Why Choose RO3003 High Frequency PCBs for Stable RF/Microwave Performance?

Introduction

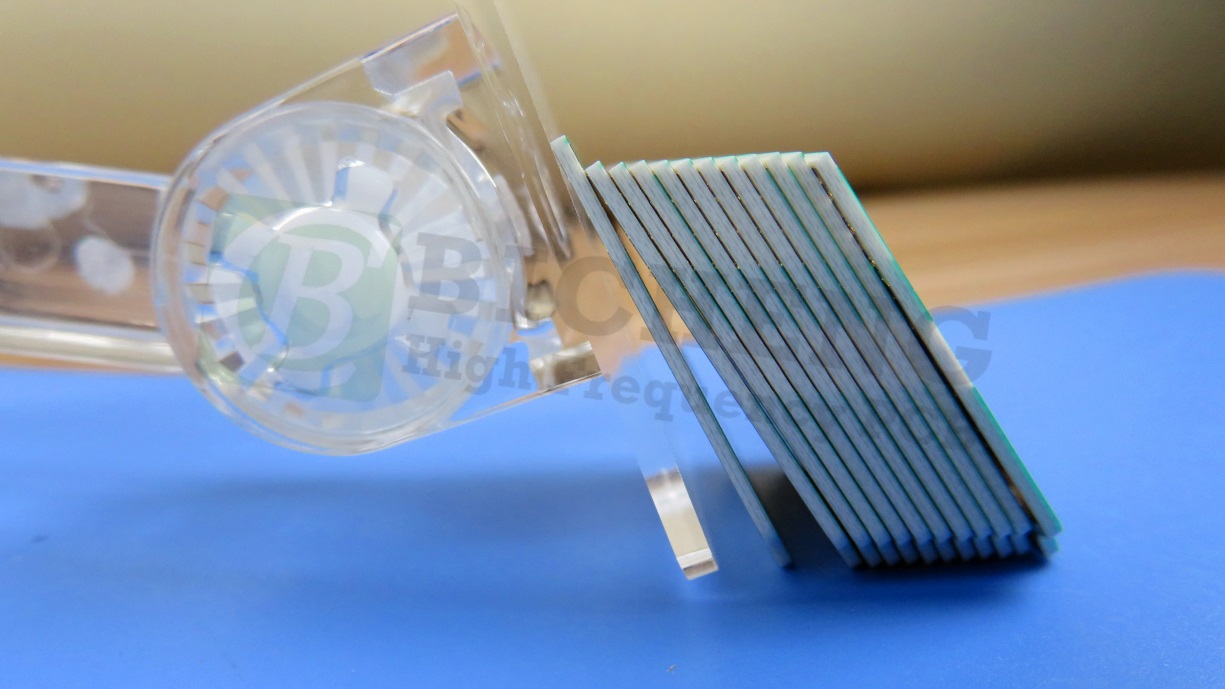

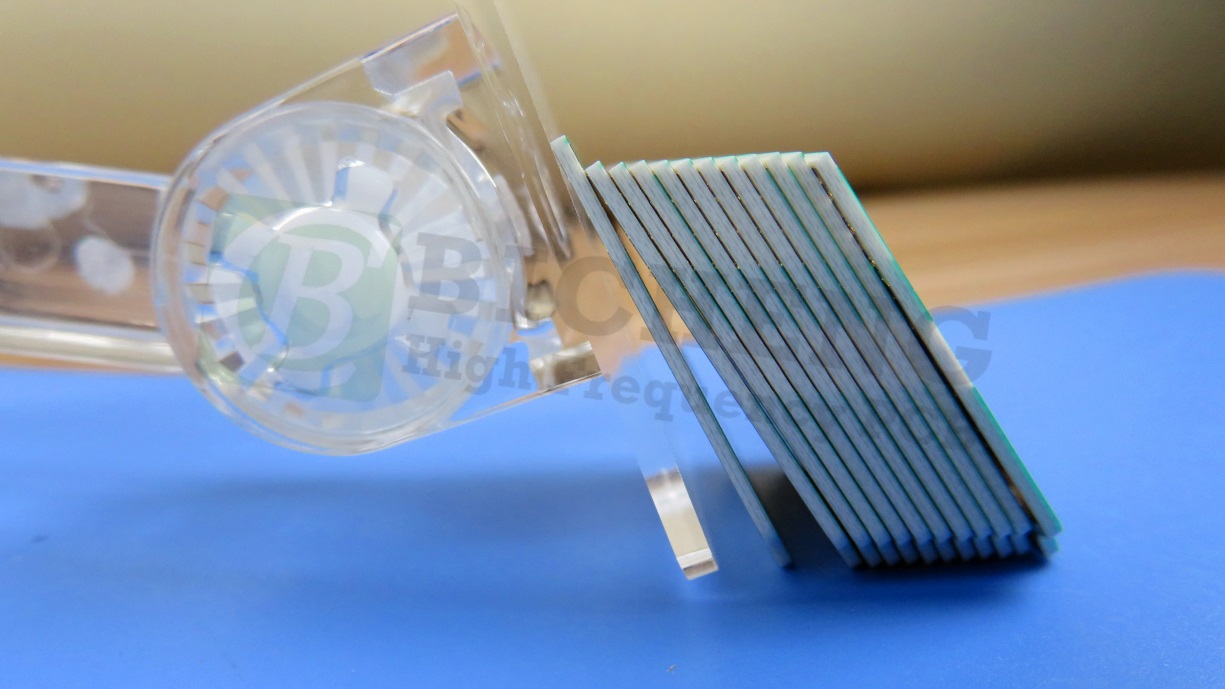

RO3003 high-frequency laminates represent a breakthrough in advanced circuit materials, engineered to deliver unparalleled electrical performance, mechanical resilience, and economic efficiency. As a ceramic-reinforced PTFE (polytetrafluoroethylene) composite, these laminates provide a superior solution for demanding microwave and RF applications. Their ability to maintain consistent signal integrity across extreme frequencies positions Rogers RO3003 as an indispensable material for next-generation technologies.

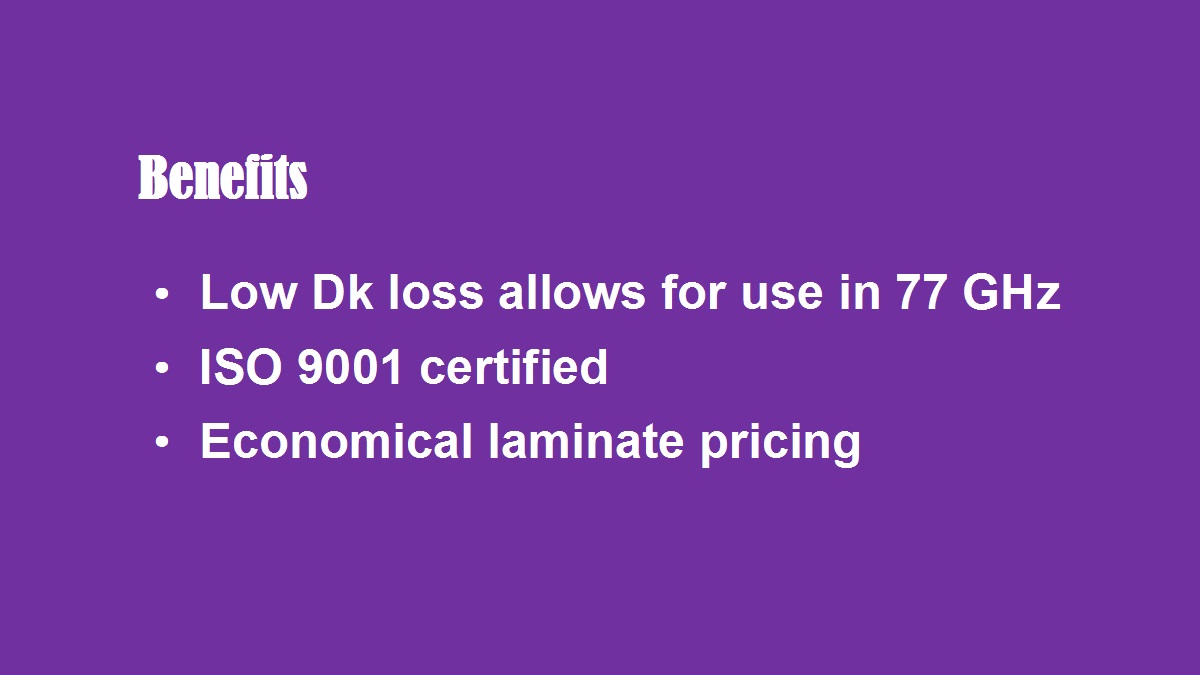

In environments where thermal and frequency fluctuations challenge conventional materials, Rogers RO3003 PCB excels with its remarkably stable dielectric constant. This stability is critical for automotive radar systems operating at 77 GHz, millimeter-wave 5G infrastructure, and Advanced Driver Assistance Systems (ADAS), where precision signal propagation directly impacts safety and functionality. By minimizing phase shifts and impedance variations, Rogers 3003 laminates ensure reliable performance in mission-critical applications.

Electrical & Mechanical Properties

2.1 Precision Dielectric Characteristics

-

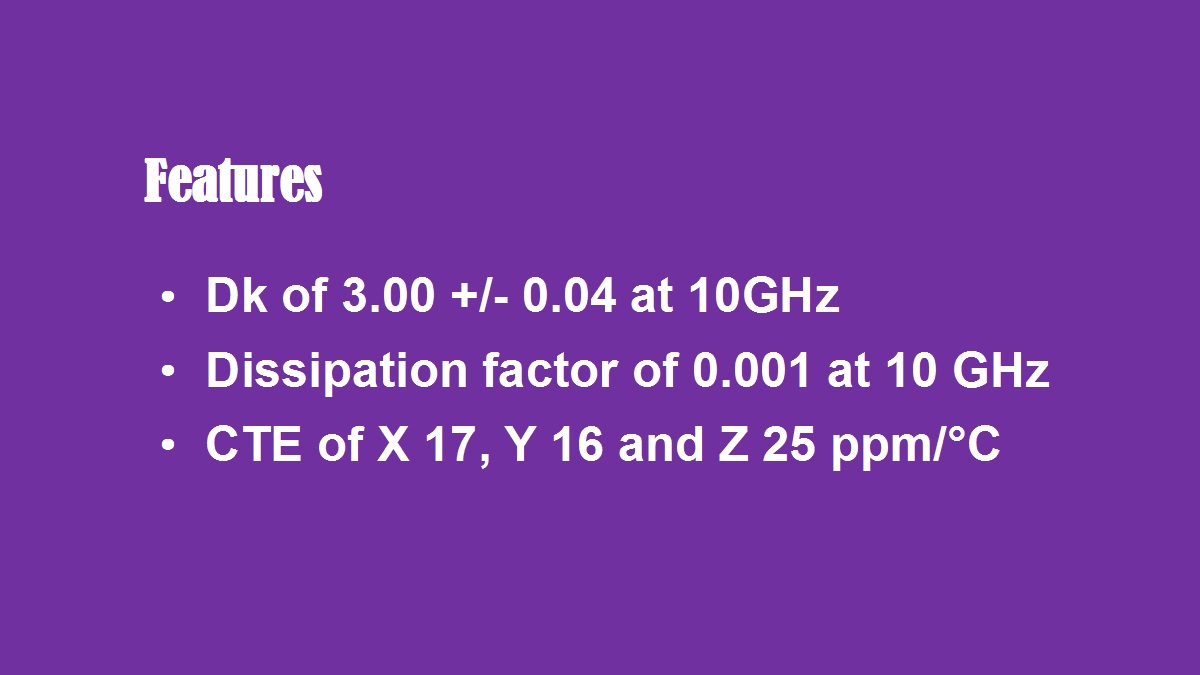

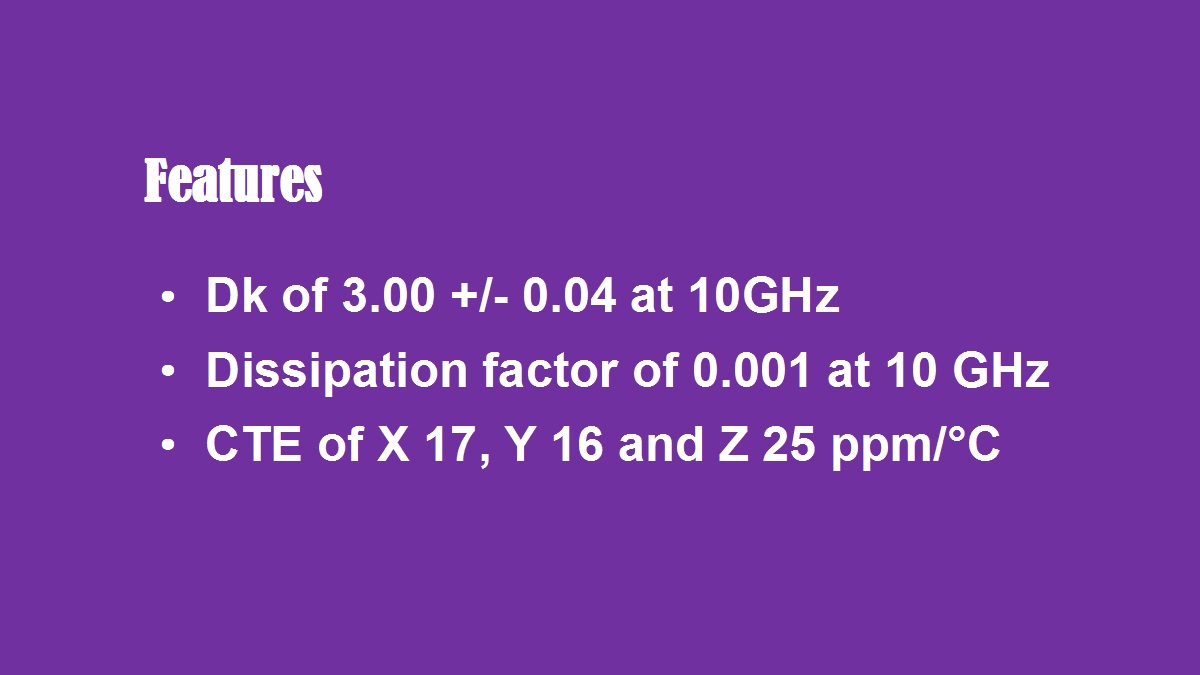

Dk Stability: With a dielectric constant (Dk) of 3.00±0.04 across temperature and frequency ranges, RO3003 enables predictable impedance control essential for high-frequency designs.

-

Ultra-Low Signal Loss: A dissipation factor of 0.0010 at 10 GHz minimizes insertion loss, preserving signal strength in mmWave applications up to 77 GHz and beyond.

2.2 Thermal Reliability

-

Minimal CTE Variation: CTE values of 17 ppm/°C (X-axis), 16 ppm/°C (Y-axis), and 25 ppm/°C (Z-axis) prevent delamination and via cracking during thermal cycling.

-

Thermal Consistency: Maintains electrical properties from -50°C to +150°C, ideal for automotive underhood electronics and outdoor RF infrastructure.

2.3 Quality & Cost Efficiency

-

ISO 9001-Certified Manufacturing: Guarantees batch-to-batch consistency and compliance with international quality standards.

-

Budget Optimization: Delivers RF performance comparable to premium laminates at 30–40% lower cost, reducing BOM expenses without sacrificing reliability.

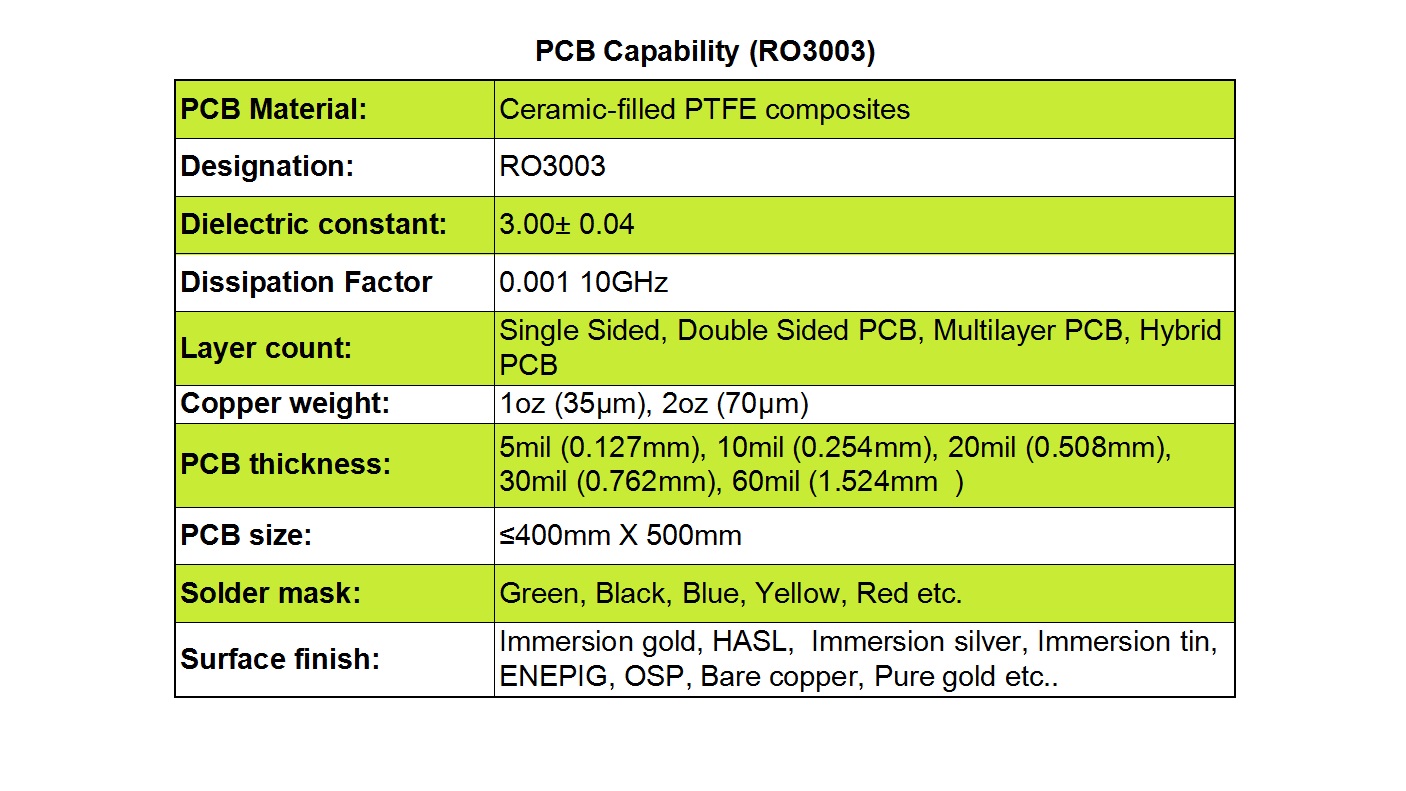

Advanced PCB Manufacturing Capabilities for RO3003

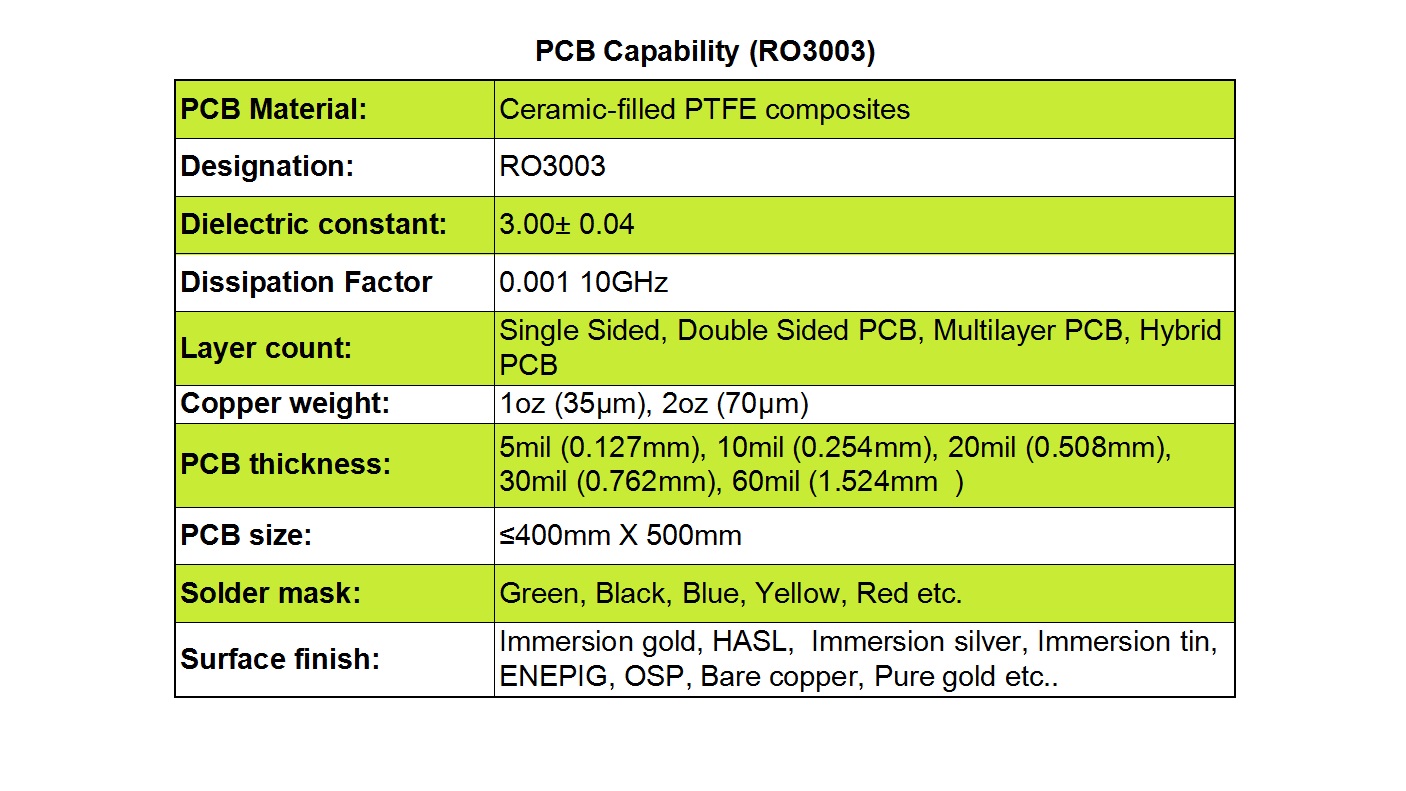

To fully leverage RO3003 High Frequency PCB’s properties, our manufacturing processes ensure precision and flexibility:

Layer Count Versatility:

We accommodate diverse design complexities, expertly manufacturing Single Sided, Double Sided, Multi-layer PCBs (including complex HDI designs), and Hybrid constructions combining RO3003 with other specialized materials for optimal performance and cost management.

Flexible Copper Weights:

Tailor current carrying capacity and trace characteristics with standard options like 1oz (35µm) and 2oz (70µm) copper foil, with custom weights available to meet specific RF and thermal requirements.

Precise Dielectric Thickness Control:

Achieve the exact impedance and performance targets with a wide range of dielectric thicknesses, spanning from a thin 5mil (0.127mm) up to a robust 60mil (1.524mm).

Generous Panel Sizing:

Our production capacity supports PCB panels up to 400mm x 500mm, efficiently handling larger boards or optimizing panelization for smaller components.

Solder Mask Options:

Maintain brand identity or functional needs with a selection of solder mask colors, including Green, Black, Blue, Yellow, Red, and others.

Comprehensive Surface Finishes:

Ensure optimal solderability, wire bonding capability, shelf life, and signal integrity by choosing from our full range of surface finishes:

-

Immersion Gold (ENIG)

-

Hot Air Solder Leveling (HASL - Leaded or Lead-Free)

-

Immersion Silver

-

Immersion Tin

-

Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

-

Organic Solderability Preservative (OSP)

-

Bare Copper (for specific controlled environments)

-

Pure Gold (Hard Gold) for edge connectors or demanding wear applications.

-

Critical Applications Leveraging RO3003

1. Automotive Radar Systems:

77 GHz long-range radar (LRR) and short-range radar (SRR) sensors for adaptive cruise control and collision avoidance.

Low moisture absorption (<0.1%) ensures performance in humid environments.

2. 5G Infrastructure:

mmWave base station antennas (24–43 GHz) requiring stable Dk across temperature gradients.

Massive MIMO arrays with ultra-low loss feed networks.

3. Aerospace & Telecommunications:

GPS/GNSS satellite antennas with precise phase stability.

5G NR small cells and remote meter readers operating in harsh outdoor conditions.

4. High-Power RF Systems:

Power backplanes and military-grade radar utilizing Z-axis CTE stability for plated-through-hole reliability.

Conclusion

RO3003 high frequency PCBs bridge the gap between cutting-edge electrical performance and manufacturability. With industry-leading Dk stability, minimal loss characteristics, and rigorous quality certification, this laminate empowers designers to push the boundaries of 77 GHz automotive radar, 5G mmWave, and ADAS innovations. Partner with us to access full-spectrum manufacturing capabilities—from rapid prototyping to complex hybrid stacks—tailored to your application’s unique demands.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com