Why is TFA300 a Superior Choice for High-Reliability, Thermal-Stable PCB Designs?

In the rapidly advancing world of electronics, where signal speeds soar into the gigahertz range and applications demand unparalleled reliability, the choice of printed circuit board (PCB) material becomes paramount. Wangling TFA300 high-frequency PCB emerges as a premier aerospace-grade solution, engineered to meet the rigorous demands of next-generation technology. This article delves into the superior properties, manufacturing capabilities, and diverse applications ofTFA300, illustrating why it is a standout alternative to comparable international products.

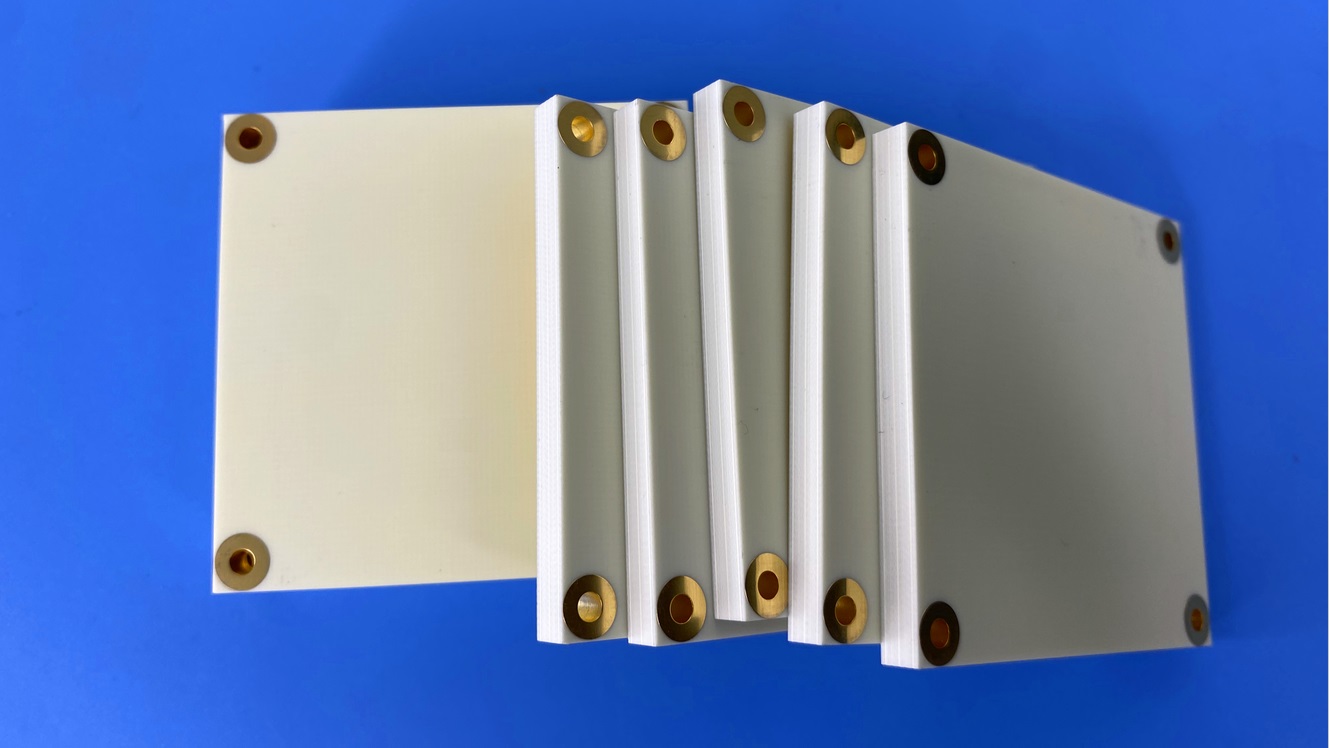

Innovative Material Composition and Manufacturing

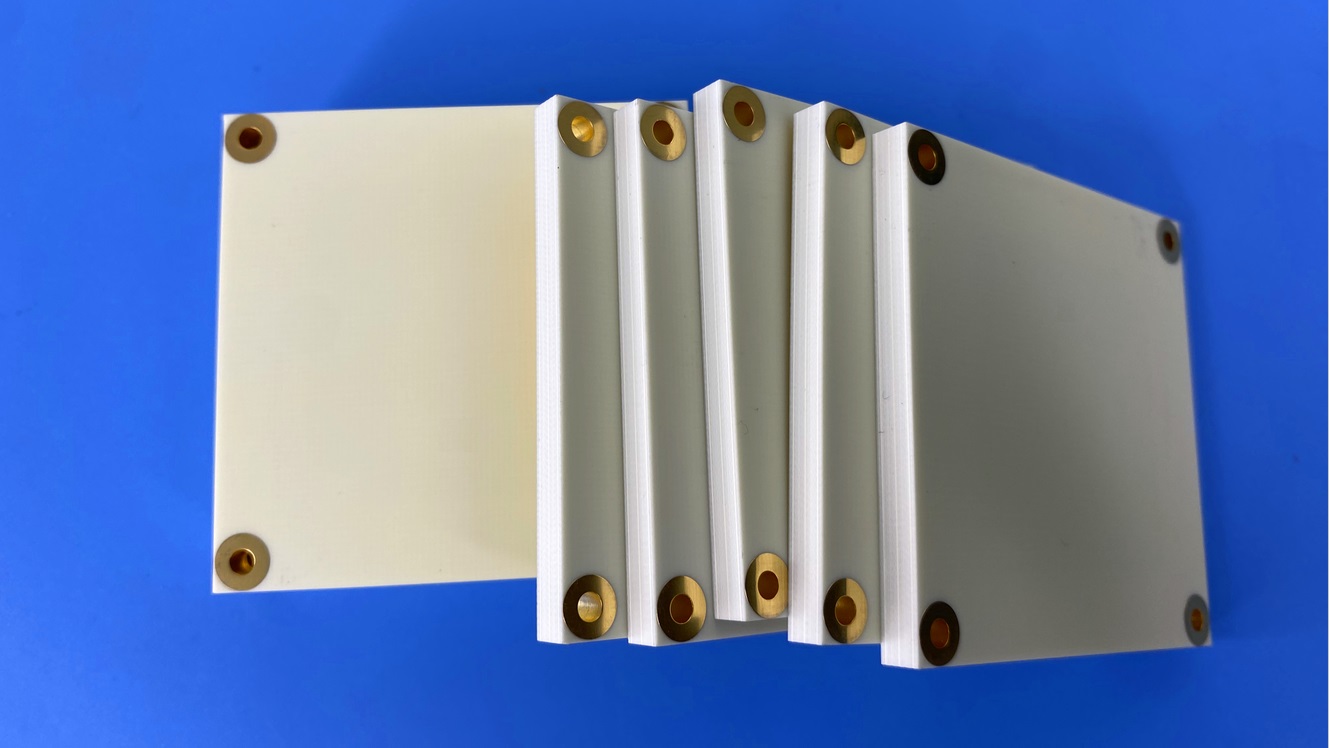

The foundational advantage of Wangling TFA300 lies in its sophisticated material architecture. It incorporates a significant proportion of uniform, special nano-ceramic particles meticulously blended with Polytetrafluoroethylene (PTFE) resin. This innovative formulation effectively eliminates the traditional fiberglass effect, which can disrupt the propagation of electromagnetic waves and impair signal quality. Through a proprietary manufacturing process, these materials are transformed into consistent prepreg sheets. These sheets are subsequently laminated using a specialized pressing technique, resulting in a substrate that exhibits exceptional electrical, thermal, and mechanical characteristics. This meticulous production ensures a stable and predictable dielectric constant, forming the bedrock of its high-performance capabilities.

Outstanding Features and Performance Advantages

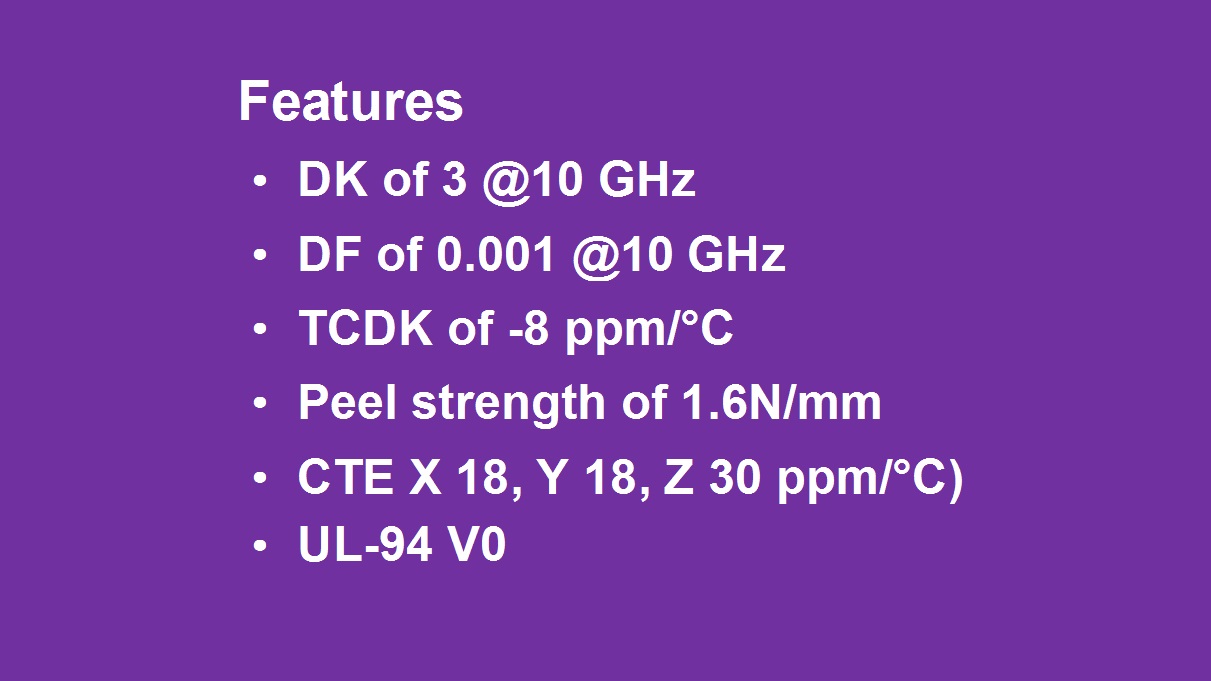

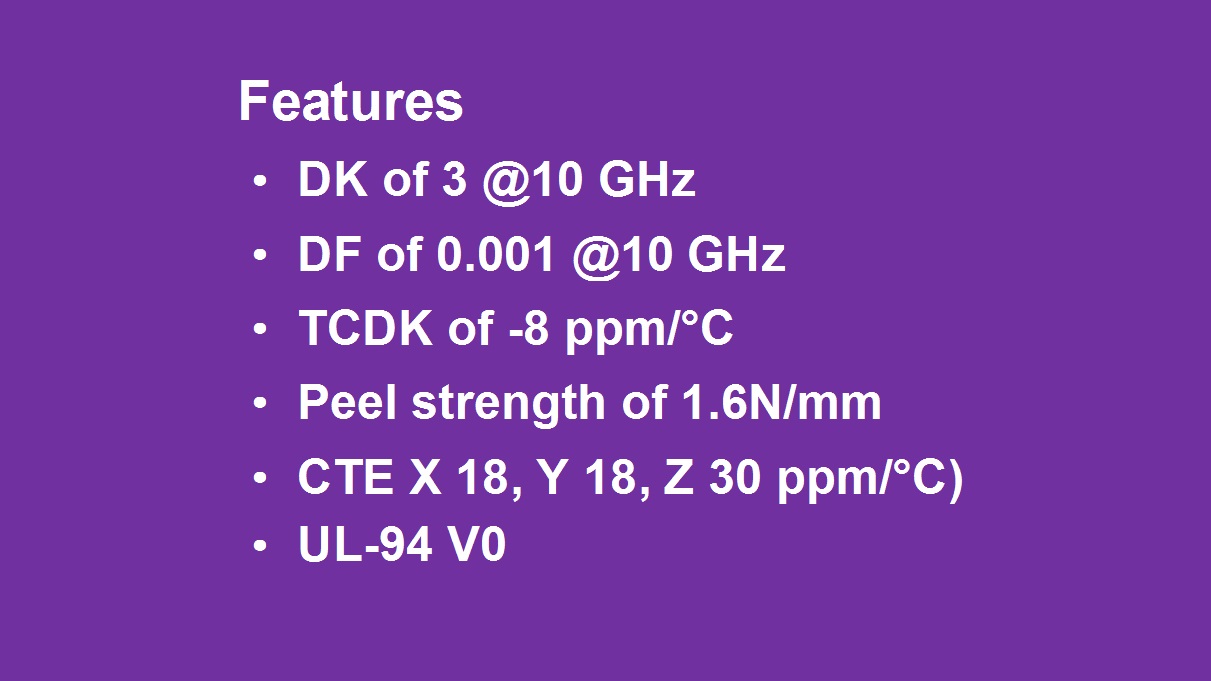

TFA300 PCB is characterized by a suite of exceptional electrical and physical properties designed for high-speed/high-frequency environments:

1) Optimal Signal Transmission: It boasts a low dielectric constant (Dk) of 3.0 at 10GHz, which minimizes signal propagation delay and enables superior impedance control, critical for 5G infrastructure, radar systems, and millimeter-wave circuits.

2) Minimal Signal Loss: An ultra-low dissipation factor (Df) of 0.001 at the same frequency ensures minimal signal attenuation, preserving signal integrity and power efficiency in sensitive RF/microwave PCBs and antenna designs.

3) Exceptional Thermal Stability: A remarkable Thermal Coefficient of Dielectric Constant (TCDk) of -8 ppm/°C guarantees outstanding dielectric constant stability across a vast temperature range from -40°C to +150°C. This stability is vital for automotive radars, aerospace avionics, and outdoor telecommunications equipment exposed to harsh environmental conditions.

4) Superior Mechanical Reliability: The material demonstrates a robust peel strength greater than 1.6N/mm, indicating excellent adhesion between copper layers and the substrate, thereby mitigating the risk of delamination in complex multilayer boards.

5) Enhanced Dimensional Stability: A low Coefficient of Thermal Expansion (CTE) of 18 ppm/°C in the X and Y axes closely matches that of copper (17 ppm/°C), significantly reducing thermal stress and preventing warpage during manufacturing and operation. A Z-axis CTE of 30 ppm/°C provides an ideal balance between rigidity and flexibility, ensuring the long-term reliability of plated through-holes (PTH).

6) Additional Robust Properties: TFA300 also features low water absorption (0.04%), reducing performance degradation in humid environments, and a higher thermal conductivity (0.8 W/m·K) for improved heat dissipation. It complies with the stringent UL-94 V-0 standard for flame retardancy.

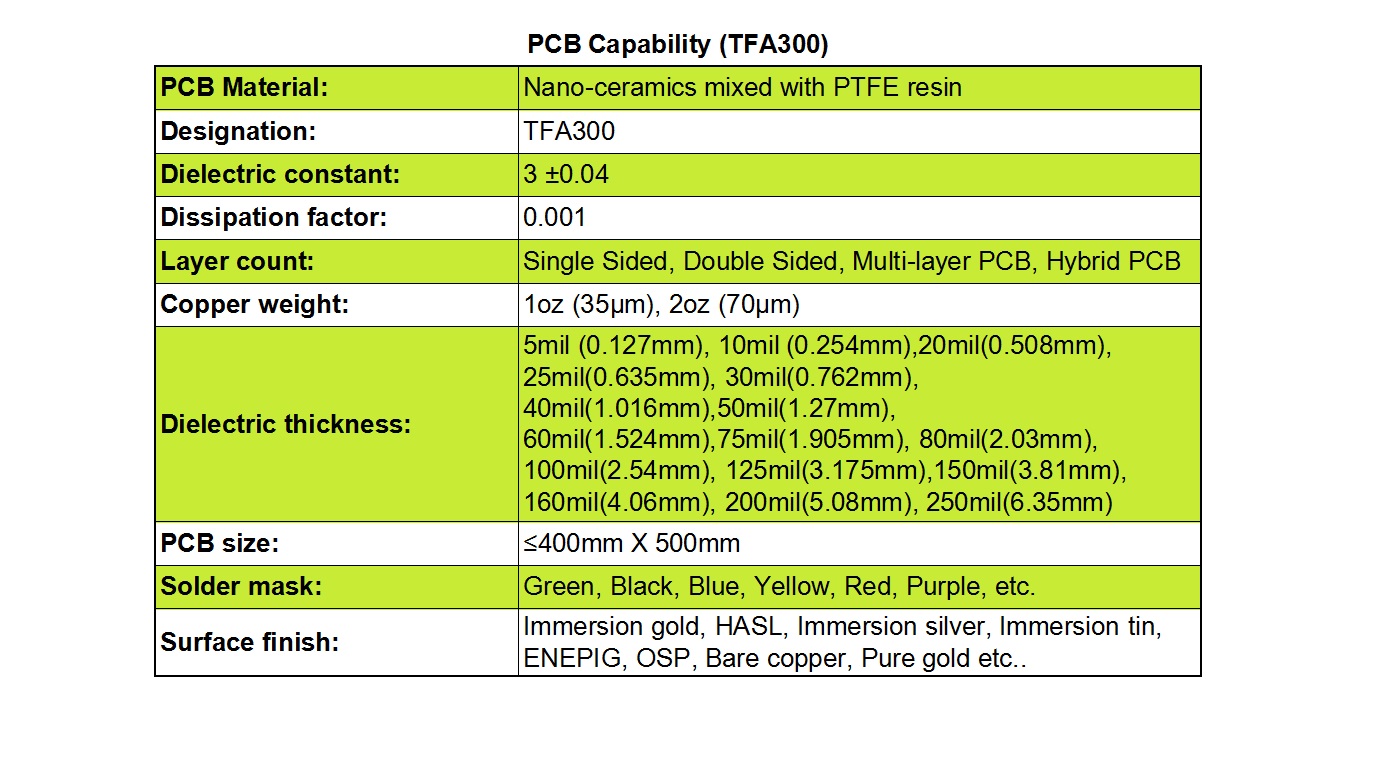

Advanced PCB Fabrication Capabilities

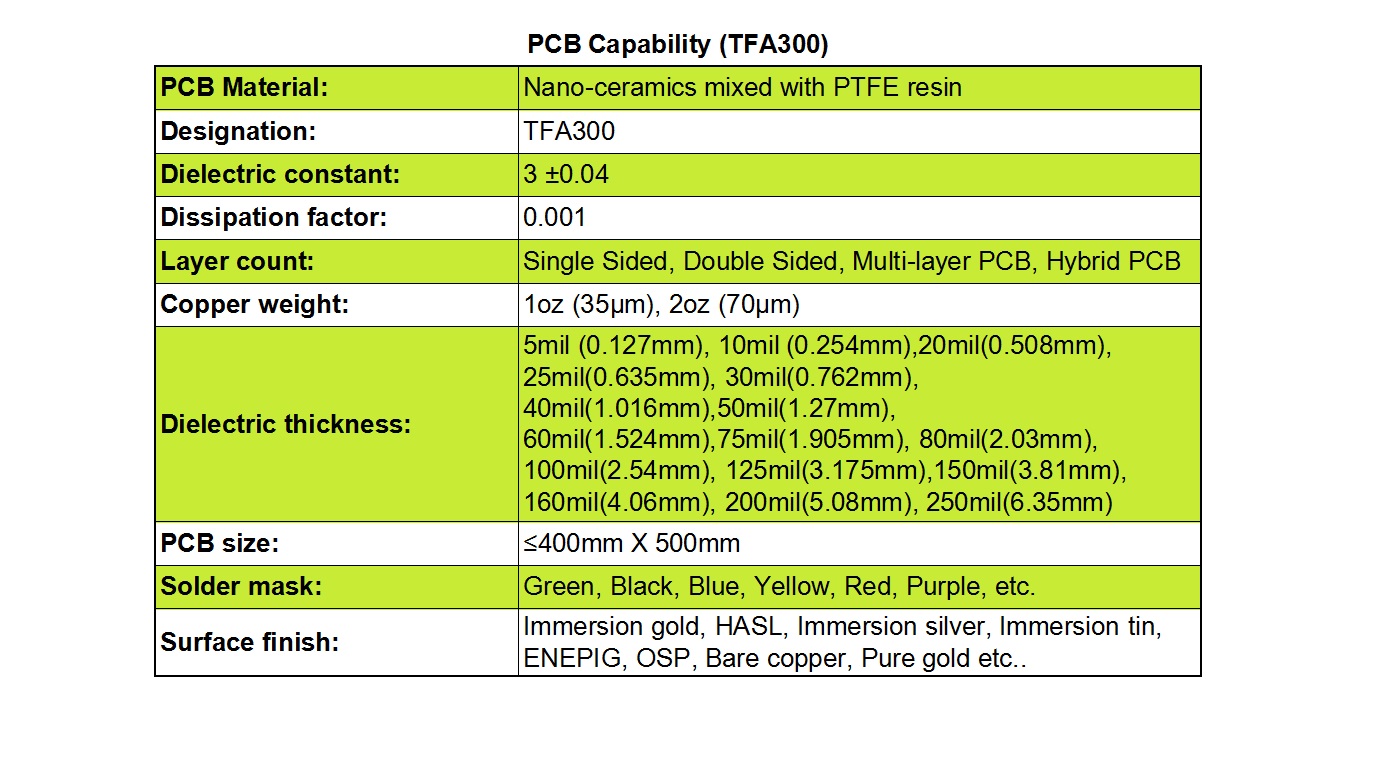

We provide end-to-end manufacturing services for high-qualityWanglingTFA300 PCBs, customized to your precise design and performance requirements:

1) Layer Count: We offer versatility, producing single-sided, double-sided, multilayer, and hybrid construction PCBs (combining different materials).

2) Copper Weight: Options include standard 1oz (35µm) for optimal signal integrity or 2oz (70µm) for designs requiring enhanced current-carrying capacity and thermal management.

3) Dielectric Thickness: Our extensive range, from 5mil (0.127mm) to 250mil (6.35mm), allows for precise impedance control and design adaptability for various high-frequency applications.

4) PCB Size: We can fabricate on large-format panels up to 400mm x 500mm, accommodating either a single large board or multiple designs in one array.

5) Solder Mask: Available in various colors including Green, Black, Blue, Yellow, and Red.

6) Surface Finishes: A comprehensive selection of finishes is available, including Immersion Gold (ENIG), Lead-Free HASL, Immersion Silver, Immersion Tin, ENEPIG, OSP, Bare Copper, and Pure Gold.

Diverse Field of Applications

TFA300 Wangling PCBs are ideally suited for high-performance industries where failure is not an option. Typical applications include aerospace and aviation equipment, phase-array antennas, airborne and ground-based radar systems, satellite communication platforms, and advanced navigation systems.

By integrating cutting-edge material science with advanced manufacturing prowess, TFA300 high frequency PCBs deliver the performance, reliability, and stability necessary to power the future of technology.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com