components, allowing for versatile circuit designs.

Total Pads: The PCB features a total of 76 pads, providing ample space for component soldering.

Thru-Hole Pads: There are 45 thru-hole pads, ensuring compatibility with traditional component mounting methods.

Top SMT Pads: The top surface of the PCB offers 31 pads for surface-mounted components.

Bottom SMT Pads: The PCB does not have bottom surface-mounted pads.

Vias: The PCB contains 67 vias, allowing for efficient signal and power routing.

Nets: There are 2 distinct nets within the PCB, promoting organized signal flow and reducing interference.

Availability and Quality Standard

The RO4003C PCB is available worldwide, ensuring easy access for engineers and manufacturers across the globe. Additionally, the PCB adheres to the quality standard of IPC-Class-2, guaranteeing excellent workmanship and reliability.

Typical Applications

The RO4003C PCB finds its application in a wide array of industries and products, including:

1)Cellular Base Station Antennas and Power Amplifiers:

The PCB's excellent electrical properties and high-frequency performance make it an ideal choice for cellular base station antennas and power amplifiers.

2)RF Identification Tags:

The RO4003C PCB enables precise signal transmission and reception, making it suitable for RF identification tags.

3)Automotive Radar and Sensors:

With its reliability, dimensional stability, and low loss, the PCB is well-suited for automotive radar systems and sensors.

4)LNB's for Direct Broadcast Satellites:

The RO4003C PCB delivers exceptional performance for low-noise block downconverters (LNBs) used in direct broadcast satellites, ensuring reliable signal reception.

Conclusion

In summary, the RO4003C 8mil Rogers substrate PCB stands out in the electronics industry. Its exceptional electrical performance, cost efficiency, and compatibility with standard manufacturing processes make it a top choice for engineers and manufacturers across various industries. Whether it's high-performance applications or cost-sensitive projects, the Rogers 4003C PCB delivers unparalleled reliability and performance, ensuring optimal results for any design. With its worldwide availability and adherence to the IPC-Class-2 quality standard, the RO4003C PCB has become the de facto choice for industry professionals who demand excellence

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com