Seeking a High-Frequency PCB with Exceptional Dimensional Stability and Low Loss? Explore F4BTMS.

In the relentless pursuit of higher speeds and greater bandwidth within the electronics industry, the choice of printed circuit board (PCB) material becomes paramount. For applications operating at radio frequency (RF) and microwave ranges, standard FR-4 materials fall short, leading to significant signal degradation and loss. Enter the F4BTMS High Frequency PCB –a technologically advanced circuit board substrate engineered to meet the rigorous demands of next-generation high-frequency applications. This article delves into the superior properties, manufacturing capabilities, and diverse applications of Wangling F4BTMS, positioning it as an indispensable solution for engineers designing cutting-edge systems.

Evolution in Material Science: The Foundation of F4BTMS

The F4BTMS series laminates represents a significant evolution from its predecessor, the F4BTM PCB series. This next-generation material achieves a remarkable leap in performance through a sophisticated material composition. The key enhancement lies in the integration of a substantial volume of special nano-ceramics within a Polytetrafluoroethylene (PTFE) resin matrix, reinforced with an ultra-thin and ultra-fine fiberglass cloth. This strategic formulation is instrumental in minimizing the interstitial voids that typically contribute to electromagnetic wave interference. The result is a dramatic reduction in dielectric loss (Df) and a significant enhancement in the material's dimensional stability across a wide temperature range.

Furthermore, F4BTMS PCB exhibits a highly reduced anisotropy in its thermal expansion characteristics across the X, Y, and Z axes. This balanced CTE (Coefficient of Thermal Expansion) is critical for maintaining the integrity of plated through-holes (PTHs) during thermal cycling, thereby ensuring long-term reliability. These combined improvements unlock the potential for higher frequency operation, increased electrical strength, and improved thermal conductivity compared to standard high-frequency materials.

Unparalleled Material Properties for Peak Performance

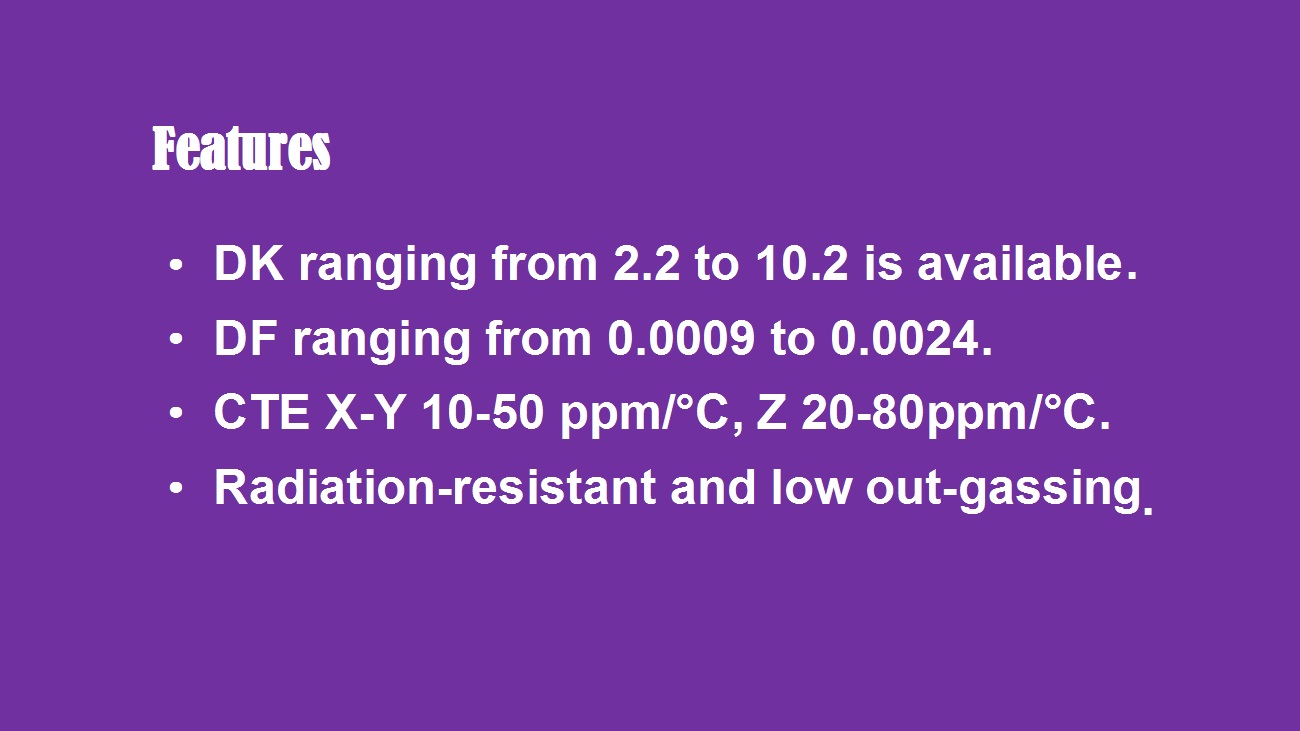

The F4BTMS material boasts a set of electrical and thermal properties that make it stand out in the high-frequency PCB market:

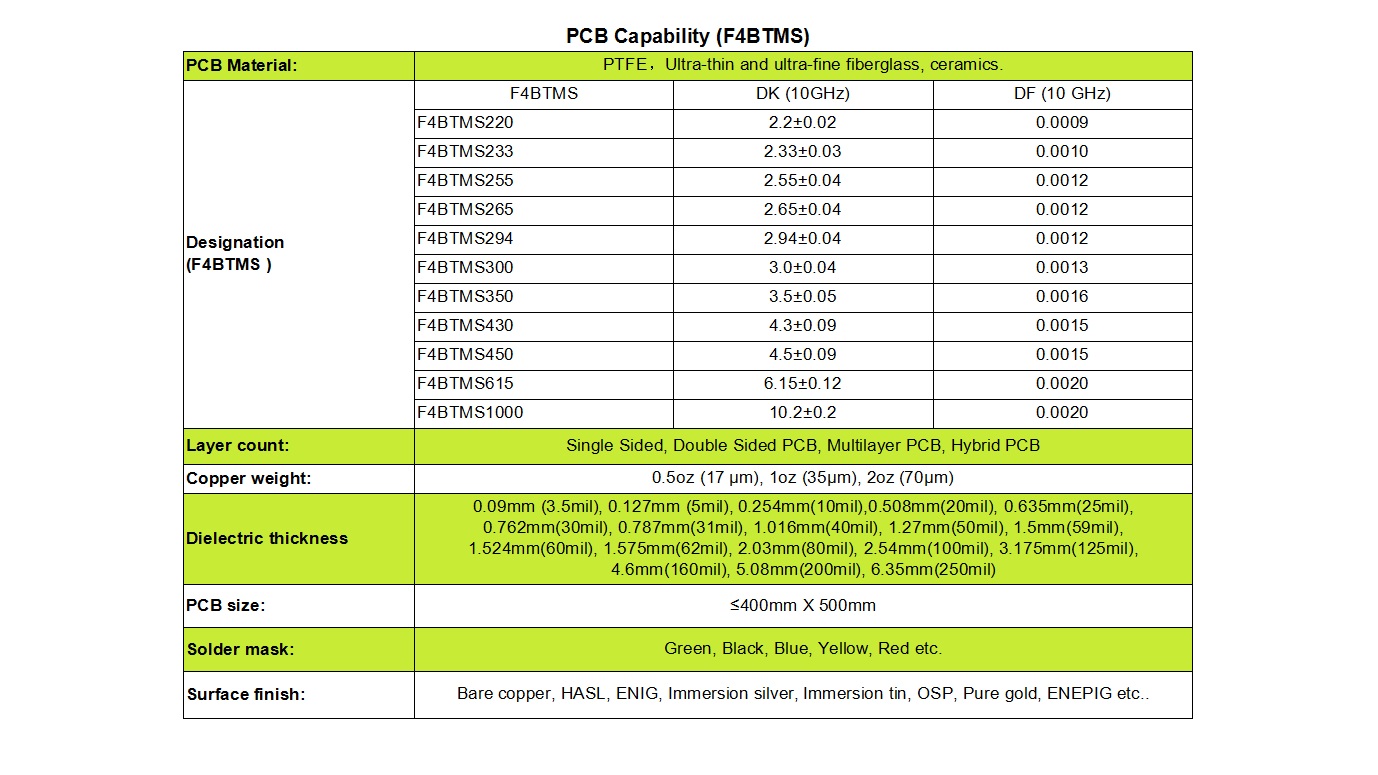

1) Tunable and Stable Dielectric Constant (Dk): Offering exceptional flexibility, F4BTMS provides a wide range of dielectric constants from 2.2 to 10.2. More importantly, this Dk value remains exceptionally stable across the board, ensuring consistent signal propagation velocity and impedance control.

2) Extremely Low Dielectric Loss (Df): With a dissipation factor ranging from an ultra-low 0.0009 to 0.0024, F4BTMS ensures minimal energy conversion into heat. This low loss tangent is crucial for enhancing overall system efficiency, preserving signal strength, and enabling clearer signal transmission in sensitive applications.

3) Excellent Thermal Stability (TCDk): The Temperature Coefficient of the Dielectric Constant (TCDk) is a critical metric. For F4BTMS, with Dk values from 2.55 to 10.2, the TCDk remains within a tight±100 ppm/°C. This stability guarantees that electrical performance remains predictable and reliable even under fluctuating operational temperatures.

4) Superior Dimensional Stability (CTE): The CTE values are meticulously controlled—between 10-50 ppm/°C in the X and Y directions and a commendably low 20-80 ppm/°C in the Z direction. This low thermal expansion is fundamental to preventing delamination and ensuring reliable via connections.

5) Aerospace-Grade Reliability: F4BTMS demonstrates remarkable resistance to radiation, maintaining stable properties even after exposure. Its low outgassing performance meets the stringent vacuum outgassing requirements (as per ECSS-Q-ST-70-02C) essential for aerospace and satellite applications.

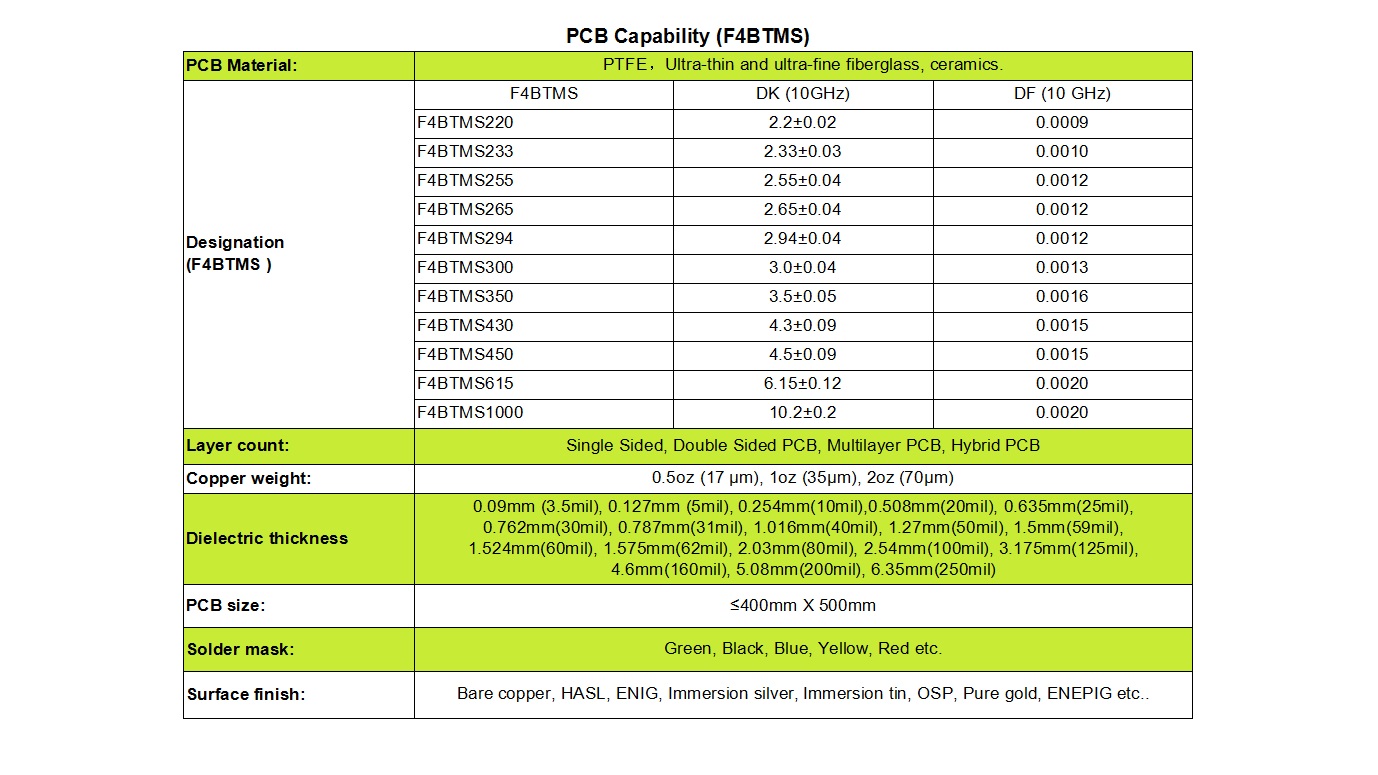

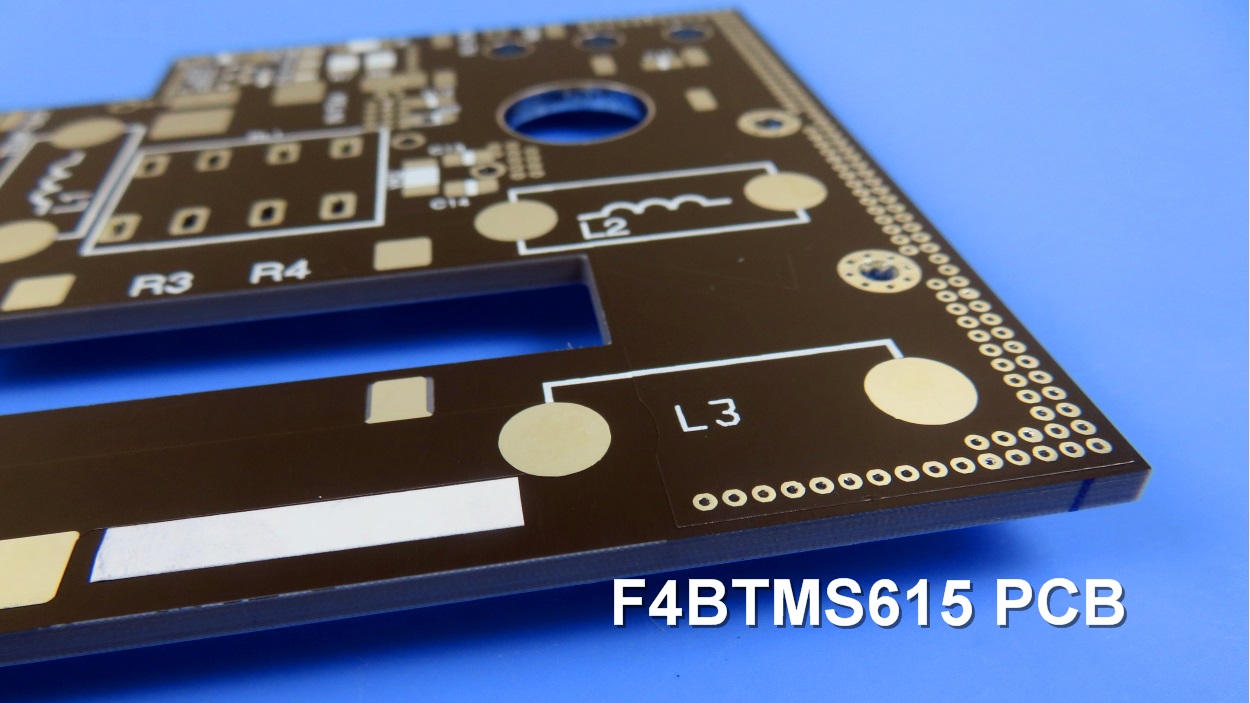

Comprehensive PCB Manufacturing Capabilities

To fully leverage the advantages of the F4BTMS substrate, our manufacturing expertise is tailored to deliver precision and quality. We support a comprehensive range of PCB structures to suit diverse design requirements, including Single-Sided, Double-Sided, Multilayer, and Hybrid constructions. Our capabilities extend to various copper weights (e.g., 1oz/35µm, 2oz/70µm) and a diverse selection of dielectric thicknesses from a thin 0.09mm (3.5mil) to a robust 6.35mm (250mil). We can accommodate PCB sizes up to 400mm x 500mm and offer multiple solder mask colors (Green, Black, Blue, etc.) and surface finishes (ENIG, Immersion Silver, OSP, ENEPIG, and more) to meet both functional and aesthetic needs.

Broad-Ranging Applications

The exceptional properties of F4BTMS High Frequency PCBs make them the ideal choice for a multitude of advanced sectors. They are extensively used in:

Aerospace and Aviation Equipment (e.g., flight control systems, communication satellites)

Microwave and RF Applications (including 5G infrastructure and point-to-point radio)

Advanced Radar Systems

Signal Distribution and Feed Networks

Phase-Sensitive Antennas and Phased Array Antennas

In conclusion, the custom F4BTMS PCB is not merely an incremental upgrade but a transformative solution for high-frequency design challenges. Its superior electrical characteristics, exceptional thermal stability, and proven reliability make it the superior substrate for pushing the boundaries of performance in today's most demanding electronic systems.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com