Why Choose RO4003C High Frequency PCBs for Superior RF Performance & Cost Efficiency?

Introduction

Rogers RO4003C high-frequency laminates revolutionize RF/microwave design by merging exceptional electrical properties with streamlined manufacturability. Engineered with proprietary hydrocarbon/ceramic matrices reinforced with precision-woven glass, these substrates deliver PTFE-level signal integrity while adopting the fabrication processes of conventional epoxy/glass composites. Available in both 1080 and 1674 glass fabric configurations, RO4003C guarantees uniform dielectric behavior across diverse layouts. Critically, it maintains ultra-tight dielectric constant (Dk) tolerances and minimizes insertion losses without requiring specialized processing infrastructure. This unique combination slashes production costs by up to 40% compared to legacy microwave laminates while sustaining uncompromised high-frequency performance–making it the pragmatic choice for next-generation RF systems.

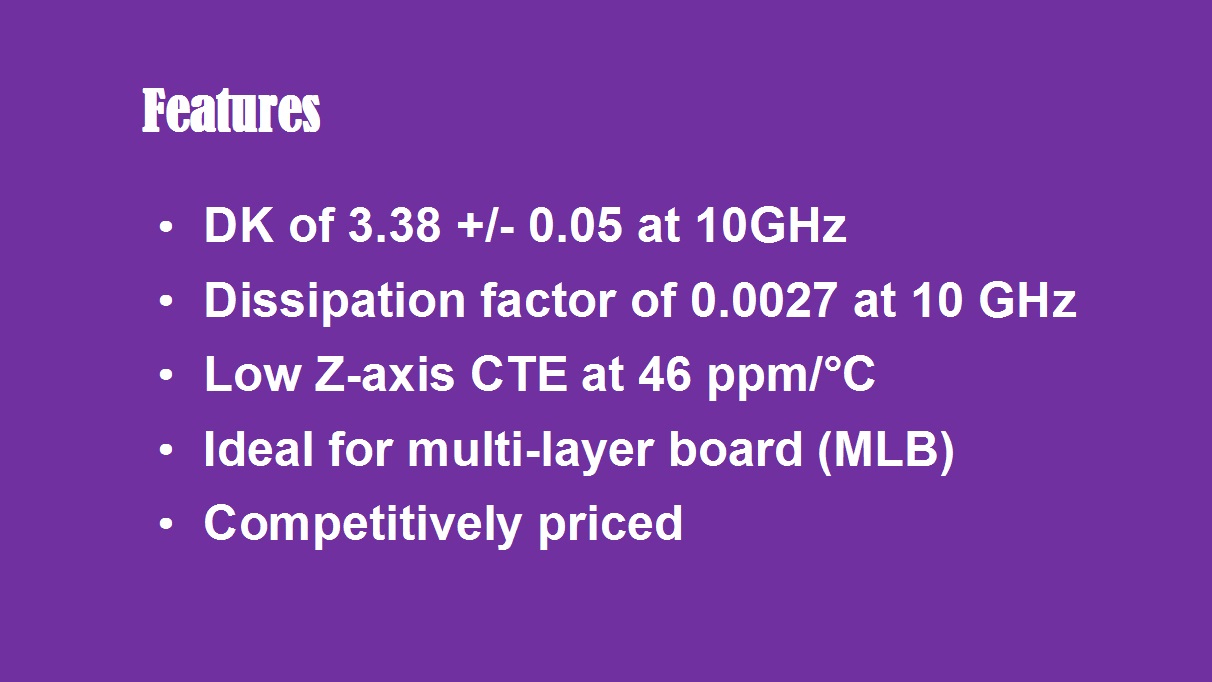

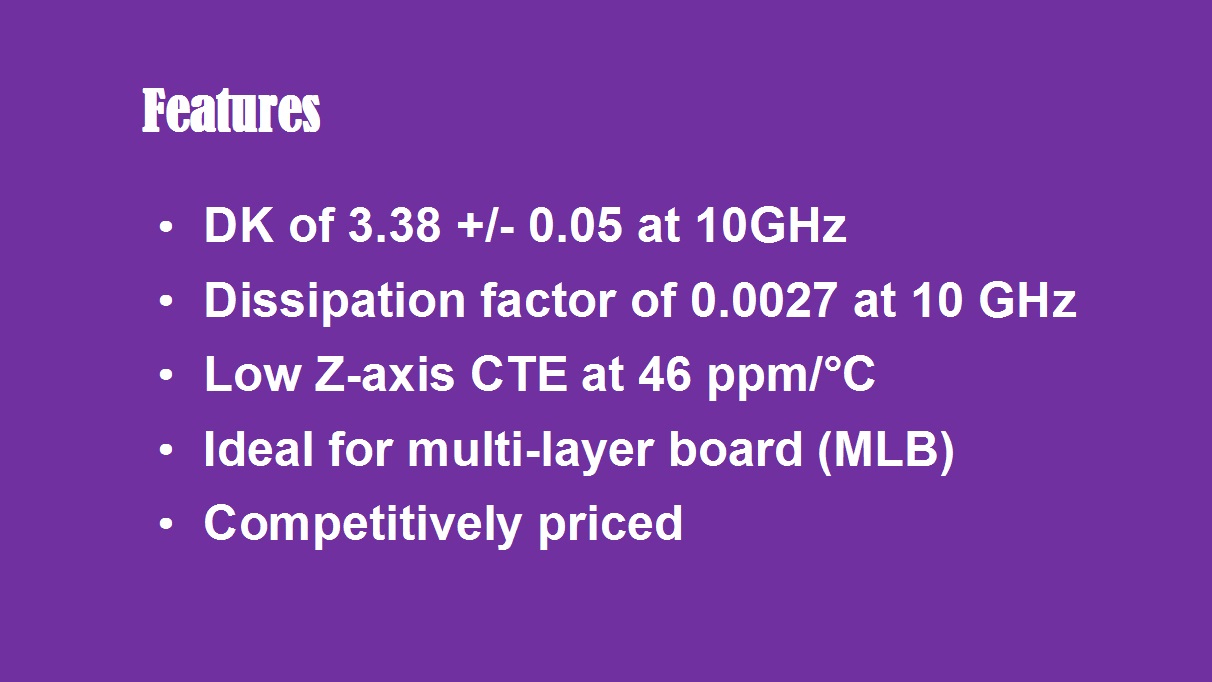

Core Features & Performance Advantages

1. Dielectric Constant Stability:

RO4003C’s hallmark Dk value of 3.38 (±0.05) provides unmatched stability across temperature fluctuations and frequency bands. This consistency enables precise impedance matching (critical for 50Ω/75Ωsystems) and eliminates phase distortion in multi-channel arrays like beamforming antennas.

2. Ultra-Low Dissipation & Signal Loss:

With a remarkably low dissipation factor (Df) of 0.0027 at 10 GHz, Rogers 4003C minimizes dielectric absorption losses. This translates to higher Q factors in resonators, extended range in RFID tags, and enhanced efficiency in 5G power amplifiers operating at mmWave frequencies.

3. Thermal Reliability for Demanding Environments:

Featuring a Z-axis CTE of just 46 ppm/°C–closely matching copper’s expansion rate–RO4003C prevents plated through-hole (PTH) barrel cracking during thermal cycling. This robustness supports automotive radar modules (-40°C to +150°C operational ranges) and aerospace systems encountering extreme thermal shocks.

4. FR-4 Process Compatibility:

Unlike costly PTFE-based alternatives, RO4003C substrate leverage existing FR-4 manufacturing workflows. This compatibility slashes fabrication costs by eliminating specialized equipment or processes, making high-frequency performance economically accessible for multilayer boards (MLBs).

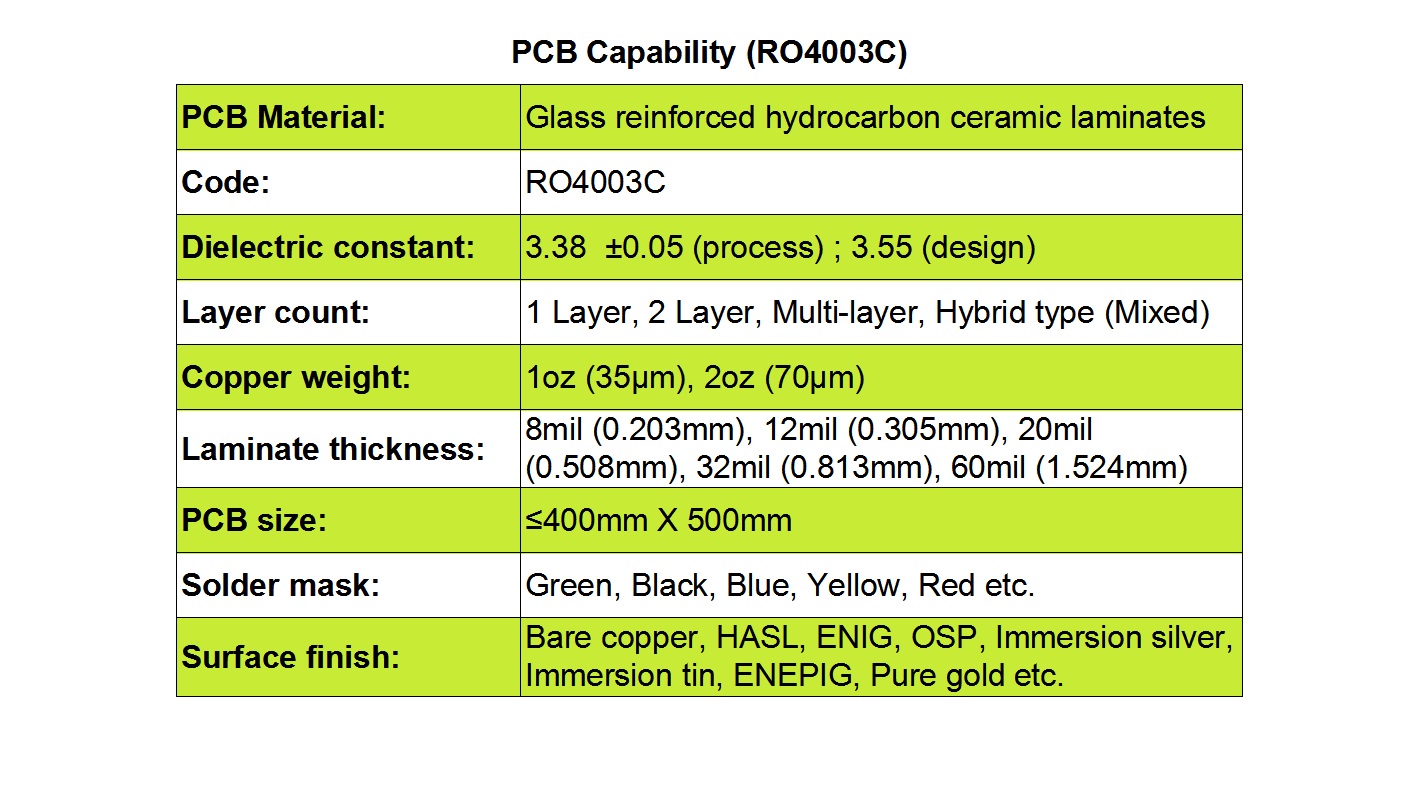

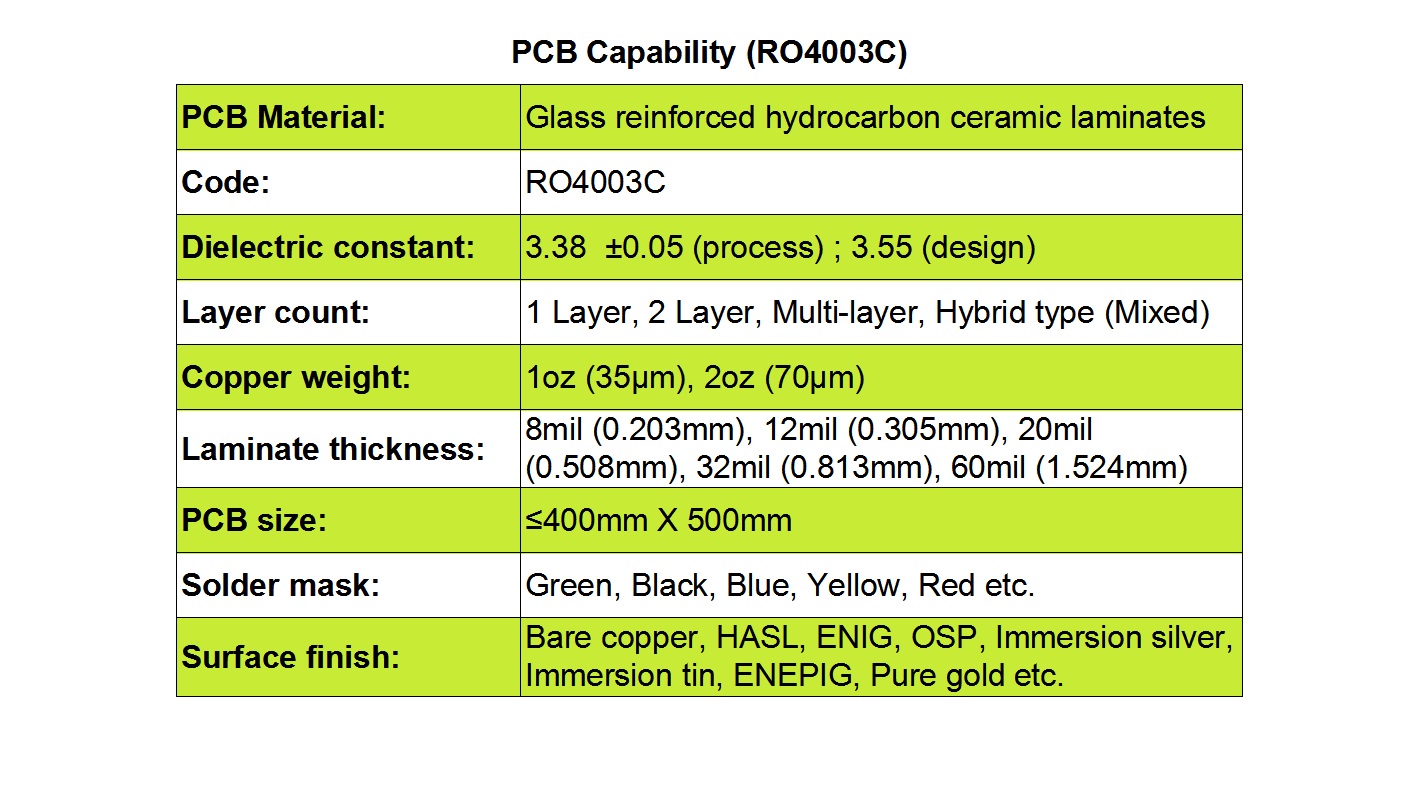

Advanced PCB Manufacturing Capabilities

Layer Flexibility & Construction

We support diverse design complexities through:

-

Layer Options: Double-sided, multilayer (up to 32 layers), and hybrid stacks.

-

Copper Weights: 1oz (35µm) and 2oz (70µm) for optimized current handling and thermal management.

Material Thickness

Select from RO4003C core thicknesses tailored to your electrical and mechanical needs:

-

Standard Thicknesses: 8mil (0.203mm), 12mil (0.305mm), 16mil (0.406mm), 20mil (0.508mm), 32mil (0.813mm), and 60mil (1.524mm).

Critical Fabrication Specifications:

-

Max Panel Size: 400mm×500mm (supports arrayed LNBs and large-format antenna panels)

Solder Mask:

-

Green (standard), Black/Blue (high-contrast alignment), or custom colors (Red/Yellow for test vehicles)

Surface Finishes:

-

HASL: Cost-effective consumer RFIDs

-

ENIG/ENEPIG: Gold wire-bondable PA modules

-

Immersion Ag/Sn: Lead-free automotive sensors

-

Flash Gold: High-reliability satellite comms

Industry-Leading Applications

Rogers RO4003C PCB excel in high-frequency environments demanding precision and durability:

-

Telecom: 5G base station antennas, power amplifiers.

-

Automotive: Radar sensors (77 GHz), ADAS modules.

-

Aerospace: Satellite LNBs (Low-Noise Block downconverters).

-

IoT: RFID tags, industrial sensors.

Why Partner with Us?

As a certified PCB supplier, we combine cutting-edge RO4003C materials with:

-

Hybrid PCB Expertise: Seamlessly integrate FR-4 and RO4003C layers.

-

Rigorous Testing: Ensure signal integrity via TDR and impedance control.

-

Rapid Prototyping: Accelerate development cycles without sacrificing quality.

Conclusion: The Cost-Performance Breakthrough

Rogers RO4003C High Frequency PCB resolve the traditional dilemma between electrical performance and manufacturability. By delivering PTFE-grade signal integrity via FR-4 production flows, they accelerate time-to-market for 5G, radar, and satellite systems while reducing total board costs by 25–40%. With our extensive processing capabilities–spanning hybrid designs, advanced finishes, and large-format panels–your high-frequency projects gain both technical superiority and supply-chain agility.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com