What Makes RT/duroid 6002 the Premier Choice for Demanding High-Frequency PCB Applications?

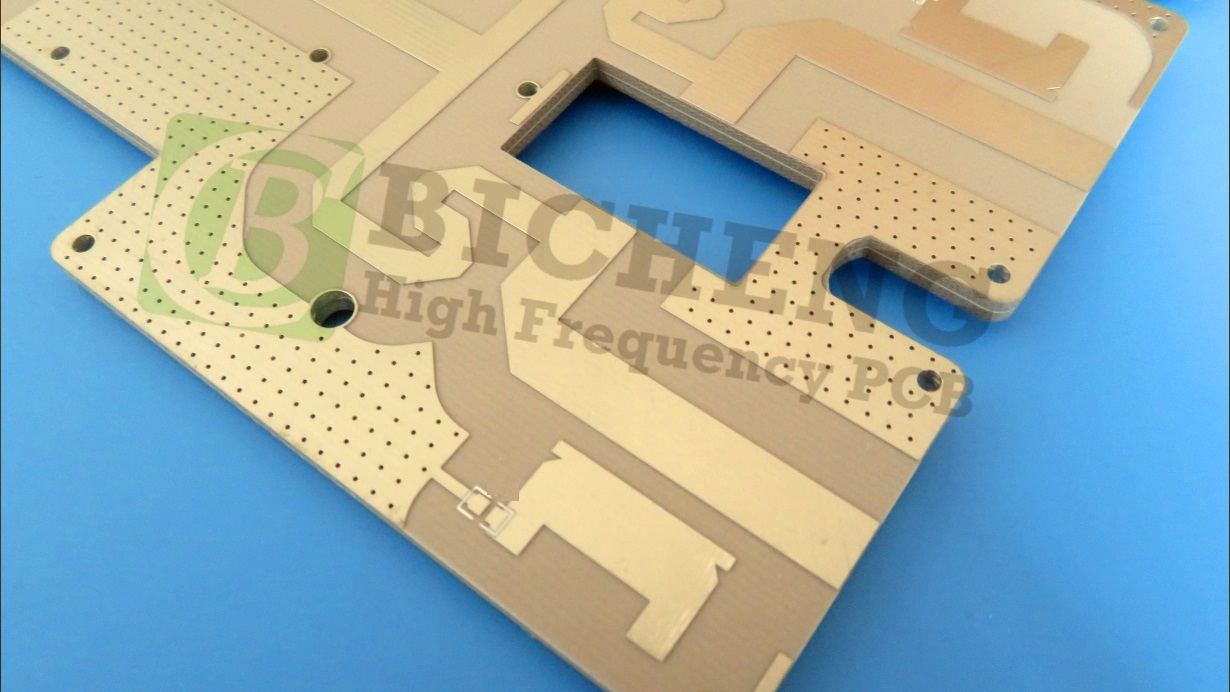

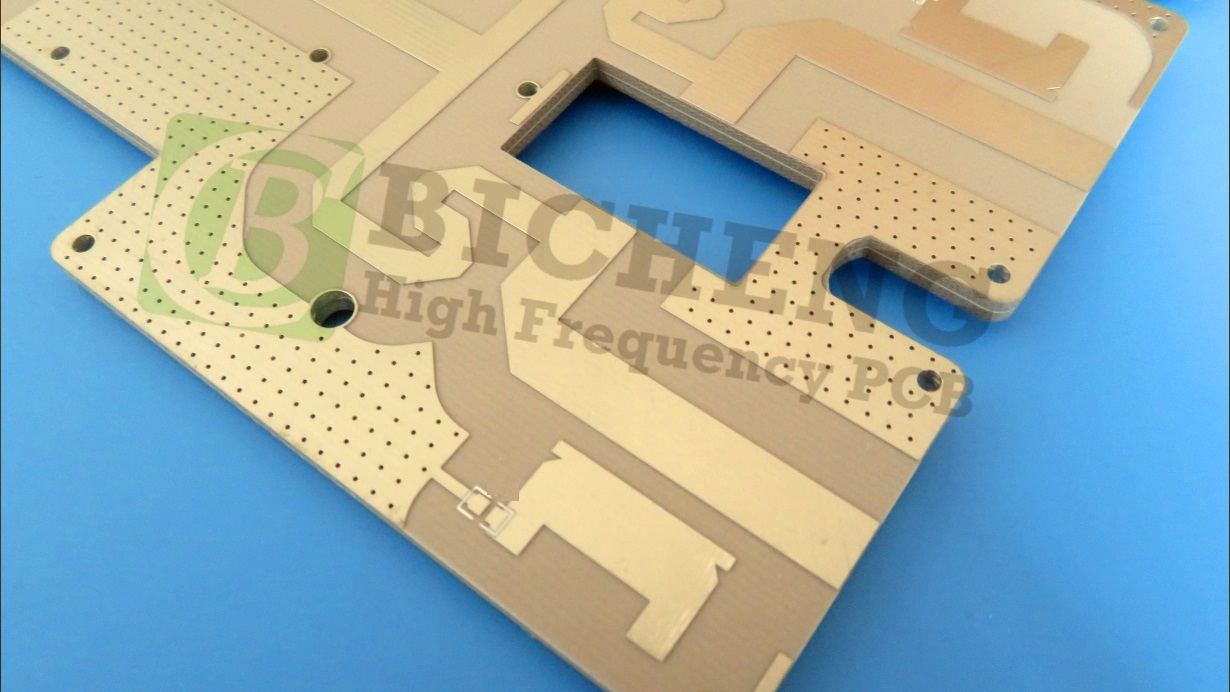

In the relentless pursuit of performance within the RF and microwave sector, the selection of printed circuit board (PCB) substrate material is a critical determinant of success. For engineers designing cutting-edge systems where signal integrity, thermal management, and reliability are non-negotiable, Rogers Corporation's RT/duroid 6002 laminates emerge as a superior microwave material solution. This advanced composite, engineered with ceramic-filled polytetrafluoroethylene (PTFE), is specifically formulated to meet the rigorous demands of complex microwave structures, offering an unparalleled blend of electrical and mechanical properties that guarantee exceptional performance and longevity in multi-layer board constructions.

Exceptional Material Properties for Peak Performance

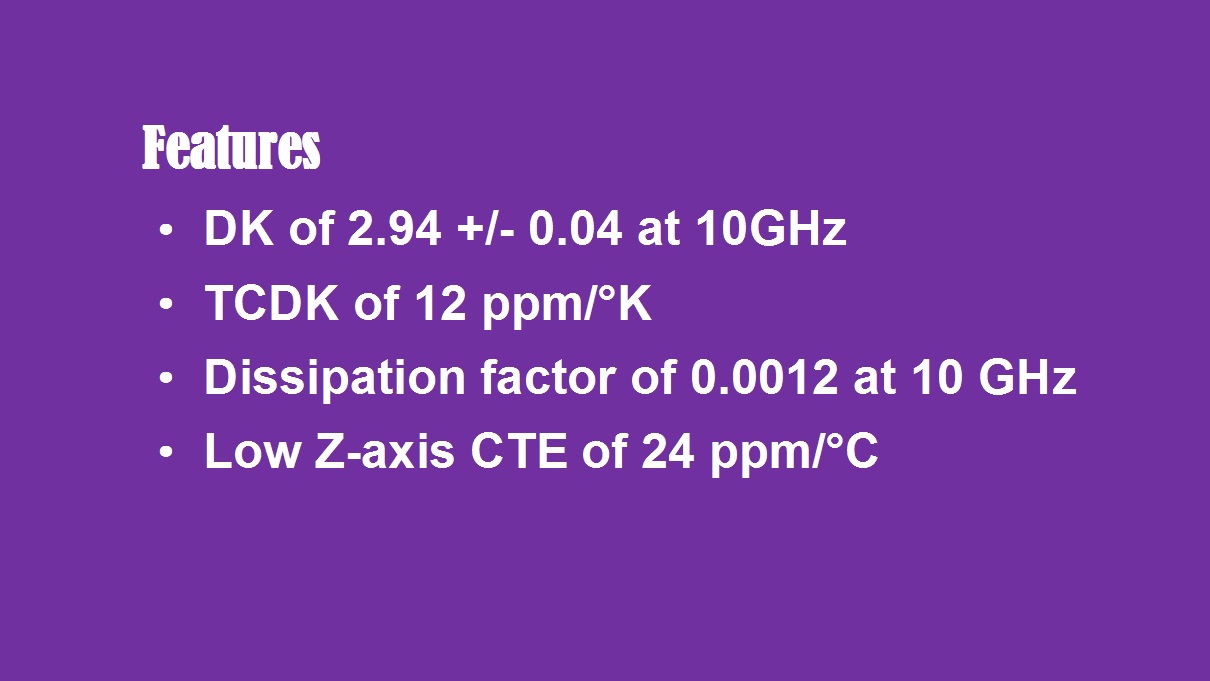

The standout characteristics of Rogers 6002 laminates are rooted in their precise and stable electrical properties, which are meticulously tailored for high-frequency applications.

1.Consistent Dielectric Constant:

With a dielectric constant (Dk) of 2.94 and an exceptionally tight tolerance of±0.04, these laminates provide a stable electrical environment that is paramount for impedance control. This consistency is vital for maintaining signal integrity, minimizing reflection, and ensuring predictable performance across the entire board.

2.Superior Thermal Stability:

A common challenge in high-frequency applications is performance drift caused by temperature fluctuations. The Rogers RT/duroid 6002 addresses this with an ultra-low thermal coefficient of dielectric constant (12 ppm/°C). This ensures that the Dk value remains stable over a broad temperature range, safeguarding the electrical performance of your design against thermal variations and ensuring operational consistency in diverse environments.

3.Minimal Signal Loss:

The dissipation factor (loss tangent) is a crucial metric for efficiency. At a remarkably low value of 0.0012 at 10 GHz, RT/duroid 6002 exhibits minimal electrical energy loss, converting it into heat. This translates to highly efficient transmission of microwave signals, reduced attenuation, and enhanced overall signal quality, which is essential for long-range and sensitive communication systems.

4.Enhanced Mechanical Reliability:

Beyond electrical performance, the laminate’s low Z-axis coefficient of thermal expansion (CTE) of 24 ppm/°C is a key feature for structural integrity. This characteristic signifies outstanding dimensional stability, drastically reducing the risk of warping, delamination, or plated through-hole failure when the board is subjected to thermal cycling during assembly and operation. This inherent stability is a cornerstone for building reliable, high-layer-count multilayer boards.

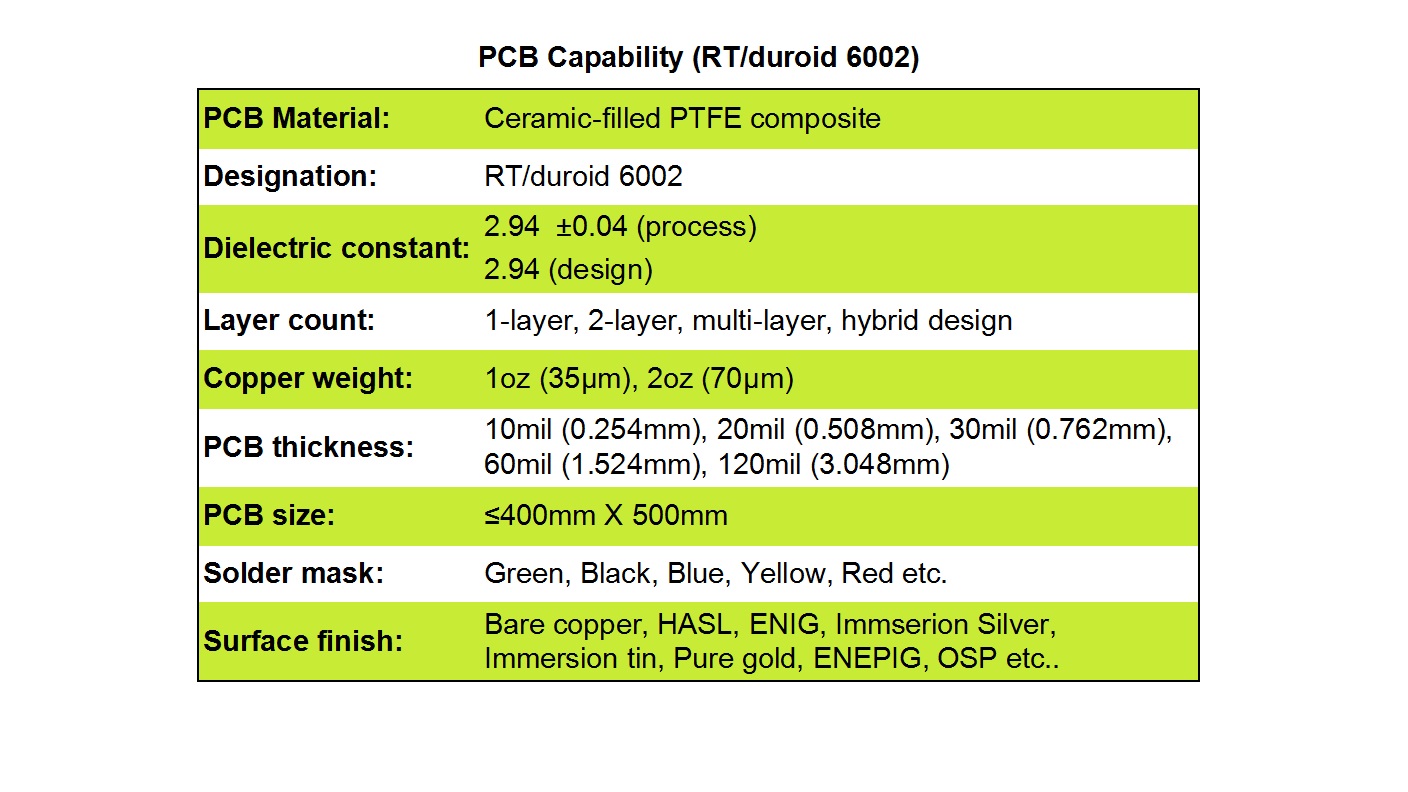

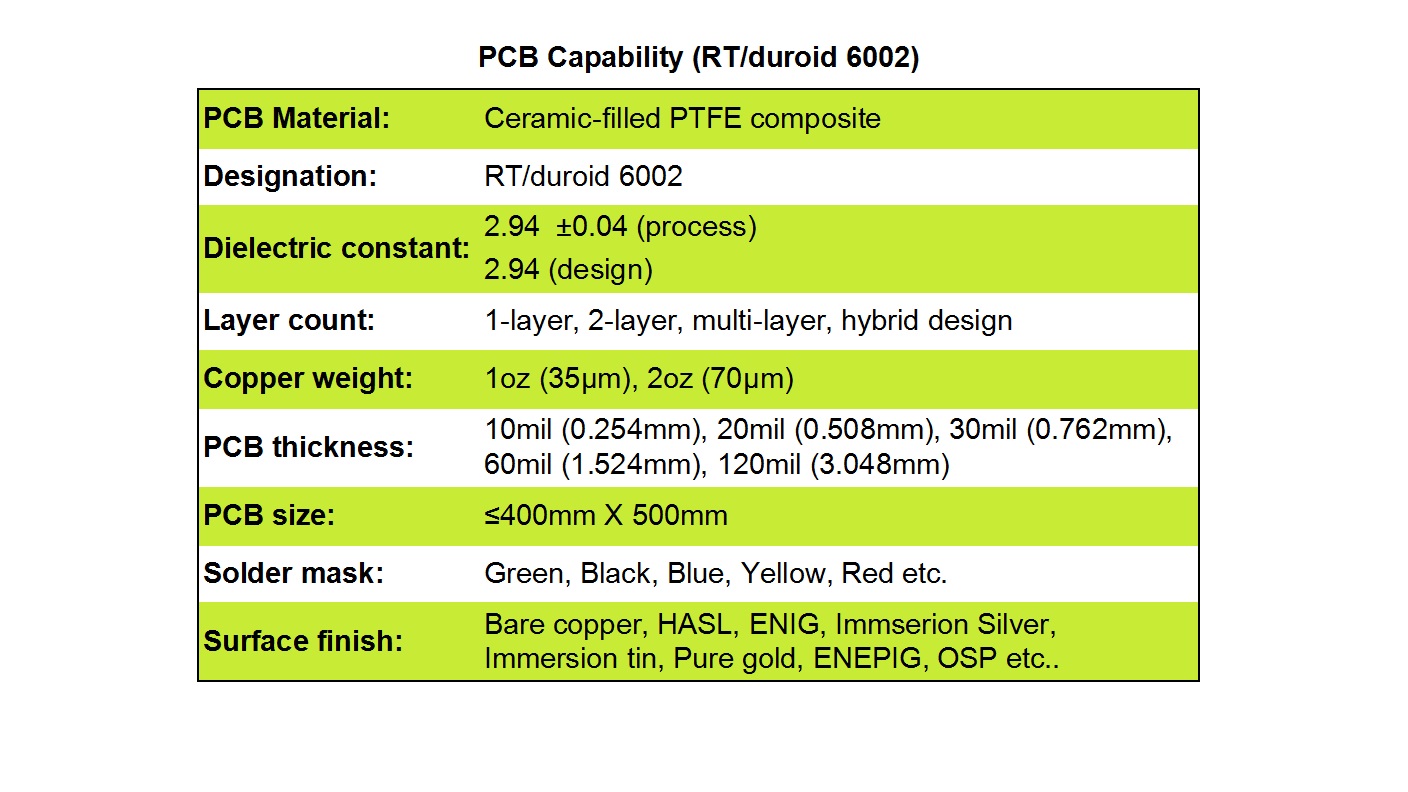

Advanced PCB Manufacturing Capabilities for RT/duroid 6002

Leveraging the superb properties of this material requires a manufacturing partner with precise expertise. Our specialized PCB fabrication services are optimized to fully harness the potential ofRogers RT/duroid 6002 material, offering extensive flexibility to meet your exact design requirements.

1.Layer Configuration Versatility:

We support a comprehensive range of structures, from simple 1-layer and 2-layer boards to sophisticated multi-layer and hybrid designs that incorporate other materials for optimized cost and performance.

2.Customizable Construction:

To achieve target impedances and manage current loads, we accommodate standard copper weights of 1oz (35µm) and 2oz (70µm). Furthermore, we provide a selection of precise PCB thicknesses, including 10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm), and 120mil (3.048mm).

3.Larger Format Boards:

Our production capabilities can accommodate PCB sizes up to 400mm x 500mm, providing ample real estate for larger, more complex circuitry often found in advanced radar and antenna systems.

4.Finishing Options:

We offer a variety of solder mask colors (Green, Black, Blue, Yellow, Red, etc.) and a complete suite of surface finishes. These include Bare Copper, HASL, ENIG, Immersion Silver, Immersion Tin, pure Gold (directly on copper), ENEPIG, and OSP, ensuring optimal solderability and protection for your specific application.

Broad-Ranging Applications

The unique combination of electrical and mechanical properties makes RT/duroid 6002 High Frequency PCBs the material of choice for a wide array of critical, high-performance applications. These include:

-Phased Array Antennas

-Ground-Based and Airborne Radar Systems

-Global Positioning System (GPS) Antennas

-High-Speed Power Backplanes

-Commercial Airline Collision Avoidance Systems

Conclusion

For designers pushing the boundaries of RF and microwave technology, the substrate is not just a foundation—it's an active component of the system's performance. Rogers RT/duroid 6002 substrates, with their proven low-loss, stable Dk, and outstanding reliability, provide the technical excellence required for next-generation applications. Partner with a supplier that possesses the advanced manufacturing capabilities to transform this exceptional material into a high-precision, reliable PCB that will elevate your product's performance. Contact us today to discuss your project requirements and discover how our expertise can benefit your next high-frequency design.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com