Overview

The Rogers RO3010 is an advanced circuit material that offers exceptional electrical and mechanical performance for high-frequency applications. This ceramic-filled PTFE composite laminate delivers a high dielectric constant of 10.2 with excellent stability, making it an ideal choice for circuit miniaturization and broadband component design.

The RO3010 stands out for its combination of superior electrical properties, dimensional stability, and cost-effectiveness - key attributes that enable its use across a wide range of high-frequency applications from radar and satellite communications to cellular infrastructure and wireless devices.

The key advantages and disadvantages of using RO3010 PCB compared to other PCB materials:

Advantages:

1.Excellent Electrical Performance:

RO3010 has a low dielectric constant (εr = 10.2) and very low loss tangent (<0.0023), making it well-suited for high-frequency, high-speed circuit applications.

2.Wide Operating Temperature Range:

RO3010 can operate from -55°C to +125°C with good stability of its electrical properties across this temperature range.

3.High Thermal Conductivity:

RO3010 has a relatively high thermal conductivity of 0.62 W/m-K, which helps dissipate heat better than many other PCB laminates.

4.Moisture Resistance:

RO3010 has very low moisture absorption, making it suitable for applications with stringent environmental requirements.

5.Good Dimensional Stability:

The low coefficient of thermal expansion (CTE) of RO3010 helps maintain dimensional stability during manufacturing and use.

Disadvantages:

1.Higher Cost:

Compared to standard FR-4 PCBs, RO3010 is more expensive due to the specialized materials and manufacturing processes involved.

2.Specialized Fabrication:

RO3010 PCBs require more specialized fabrication techniques and equipment, which can increase manufacturing complexity and lead times.

3.Limited Availability:

RO3010 is a specialty material, so the range of suppliers and board shops that can readily fabricate RO3010 PCBs may be more limited.

4.Higher Dielectric Constant:

While excellent for high-frequency use, the relatively high dielectric constant of RO3010 (εr = 10.2) can be a limitation compared to lower-εr materials for some applications.

5.Rigidity:

RO3010 is a relatively rigid material, which may make it less suitable for applications requiring flexible or bendable PCBs.

6.Thermal Management Complexity:

The higher thermal conductivity of RO3010 requires careful thermal management design to ensure proper heat dissipation.

Overall, RO3010 is an excellent choice for high-frequency, high-performance circuit boards, but the higher cost and specialized fabrication needs should be carefully evaluated against the specific requirements of the application.

Electrical Properties for High-Frequency Performance

At the heart of the RO3010's performance is its impressive dielectric characteristics. The RO3010 laminate maintains a dielectric constant (Dk) of 10.2 ± 0.3 at 10 GHz and 23°C, providing a high-Dk material option for compact, high-density circuit designs. Equally important, this Dk value remains highly stable across a broad frequency range and operating temperatures, with a low dissipation factor of 0.0022 at 10 GHz and 23°C.

The RO3010's stable electrical properties stem from its ceramic-filled PTFE composite construction. This proprietary material formulation yields exceptional frequency and thermal stability, allowing designers to confidently use the laminate in applications spanning DC to 40 GHz. The material's loss tangent remains low, even at millimeter-wave frequencies, minimizing signal degradation and enabling efficient, high-performance circuit designs.

Dimensional Stability for Design Simplification

In addition to its electrical prowess, the RO3010 high frequency PCB stands out for its excellent dimensional stability. The laminate's coefficient of thermal expansion (CTE) is closely matched to that of copper, greatly simplifying the design of multilayer PCBs and minimizing issues like thermal expansion mismatch, registration shifts, and reliability concerns.

Specifically, the RO3010 25mil substrate exhibits a low CTE of 13 ppm/°C in the X-axis, 11 ppm/°C in the Y-axis, and 16 ppm/°C in the Z-axis over the critical -55°C to 288°C temperature range. This dimensional stability, combined with the material's low moisture absorption (0.05%), helps ensure long-term reliability and consistent electrical performance, even in demanding operating environments.

The RO3010's thermal properties are equally impressive, with a glass transition temperature (Tg) greater than 500°C and a continuous use temperature range of -40°C to +85°C. These characteristics make the laminate well-suited for high-temperature processing and assembly, as well as reliable operation in harsh conditions.

Cost-Effective Laminate for Volume Manufacturing

Beyond its technical merits, the RO3010 also stands out for its economic advantages. As a competitively priced circuit material, the RO3010 enables cost-effective volume manufacturing, a critical consideration for many high-frequency product applications.

The laminate's ceramic-filled PTFE construction allows for streamlined, high-yield production processes compared to traditional PTFE-based laminates. This manufacturing efficiency, combined with Rogers Corporation's global supply chain and economies of scale, results in a laminate that delivers superior electrical and mechanical performance at a price point accessible for high-volume applications.

Versatile Design Flexibility

The RO3010's combination of electrical, mechanical, and cost advantages make it a versatile circuit material suitable for a wide range of high-frequency applications. Its stable Dk and low loss characteristics allow for the design of efficient, broadband components and circuits, while its dimensional stability simplifies the development of multilayer PCB designs.

Some of the key application areas for the RO3010 include:

1.Automotive Radar:

The RO3010's high Dk, low loss, and dimensional stability make it an excellent choice for automotive radar systems, enabling the compact, high-performance antenna and RF designs required for advanced driver assistance systems (ADAS) and autonomous driving applications.

2.Satellite Communications:

The RO3010 is well-suited for satellite communications equipment, including GPS antennas, direct broadcast satellites, and datalink systems on cable networks. Its stable electrical performance, thermal capabilities, and cost-effectiveness are all critical factors for these space-constrained, high-reliability applications.

3.Cellular Infrastructure:

The RO3010 is an ideal laminate for cellular base station power amplifiers and antennas, providing the high-frequency performance, thermal management, and cost-effectiveness required for the rollout of 5G and future cellular networks.

4.Wireless Communications:

The RO3010's versatility extends to a variety of wireless communications applications, from patch antennas in consumer devices to power backplanes in industrial wireless equipment. Its material properties enable the development of compact, reliable, and cost-effective RF circuits and subsystems.

Designed for Reliable, Cost-Effective Manufacturing

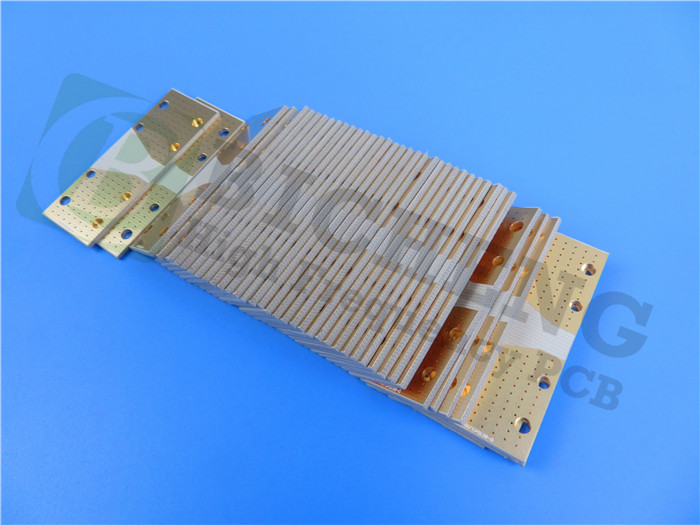

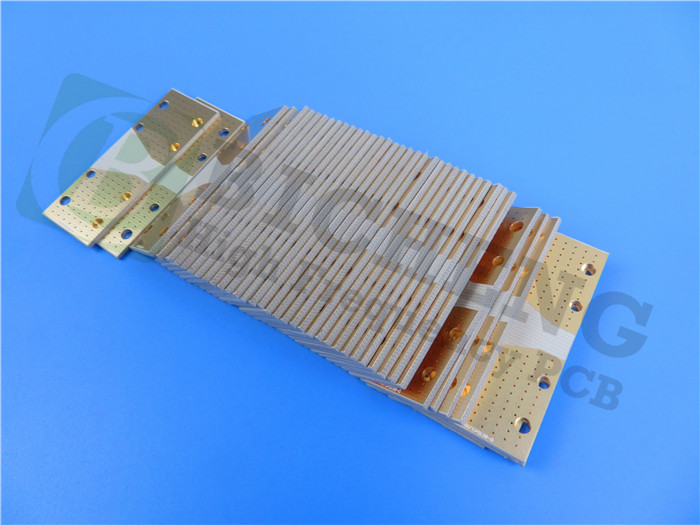

To support the RO3010's use across these diverse high-frequency applications, the laminate is designed for reliable, cost-effective manufacturing. The 25mil-thick RO3010 substrate is available in a standard 2-layer PCB construction, with 35μm copper foil on both the top and bottom sides.

Key construction details include:

Board dimensions: 90mm x 45mm

Minimum trace/space: 5/5 mils

Minimum hole size: 0.4mm

Finished board thickness: 0.8mm

Finished copper weight: 1oz (1.4 mils) on outer layers

Via plating thickness: 20μm

Surface finish: Immersion gold

Top silkscreen: White

Bottom silkscreen: None

Solder mask: None on top or bottom

This comprehensive set of design specifications, combined with the laminate's material properties, enables the RO3010 to be readily integrated into a wide range of PCB fabrication and assembly processes. The board can be easily customized to meet application-specific requirements, with the assurance of reliable, high-quality manufacturing.

All Rogers 3010 PCBs undergo 100% electrical testing prior to shipment, ensuring consistent quality and performance. The boards are produced to IPC Class 2 standards, meeting the requirements for general electronic products.

Superior Performance, Simplified Design

In summary, the Rogers RO3010 25mil high-performance laminate offers an exceptional combination of electrical, mechanical, and economic advantages that make it an ideal choice for a wide variety of high-frequency applications. Its stable, high-Dk dielectric properties, dimensional stability, and cost-effective manufacturing enable simplified, reliable circuit designs that deliver superior performance.

Whether your application requires compact, high-density RF circuits, efficient broadband components, or rugged, reliable PCBs for harsh environments, the Rogers 3010 laminate provides the technical capabilities and economic benefits to meet your design challenges. Contact Rogers Corporation today to learn more about how this advanced circuit material can optimize your high-frequency products.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com