How to Choose the Right PCB Substrate for High-Frequency Applications?

(Rogers vs. FR4 Comparison)

Introduction

In today's rapidly advancing electronics industry, selecting the right printed circuit board (PCB) substrate material has become increasingly critical—especially for high-frequency applications. Whether you're designing cellular base stations, automotive radar systems, or satellite communication devices, your choice betweenRogers materials (like RO4350B) and conventional FR4 can significantly impact performance, reliability, and cost. This comprehensive guide will explore the key differences between these materials, their advantages in high-frequency scenarios, and why our RO4350B-based PCB solutions offer superior performance for demanding RF applications.

Understanding High-Frequency PCB Requirements

High-frequency applications (typically above 500MHz) present unique challenges that standard PCB materials struggle to address:

-

Signal Integrity Concerns: At high frequencies, signal loss becomes more pronounced

-

Dielectric Constant Stability: Variations in Dk can cause impedance mismatches

-

Thermal Management: Increased heat generation requires materials with better thermal properties

-

Dimensional Stability: Thermal expansion must be minimized to maintain circuit integrity

These requirements eliminate many conventional materials from consideration, narrowing the field to specialized substrates like Rogers laminates and high-performance FR4 variants.

Rogers RO4350B vs. FR4: Critical Performance Comparison

1. Dielectric Properties

Our RO4350B material boasts exceptional dielectric properties that outperform standard FR4:

-

Dielectric Constant (Dk): 3.48±0.05 at 10GHz (compared to FR4's 4.3-4.8 with±10% variation)

-

Dissipation Factor (Df): 0.0037 at 10GHz (versus 0.020 for typical FR4)

This translates to:

-

75% lower signal loss at high frequencies

-

More predictable impedance control (critical for RF designs)

-

Better signal propagation with reduced distortion

2. Thermal Performance

The thermal characteristics of Rogers 4350B demonstrate clear advantages:

-

Thermal Conductivity: 0.69 W/m/°K (nearly 3×FR4's 0.25 W/m/°K)

-

Glass Transition Temperature (Tg): >280°C (versus 130-180°C for FR4)

-

CTE Matching: X/Y CTE of 10-12 ppm/°C closely matches copper (FR4: 12-16 ppm/°C)

These properties result in:

-

Better heat dissipation for power applications

-

Superior reliability in thermal cycling environments

-

Reduced plated through-hole failures

3. Manufacturing Considerations

While FR4 has traditionally been easier to process, RO4350B bridges the gap:

-

Uses standard FR4 processing methods (no special handling required)

-

Compatible with mixed dielectric multilayer constructions

-

Doesn't require PTFE-specific treatments (reducing fabrication costs)

Our 2-layer PCB example demonstrates this manufacturability:

-

Standard 4/4 mil trace/space capability

-

Conventional 0.2mm minimum hole size

-

Immersion Gold surface finish for excellent solderability

4. Cost Analysis

While Rogers materials carry a premium over FR4,Rogers RO4350B offers a compelling value proposition:

-

30-50% lower cost than PTFE-based microwave laminates

-

Reduced processing costs compared to other high-frequency materials

-

Long-term reliability lowers total cost of ownership

For our featured double-sided PCB (40.8mm×51.6mm), the performance benefits often justify the moderate cost increase in critical applications.

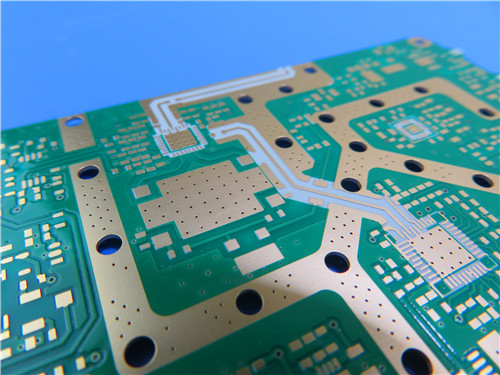

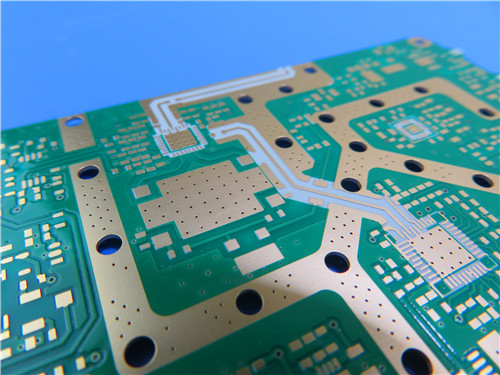

RO4350B in Practice: Our Featured PCB Solution

Let's examine how these material advantages translate to real-world performance in our standard offering:

PCB Construction Highlights

-

Base Material:RO4350B core0.168mm with 35μm copper layers

-

Thickness Control: Finished board thickness of 0.29mm (±0.03mm)

-

Precision Features: 4/4 mil trace/space, 0.2mm minimum holes

-

Reliable Plating: 20μm via plating thickness ensures conductivity

-

Surface Finish: Immersion Gold for optimal RF performance

Quality Assurance

IPC-Class 2 compliance

100% electrical testing before shipment

UL 94 V-0 rated for fire safety

Low moisture absorption (0.06%) enhances reliability

Application-Specific Recommendations

When to Choose RO4350B:

1.Cellular Infrastructure

Base station antennas (3G/4G/5G)

Power amplifiers requiring stable Dk

2.Automotive Radar

77GHz ADAS systems

Millimeter-wave sensors

3.Aerospace & Defense

Radar systems

Satellite communications (LNBs)

4.High-Speed Digital

5Gbps serial links

Low-jitter clock distribution

When FR4 Might Suffice:

-

Low-frequency analog circuits (<500MHz)

-

Non-critical digital applications

-

Cost-sensitive prototypes

Technical Deep Dive: Material Science Perspective

The superior performance of RO4350B stems from its unique composition:

1.Ceramic-Filled Hydrocarbon System:

Combines low-loss characteristics with mechanical stability

Woven glass reinforcement enhances dimensional stability

2.CTE Management:

X/Y CTE matches copper (10-12 ppm/°C)

Z-axis CTE of 32 ppm/°C ensures PTH reliability

3.Frequency Response:

Stable Dk from 1MHz to 10GHz

Minimal dispersion effects

Design Considerations for RO4350B PCBs

To maximize the benefits of RO4350B in your designs:

1.Impedance Control:

Leverage the stable Dk for accurate calculations

Our 4/4 mil capability supports precise RF traces

2.Thermal Management:

Utilize the enhanced thermal conductivity

Consider copper weight options for current handling

3.Multilayer Constructions:

RO4350B's CTE properties enable reliable MLB designs

Compatible with FR4 in hybrid stacks

Global Availability and Support

We offer these high-performance PCBs with worldwide availability, supported by:

-

Standard Gerber RS-274-X artwork acceptance

-

Comprehensive electrical testing

-

IPC quality standards compliance

-

Technical support for material selection

Conclusion: Making the Right Substrate Choice

The decision between Rogers RO4350B and FR4 ultimately depends on your application requirements:

Choose RO4350B for:

-

Frequencies above 1GHz

-

Critical impedance control

-

Thermal reliability needs

-

Long-term field performance

Consider FR4 for:

-

Cost-driven projects

-

Low-frequency applications

-

Non-critical environments

Our featured RO4350B-based PCB solution represents the ideal balance of high-frequency performance, reliability, and manufacturability—offering a cost-effective alternative to traditional microwave laminates without compromising on quality.

For designers pushing the limits of RF and high-speed digital performance, Rogers RO4350B provides the material foundation needed for success in today's demanding electronic applications. Contact our team to discuss how we can optimize your next high-frequency PCB design with our RO4350B solutions.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com