How Can TF High-Frequency PCB Technology Meet Your Design Requirements?

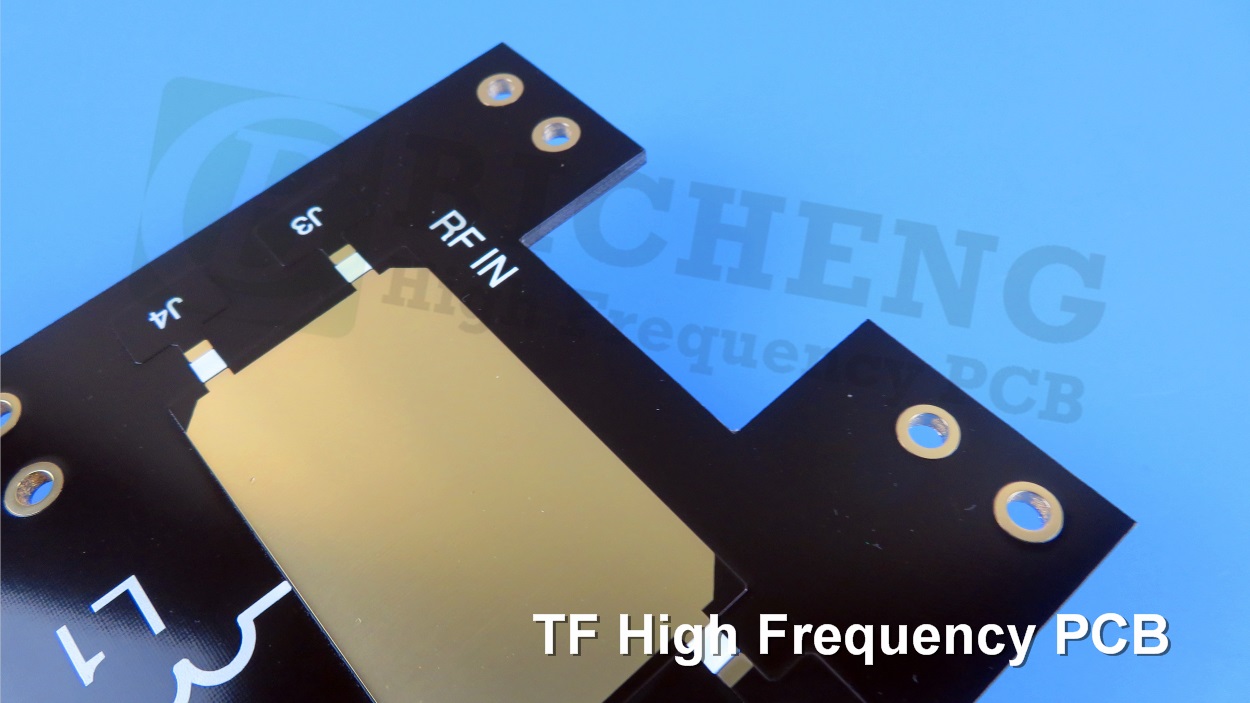

In the rapidly advancing world of wireless communication, radar systems, and high-speed digital applications, the performance of your printed circuit board (PCB) is non-negotiable. At the heart of every high-frequency system lies the PCB substrate, a material that fundamentally determines signal integrity, loss, and overall reliability. For engineers pushing the boundaries of technology, standard FR-4 materials fall short. This is where Wangling TF PCBs, engineered with specialized ceramic-filled PTFE composites, emerge as the superior solution. But what specific attributes make them the ideal choice for your most demanding projects?

Advanced Material Composition: The Foundation of Performance

Wangling TF laminates are not your ordinary PCB materials. They represent a sophisticated composite engineered for excellence. The core structure is based on a unique formulation of polytetrafluoroethylene (PTFE) resin, renowned for its exceptional microwave properties, combined with a precisely measured ceramic filler. A key differentiator is the deliberate absence of fiberglass cloth, which can introduce inconsistencies in the dielectric constant (Dk). By eliminating this variable and fine-tuning the ratio of ceramic to PTFE, we achieve unparalleled control over the dielectric constant. This meticulous material science, coupled with specialized production processes, results in a laminate that delivers outstanding dielectric performance and a high degree of long-term reliability, essential for mission-critical applications.

In-Depth Look at Key Features and Benefits

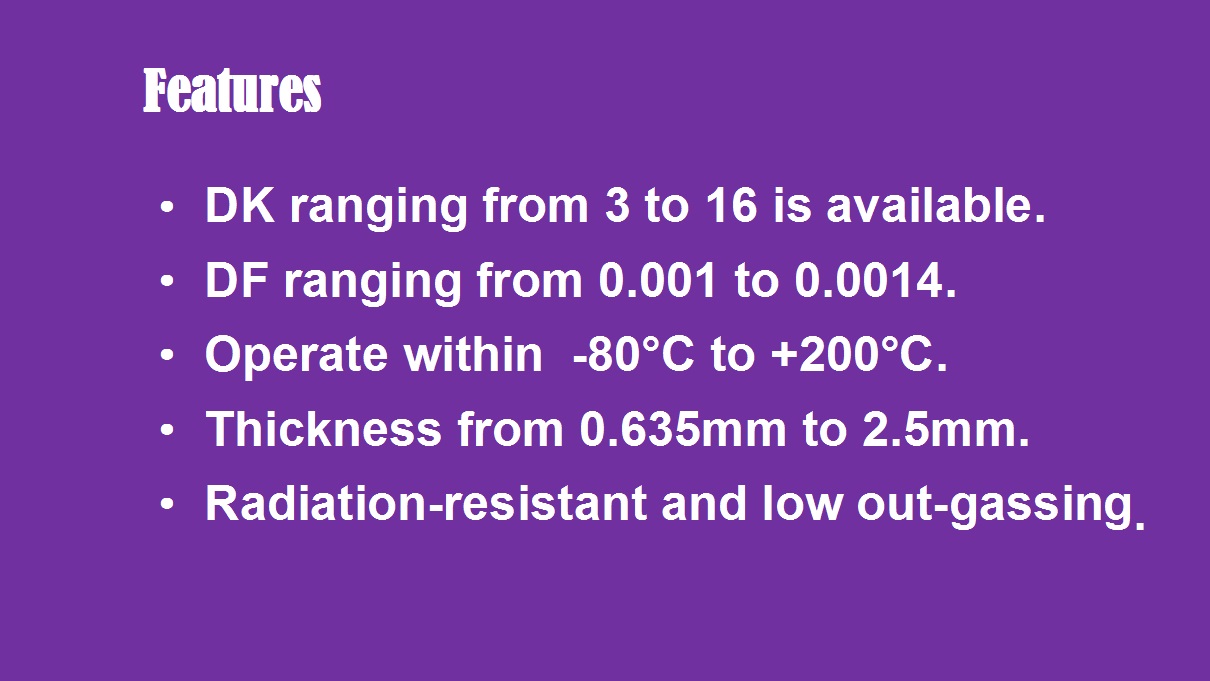

The superiority of TF High-Frequency PCBs is quantified through a set of exceptional characteristics:

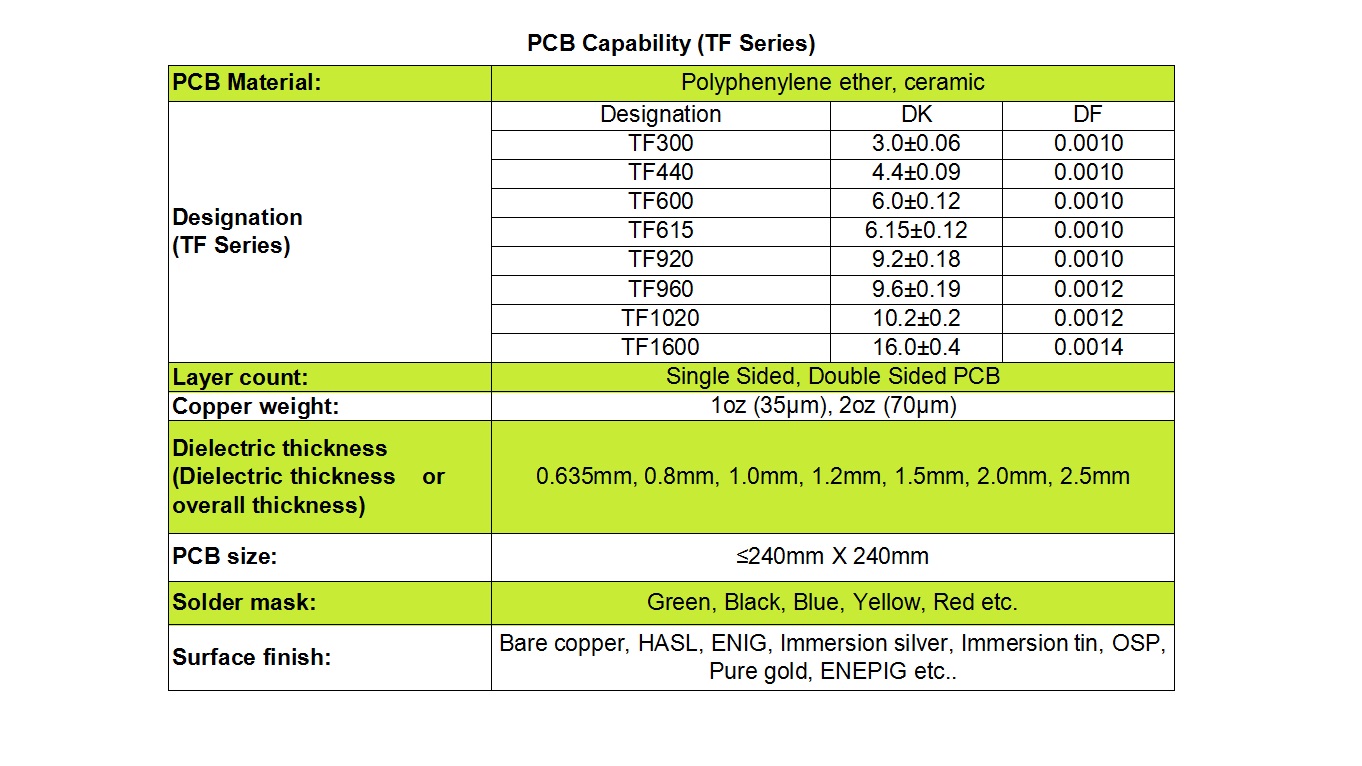

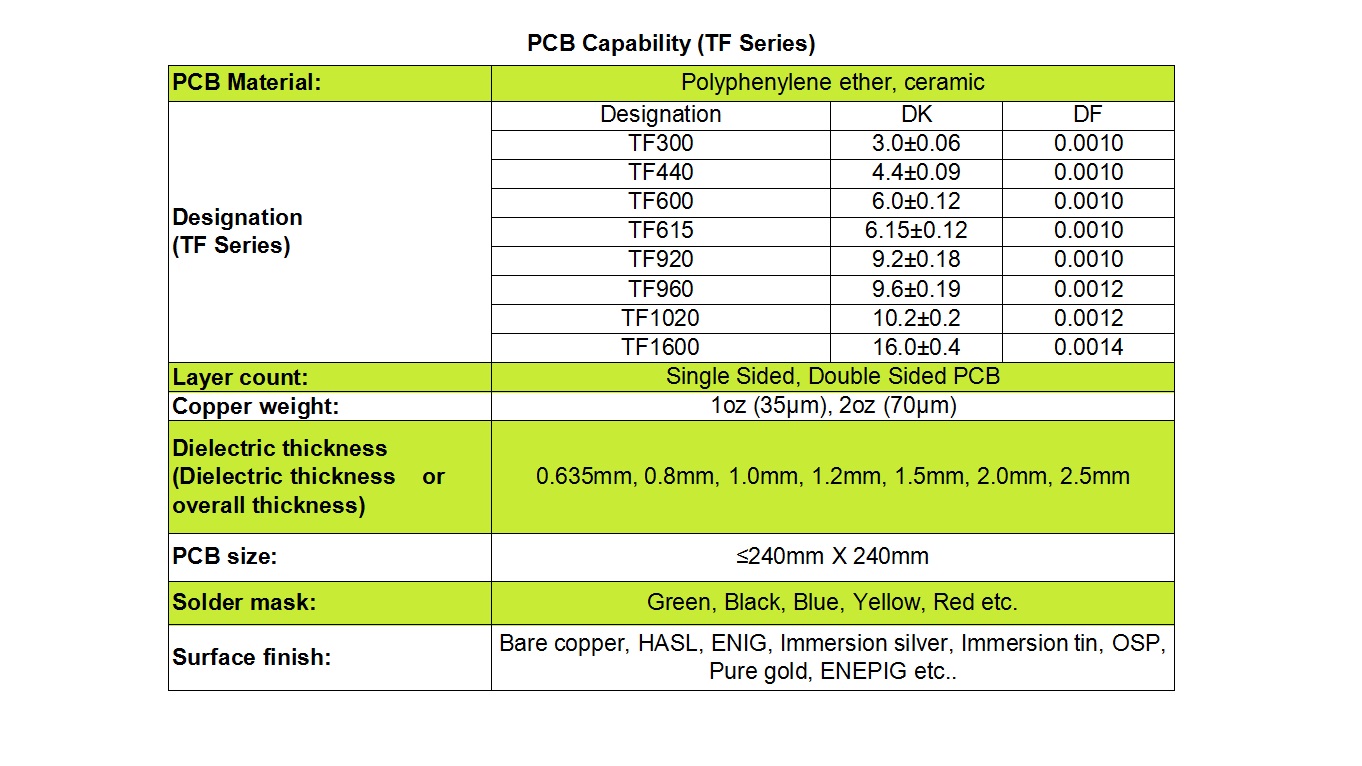

1) Precise and Stable Dielectric Constant (Dk): TF laminates offer a stable and broad range of dielectric constants, spanning from 3.0 to 16.0. Common values such as 3.0, 6.0, 9.2, 9.6, 10.2, and 16 are readily available. This stability across frequencies is critical for maintaining consistent impedance control and preventing signal distortion in high-speed designs.

2) Exceptionally Low Loss Tangent (Df): Signal loss is a primary concern in high-frequency circuits. TF laminates excel with an ultra-low dissipation factor (Df), a measure of signal energy lost as heat. For instance, for Dk values between 3.0 and 9.5 at 10GHz, the loss tangent is an impressively low 0.0010. This minimal loss ensures stronger signals, greater range, and improved overall system efficiency.

3) Exceptional Thermal Stability and Range: Performance cannot falter under thermal stress. TF materials surpass standard high-temperature options with an extensive operational temperature range of -80°C to +200°C. This ensures reliable performance in harsh environments, from aerospace applications to high-power equipment, without degradation of electrical properties.

4) Versatile Physical Properties: To accommodate diverse design requirements, these laminates are available in thicknesses from 0.635mm to 2.5mm. Furthermore, they boast inherent resistance to radiation and exhibit low outgassing properties, making them suitable for sensitive vacuum environments like space and satellite systems.

Comprehensive PCB Manufacturing Capabilities

Having a superior material is only half the battle; precision manufacturing is key. We provide a full spectrum of PCB fabrication services tailored to harness the full potential of TF laminates:

1) Board Configurations: We accommodate both Single-Sided and Double-Sided PCB designs.

2) Copper Cladding: Select from standard copper weights like 1oz (35µm) and 2oz (70µm) to meet specific current-carrying capacity and conductivity needs.

3) Dielectric Thickness: A diverse selection of dielectric layer thicknesses is available, ranging from 0.635mm to 2.5mm.

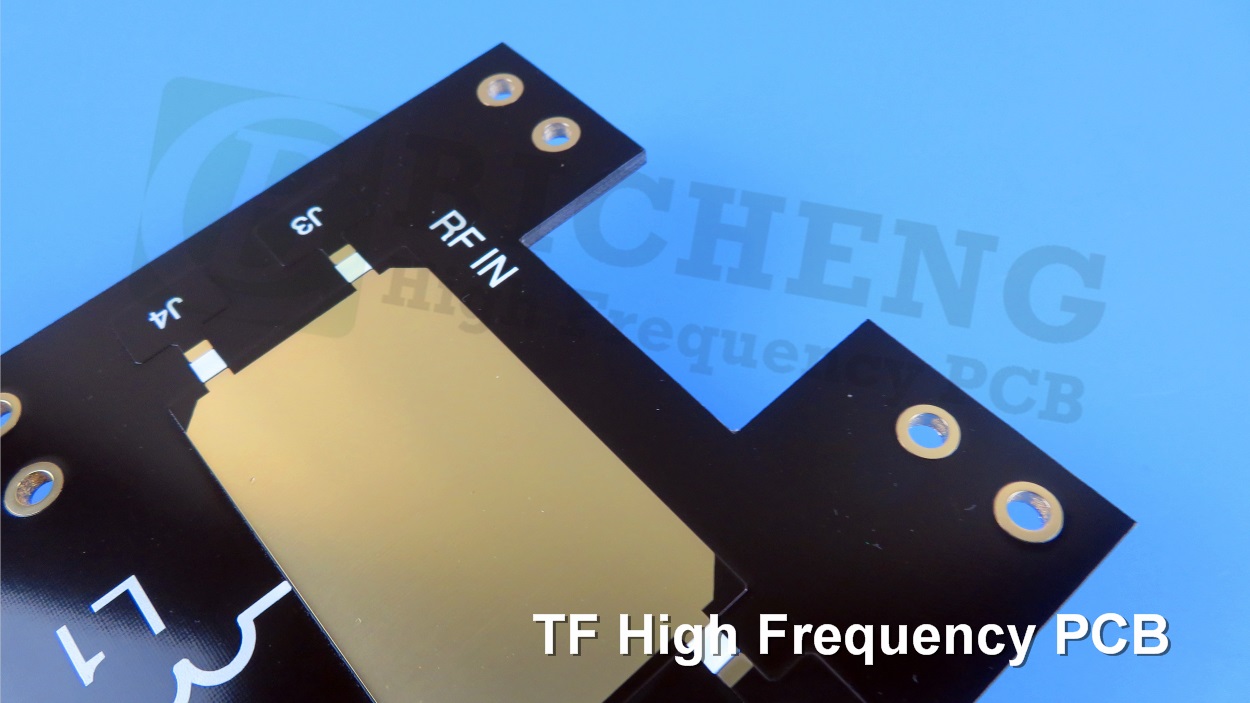

4) Board Size and Solder Mask: We support PCB sizes up to 240mm x 240mm and offer a variety of solder mask colors including Green, Black, Blue, Yellow, and Red.

5) Surface Finishes: Choose from a wide array of surface finishes to suit your assembly and performance requirements, including Bare Copper, HASL, ENIG, Immersion Silver, Immersion Tin, OSP, Pure Gold, and ENEPIG.

Broad Range of Applications

CustomTF PCBs are indispensable in advanced microwave and millimeter-wave domains. Their unique properties make them the substrate of choice for:

1) Millimeter-Wave Radar Sensors: For automotive ADAS, security, and industrial sensing.

2) High-Frequency Antennas and Transceivers: Enabling 5G/6G infrastructure, satellite communication, and point-to-point radio links.

3) RF Components: Such as modulators, multiplexers, and filters requiring minimal signal loss.

4) Critical Power Supply and Automatic Control Equipment: Where stability and reliability under thermal stress are paramount.

Conclusion

When your application demands uncompromising performance at high frequencies, the choice of PCB material is critical.Wangling TF High-Frequency PCBs, with their ceramic-PTFE composition, stable electrical properties, ultra-low loss, and robust thermal characteristics, provide the technological edge needed for next-generation electronics. By partnering with us, you gain access to both the advanced materials and the specialized manufacturing expertise to bring your most ambitious high-frequency designs to life.

Contact us today to discuss how our TF PCB solutions can meet the specific challenges of your application.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com