Why Should You Choose TMM4 Thermoplastic Microwave Material for Your Next RF and Microwave Project?

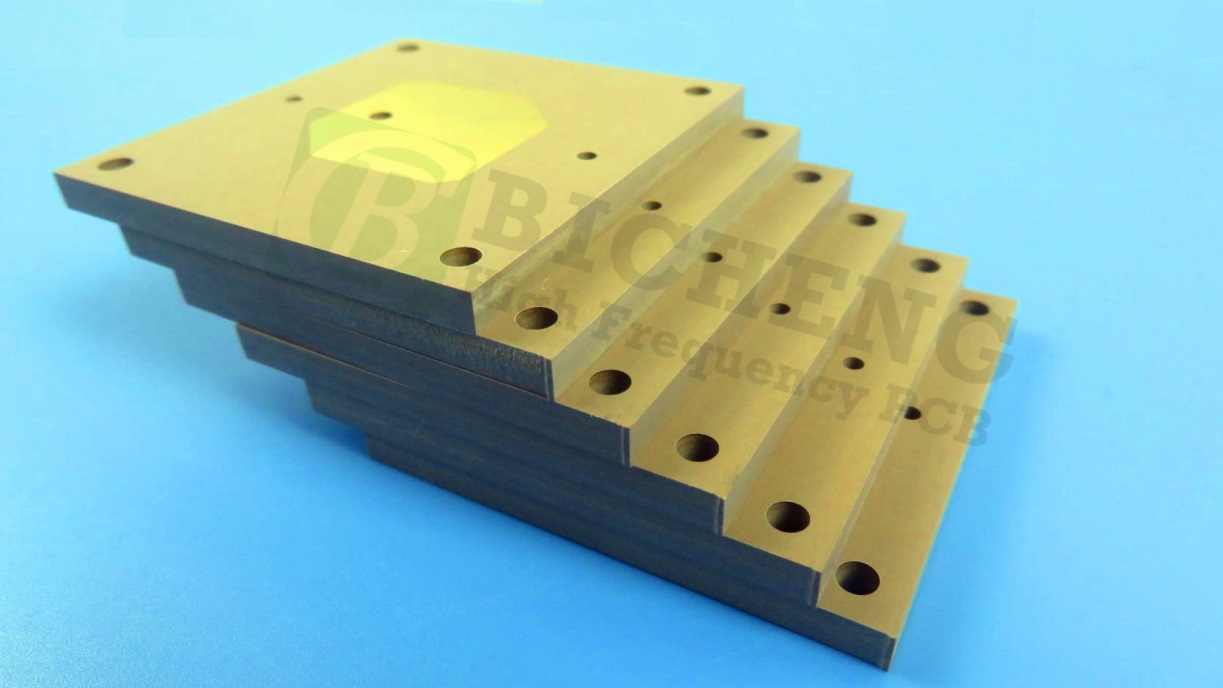

In the world of high-frequency electronics, the choice of printed circuit board (PCB) material is critical to the performance, reliability, and overall success of an application. Rogers TMM4 stands out as an exceptional thermoset microwave composite material specifically engineered to provide outstanding plated-through-hole reliability. It is ideally suited for a variety of high-frequency designs, including sophisticated strip-line and micro-strip circuit configurations. By uniquely combining the beneficial properties of ceramic fillers, hydrocarbon resins, and thermoset polymers,TMM4 delivers a superior blend of electrical, mechanical, and thermal characteristics. This makes it a highly robust and dependable substrate that meets the stringent demands of advanced microwave and RF systems.

A significant advantage of TMM4 laminates is their ability to provide the high performance of ceramic and traditional PTFE-based materials without the associated manufacturing complexities. These laminates are based on a user-friendly thermoset resin system, which streamlines the Rogers PCB fabrication process. This inherent ease of processing eliminates the need for specialized equipment or techniques often required for polytetrafluoroethylene (PTFE) materials. Furthermore, the robust thermoset structure guarantees excellent wire-bonding integrity, virtually eliminating concerns such as pad lifting or substrate deformation during assembly or operation.

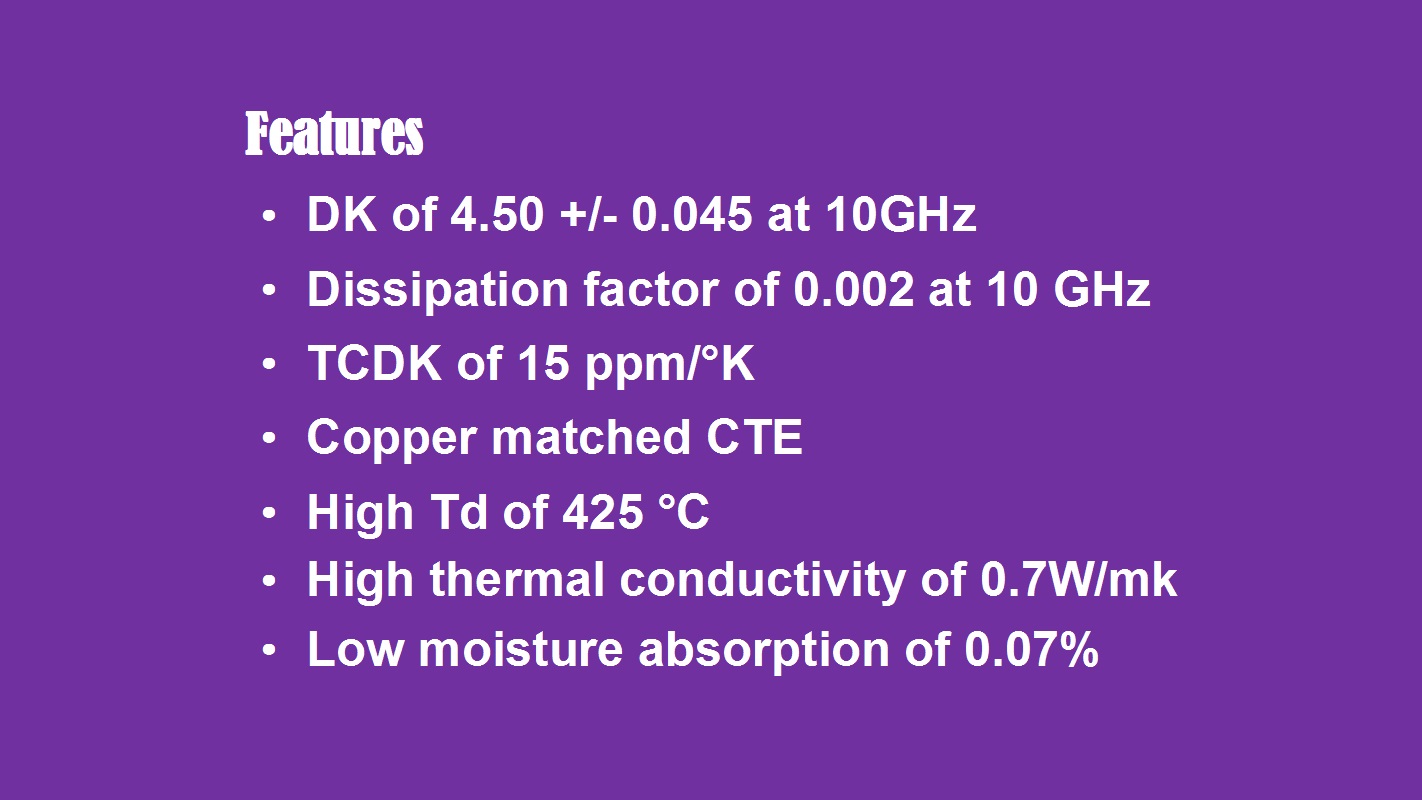

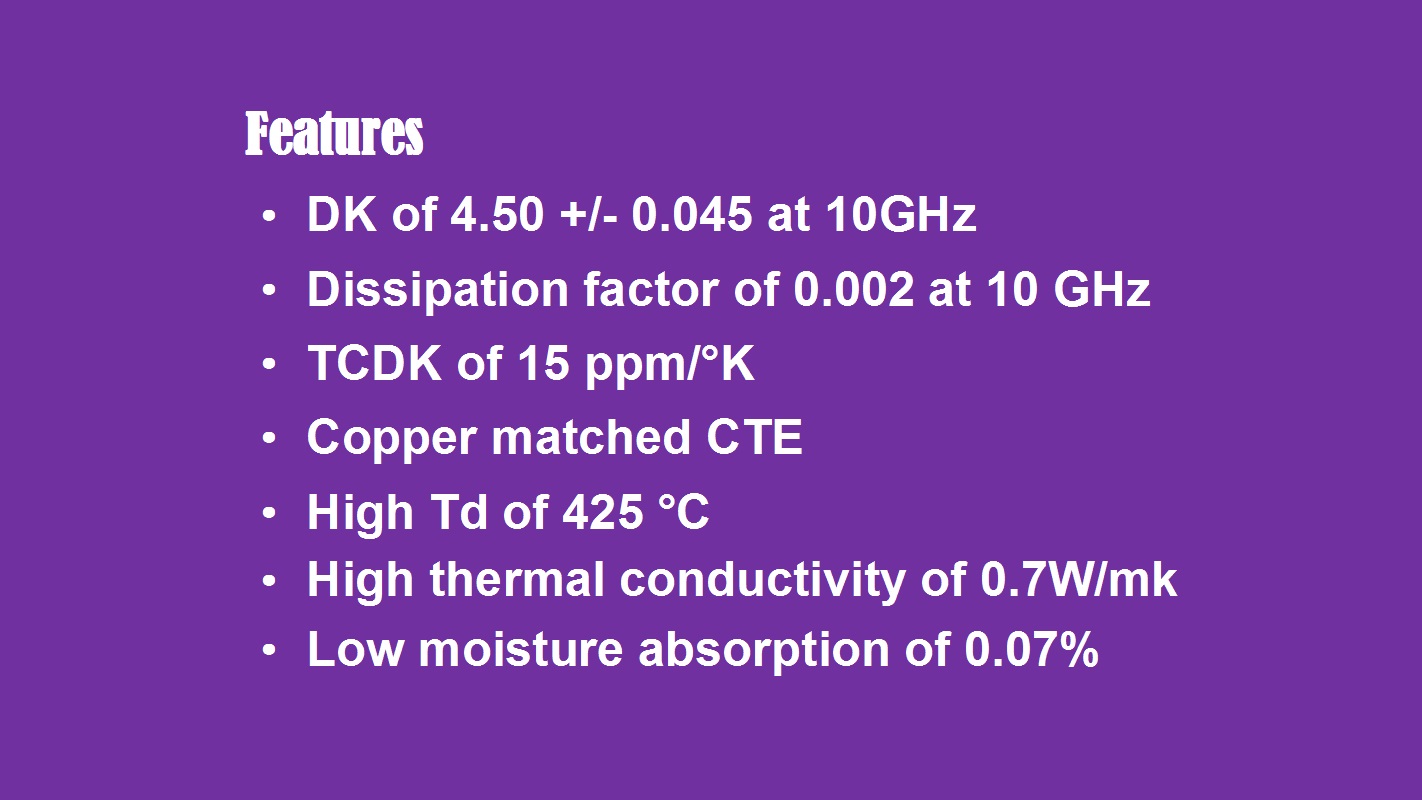

Key Features and Performance Advantages

The exceptional performance of TMM4 High-Frequency PCBs is anchored in a set of well-defined and stable material properties:

1.Stable Dielectric Properties:

TMM4 exhibits a consistent dielectric constant (Dk) of 4.50 with a very tight tolerance of±0.045. This stability is paramount for maintaining impedance control and signal integrity across the board. Coupled with an ultra-low dissipation factor (loss tangent) of 0.0020 at 10 GHz, TMM4 ensures minimal signal loss, enabling efficient and clean signal transmission even in high-power and high-frequency scenarios.

2.Excellent Thermal Stability:

The electrical performance of TMM4 remains highly consistent across a wide temperature range, thanks to its remarkably low thermal coefficient of dielectric constant (20 ppm/°C). This means the material's Dk does not drift significantly with temperature fluctuations, which is crucial for applications exposed to varying environmental conditions. Its thermal expansion properties are meticulously matched to copper, with CTE values of 16 ppm/°K in the X and Y axes and 21 ppm/°K in the Z-axis. This CTE matching significantly reduces mechanical stress on plated through-holes during thermal cycling, dramatically enhancing the long-term reliability and longevity of the PCB.

3.Superior Thermal Performance:

TMM4 substrates are built to withstand harsh operating environments. They possess a high decomposition temperature (Td) of 425°C as measured by TGA, ensuring material integrity during high-temperature soldering processes and in end-use applications. A thermal conductivity of 0.7 W/m/K allows for effective heat dissipation away from active components, which is vital for maintaining performance and preventing overheating in power amplifiers and other heat-generating circuits.

4.Low Moisture Absorption:

The hygroscopic nature of a PCB substrate can severely impair its electrical properties. TMM4 demonstrates outstanding resistance to moisture, with absorption rates as low as 0.07% for a 50mil thickness and 0.18% for a 125mil thickness. This low moisture uptake ensures stable electrical performance and prevents delamination or other moisture-induced failures, even in humid conditions.

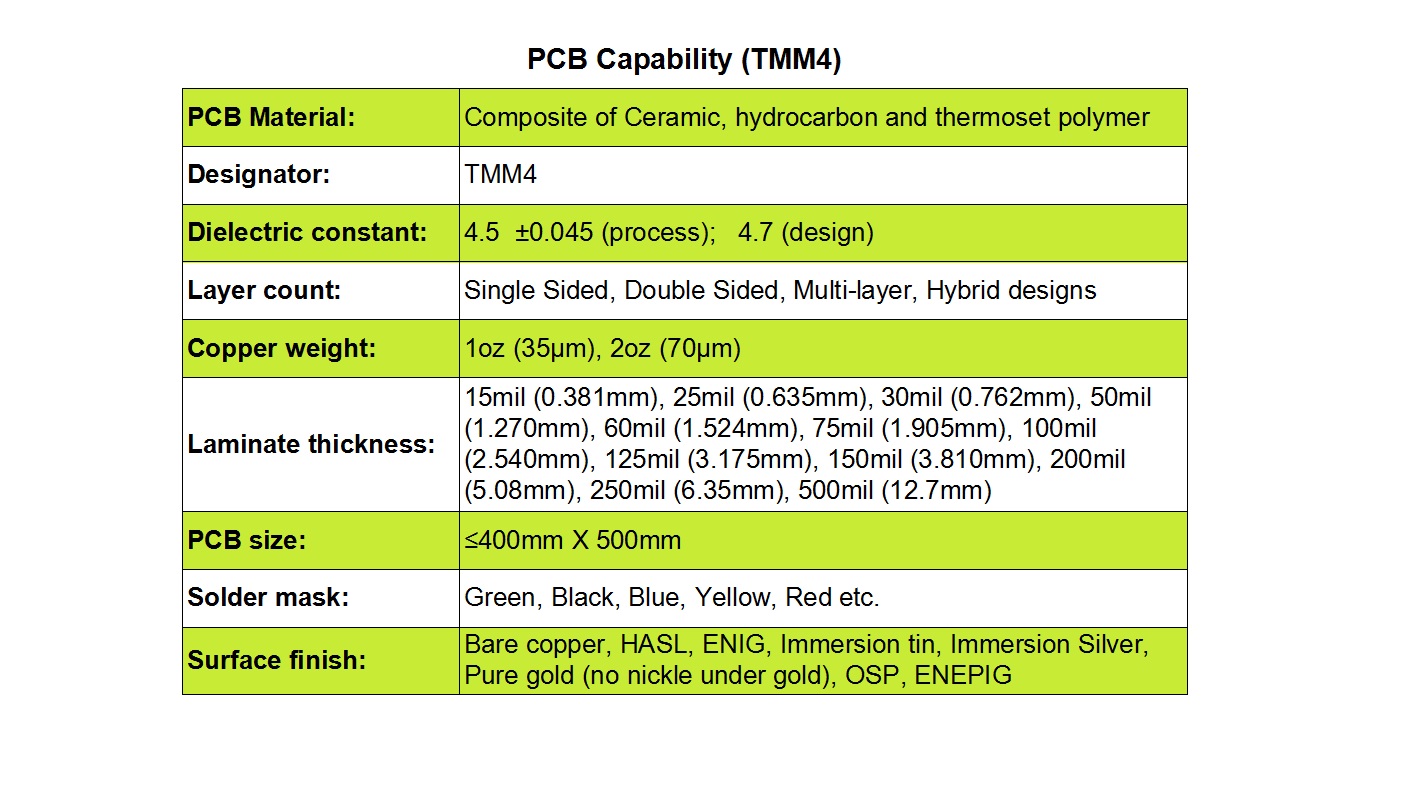

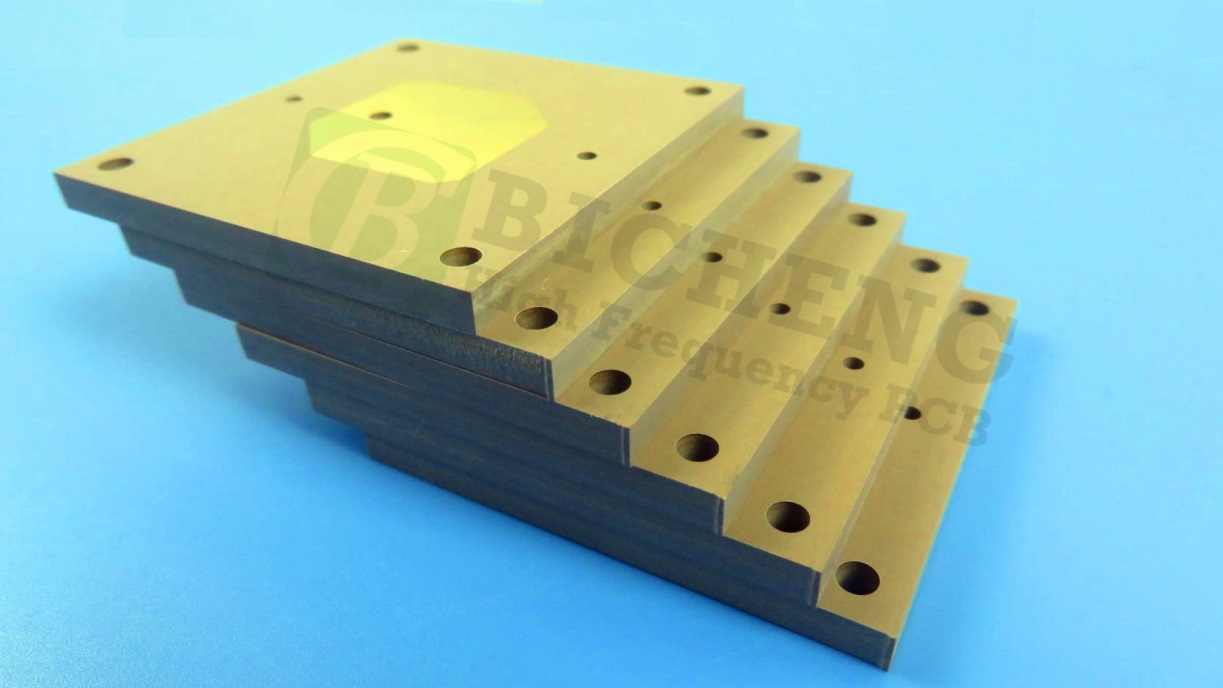

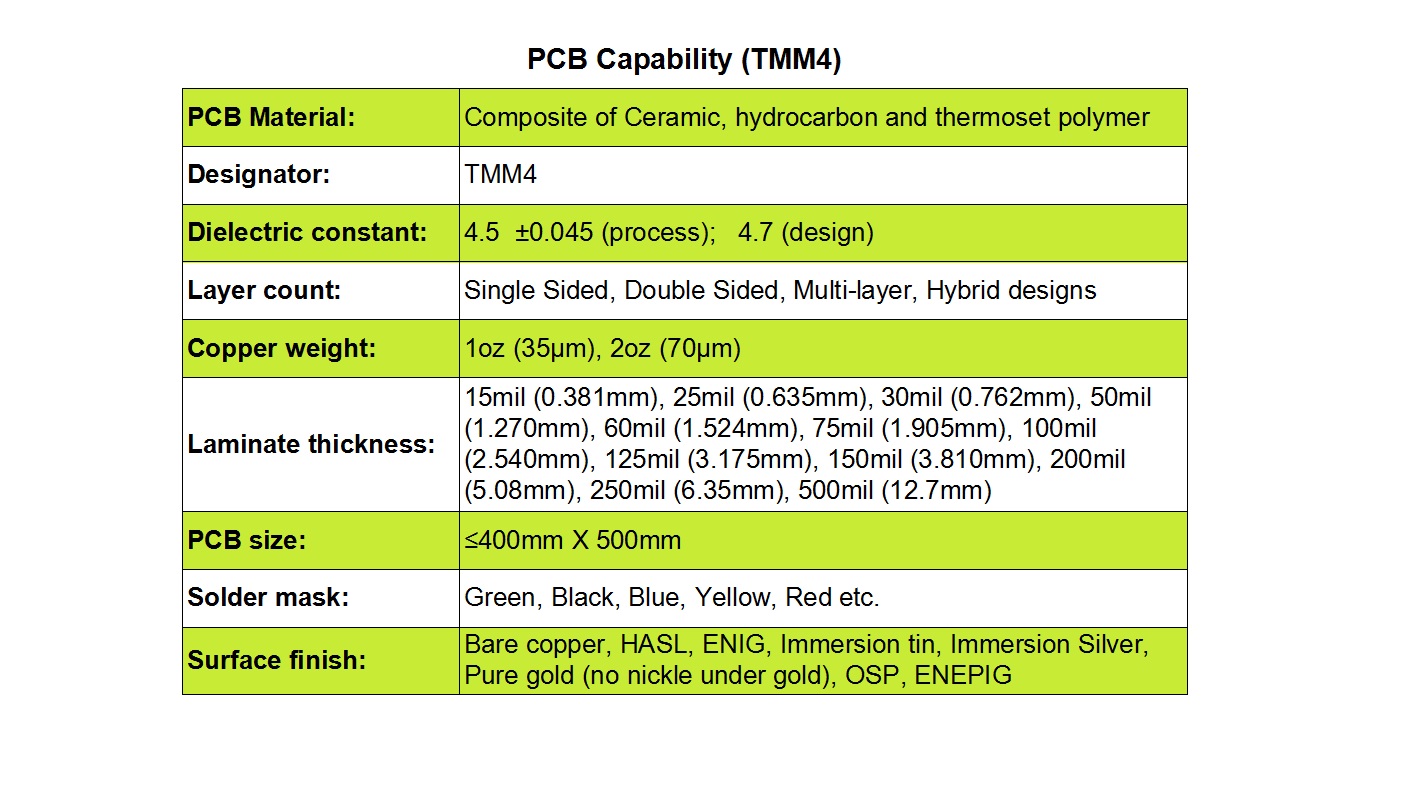

Advanced PCB Manufacturing Capabilities with TMM4

Our state-of-the-art manufacturing facilities are fully equipped to handle TMM4 laminates, transforming their inherent material advantages into high-performance, reliable PCBs. We offer comprehensive solutions tailored to your specific design requirements.

1.PCB Type:

-

Single-sided, Double-sided, Multi-layer, and Hybrid Constructions (combining TMM4 with other materials)

2.Copper Weight

-

(Finished):1 oz (35 µm) and 2 oz (70 µm)

3.Laminate Thickness:

-

From 15mil (0.381mm) and 25mil (0.635mm) up to 500mil (12.7mm), including 30mil, 50mil, 60mil, and more.

4.Max. Panel Size:

5.Solder Mask Colors:

-

Green, Black, Blue, Yellow, Red, and more

6. Surface Finish Options:

-

Bare Copper, HASL, ENIG, Immersion Tin, Immersion Silver, Pure Gold (no nickel), OSP, ENEPIG, and others.

This extensive range of capabilities provides design engineers with the flexibility needed to push the boundaries of their high-frequency designs without being constrained by manufacturing limitations.

Typical Applications

The unique property set of TMM4 high frequency PCB makes it the material of choice for a wide spectrum of demanding high-frequency electronic applications, including:

1.Telecommunications Infrastructure:

Power amplifiers, combiners, filters, and couplers for base stations and network equipment.

2.Aerospace and Satellite Systems:

Satellite communication transceivers, GPS antenna systems, and onboard radar systems where reliability is non-negotiable.

3.Radar and Sensing Systems:

Patch antennas and array antennas for automotive radar, industrial sensing, and defense applications.

4.Test and Measurement:

High-performance chip testers, probe cards, and RF test fixtures that require stable and low-loss signal paths.

Conclusion

For engineers and designers tasked with developing next high-frequency circuits, Rogers TMM4 presents a compelling solution. It successfully bridges the gap between the high performance of ceramic and PTFE laminates and the manufacturability and reliability of thermoset resins. By choosing TMM4 and partnering with a capable PCB supplier, you can achieve superior electrical performance, enhanced thermal management, and unwavering reliability in your most critical applications. Contact us today to discuss how we can leverage TMM4 laminates to optimize your next high-frequency PCB project.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com