Introduction :

In the fast-paced world of technology, the demand for high-performance electronic devices is ever-increasing. To meet this demand, we are excited to introduce the newly shipped PCB-Rogers RO4533, an advanced circuit board material designed to deliver unmatched performance and reliability. In this comprehensive blog article, we will explore the key features, benefits, construction details, and typical applications of this exceptional PCB. Join us on this journey as we unveil how the RO4533 can revolutionize various industries with its low loss, low Dk, and low PIM response, along with its outstanding thermal conductivity and dimensional stability.

Features and Benefits:

The Rogers RO4533 offers a host of features and benefits that set it apart from conventional PCB materials:

Low Loss, Low Dk, and low PIM response:

The RO4533 exhibits minimal signal loss and low dielectric constant, enabling efficient signal transmission and optimal performance for high-frequency applications.

Compatibility with standard PCB fabrication:

The RO4533 utilizes a thermoset resin system that is fully compatible with standard PCB fabrication processes. This compatibility streamlines integration into existing production lines, saving valuable time and costs.

Excellent dimensional stability:

With its superior dimensional stability, the RO4533 material PCB ensures greater yield on larger panel sizes, reducing the risk of warping or delamination during manufacturing and operation.

Uniform mechanical properties:

The RO4533 maintains consistent mechanical properties throughout the board, ensuring the board's form is maintained during handling. This minimizes the risk of damage or failure during assembly and throughout the product's lifespan.

High thermal conductivity:

The advanced RO4533 Rogers material boasts high thermal conductivity, making it an excellent choice for power amplifier designs. This feature enhances power handling capabilities, allowing for efficient dissipation of heat and ensuring optimal performance even under demanding conditions.

Stackup and Construction Details:

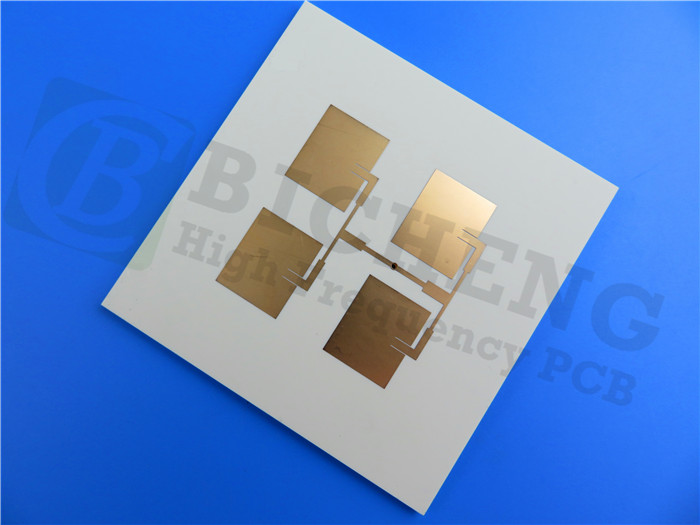

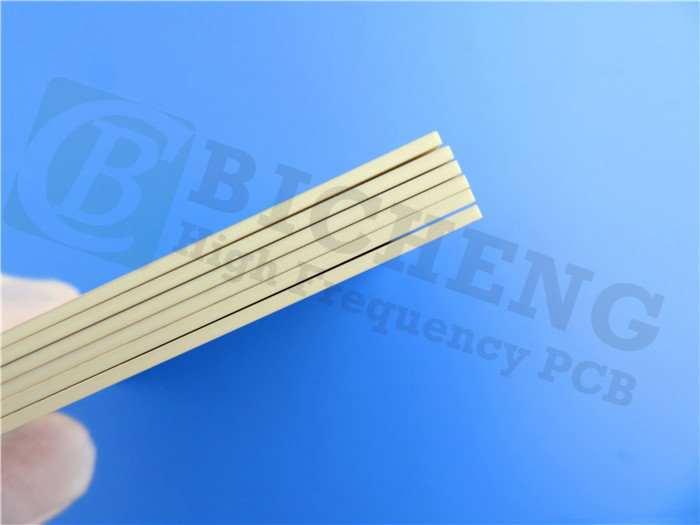

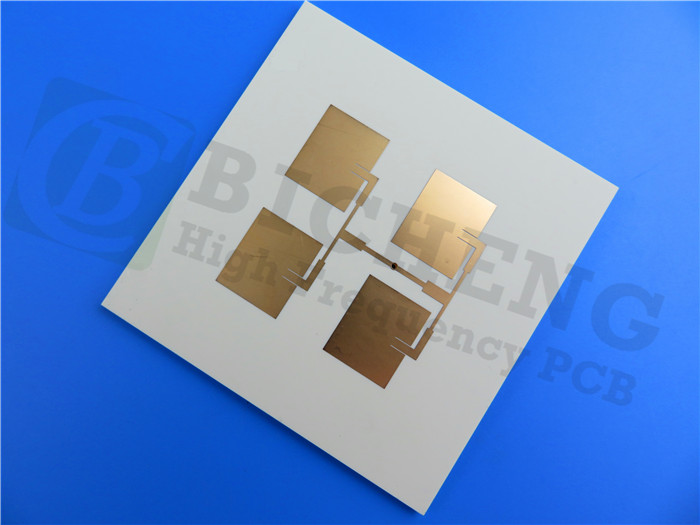

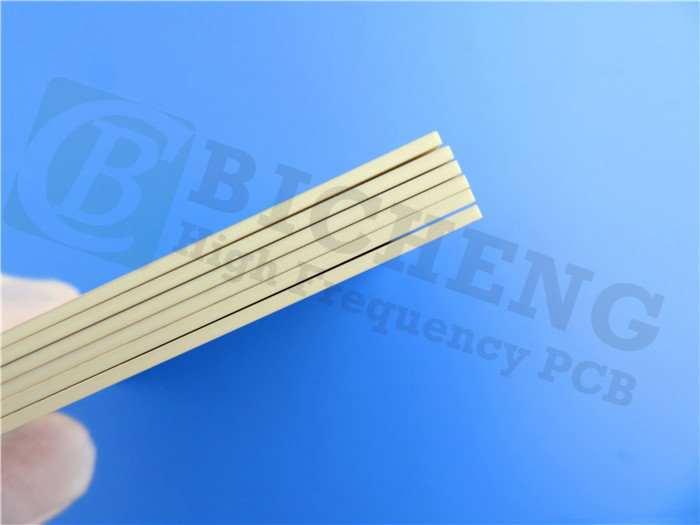

The RO4533 is a 2-layer rigid PCB with the following construction details:

Copper_layer_1: 35 μm

Rogers 4533 Core: 0.508 mm

Copper_layer_2: 35 μm

The board dimensions are 185.78mm x 139.87mm, with a tolerance of +/- 0.15mm. It supports a minimum trace/space of 5/6 mils and a minimum hole size of 0.4mm. With a finished board thickness of 0.6mm and a 1oz (1.4 mils) outer layer copper weight, the RO4533 strikes the perfect balance between performance and flexibility. Via plating thickness is 20 μm, ensuring robust connectivity. The board is finished with an immersion gold surface finish, providing excellent corrosion resistance, while the top silkscreen is in white, ensuring clear visual identification during assembly.

PCB Statistics:

The RO4533 PCB offers versatility and flexibility, accommodating complex circuit designs. With 106 components and 230 total pads, including 132 thru-hole pads and 98 top SMT pads, it provides ample space for various components. The design incorporates 249 vias, facilitating efficient signal routing. The board consists of 4 nets, ensuring seamless connectivity between components. These statistics highlight the RO4533's ability to handle diverse applications and support the integration of advanced electronic systems.

PCB Material and Dielectric Constant:

The RO4533 20mil substrate utilizes Rogers' state-of-the-art Ceramic-filled, Glass-reinforced Hydrocarbon Laminates, resulting in exceptional performance. The Dielectric Constant (DK) of the RO4533 is 3.3 ± 0.08 at 10 GHz, ensuring minimal signal loss and superior signal integrity. This characteristic is crucial for high-frequency applications that require efficient signal transmission.

Dissipation Factor and PIM Response:

The RO4533 exhibits a low Dissipation Factor (DF) of 0.0025 at 10 GHz and 0.002 at 2.5 GHz, indicating its ability to minimize energy loss during signal transmission. Additionally, the PCB demonstrates excellent Passive Intermodulation (PIM) response, with a typical rating of -157 dBc when subjected to reflected 43 dBm swept tones. This exceptional performance ensures reliable and high-quality signal transmission.

Dimensional Stability and Thermal Conductivity:

The RO4533 high frequency PCB boasts outstanding dimensional stability, with a maximum dimensional change of less than 0.2 mm/m (mils/inch) after etching. This stability is critical for maintaining precise component alignment during the manufacturing process, minimizing the risk of misalignments or mechanical failures.

Furthermore, the RO4533substrateexhibits a high thermal conductivity of 0.6 W/(m.K) at 80℃, enabling efficient heat dissipation in power amplifier designs. This feature ensures optimal performance even in demanding thermal conditions, enhancing the reliability and longevity of electronic devices.

Coefficient of Thermal Expansion and Tg:

The RO4533 demonstrates a low Coefficient of Thermal Expansion (CTE) in the X and Y directions, with values of 13 ppm/℃ and 11 ppm/℃ respectively. This characteristic ensures dimensional stability over a wide temperature range, minimizing the risk of warping or distortion. The Z-direction CTE of 37 ppm/℃ enhances the material's ability to withstand thermal stress.

Additionally, the Rogers RO4533 high TG PCB exhibits a high Glass Transition Temperature (Tg) of >280℃, indicating its ability to withstand high-temperature environments. This feature is crucial for applications that operate in extreme temperature conditions, ensuring the PCB's structural integrity and long-term performance.

Moisture Absorption and Copper Peel Strength :

The RO4533 has a low moisture absorption rate of only 0.02%, as per the D48/50 test method. This characteristic ensures the material's stability and reliability, even in high humidity environments.

Moreover, the RO4533 Rogers 0.508mm material has a Copper Peel Strength of 6.9 lbs/in (1.2 N/mm), as per the IPC-TM-650, 2.4.8 test method. This strength indicates the material's excellent adhesion to copper layers, ensuring reliable electrical connections and mechanical stability.

Flammability, Lead-Free Compatibility, and Quality Standards:

TheRO453320mil substrate is a non-flammable material, meeting the UL 94 standard for flammability. This characteristic ensures the PCB's safety and reliability, reducing the risk of fire hazards.

Additionally, the Rogers 4533 PCB is compatible with lead-free processes, making it suitable for eco-friendly manufacturing practices and complying with environmental regulations.

The RO4533 PCB adheres to the IPC-Class-2 quality standard, ensuring strict quality control and manufacturing precision. By meeting this standard, the PCB guarantees reliability, high performance, and consistent quality.

Conclusion:

The Rogers RO4533 PCB 20mil represents a breakthrough in high-performance electronics, offering unmatched features and benefits. With its low loss, low Dk, low PIM response, excellent dimensional stability, high thermal conductivity, and various other impressive attributes, the RO4533 is poised to revolutionize a multitude of industries. Contact us today to unlock the immense potential of the RO4533 and elevate your electronic designs to new heights.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com