How Does WL-CT338 Achieve Superior Thermal Stability and Low Loss in High-Frequency Designs?

In the rapidly advancing fields of telecommunications, automotive safety, and aerospace, the demand for reliable high-frequency printed circuit boards (PCBs) is greater than ever. These applications require components that can operate efficiently at high frequencies with minimal signal loss, exceptional thermal stability, and consistent performance. Enter the WL-CT338 High Frequency PCB, a standout member of the WL-CT PCB series engineered to meet and exceed these rigorous demands. This article delves into the unique material composition, exceptional properties, and extensive manufacturing capabilities that make theWanglingWL-CT338 an premier choice for cutting-edge electronic designs.

Advanced Material Composition: The Foundation of Performance

The superior performance of the WL-CT338 PCB originates from its sophisticated material formulation. WL-CT series laminates are constructed from a unique thermosetting resin system that expertly integrates hydrocarbon resin, ceramic filler, and glass fiber cloth. This specific combination is not arbitrary; it is meticulously designed to achieve a perfect balance of low-loss characteristics and robust mechanical properties. The hydrocarbon resin contributes to excellent electrical performance, while the composite ceramics are key to achieving remarkable temperature resistance and dimensional stability. This synergy results in a material that offers a stable dielectric constant, a low coefficient of thermal expansion (CTE), and an exceptionally high glass transition temperature (Tg) exceeding 280°C, ensuring reliability even under extreme operating conditions.

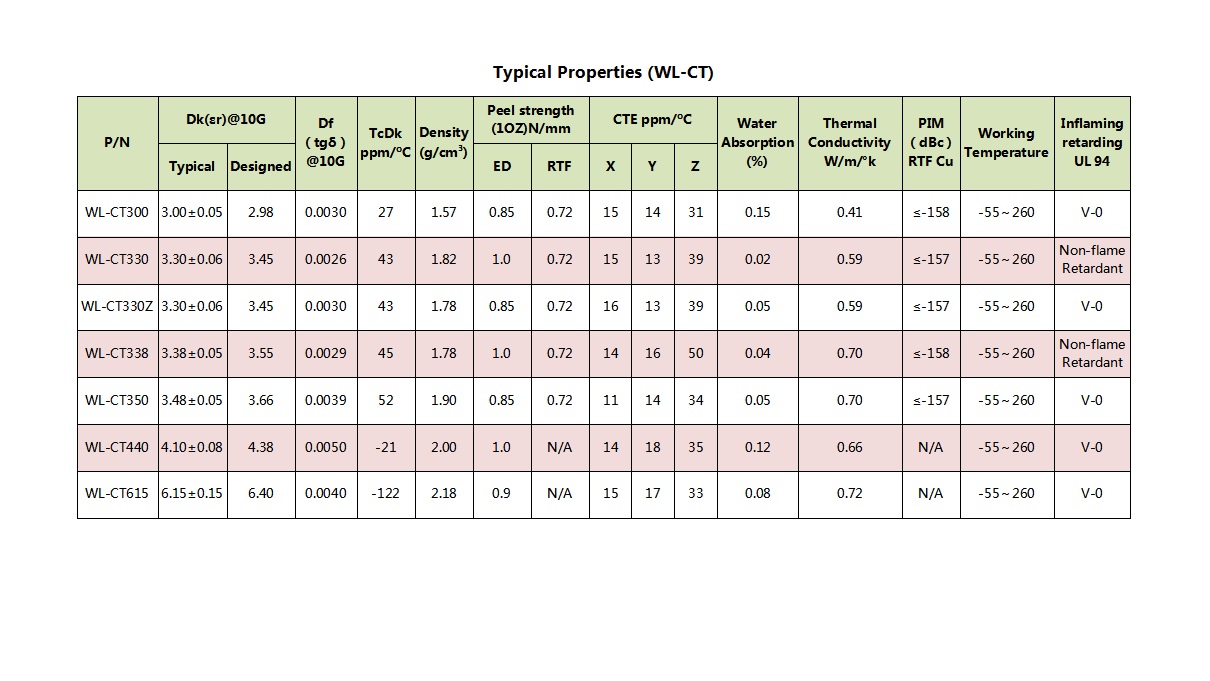

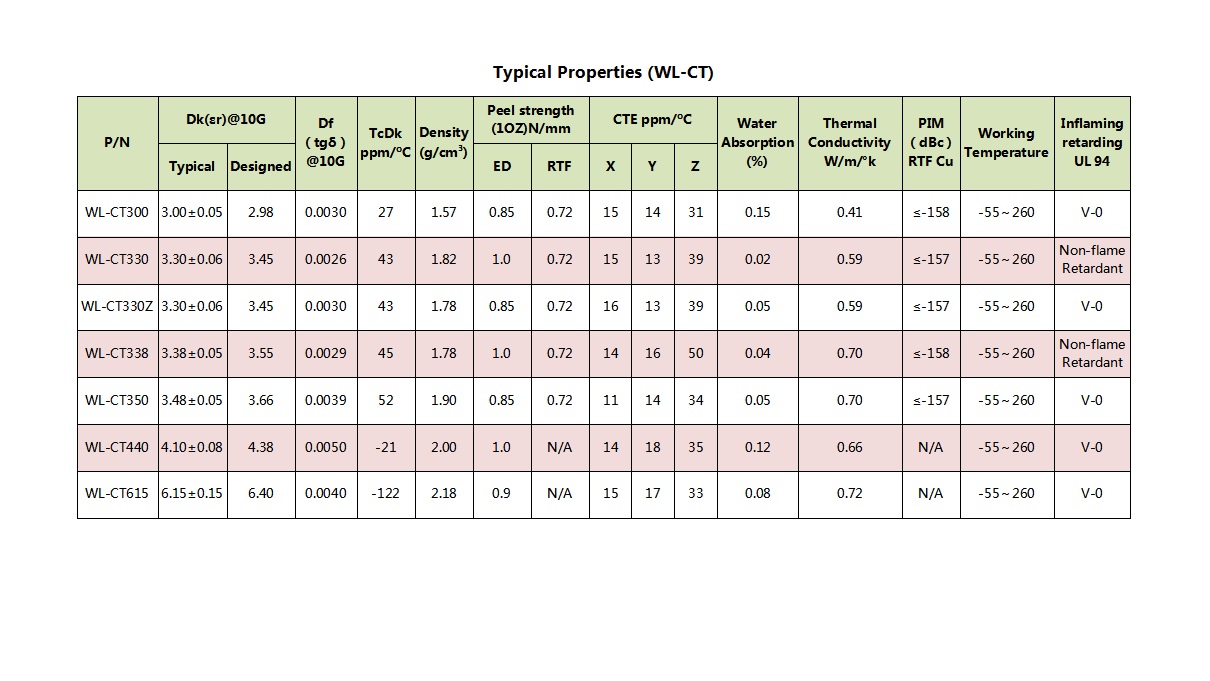

Key Electrical and Thermal Characteristics

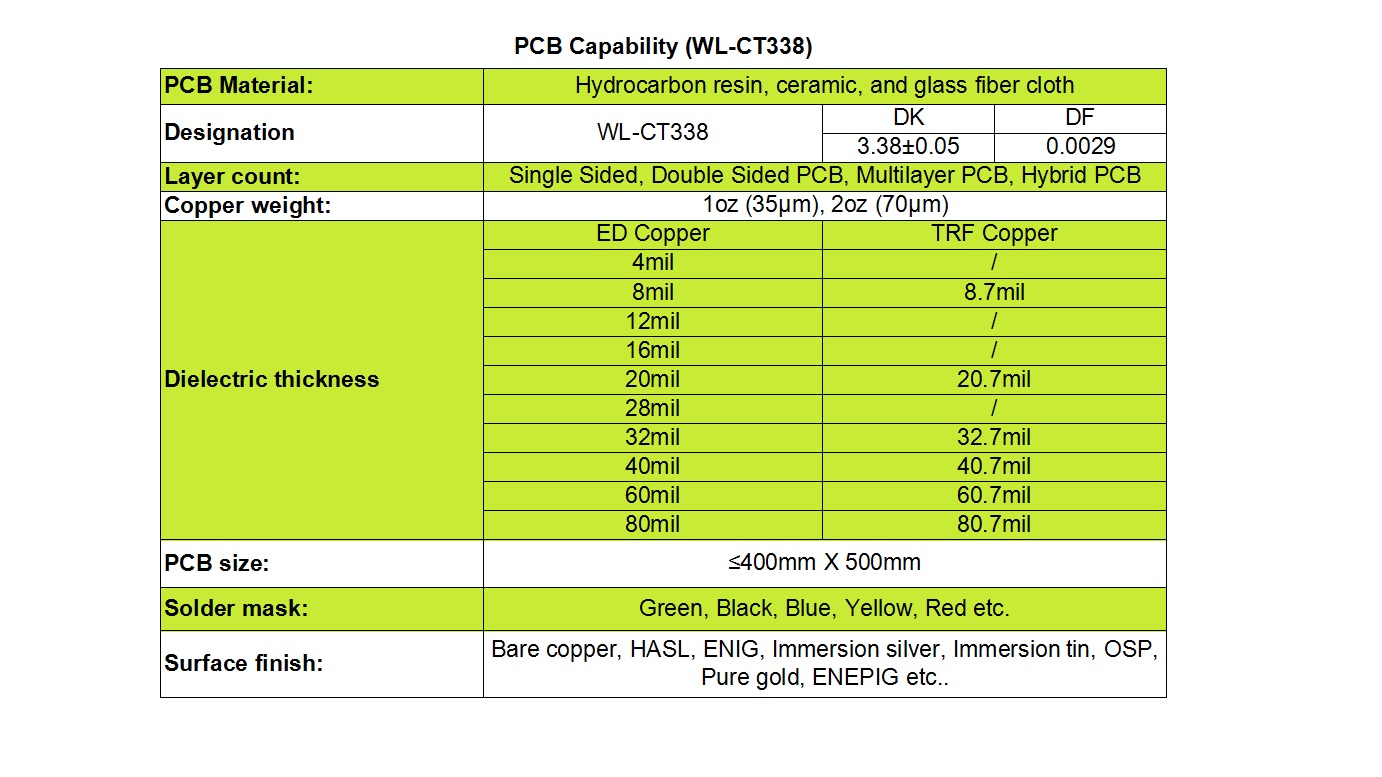

The defining metrics for any high frequency PCB material are its dielectric constant (Dk) and dissipation factor (Df). The WL-CT338 High Frequency PCB exhibits an excellent Dk value of 3.38 and an ultra-low Df of just 0.0029. These values are critical as they directly impact signal propagation speed and signal loss. A stable, low Dk ensures consistent impedance control, while an ultra-low Df guarantees that minimal signal energy is lost as heat, which is paramount for maintaining signal integrity in high-speed RF applications like base station antennas and automotive radar.

Beyond electrical performance, the WL-CT338 demonstrates outstanding thermal management properties:

1) Controlled Thermal Expansion: The CTE in the X/Y direction is carefully matched to copper foil (11-18 ppm/°C), preventing delamination and stress during thermal cycling. The Z-axis expansion is also minimized (31-50 ppm/°C).

2) High Thermal Conductivity: Ranging from 0.41 to 0.72 W/mK, this property aids in dissipating heat away from active components, enhancing the overall reliability and lifespan of the assembly.

3) Low Water Absorption: With a rate between 0.02% and 0.15%, the material maintains its electrical properties in humid environments, ensuring long-term performance stability.

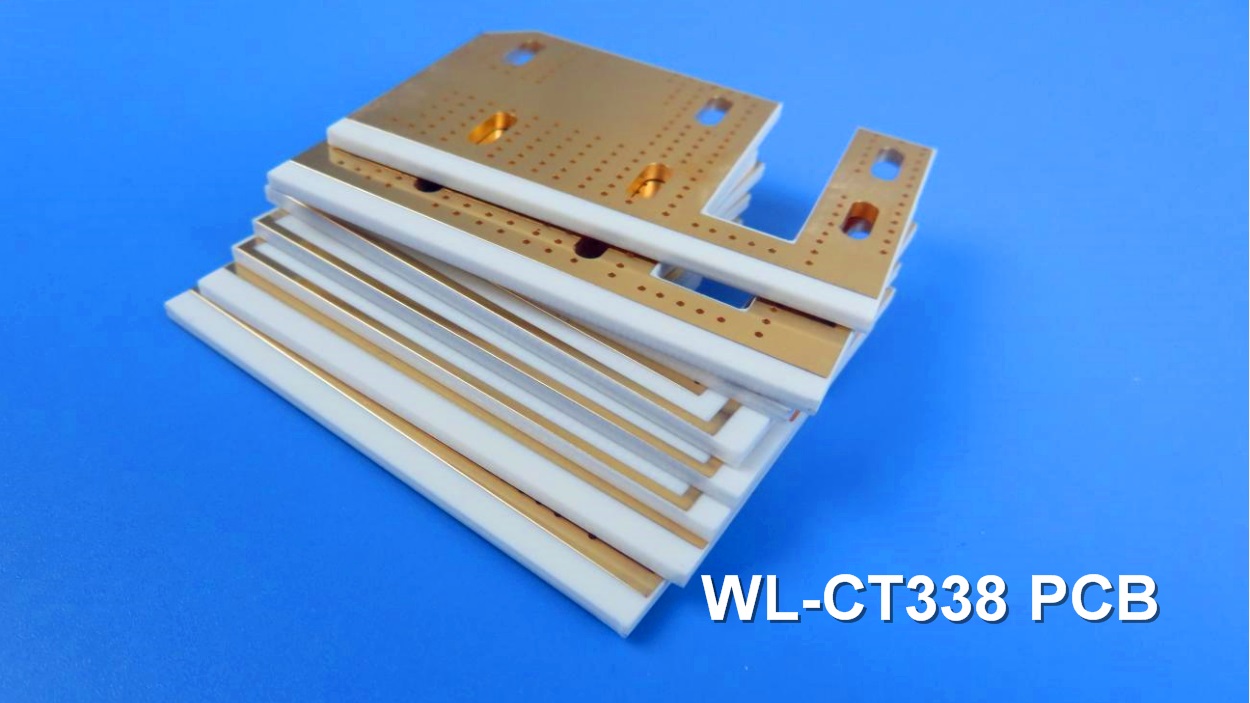

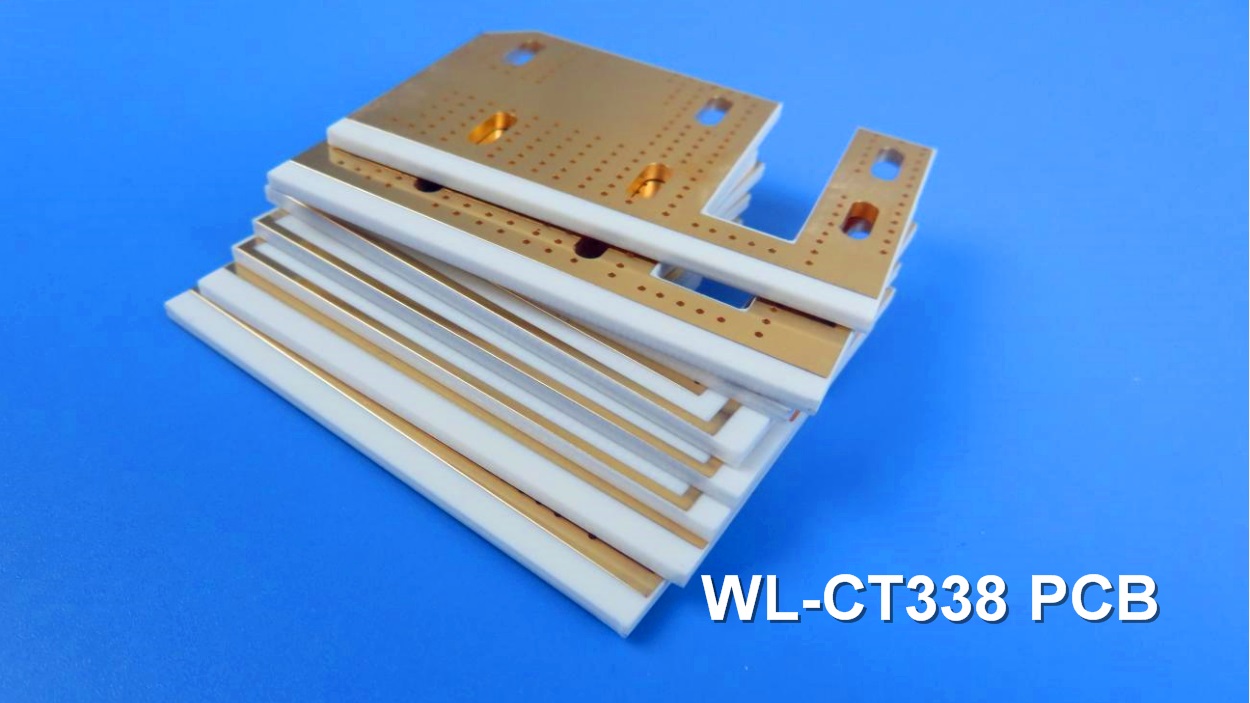

Robust Construction and Manufacturing Flexibility

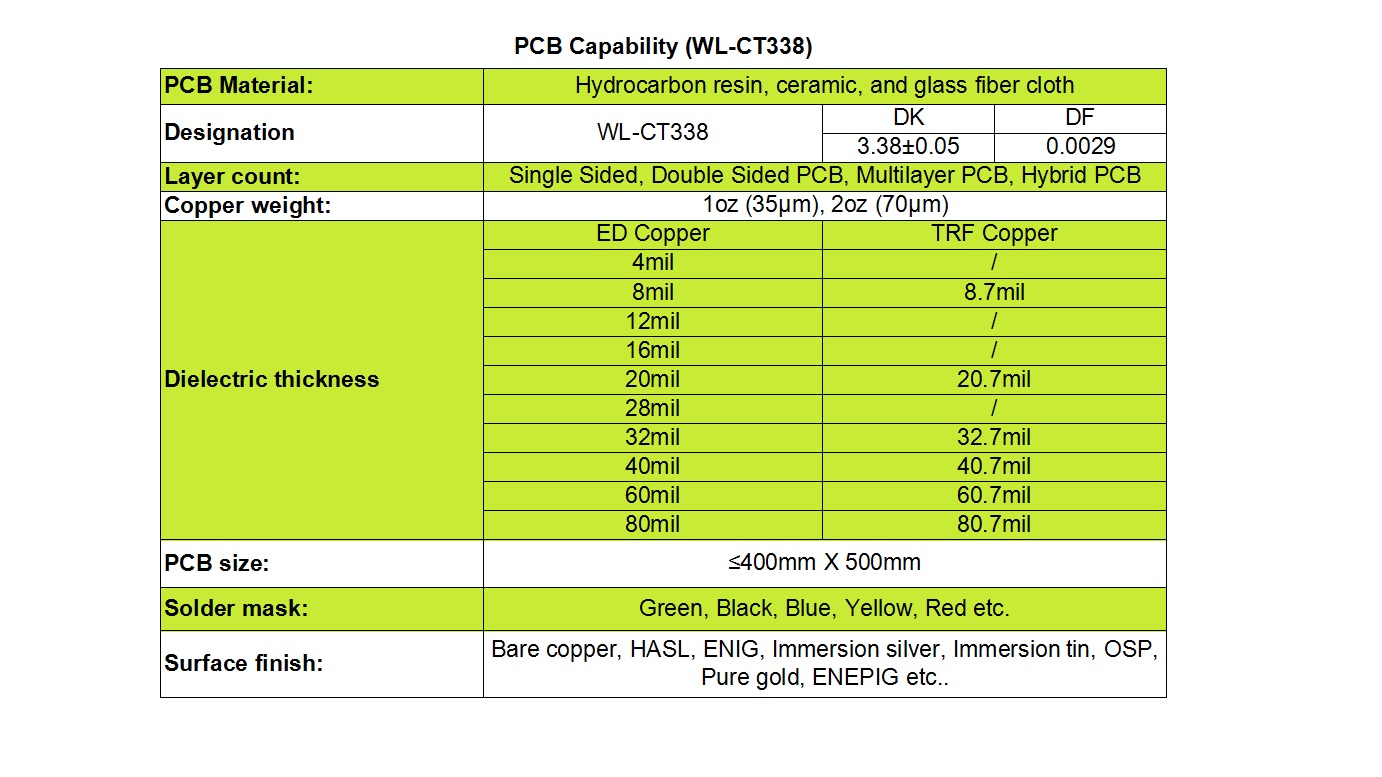

The WL-CT338 is clad with a combination of forward-rotating electro-deposited (ED) copper and reverse-treated foil (TRF). The TRF foil, which includes an adhesive layer, results in a substrate approximately 7 mil thicker than standard ED copper and offers an impressive peel strength of 0.72 N/mm, ensuring strong adhesion between the copper and laminate. We offer standard copper weights of 0.5oz and 1oz, with customization available for heavier requirements.

Our manufacturing capabilities for WL-CT338 Wangling PCBs are designed to provide maximum design flexibility:

1) Layer Configurations: We produce single-sided, double-sided, complex multilayer, and hybrid PCBs.

2) Dielectric Thickness: A wide range is available, from 4mil to 80mil for ED Copper and 8.7mil to 80.7mil for TRF Copper.

3) Board Size: We support PCB sizes up to 400mm x 500mm.

4) Aesthetics and Protection: Choose from various solder mask colors (green, black, blue, etc.) and surface finishes, including ENIG, Immersion Silver, OSP, and ENEPIG, to meet both technical and aesthetic needs.

Diverse Application Spectrum

Thanks to its exceptional properties, the WL-CT338 PCB is incredibly versatile and is ideally suited for a wide array of high-frequency applications. These include 5G base station antennas, satellite communication systems, WIMAX antennas, automotive radar systems (ADAS), distributed antenna systems (DAS), and miniature patch antennas for compact wireless devices.

In conclusion, the WL-CT338 High Frequency PCB stands out as a top-tier solution due to its advanced material science, guaranteed electrical performance, and adaptable manufacturing options. For engineers designing next-generation communication and radar systems, it provides the necessary reliability and performance to ensure success in the most demanding environments.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com