How Does RO3203 Laminate Deliver Superior Electrical and Mechanical Performance Cost-Effectively?

Introduction

In the rapidly advancing world of wireless communication and high-speed electronics, the choice of printed circuit board (PCB) substrate material is paramount. For engineers and designers working on cutting-edge RF, microwave, and millimeter-wave applications, achieving optimal electrical performance without compromising mechanical reliability or budget is a constant challenge. Enter RO3203 high-frequency circuit materials, a superior class of laminates engineered to meet these exacting demands. As a strategic extension of the renowned RO3000 PCB series, Rogers RO3203 stands out by offering an exceptional balance of electrical properties, enhanced mechanical stability, and cost-effectiveness. This blog post provides a comprehensive exploration of the RO3203 material, its key characteristics, our advanced PCB fabrication capabilities, and its diverse application fields, illustrating why it is a premier choice for high-frequency designs.

The Properties of RO3203 Material

Rogers 3203 PCB is constructed as a ceramic-filled polytetrafluoroethylene (PTFE) composite laminate, reinforced with a woven fiberglass substrate. This specific engineering delivers a consistent and stable platform for high-frequency circuits.

1) Superior Electrical Performance: The cornerstone of RO3203's appeal is its outstanding electrical properties. It boasts a stable dielectric constant (Dk) of 3.02, which remains consistent across a broad frequency spectrum. Coupled with an exceptionally low dissipation factor (Df) of 0.0016, this material ensures minimal signal loss and excellent signal integrity. These properties collectively enable reliable operation in an extended useful frequency range that surpasses 40 GHz, making it suitable for sophisticated millimeter-wave applications.

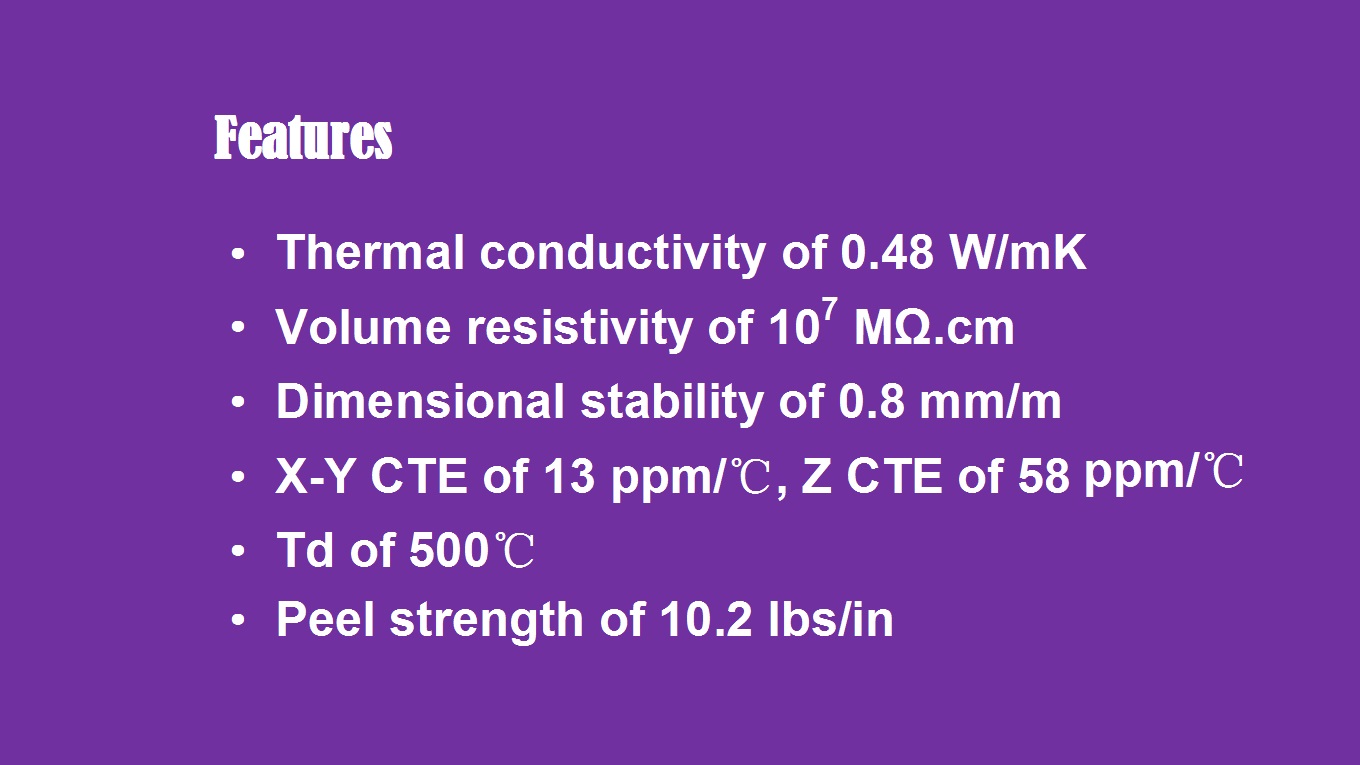

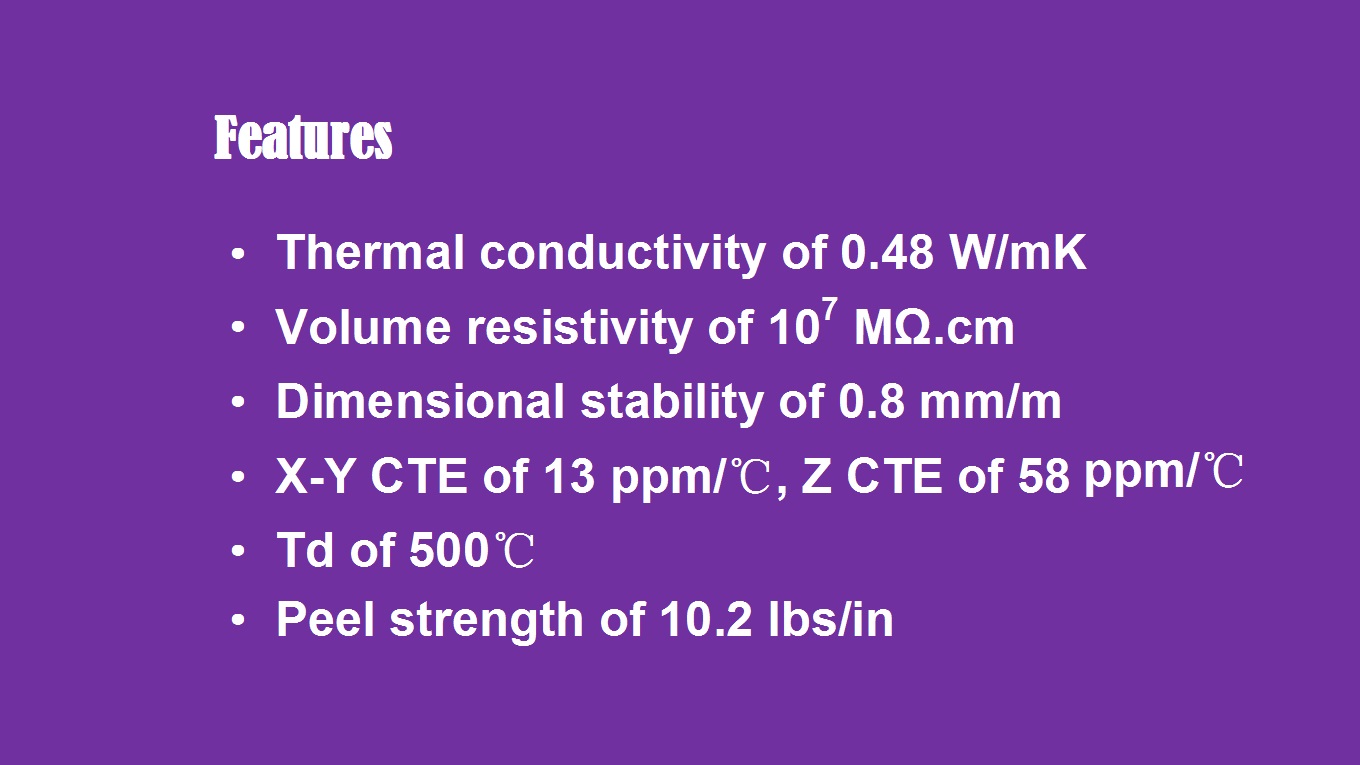

2) Enhanced Thermal and Mechanical Characteristics: Beyond electrical performance, RO3203 provides robust thermal and mechanical stability. Its thermal conductivity of 0.48 W/m/K contributes to effective heat dissipation from active components. The material demonstrates remarkable dimensional stability, with a value of 0.8 mm/m in both the X and Y axes, which is critical for maintaining registration in multilayer boards. Furthermore, its low moisture absorption rate of less than 0.1% ensures performance reliability even in humid environments. The material's coefficients of thermal expansion (CTE) are carefully controlled—13 ppm/°C in the X and Y directions and 58 ppm/°C in the Z-direction—which helps in minimizing stress during thermal cycling, such as in soldering processes.

3) Reliability and Durability: RO3203 is designed for long-term reliability. It features high volume and surface resistivity, both at 10^7 MΩ, ensuring excellent insulation properties. The copper peel strength after soldering is a robust 10.2 lbs/in, indicating strong adhesion between the copper foil and the substrate. With a Thermal Decomposition Temperature (Td) of 500°C and a UL 94 V-0 flammability rating, the material meets stringent safety and durability standards. Its full compatibility with lead-free assembly processes makes it a future-proof choice for modern electronics manufacturing.

Advanced PCB Manufacturing Capabilities for RO3203

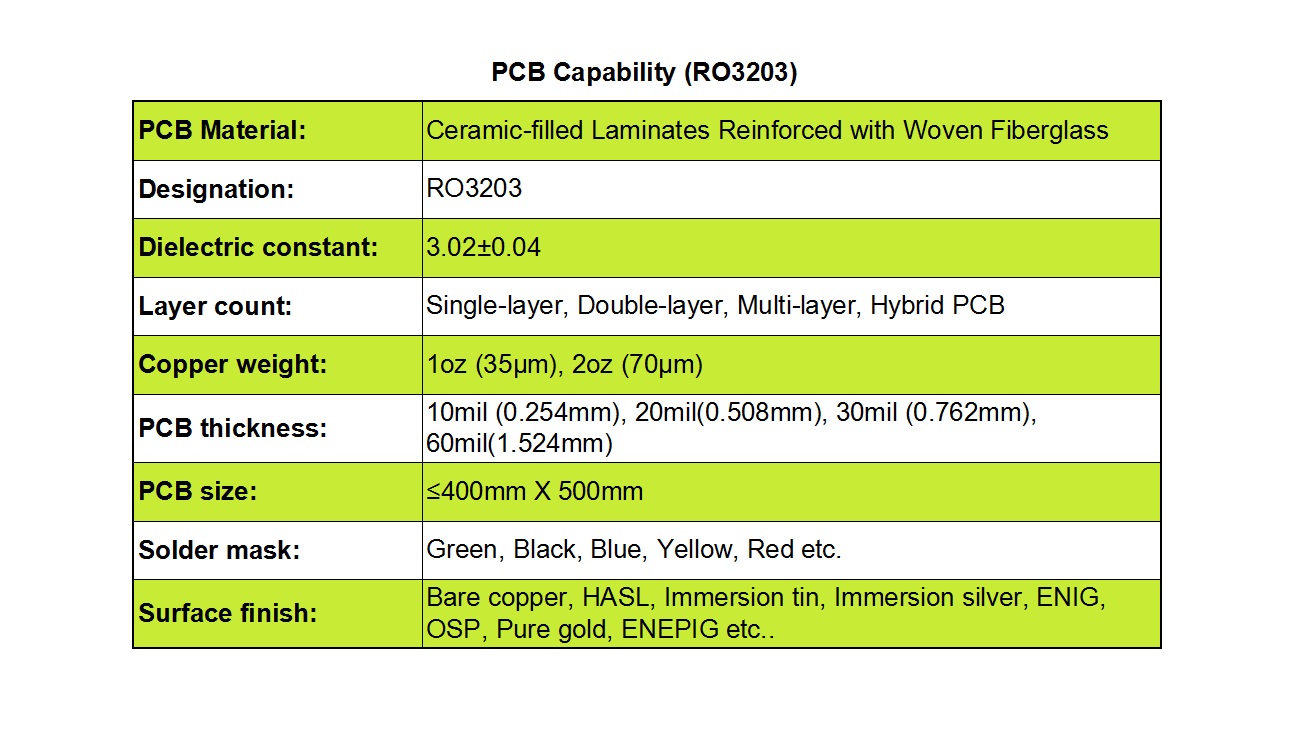

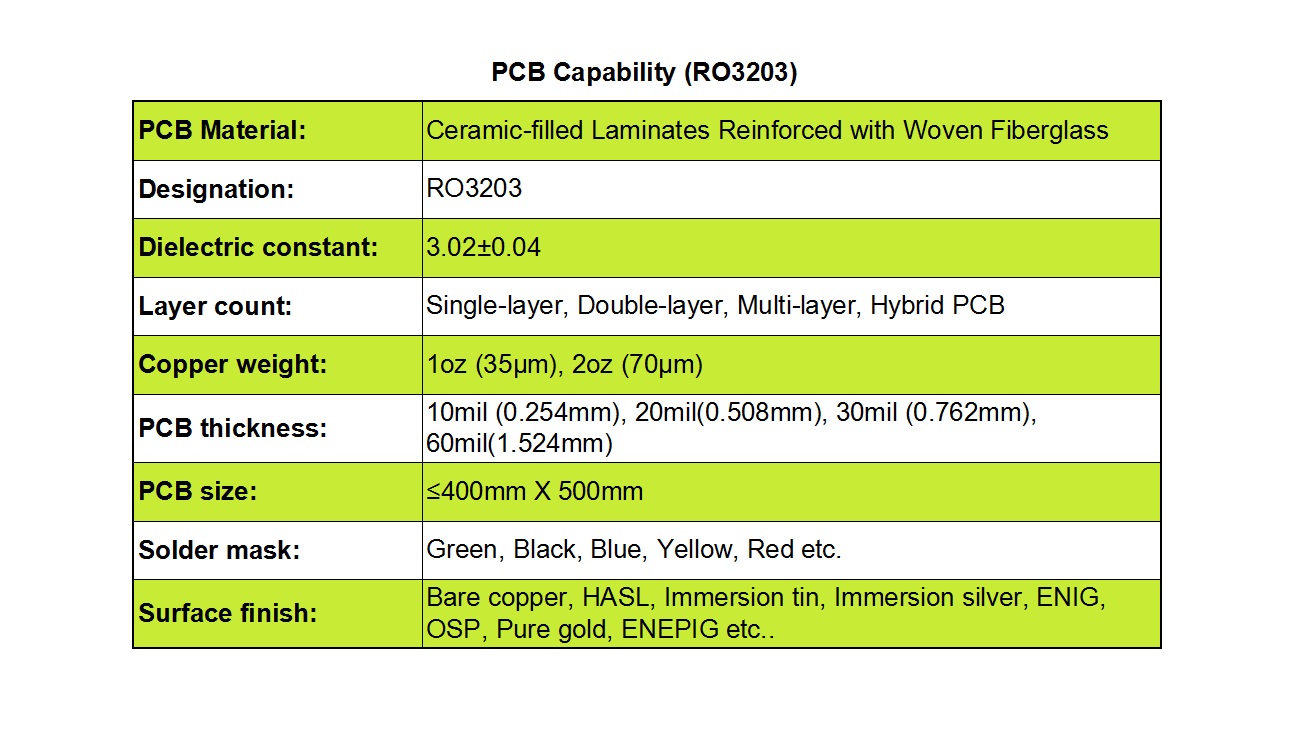

As a leading PCB supplier, we possess the specialized expertise and equipment to fully leverage the advantages of RO3203 substrate. Our manufacturing capabilities are tailored to meet the precise requirements of high-frequency applications.

1) Versatile Board Constructions: We offer comprehensive solutions including single-layer, double-layer, complex multi-layer, and hybrid stack-up configurations. Hybrid designs allow for the integration of RO3203 with other materials, such as FR-4, optimizing performance and cost for specific sections of a circuit.

2) Flexible Specifications: To accommodate diverse design needs, we provide a wide range of options. This includes various standard and custom thicknesses (e.g., 10mil, 20mil, 30mil, 60mil) and copper weights (e.g., 1oz, 2oz). We can handle large-format boards up to 400mm x 500mm.

3) Comprehensive Finishing Options: We offer a full spectrum of surface finishes to protect the circuitry and ensure solderability. Choices include Bare Copper, HASL (Hot Air Solder Leveling), Immersion Tin (ImSn), Immersion Silver (ImAg), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), Pure Gold, and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold). Additionally, a variety of solder mask colors like green, black, blue, yellow, and red are available for identification and protection.

Key Application Areas for RO3203 High Frequency PCBs

The unique property set of RO3203 PCB makes it an ideal substrate for a wide array of high-performance applications across multiple industries. Its primary use is in areas where signal speed and integrity are non-negotiable.

1) Automotive Radar Systems: It is extensively used in advanced driver-assistance systems (ADAS), particularly in automotive collision avoidance and adaptive cruise control radar operating at 24 GHz and 77 GHz.

2) Telecommunications Infrastructure: RO3203 is perfect for GPS antennas, microstrip patch antennas, and base station antennas that require low loss and stable performance.

3) Satellite Communication: Its reliability makes it suitable for direct broadcast satellite (DBS) systems and other satellite communication equipment.

4) IoT and Smart Metering: Applications like remote meter readers and other RF-enabled IoT devices benefit from the material's consistent performance.

Conclusion

RO3203 high frequency PCB represents a technologically advanced and economically viable solution for designers pushing the boundaries of high-frequency electronics. Its blend of stable electrical properties, mechanical robustness, and thermal reliability, combined with our extensive manufacturing expertise, ensures that your next high-frequency project will be built on a foundation of quality and performance. For your upcoming designs requiring operation beyond 40 GHz, consider custom RO3203 PCB materialas your substrate of choice.

Contact us today to discuss your specific RO3203 Rogers PCB requirements and receive a competitive quote.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com