Rogers TMM13i PCB:Unlocking the Potential of High-Performance Microwave Applications

In the ever-evolving world of RF and microwave technology, the demand for innovative and reliable circuit board materials has never been higher. As engineers and designers push the boundaries of what's possible, they require materials that can keep up with their increasingly complex and demanding requirements. Enter the Rogers TMM13i, a cutting-edge PCB solution that is poised to transform the way we approach high-frequency applications.

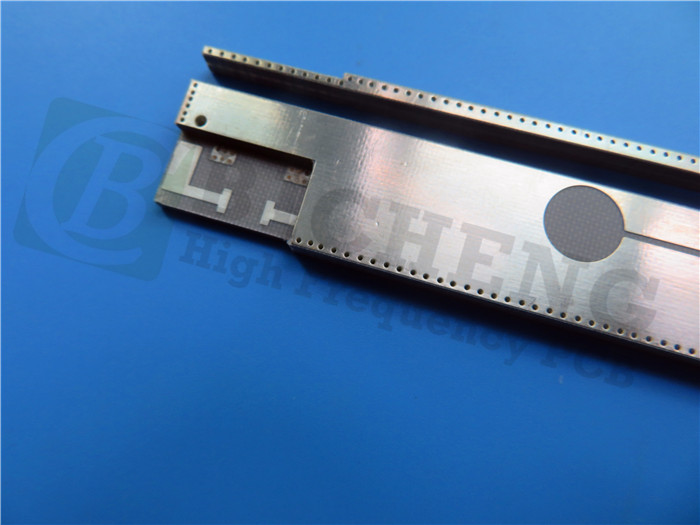

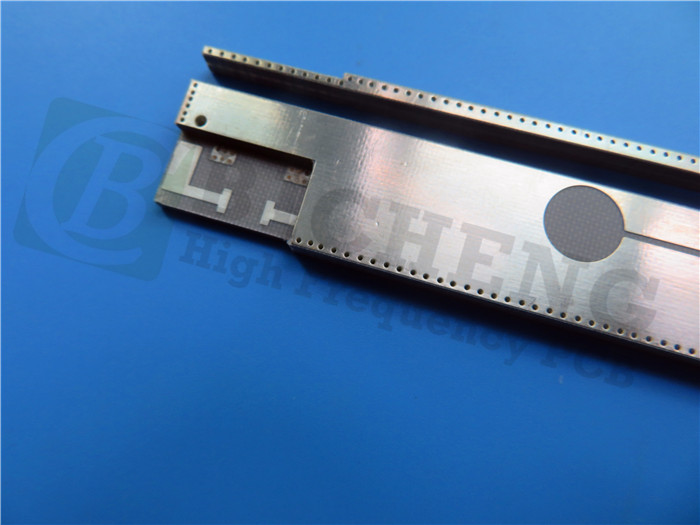

TMM13i is renowned TMM series of microwave materials from Rogers Corporation. This isotropic thermoset composite boasts a unique combination of exceptional electrical, thermal, and mechanical properties, making it an ideal choice for a wide range of mission-critical applications.

Unparalleled Electrical Performance

At the heart of the TMM13i's impressive capabilities is its meticulously engineered dielectric properties. With a dielectric constant (Dk) of 12.85 ± 0.35, this material offers an unparalleled level of consistency and precision, ensuring exceptional signal integrity and predictable circuit behavior.

One of the most remarkable aspects of theTMM13i15mil PCB is its exceptionally low dissipation factor (Df) of 0.0019 at 10 GHz. This low-loss characteristic is crucial for maintaining efficient power transmission and minimizing unwanted signal degradation, a critical requirement for high-frequency applications such as power amplifiers, filters, and couplers.

Furthermore, the TMM13i boasts a remarkably stable thermal coefficient of dielectric constant (TCDk) of -70 ppm/°C, ensuring that the dielectric properties remain consistent even in the face of temperature fluctuations. This stability is particularly important in applications where environmental conditions can be challenging, such as satellite communication systems and global positioning antennas.

Uncompromising Mechanical Resilience

Alongside its impressive electrical performance, theTMM13i15mil laminate PCB also excels in its mechanical properties, making it a robust and reliable choice for a wide range of applications.

One of the standout features of the TMM13i is its exceptional resistance to creep and cold flow, a common issue with many traditional microwave materials. This mechanical stability, combined with a coefficient of thermal expansion (CTE) that is closely matched to copper, allows for the precise dimensional control needed for high-frequency circuit designs.

The TMM13i's decomposition temperature (Td) of 425°C, as measured by Thermogravimetric Analysis (TGA), is another testament to its exceptional thermal stability. This high-temperature resistance ensures that the material can withstand the rigors of various manufacturing processes, including soldering and assembly, without compromising its structural integrity or electrical performance.

Fabrication and Processing

In addition to its superior electrical and mechanical properties, the Rogers TMM13i PCB also excels in its fabrication and processing characteristics, making it a highly versatile and user-friendly option for PCB manufacturers and designers.

One of the key advantages of the TMM13i is its compatibility with standard soft substrate processing techniques, eliminating the need for specialized equipment or complex handling procedures. This ease of processing translates to reduced manufacturing costs and increased production efficiency, further enhancing the material's appeal in the competitive microwave market.

Notably, the TMM13i 15mil substrate PCB does not require a sodium napthanate treatment prior to electroless plating, a common requirement for many traditional microwave materials. This simplifies the fabrication process and reduces the risk of potential issues during the manufacturing stages.

Furthermore, the TMM13i's thermoset resin formulation allows for reliable wire-bonding, a crucial feature for applications such as chip testers and power amplifier modules.

Unleashing the Potential of High-Frequency Applications

The exceptional properties of the TMM13i make it an ideal choice for a wide range of high-frequency applications, from RF and microwave circuitry to satellite communication systems and global positioning antennas.

1.RF and Microwave Circuitry:

The TMM13i's low dielectric loss, thermal stability, and dimensional control make it an excellent substrate for the design and fabrication of high-performance RF and microwave circuits, including power amplifiers, filters, and couplers. Its isotropic nature ensures uniform electrical properties, simplifying circuit design and optimization.

2.Satellite Communication Systems:

The TMM13i's resistance to environmental factors, such as temperature fluctuations and humidity, makes it a compelling choice for satellite communication systems. Its low-loss characteristics and stable dielectric properties are crucial for maintaining signal integrity and maximizing system performance in the demanding conditions of space-based applications.

Global Positioning System (GPS) Antennas:

The TMM13i's low dielectric constant and excellent thermal stability make it an ideal material for the development of high-precision GPS antennas. Its dimensional stability and consistent electrical performance help ensure accurate positioning and navigation, even in challenging environmental conditions.

Patch Antennas:

The TMM13i's combination of a relatively high dielectric constant and low loss tangent make it an excellent choice for the design and fabrication of high-performance patch antennas. Its ability to support compact, efficient antenna structures is particularly advantageous for applications where size and weight are critical factors.

Dielectric Polarizers and Lenses:

The TMM13i's isotropic nature and predictable dielectric properties make it a suitable material for the development of dielectric polarizers and lenses, essential components in various microwave and millimeter-wave systems, such as radar and imaging applications.

Chip Testers:

The TMM13i's reliable wire-bonding capabilities and dimensional stability make it an ideal substrate for chip testers and other high-frequency measurement applications, where precise signal transmission and repeatable performance are paramount.

Unlocking New Possibilities with Rogers TMM13i

The introduction of the Rogers TMM13i PCB material marks a significant milestone in the evolution of high-frequency circuit board solutions. With its unparalleled electrical performance, exceptional mechanical resilience, and seamless fabrication capabilities, this cutting-edge material opens the door to a new era of innovation and possibility in the world of RF and microwave technology.

Whether you're designing cutting-edge satellite communication systems, developing high-precision GPS antennas, or pushing the boundaries of power amplifier performance, the TMM13i high frequency PCB stands ready to be your partner in unlocking unprecedented levels of functionality and reliability. Embrace the future of microwave applications with the Rogers TMM13i – a material that redefines the standards of excellence in the industry.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com