How Does RT/duroid 6202 PCB Achieve Superior High-Frequency Performance with Low Loss and Stable Dk?

In the demanding world of high-frequency electronics, the choice of printed circuit board (PCB) substrate is paramount to the success of any design. For applications operating at microwave frequencies, standard FR-4 materials fall short due to their higher signal loss and less stable electrical characteristics. This is where advanced high-frequency laminates, specifically engineered for peak performance, come into play. Among these, Rogers Corporation's RT/duroid 6202 high frequency PCB stands out as a premier choice for designers seeking an optimal balance of electrical precision, mechanical reliability, and manufacturing efficiency.

An In-Depth Look at RT/duroid 6202 Laminates

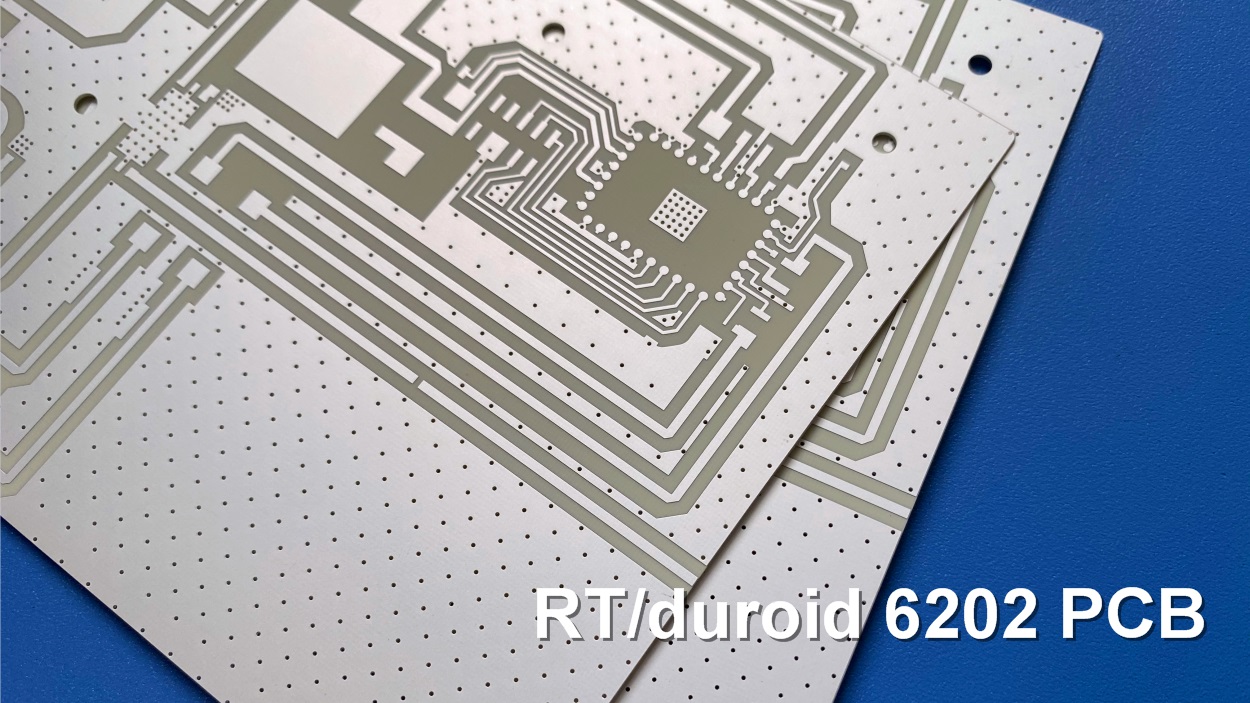

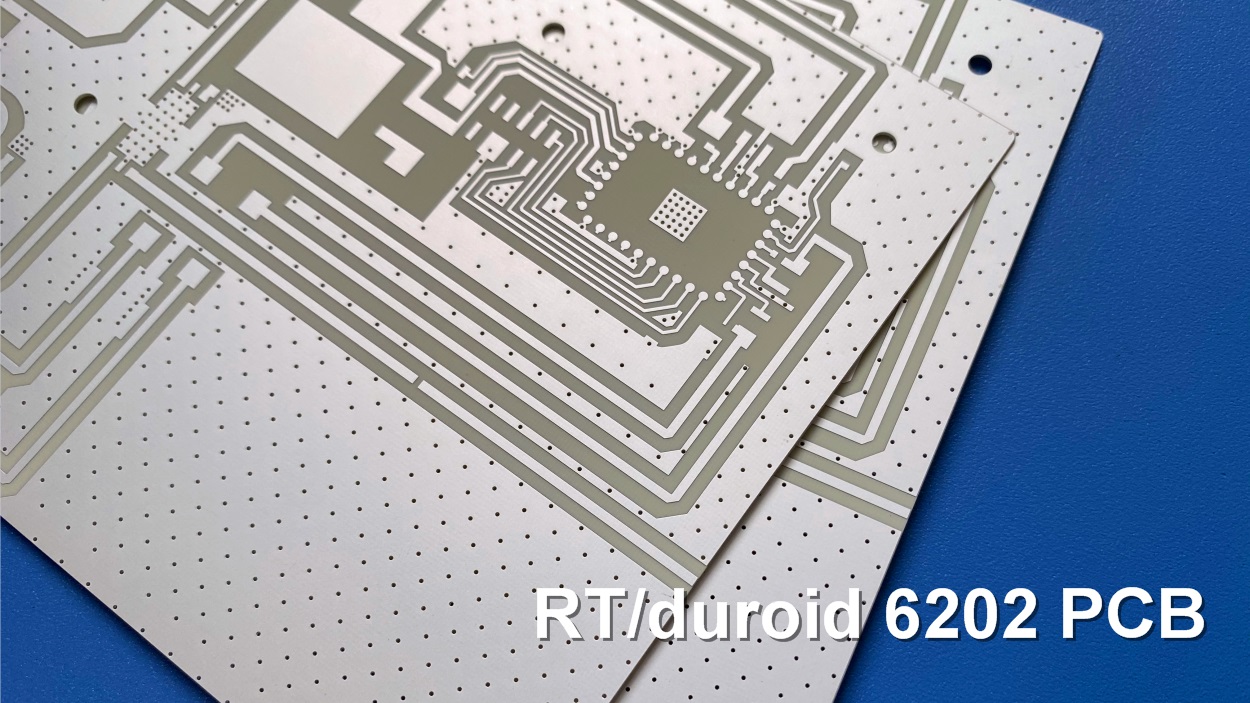

Rogers RT/duroid 6202 is a class of ceramic-PTFE composite laminates renowned for their exceptionally low loss and a consistent, low dielectric constant (Dk). A key differentiator in its construction is the incorporation of a limited, controlled amount of woven glass reinforcement. This strategic design element is crucial as it provides the necessary mechanical integrity for robust PCB structures while minimally impacting the material's superior high-frequency electrical properties. This unique formulation makes duroid 6202 an ideal foundation for complex microwave circuits that cannot compromise on either electrical stability or mechanical durability.

Unpacking the Key Features and Tangible Benefits

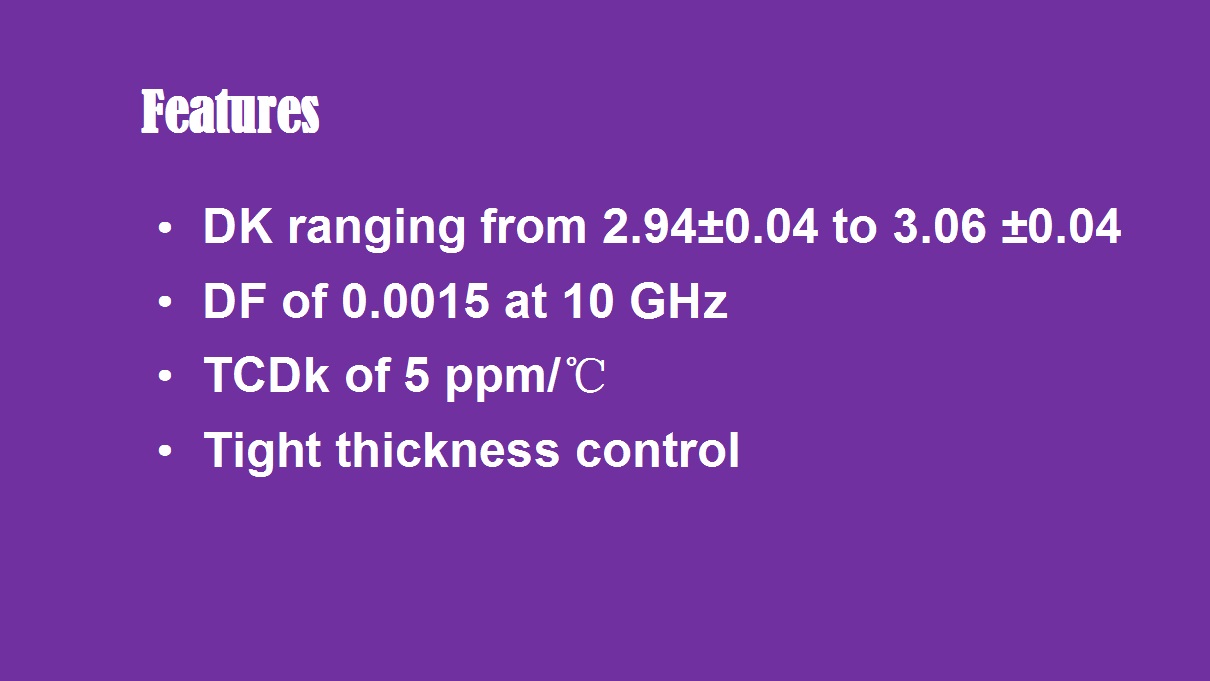

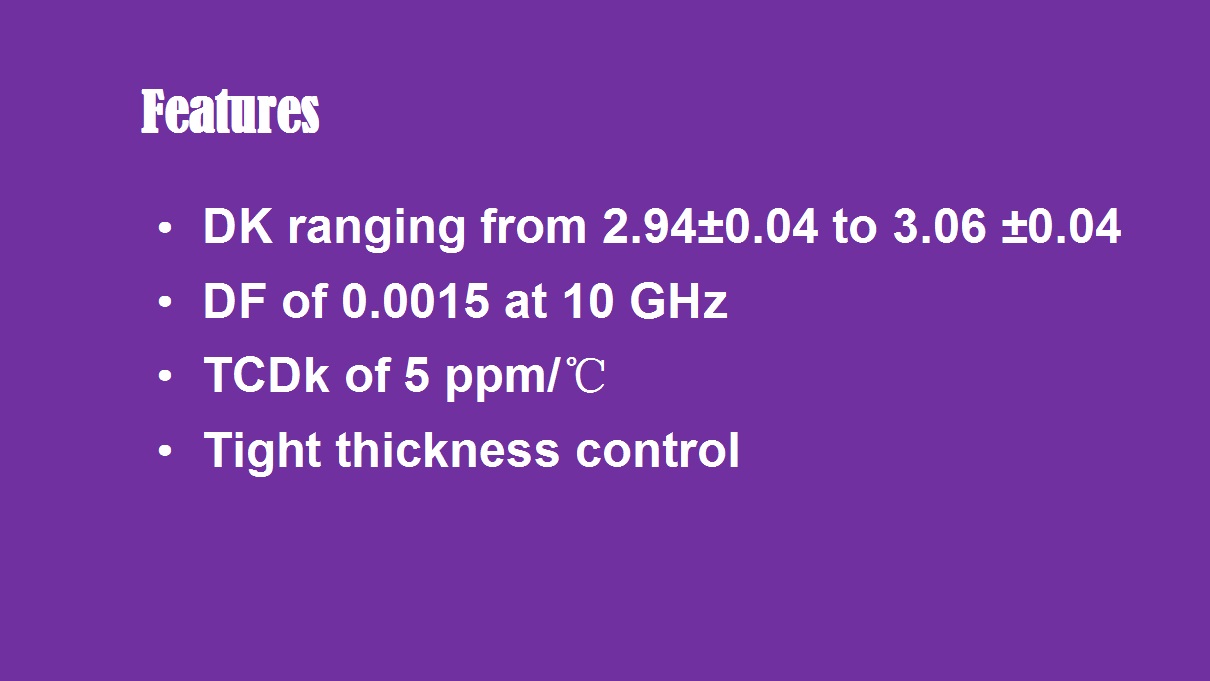

The exceptional performance of Rogers 6202 PCB is quantified through its tightly controlled electrical specifications:

1) Stable and Consistent Dielectric Constant (Dk): The laminate offers a dielectric constant ranging from 2.94 to 3.06, depending on the specific thickness, with an impressively tight tolerance of±0.04. This consistency is vital for maintaining impedance control across the entire board, ensuring signal integrity. Furthermore, the material exhibits a very low thermal coefficient of Dk (5 ppm/°C), meaning its electrical properties remain stable over a wide temperature range, a critical factor for applications in varying environmental conditions.

2) Ultra-Low Dissipation Factor (Df): With a remarkably low dissipation factor of just 0.0015 at 10 GHz, RT/duroid 6202 ensures minimal signal attenuation. This characteristic of low loss is essential for enhancing the efficiency and range of high-frequency systems, allowing signals to travel further with less power loss.

3) Excellent Dimensional Stability: The woven glass reinforcement endows the material with outstanding dimensional stability, typically between 0.05 to 0.07 mils/inch. This precise stability is a significant advantage during the manufacturing process, as it often eliminates the need for complex and costly double-etching procedures to achieve stringent positional tolerances for fine features and plated through-holes.

The synergy of these features translates into direct benefits for your designs: superior signal integrity, excellent reliability due to in-plane expansion coefficient matching with copper, and overall exceptional electrical and mechanical performance with minimal etch shrinkage.

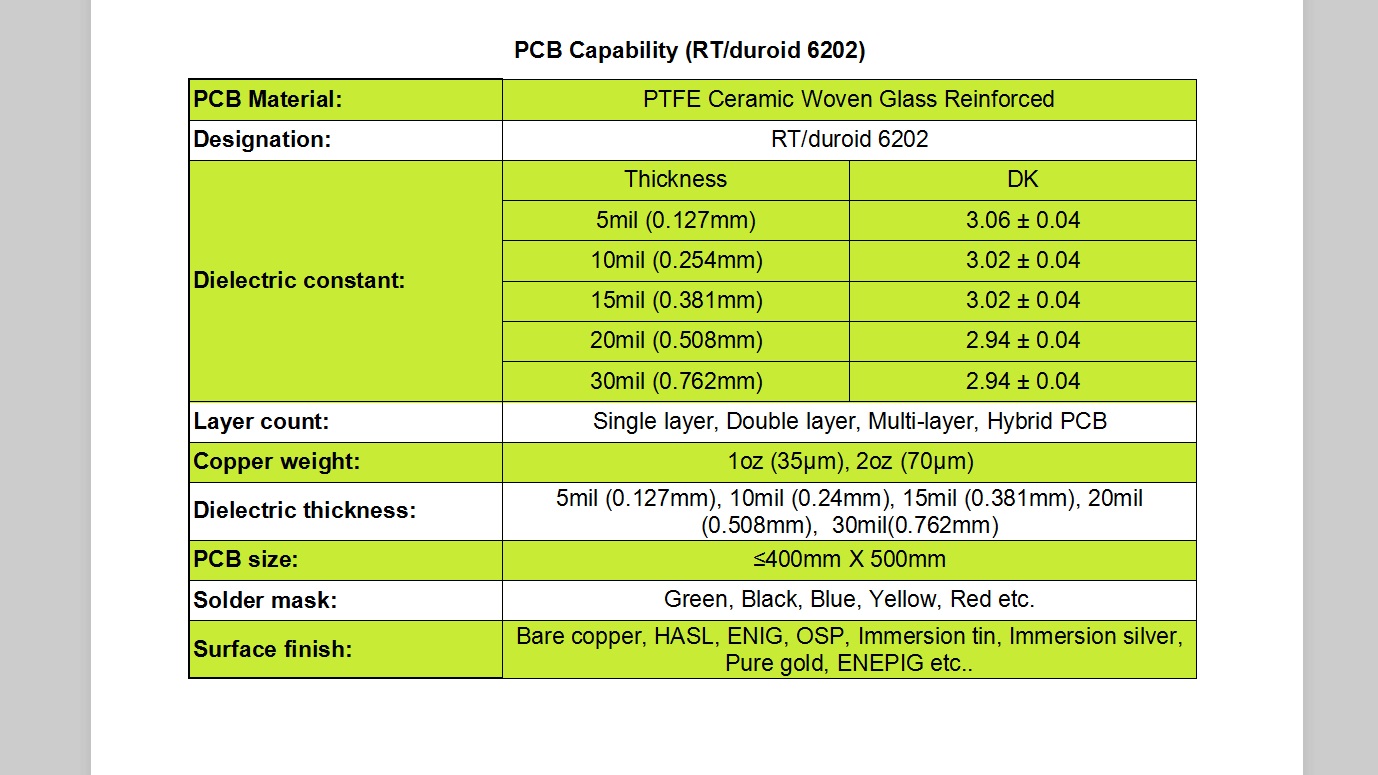

Our Advanced PCB Manufacturing Capabilities with RT/duroid 6202

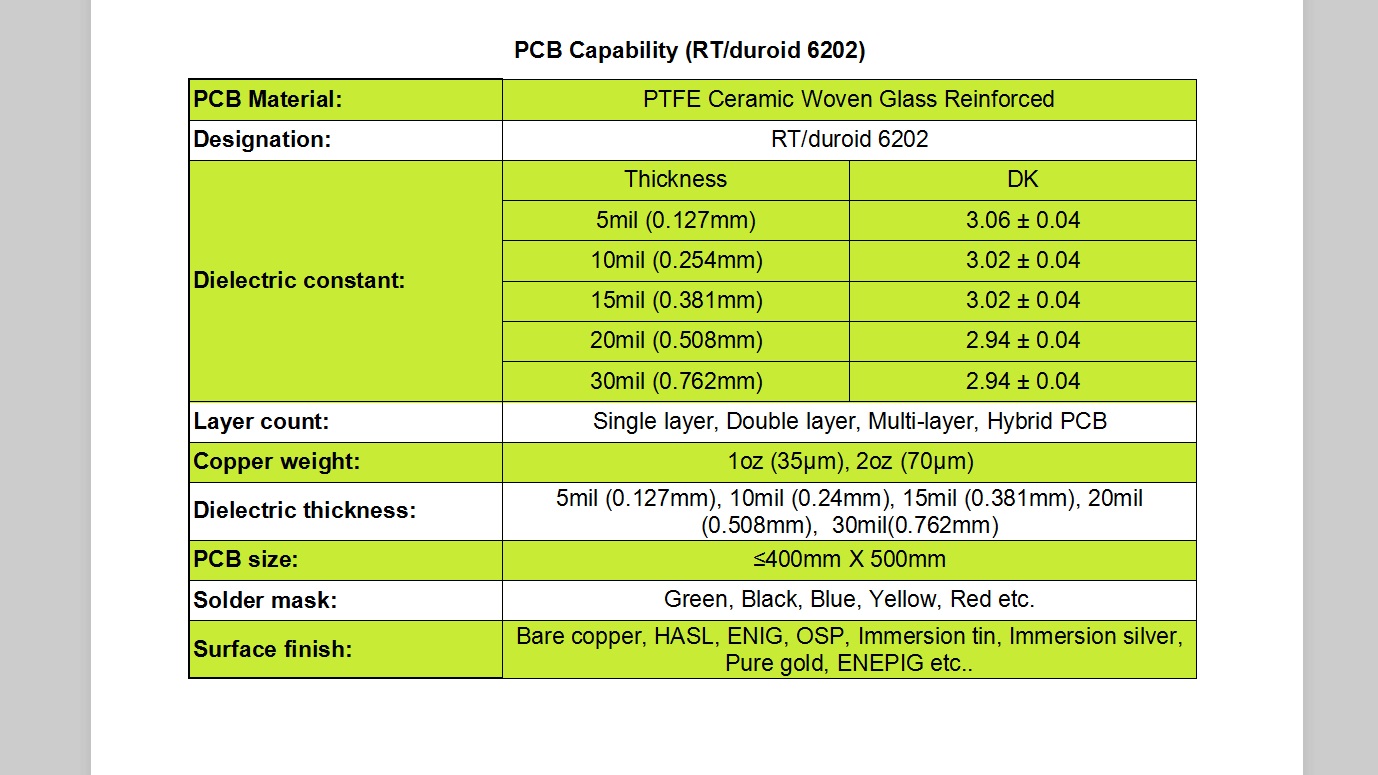

To fully leverage the potential of this high-performance material, advanced manufacturing expertise is required. Our production facilities are equipped to process RT/duroid 6202 laminates to your exact specifications.

1) Layer Configurations: We offer flexible solutions, from simple single-layer and double-layer boards to complex multi-layer and hybrid PCB constructions, where RT/duroid 6202 can be combined with other materials.

2) Copper Weights and Dielectric Thickness: We provide standard copper weights of 1oz (35µm) and 2oz (70µm). For the dielectric layer, we offer a range of thicknesses including 5mil (0.127mm), 10mil (0.24mm), 15mil (0.381mm), 20mil (0.508mm), and 30mil (0.762mm) to meet your target impedance and mechanical needs.

3) Board Size and Finishes: We can manufacture PCBs up to 400mm x 500mm. A variety of solder mask colors (green, black, blue, yellow, red, etc.) and surface finishes (ENIG, HASL, OSP, Immersion Silver, ENEPIG, and bare copper) are available to meet both aesthetic and functional requirements.

Diverse Applications for RT/duroid 6202 High Frequency PCBs

The combination of low loss and stable electrical properties makes custom RT/duroid 6202 PCB material of choice for a wide array of critical high-frequency applications. These include:

-

Phased Array Antennas

-

Radar Systems (including commercial airline collision avoidance systems)

-

GPS Antennas

-

High-Speed Power Backplanes

-

Beam Forming Networks for Aerospace and Defense

In conclusion, the RT/duroid 6202 high frequency PCB provides an unparalleled combination of electrical performance, mechanical robustness, and manufacturing-friendly characteristics. By choosing this laminate and partnering with our specialized manufacturing team, you can ensure that your next high-frequency project achieves its maximum potential for performance and reliability.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com