Rogers TMM 6 PCB: A High-Performance Solution for Advanced Microwave Applications

Introduction

In the realm of high-frequency electronics, the demand for reliable and efficient printed circuit boards (PCBs) is constantly growing. Rogers TMM 6 PCB, the latest addition to the Rogers Corporation's product family, emerges as an exceptional thermoset microwave material designed to meet the stringent requirements of modern microwave circuits. This comprehensive blog post delves deep into the features, benefits, construction details, and typical applications of the TMM 6 PCB, shedding light on its unique properties and highlighting its suitability for a wide range of cutting-edge applications.

TMM 6 Introduction

Rogers TMM6 25mil PCB is a ceramic thermoset polymer composite specifically engineered to deliver exceptional performance in high-frequency applications. It combines the advantages of ceramic and traditional polytetrafluoroethylene (PTFE) microwave circuit laminates without the need for specialized production techniques associated with these materials. One of the key differentiators of TMM 6 is its unique dielectric constant (Dk) when compared to other materials in the Rogers product family.

Features

The TMM 6 PCB exhibits an array of impressive features that make it an ideal choice for demanding microwave applications. Here are the notable features of the TMM 6 PCB:

1)Dielectric constant (Dk) of 6.0 +/- .08 at 10GHz:

The precise and stable Dk enables accurate signal propagation and impedance control, ensuring reliable performance in microwave circuits.

2)Dissipation factor of .0023 at 10GHz:

The low dissipation factor minimizes signal loss, allowing for efficient power transfer in high-frequency applications.

3)Thermal coefficient of Dk of -11 ppm/°K:

TMM 6 PCB maintains its electrical characteristics over a wide temperature range, ensuring consistent performance in various operating conditions.

4)Coefficient of thermal expansion matched to copper:

The TMM 6 material exhibits a coefficient of thermal expansion that is well-matched with copper, reducing the risk of delamination or mechanical stress during thermal cycling.

5)Decomposition Temperature (Td) of 425 °C TGA:

The high decomposition temperature ensures the stability and integrity of the PCB even under extreme temperature conditions.

6)Coefficient of Thermal Expansion - x, y, z:

The carefully matched coefficients of thermal expansion (CTE) in the x, y, and z directions minimize the risk of warpage and ensure dimensional stability during temperature variations.

7)Thermal Conductivity of 0.72W/mk:

TMM 6 PCB offers efficient heat dissipation, enabling the effective cooling of power components and reducing the risk of thermal issues in high-power applications.

8)Available in a thickness range of .0015 to .500 inches +/- .0015”:

The TMM 6 PCB provides flexibility in design by offering a wide range of thickness options to accommodate diverse application requirements.

Benefits

The TMM 6 PCB offers several key benefits that make it a compelling choice for microwave circuit designers and manufacturers. These benefits include:

1)Mechanical properties resist creep and cold flow:

The TMM 6 material exhibits excellent mechanical stability, preventing deformation or degradation over time, even under continuous stress.

2)Resistant to process chemicals, reducing damage during fabrication:

The chemical resistance of TMM 6 PCB ensures that it can withstand the various chemical processes involved in PCB fabrication, minimizing the risk of damage and ensuring high yield rates.

3)Based on a thermoset resin, allowing for reliable wire-bonding:

The thermoset nature of TMM 6 PCB ensures reliable wire-bonding, critical for interconnectivity in complex microwave circuits.

4)All common PCB processes can be used with TMM 6 materials:

TMM 6 PCB can be seamlessly integrated into existing manufacturing processes, allowing for easy adoption without significant changes to production workflows.

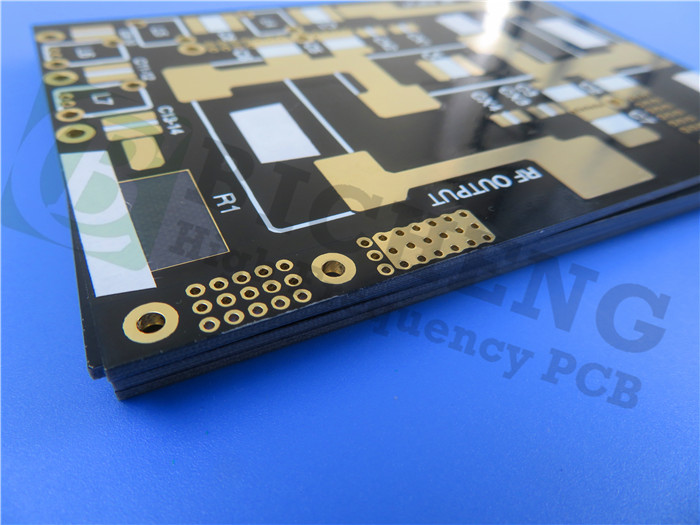

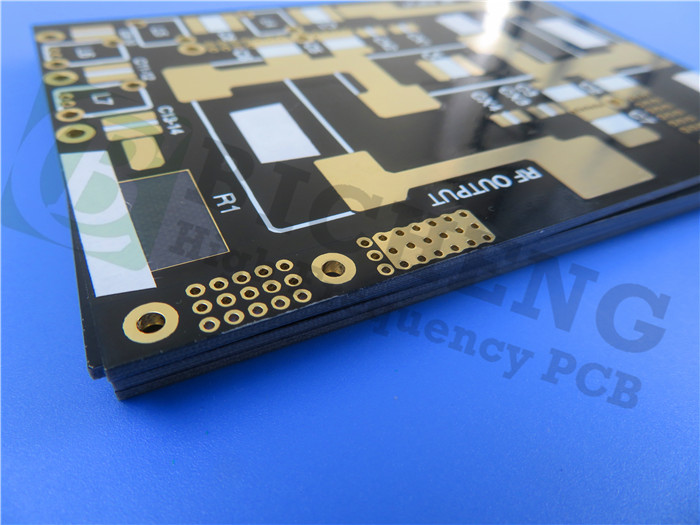

PCB Construction Details

The construction of the TMM 6 PCB follows a reliable and robust design that ensures optimal performance. Here are the key construction details:

PCB Stackup:

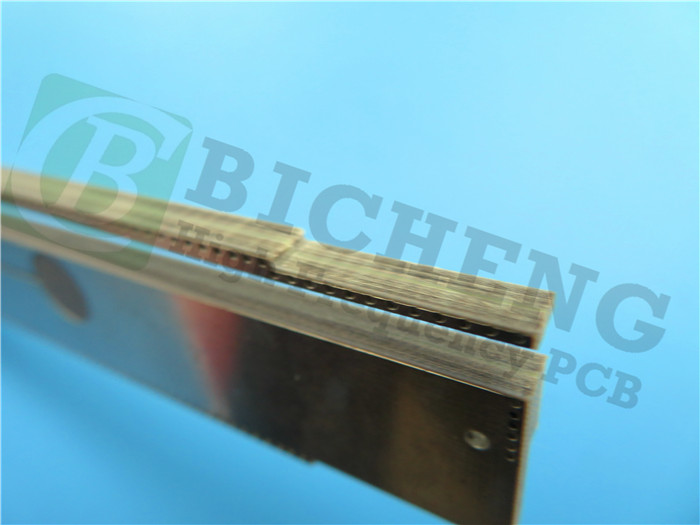

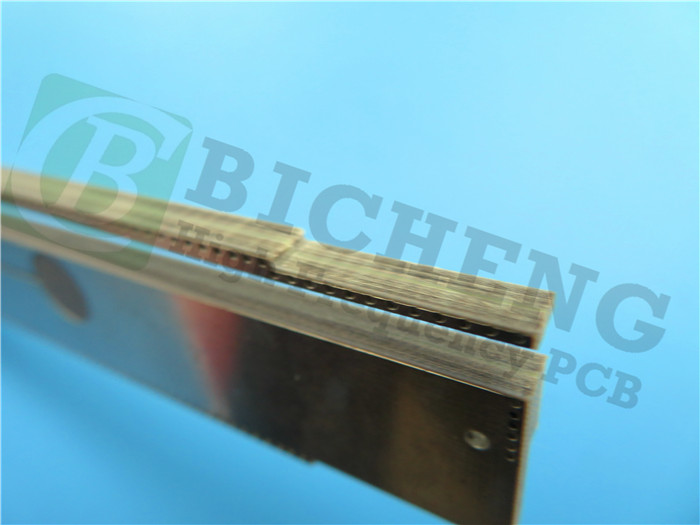

The 2-layerTMM 6 PCB is a rigid PCB with copper layers on both sides of the TMM6 core.

Copper_layer_1: 35 μm

Rogers TMM6 Core: 0.635 mm (25mil)

Copper_layer_2: 35 μm

Board dimensions: The TMM 6 PCB is available in a standard size of 56.04mm x 53.18mm, with a tolerance of +/- 0.15mm.

Minimum Trace/Space: The TMM 6 PCB supports a minimum trace/space width of 4/4 mils, enabling the creation of intricate and compact circuit designs.

Minimum Hole Size: The TMM 6 PCB accommodates holes with a minimum size of 0.3mm, allowing for the integration of various through-hole components.

Finished board thickness: The finished thicknessof the TMM 6 PCB is 0.7mm, providing a balance between structural integrity and space constraints.

Finished Cu weight: The outer layers of the TMM 6 PCB have a finished copper weight of 1oz (1.4 mils), ensuring good conductivity and optimal signal transmission.

Via plating thickness: The vias of the TMM 6 PCB are plated with a thickness of 20 μm, guaranteeing reliable electrical connections between layers.

Surface finish: The TMM 6 PCB is coated with immersion silver as the surface finish, offering excellent solderability and preserving signal integrity.

Top Silkscreen/Bottom Silkscreen: The TMM 6 PCB have white silkscreen for top, providing a clean and minimalistic appearance.

Top Solder Mask/Bottom Solder Mask: The TMM 6 PCB have top or bottom with black solder mask layers, although the option for solder mask application can be customized based on specific requirements.

100% Electrical test used prior to shipment: To ensure the highest quality and reliability, each TMM 6 PCB undergoes a rigorous electrical test before leaving the manufacturing facility.

PCB Statistics

To provide a comprehensive overview, here are some key statistics about the TMM 6 PCB:

Components: The TMM 6 PCB can accommodate up to 16 components, enabling the integration of complex microwave circuitry.

Total Pads: There are a total of 33 pads on the TMM 6 PCB, facilitating secure connections for various components and interconnects.

Thru-Hole Pads: The TMM 6 PCB features 23 thru-hole pads, allowing for the insertion of through-hole components for enhanced functionality.

Top SMT Pads: The TMM 6 PCB provides 10 surface-mount technology (SMT) pads on the top layer, enabling the placement of SMT components for compact designs.

Bottom SMT Pads: The TMM 6 PCB does not have bottom SMT pads, as it is a 2-layer PCB.

Vias: The TMM 6 PCB incorporates 15 vias, facilitating electrical connections between different layers and ensuring signal continuity.

Nets: The TMM 6 PCB contains 3 nets, representing the interconnections between various components and circuit elements.

Type of Artwork Supplied and Quality Standard

The TMM6 25mil substrate PCB is manufactured based on Gerber RS-274-X artwork, ensuring compatibility with standard PCB design tools and streamlining the manufacturing process. Moreover, the TMM 6 PCB adheres to the IPC-Class-2 quality standard, guaranteeing a high level of quality and reliability in accordance with industry benchmarks.

Availability and Typical Applications

The TMM6 25mil material PCB is readily available worldwide, making it accessible to engineers, designers, and manufacturers across different regions. Its exceptional performance and versatile characteristics make it suitable for a wide range of applications, including:

1)RF and microwave circuitry:

The TMM 6 PCB excels in high-frequency applications, making it ideal for RF and microwave circuit designs that require precise signal transmission and low loss.

2)Power amplifiers and combiners:

With its excellent thermal conductivity and stability, the TMM 6 PCB is well-suited for power amplifiers and combiners in communications and broadcasting systems.

3)Filters and couplers:

The TMM 6 PCB's high-quality dielectric properties enable the realization of efficient filters and couplers, essential components in various communication and signal processing systems.

4) Satellite communication systems:

The TMM 6 PCB's reliability and performance make it an excellent choice for satellite communication systems, ensuring consistent and uninterrupted data transmission.

5)Global Positioning Systems Antennas:

The TMM 6 PCB's low-loss characteristics and stability make it an ideal substrate for high-performance GPS antennas, enabling accurate positioning and navigation.

6)Patch Antennas:

With its high-frequency capabilities and precise Dk control, the TMM 6 PCB is well-suited for patch antennas used in wireless communication systems and radar applications.

7)Dielectric polarizers and lenses:

The TMM 6 PCB's unique properties make it suitable for dielectric polarizers and lenses used in advanced optical systems, such as radars and imaging devices.

8)Chip testers:

The TMM 6 PCB's reliability and compatibility with common PCB processes make it a valuable component in chip testers, ensuring accurate and efficient testing of integrated circuits.

Conclusion

In conclusion, the Rogers TMM 6 PCB stands as a remarkable solution for high-frequency and microwave applications. With its exceptional dielectric properties, mechanical stability, and compatibility with standard PCB processes, it offers a reliable and efficient platform for advanced circuit designs. From RF and microwave circuitry to satellite communication systems and beyond, the TMM6 high frequency PCB empowers engineers and designers to push the boundaries of high-frequency electronics and unlock new possibilities in the realm of technology.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com