How Do You Handle PCB Panelization?

PCB Panelization: Optimizing Panel Size for Cost-Efficiency (V-Cut vs. Tab Routing)

Introduction

In PCB manufacturing, panelizationis a critical step that directly impacts production efficiency, material utilization, and overall cost. Panelization involves arranging multiple PCB designs onto a single manufacturing panel to optimize fabrication and assembly processes. The two most common methods for separating individual PCBs from the panel areV-cut scoringandtab routing with breakaway tabs.

This article explores best practices for PCB panelization, focusing on how we optimize panel sizes for cost-efficiency while maintaining structural integrity and electrical performance. We’ll also highlight how our high-frequency Rogers RO3003 PCB benefit from precise panelization techniques.

Why PCB Panelization Matters

Panelization maximizes material usage, reduces handling time, and improves assembly efficiency. Without proper panelization, manufacturers risk:

-Higher material waste–Poor panel design leads to unused board space.

-Increased assembly costs–Manual handling of small PCBs slows down production.

-Lower structural stability–Thin or high-frequency PCBs (like Rogers RO3003) require careful panelization to avoid warping or cracking.

By optimizing panel size and separation methods, we ensure cost-effective, high-yield production—especially for advanced applications like automotive radar, 5G infrastructure, and RF communications.

V-Cut vs. Tab Routing: Choosing the Right Method

1. V-Cut (Scoring) Panelization

Best for:Straight-line separations,rigid PCBs, and high-volume production.

How it works:

- A V-shaped groove is cut partially through the PCB panel, leaving a thin connecting layer.

- After assembly, boards are snapped apart along the V-cut lines.

Advantages:

-Fast separation–Ideal for automated assembly lines.

-Clean edges–Minimal post-processing required.

-Space-efficient–Allows tighter PCB placement.

Limitations:

-Not suitable for complex shapes–Only works for straight-line separations.

-Risk of stress fractures–Thin or flexible PCBs (like our 0.2mm RO3003 boards) may require additional support.

2. Tab Routing (Breakaway Tabs)

Best for:Irregular PCB shapes, flexible circuits, and high-frequency boards.

How it works:

- Small perforated tabs (mouse bites) hold PCBs in place within the panel.

- After assembly, boards are broken free by applying pressure.

Advantages:

-Flexible design–Supports complex PCB outlines.

-Better for thin PCBs–Reduces stress on delicate materials like Rogers RO3003.

-No sharp edges–Minimizes risk of damage during handling.

Limitations:

-Requires manual de-panelization–Slower than V-cut for high-volume orders.

-May need additional finishing–Breakaway tabs can leave small protrusions.

Optimizing Panel Size for Cost Efficiency

To maximize cost savings, we consider:

1. Material Utilization

-Standard panel sizes(e.g., 18"x24", 21"x24") minimize waste.

- Our 69.25mm x 92.45mm RO3003 PCBs are strategically arranged to maximize yield.

2. Assembly Compatibility

- Panels must fit pick-and-place machines and reflow ovens.

-High-frequency PCBs (like RO3003 PCB) require careful handling to avoid impedance variations.

3. Breakaway Method Selection

-V-cut for simple, rigid boards→Faster production.

-Tab routing for complex, thin boards→Prevents cracking.

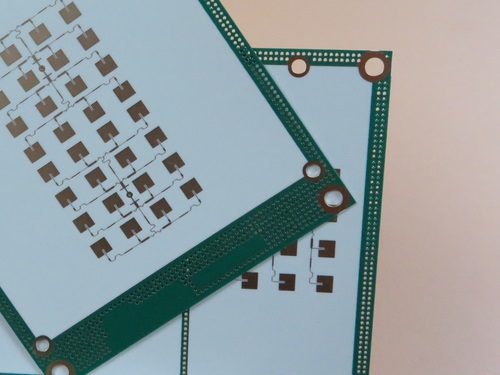

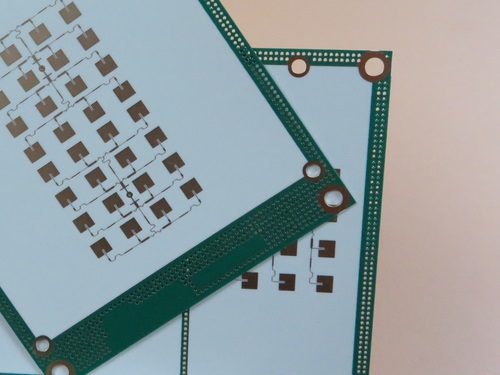

Case Study: High-Frequency Rogers RO3003 PCB Panelization

Our 2-laye rRogers RO3003 PCB is designed for RF and microwave applications, where precision and material stability are critical.

Key Specifications:

-Base Material:Rogers RO3003 (ceramic-filled PTFE)

-Dimensions:69.25mm x 92.45mm (2 types, 2 pieces per panel)

-Thickness:0.2mm (ultra-thin for high-frequency performance)

-Surface Finish:Immersion Gold (optimal for RF signal integrity)

-Trace/Space:5/5 mils (high-density routing)

Why Panelization Matters for RO3003 PCBs:

-Thermal Stability: Rogers 3003 has a low CTE (17 ppm/°C in X/Y axis), reducing warping risk during depaneling.

-High-Frequency Performance:Proper panelization ensures consistent dielectric properties (Dk = 3.0±0.04).

-Cost Efficiency:Optimized panel layouts reduce material waste, lowering production costs.

Best Practices for PCB Panelization

1.Minimize Waste–Use CAD software to optimize PCB arrangement.

2.Consider Depaneling Method Early–Choose V-cut or tab routing during design.

3.Account for Tooling Holes–Ensure panels fit assembly equipment.

4.Test Electrical Continuity–Our100% electrical testing ensures reliability post-panelization.

Conclusion

Effective PCB panelization balances cost-efficiency, manufacturability, and performance. For high-frequency PCBs like Rogers RO3003 PCB, selecting the right depaneling method (V-cut or tab routing) ensures structural integrity and electrical stability.

As a trusted PCB supplier, we optimize panelization for maximum yield and minimal waste, delivering high-performance boards for 5G, automotive radar, and RF applications.

Need a cost-optimized PCB solution? Contact us today for a panelization strategy tailored to your design!

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com