A Comprehensive Guide to F4BME PCBs: Material Properties, Capabilities, and Use Cases.

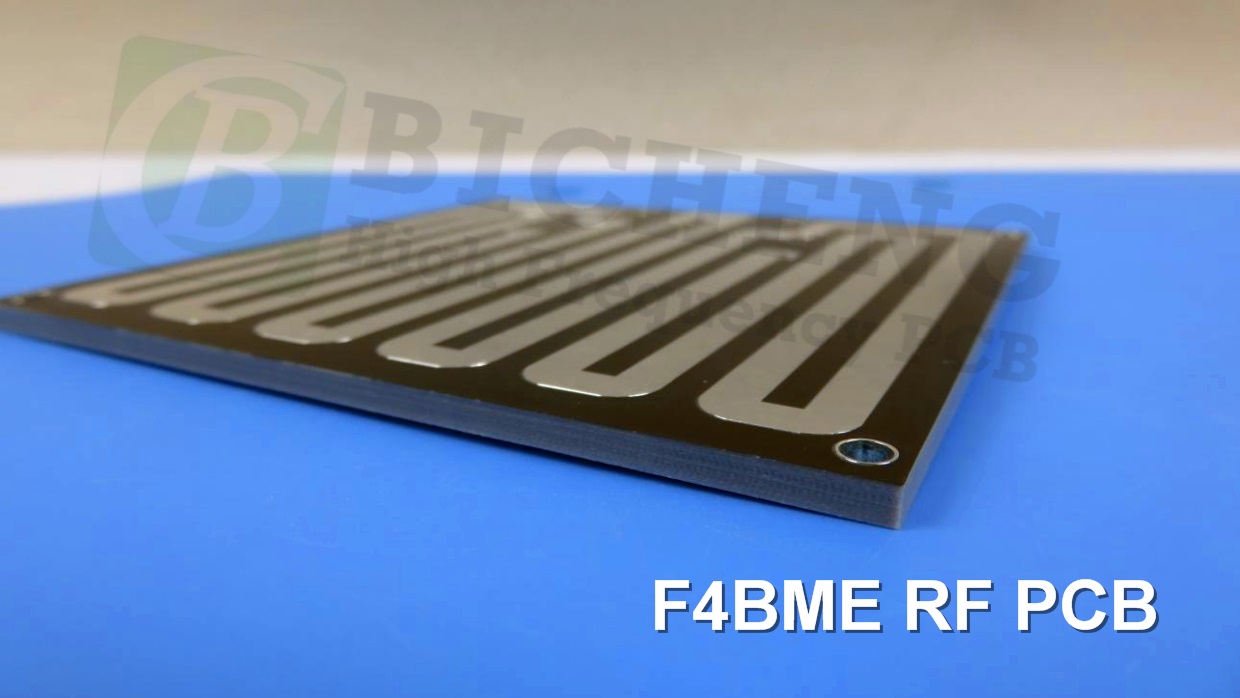

In the demanding realm of high-frequency electronics, the choice of printed circuit board (PCB) material is paramount to achieving optimal performance. Wangling F4BME High Frequency PCBs, engineered with advanced PTFE-based materials, stand as a superior solution for applications where signal integrity, low loss, and stability are non-negotiable. These laminates are meticulously crafted for engineers and designers pushing the boundaries of RF and microwave technology.

Advanced Material Composition for Enhanced Performance

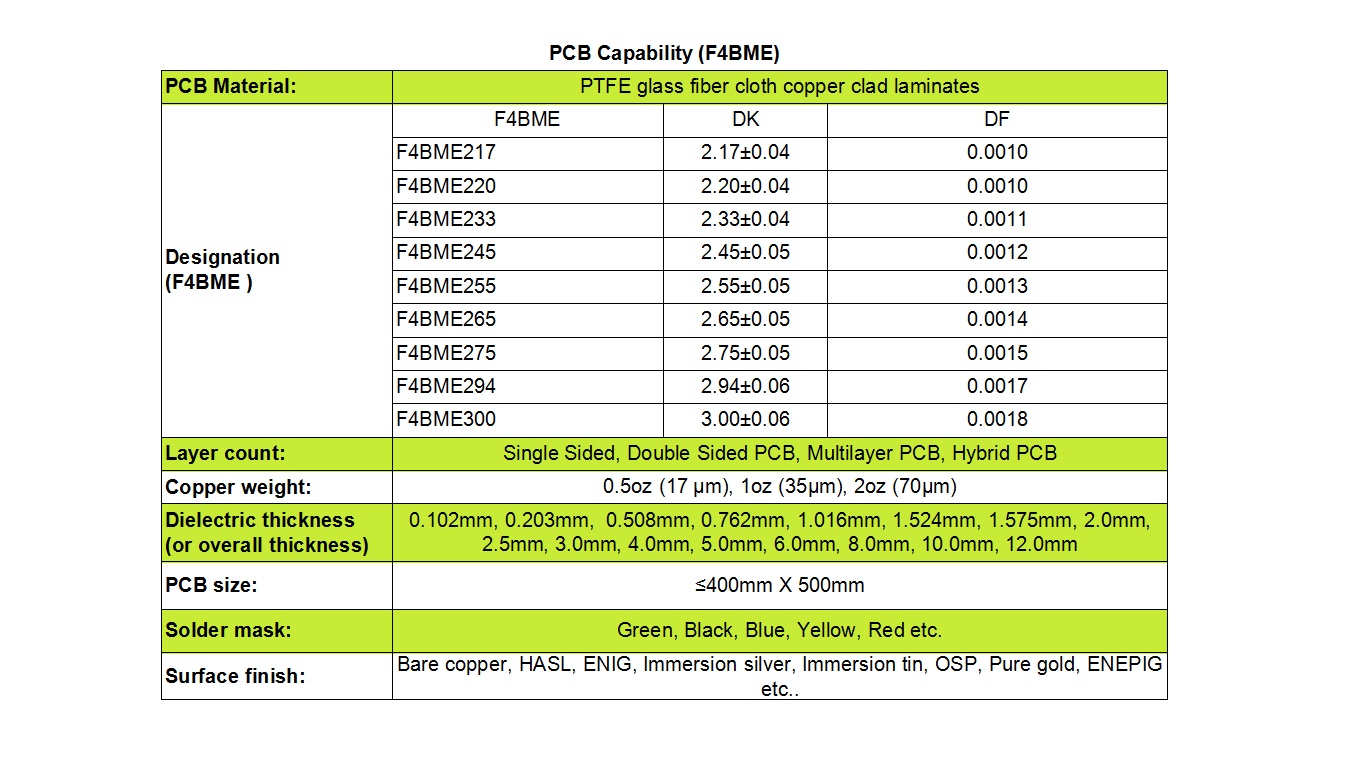

Wangling F4BME materials represent a significant advancement in PTFE glass fiber cloth copper clad laminate technology. They are constructed through a sophisticated manufacturing process that integrates glass fiber cloth, PTFE resin, and a PTFE film. This unique composition results in a material set that delivers substantially improved electrical characteristics compared to standard F4B laminates.

The key advantages of the F4BME PCB series include a broader selection of dielectric constants, exceptionally low dielectric loss (dissipation factor), increased insulation resistance, and superior environmental stability. This enhanced performance profile makes F4BME an excellent domestic alternative to similar international high-frequency products, offering comparable or superior quality without reliance on foreign supply chains.

A critical differentiator within the F4BM laminate series is the type of copper foil used. While F4BME shares the same high-quality dielectric layer as its counterparts, it specifically utilizes Reversed Treated Foil (RTF). This choice provides exceptional Passive Intermodulation (PIM) performance, which is crucial for reducing interference in multi-carrier systems like base stations. Additionally, RTF foil enables more precise control over fine line geometries during etching and contributes to lower overall conductor loss, further enhancing the high-frequency efficacy of the final PCB.

Tailored Features for Design Flexibility and Cost-Efficiency

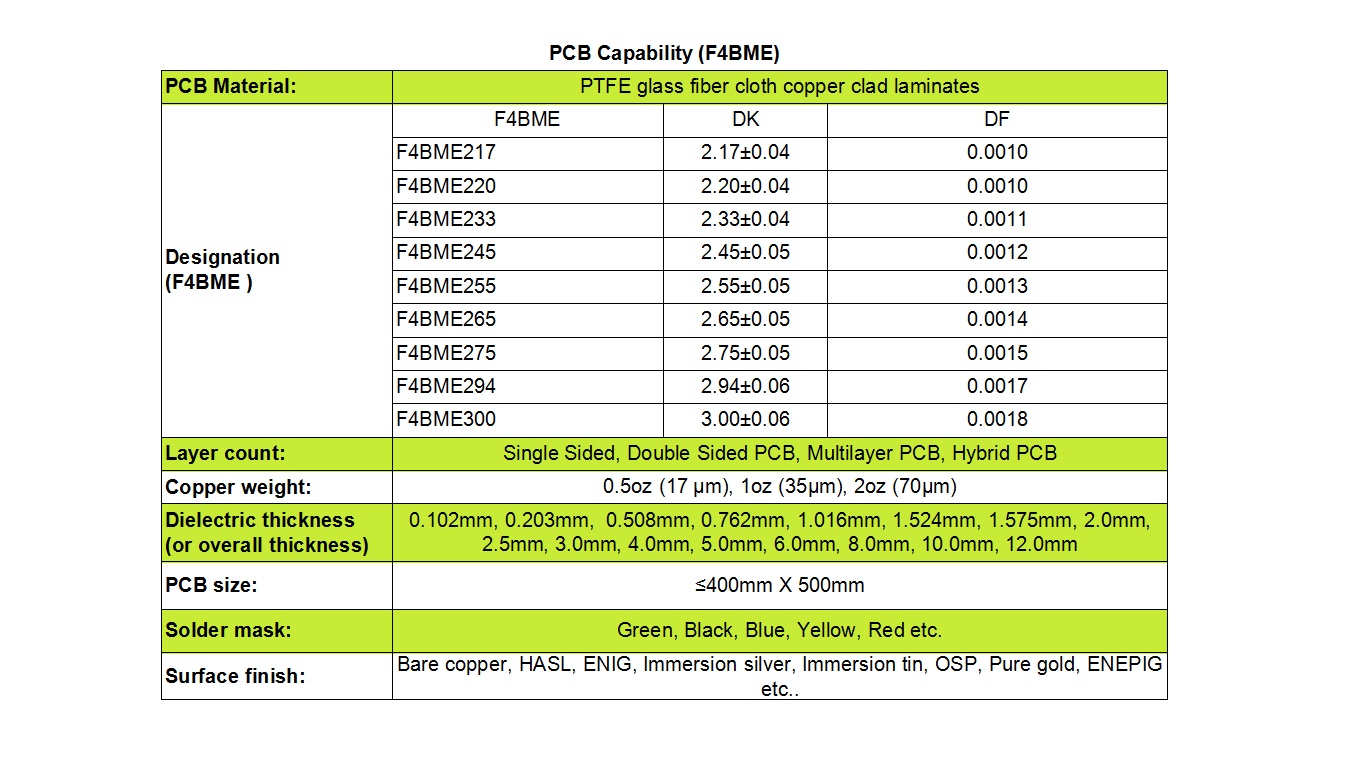

The F4BME substrate is designed to offer unparalleled flexibility to circuit designers. Engineers can select from a diverse spectrum of dielectric constant (Dk) values, typically ranging from 2.17 to 3.0, allowing for precise impedance matching and circuit optimization. The dissipation factor (Df) remains consistently low, within the range of 0.001 to 0.0018, ensuring minimal signal attenuation even at high frequencies.

To accommodate a wide array of design requirements, a comprehensive selection of substrate thicknesses is available. Furthermore, the variety of standard panel sizes offered can lead to significant material utilization improvements and cost savings. This combination of electrical excellence and manufacturing versatility makes F4BME highly suitable for demanding commercial applications, large-scale production runs, and projects where achieving a cost-effective yet high-performance solution is critical.

Comprehensive PCB Manufacturing Capabilities

To fully leverage the benefits of F4BME materials, Wangling supports them with a robust set of PCB fabrication capabilities. We can manufacture Single-Sided, Double-Sided, Multilayer, and Hybrid PCBs (combining different materials) tailored to your specific design needs. Designers have the flexibility to specify copper weights, typically 1oz (35µm) or 2oz (70µm), to handle required current levels.

Our manufacturing process accommodates a wide range of dielectric thicknesses, from 0.8mm up to 12.0mm, including precise measurements like 1.524mm and 1.575mm for critical impedance applications. We can produce PCBs in sizes up to 400mm x 500mm. For customization, we offer a variety of solder mask colors, including Green, Black, Blue, Yellow, and Red. Multiple surface finish options are available to ensure solderability and protect the copper traces, such as Bare copper, HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), Immersion Silver, Immersion Tin, OSP (Organic Solderability Preservative), Pure Gold, and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold).

Broad Spectrum of High-Frequency Applications

The exceptional properties of F4BME PCBs make them ideal for a diverse range of advanced electronic systems. Their primary applications include, but are not limited to:

-

RF Components: Phase shifters, passive devices, power dividers, couplers, and combiners.

-

Antenna Systems: Feed networks for phased array antennas and base station antennas.

-

Telecommunications: Critical components in satellite communication systems.

-

Defense and Aerospace: Radar systems and other high-reliability RF applications.

By choosing F4BME High Frequency PCBs, you are selecting a material solution that ensures signal integrity, enhances performance, and supports the rigorous demands of next-generation high-frequency electronics.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com