Why Choose a Silver/Gold Surface Finish for High-Frequency PCBs?

In the world of high-frequency and radio frequency (RF) PCB design, every decision impacts performance. From the laminate material to the trace geometry, engineers labor over details to minimize loss and preserve signal integrity. One of the most critical choices lies in the surface finish—the final coating applied to the exposed copper circuitry. While options like ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling) are common, for demanding applications, the silver/gold plate (gold over silver) finish stands out as a superior solution.

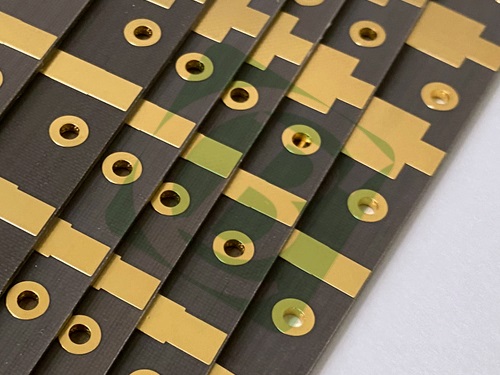

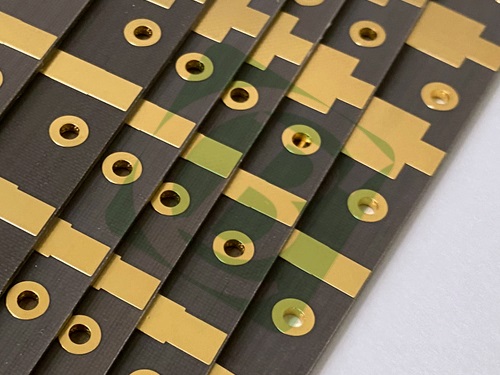

Here’s a breakdown of why this specific finish is the go-to choice for high-performance PCBs, such as our TLY-3 2-layer 20mil board.

1. The Unmatched Electrical Performance of Silver

At high frequencies, especially into the millimeter-wave range (like 24 GHz, 77 GHz, and beyond), the "skin effect" becomes dominant. This phenomenon causes the electrical current to flow primarily on the outer surface of the conductor. Therefore, the properties of the surface finish itself directly influence the signal's insertion loss.

-

High Conductivity: Pure silver is the most electrically conductive metal, even slightly better than copper. When used as a base plating layer, it creates an exceptionally low-loss path for RF signals. Compared to a standard ENIG finish, which uses a less-conductive nickel barrier layer, silver plating offers significantly lower signal loss at high frequencies.

-

Smooth Surface Profile: The electroplating process for silver results in a very flat and uniform surface. This smoothness is crucial for consistent impedance control in delicate transmission lines like microstrips or coplanar waveguides, where surface roughness can increase loss and scatter signals.

2. The Protective and Reliable Role of Gold

While silver is an excellent conductor, it has a major Achilles' heel: it tarnishes and oxidizes easily when exposed to sulfur in the atmosphere. This oxidation layer is non-conductive and would severely degrade performance over time. This is where the thin layer of gold comes in.

-

Inert Protection: Gold is a noble metal, meaning it does not oxidize or corrode in normal environments. The thin, immersion gold layer hermetically seals the underlying silver, protecting it from the elements and ensuring long-term shelf life and reliability.

-

Excellent Contact Properties: For PCBs designed to be plugged into a connector or make direct contact with a metal housing (e.g., in an antenna module), gold is ideal. It provides a stable, low-resistance contact interface that won't degrade through repeated mating cycles.

3. The Synergy of the Duo: Best of Both Worlds

The "gold over silver" finish is a classic case of a perfect partnership. Each metal plays a distinct role:

-

Silver serves as the workhorse conductor, providing the ultimate electrical performance.

-

Gold acts as the protective shield, guaranteeing long-term solderability, stable contact resistance, and reliability.

-

This combination delivers a surface that is both electrically superior at high frequencies and robust enough for demanding automotive, aerospace, and telecommunications applications.

Comparison to Other Common Finishes

To fully appreciate the silver/gold finish, it helps to compare it to alternatives:

-

vs. ENIG (Electroless Nickel Immersion Gold): ENIG is popular but problematic for very high frequencies. The nickel layer, while preventing copper diffusion, has poor conductivity and introduces magnetic losses, which are detrimental above a few GHz. Silver/gold avoids this lossy nickel layer entirely.

-

vs. Immersion Silver: Immersion silver alone is a good option but is more susceptible to tarnishing and has a shorter shelf life than the gold-protected version.

-

vs. OSP (Organic Solderability Preservative): OSP is a thin, organic layer that offers little to no protection for exposed contacts and can be unsuitable for certain assembly processes.

Conclusion: A Finish for Mission-Critical Applications

Choosing a silver/gold surface finish is not about luxury; it's a calculated engineering decision for applications where signal integrity and long-term reliability are non-negotiable. For our TLY-3 PCB 20mil Silver Gold board, this finish is the perfect complement to the high-frequency properties of the TLY-3 laminate. It ensures that the exceptional signal performance designed into the board is not compromised at the surface level, making it the ideal choice for:

-

77 GHz Automotive Radar Sensors

-

Satellite Communication Phased Arrays

-

Millimeter-Wave Antennas (Ka, E, W-Band)

When your design cannot afford unnecessary losses, the silver/gold finish PCB provides the electrical edge and enduring protection you need.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com