What Makes Rogers RT/duroid 5870 Laminates Ideal for High-Frequency Electronics and Precision Circuits?

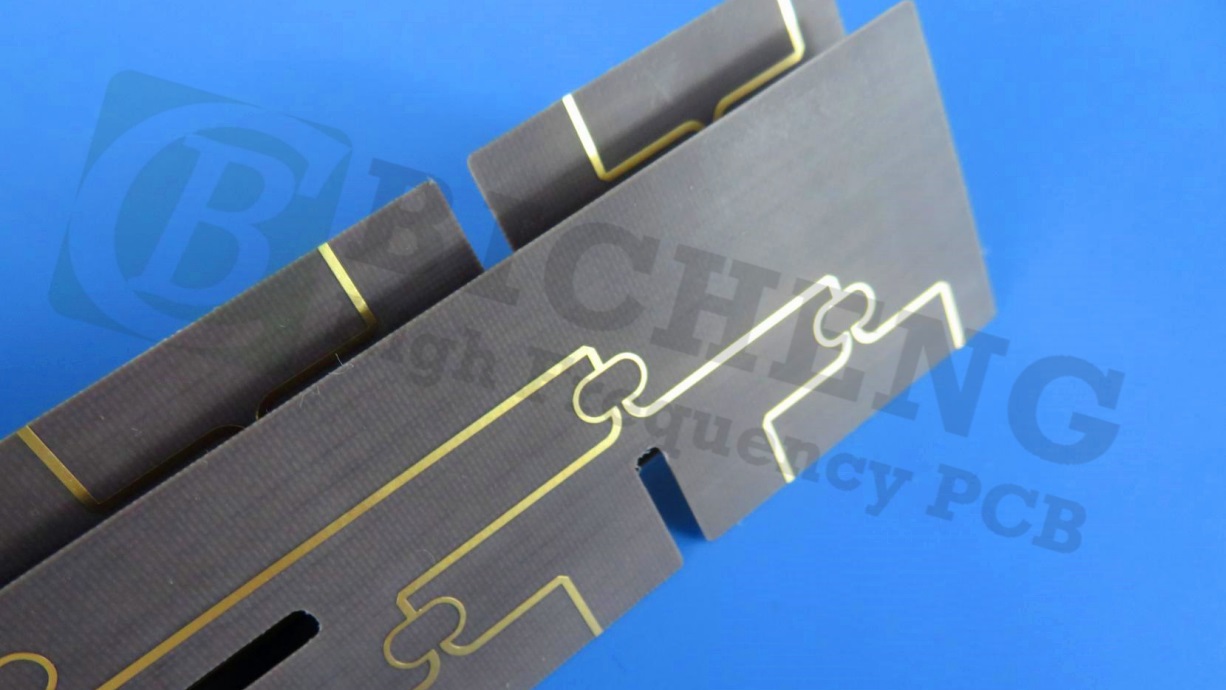

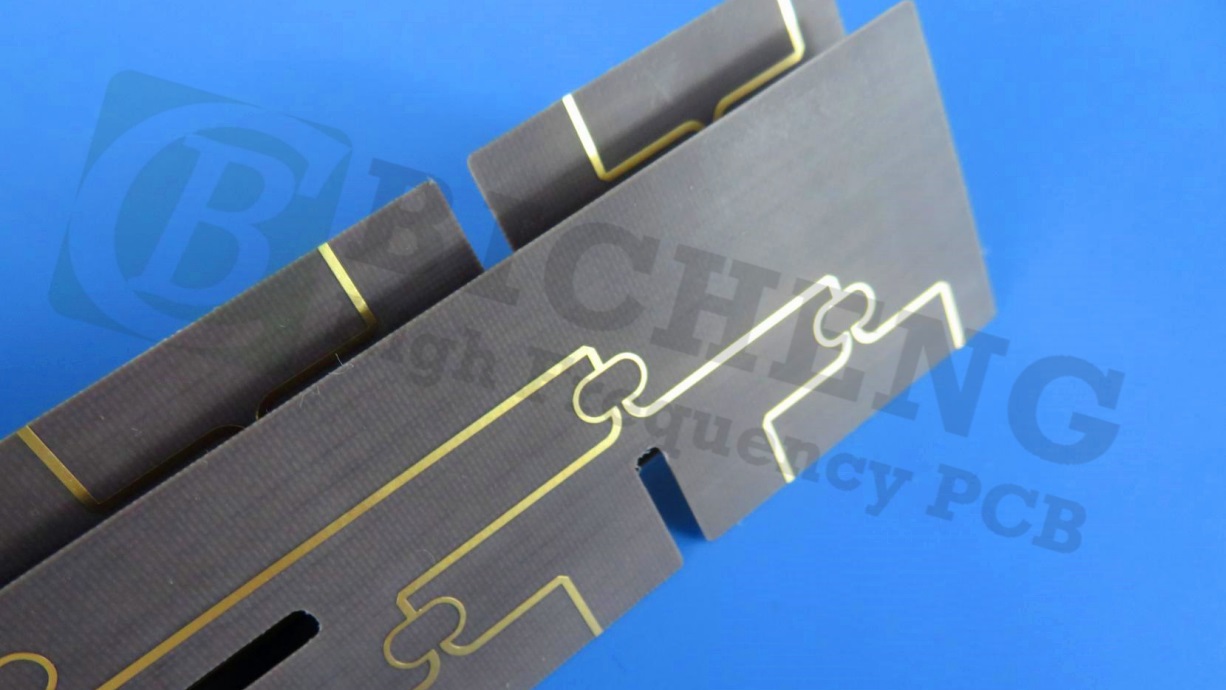

In the demanding landscape of high-frequency electronics, Rogers 5870 laminates stand as a pinnacle of engineering excellence. These PTFE-based composites, reinforced with randomly dispersed glass microfibers, deliver unparalleled dielectric consistency—making them the substrate of choice for precision stripline and microstrip circuitry. Engineered to thrive in broadband and high-frequency environments, RT/duroid 5870 Material minimizes signal dispersion and energy loss while extending operational efficiency into the Ku-band and beyond.

Critical Performance Attributes

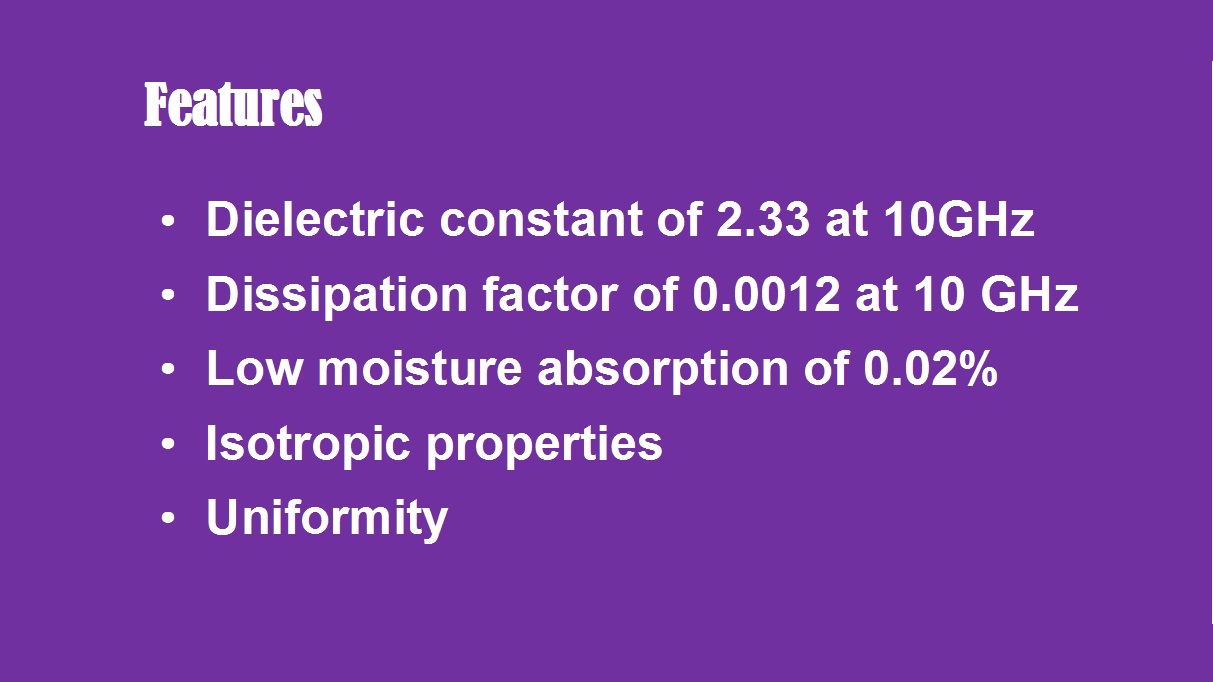

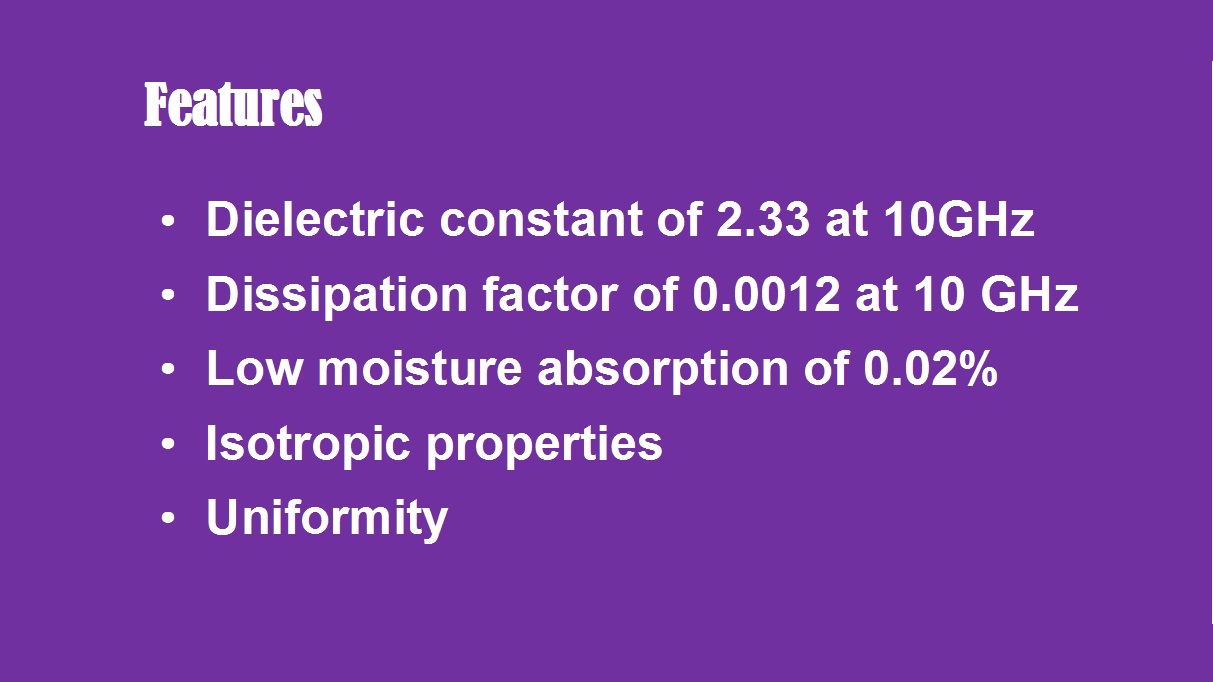

1.Ultra-Low Dielectric Properties

With a dielectric constant (Dk) of 2.33 and dissipation factor (Df) of 0.0012 (verified at 10 GHz),Duroid 5870 PCBensures minimal signal delay and attenuation. These properties enable high-speed signal integrity for 5G infrastructure, satellite communications, and phased-array radar.

2.Moisture Resistance for Harsh Environments

Leveraging inherent PTFE characteristics, the material exhibits remarkably low moisture absorption (0.02%). This resilience guarantees stable performance in high-humidity conditions—critical for avionics, maritime systems, and tropical deployments.

3.Unmatched Signal Integrity

As the lowest-loss reinforced PTFE material available,Rogers RT/Duroid 5870 provides isotropic behavior with uniform electrical properties across all axes. This eliminates directional performance variances, ensuring consistent impedance control for multi-layer RF designs.

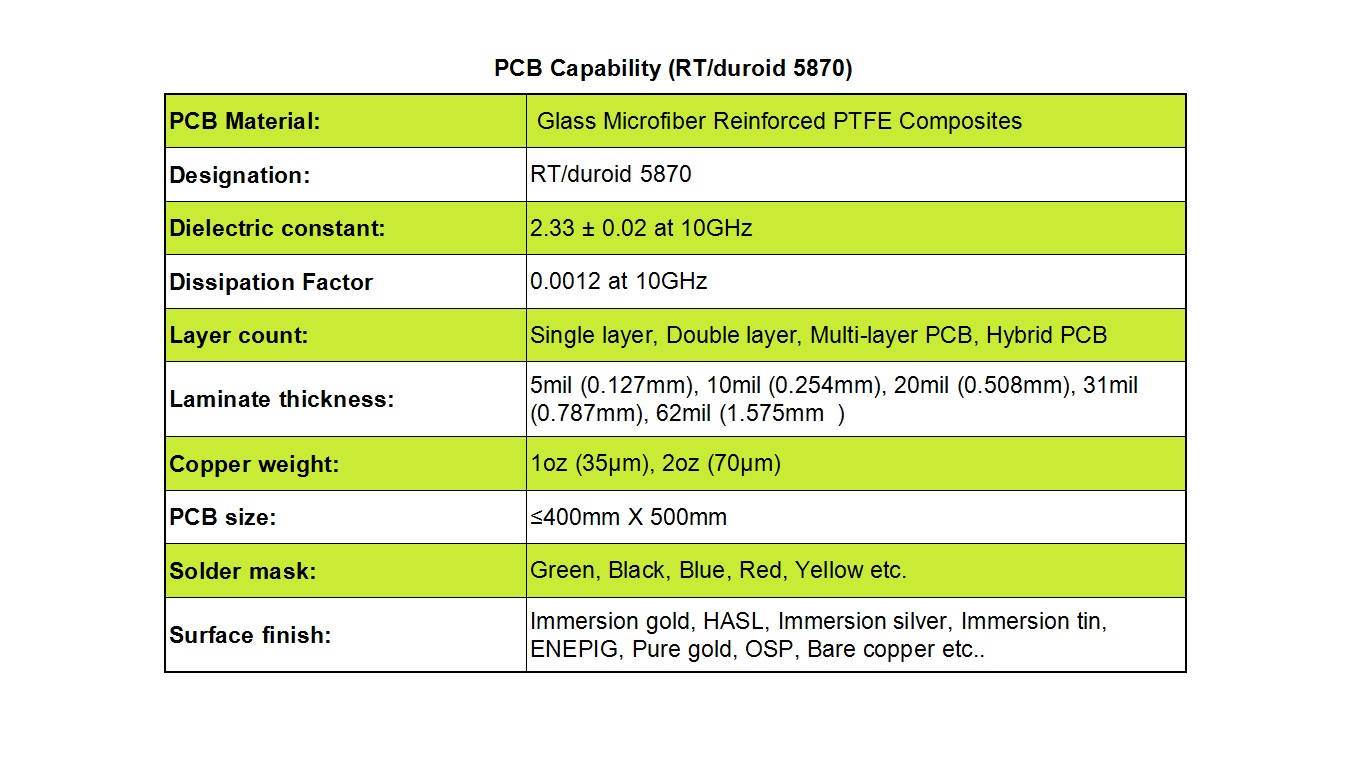

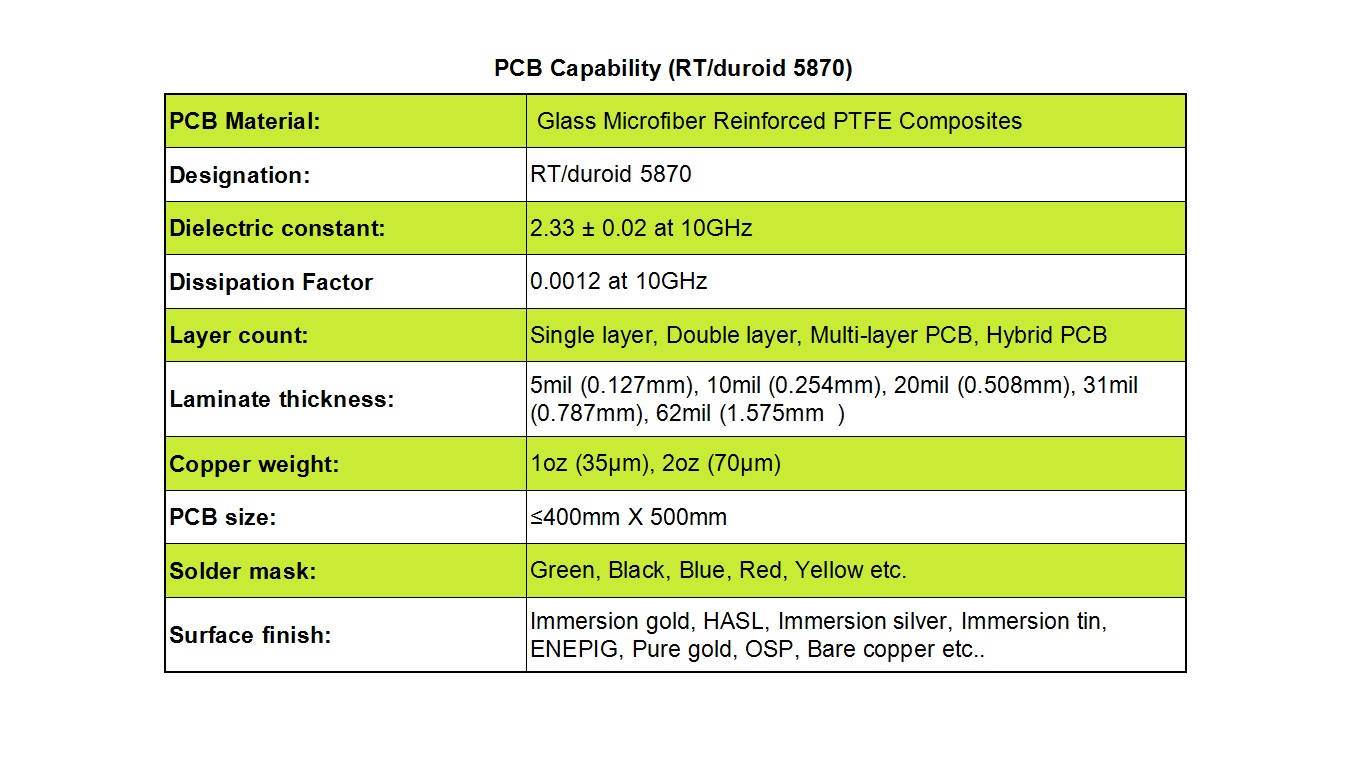

Advanced PCB Manufacturing Capabilities

We deliver end-to-end solutions for Duroid 5870 High Frequency PCB-based circuits, supporting the most complex high-frequency applications:

Structural Versatility

Layer Configurations: Single-layer, double-layer, multi-layer (up to 24 layers), and hybrid stacks combining FR-4/Rogers materials.

Thickness Range: Standard options from 10 mil to 62 mil, including 15 mil, 20 mil, and 31 mil profiles. Custom thicknesses available.

Panel Scalability: Maximum panel size of 400mm×500mm—ideal for large-format antennas or multi-project arrays.

Surface Engineering

Copper Weights: 1oz or 2oz finished copper with±0.07 mil tolerance.

Solder Masks: Green, black, blue, red, yellow, and matte finishes.

Surface Finishes:

Immersion Gold (ENIG)

HASL (Lead/Lead-free)

Immersion Silver/Tin

ENEPIG (for wire bonding)

Electrolytic Hard Gold

OSP & Bare Copper

Mission-Critical Applications

Rogers 5870’s blend of electrical stability and environmental endurance makes it indispensable across defense, aerospace, and telecom sectors:

-

Aerospace: Airborne broadband antennas, collision avoidance systems.

-

Military: Radar arrays, missile guidance PCBs, electronic warfare modules.

-

Telecom: Point-to-point radio antennas, millimeter-wave backhaul links.

-

Emerging Tech: Automotive radar (77/79 GHz), quantum computing interconnects.

Why Partner with Us?

As an ISO 9001-certified supplier, we combine Rogers material expertise with:

-

Impedance Control:±5% tolerance via TDR testing.

-

Hybrid Bonding: Seamless integration of RT/duroid 5870 with FR-4/ceramics.

-

High-Tg Processing: Lamination cycles optimized for PTFE’s low thermal expansion.

-

DFM Support: Signal layer adjacency planning and via optimization.

Industry Challenge Solved: Traditional FR-4 laminates suffer from erratic Dk values above 6 GHz. RT/duroid 5870’s glass microfiber matrix eliminates this variability—enabling precise phase matching in 40 GHz beamforming networks.

Conclusion

For engineers pushing the boundaries of high-frequency design,RT/duroid 5870 high frequency PCBs deliver uncompromised signal fidelity, thermal resilience, and manufacturing flexibility. Whether developing next-gen radar or satellite payloads, this material system bridges the gap between theoretical performance and real-world reliability.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com