What Are Rogers Materials?

We shall start this section of the article with defining the

Rogers PCB materials. The primary materials used in Rogers PCBs are high frequency and hydrocarbon ceramics. It supports improved production development and has a significant impact. Additionally, it lowers the cost of the printed construction, which allows for continuous heating. As a result, it lessens the electrical harm or expense caused by certain wave loss.

Some of the components on the Rogers PCB are Flame Retardant Level 4 materials. Numerous PCBs have this FR4. Some reflector fiber or adhesive components have amber foil coated on one or both surfaces, depending on the component.

These PCBs are crucial to the production of electrical products. Because of this, it's critical to carefully choose the appropriate components while making PCBs. Every designer or engineer needs to become knowledgeable about the best PCB material. This is due to the fact that they are mostly involved in the design and manufacture of electrical devices.

Some of these boards' characteristics are high-frequency. The Rogers materials are more expensive than methamphetamine. These materials are approximately 6.15 DK or 11 DK in weight. The Rogers PCB is consistently resilient. Additionally, it frequently has a constant temperature. It is not the kind of PCB with a component that is notoriously unstable.

There are roughly three primary groups of Rogers PCB components. The laminates, bonding agents, and metal facing or lining fall under these three categories. The metal liner serves as a kind of shield for the PCB. There are several resistance settings. The electrically heated glue and prepreg are among the bonding agents.

Both the field of automation and aeronautical engineering cannot be disregarded. This is crucial for military jamming devices. This is also helpful for amplifiers and anything involving RF engineering.

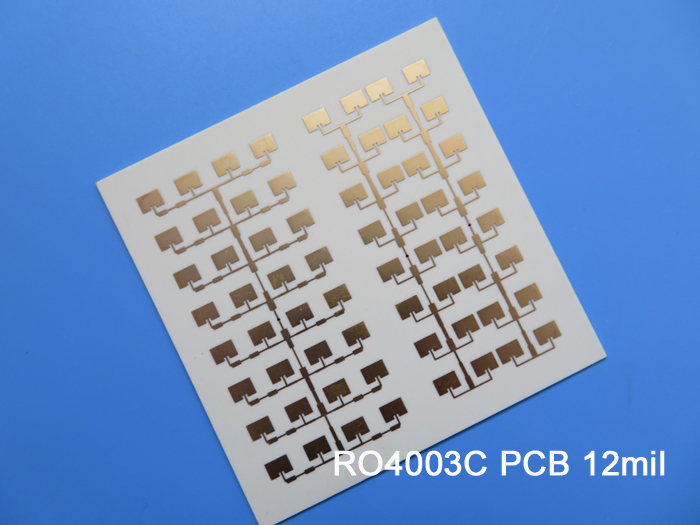

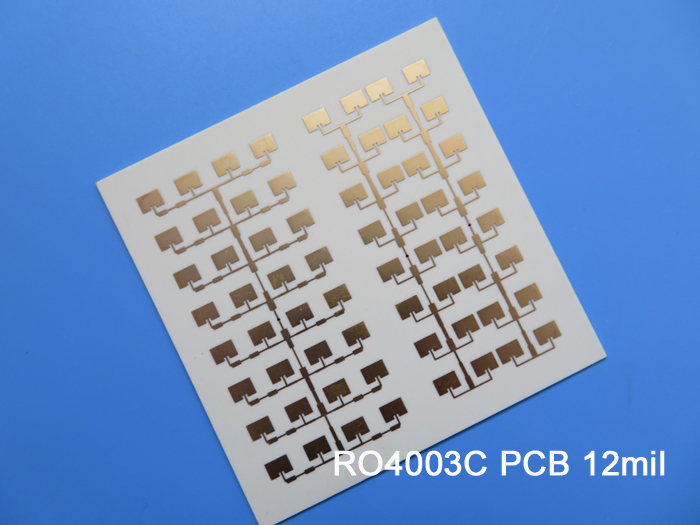

What is Rogers 4003?

A printed circuit board model that uses a woven reflective surface is the Rogers 4003 PCB. You use either tile or petroleum to support it. A laminate with high-speed performance is Rogers 4003. Due to its low dielectric loss and tolerance, this is the case. The features of this high-frequency PCB are excellent. These consist of

A low thermal coefficient of dielectric constant

Great dimensional stability

Other mechanical and electrical properties

This PCB has certain dielectric regularity thermal measurements that are stunted. Additionally, it has excellent depth stability and negligible in-plane extension quantity.

The RO4003's significance is widely acknowledged. The value of this PCB to designs must also be understood by designers. It is helpful in the creation of FR4. This also applies to the complex PCB development. Additionally, it supports certain reliable lead loose braze modification. Engineers oversee the creation and expansion of materials, the creation of circuits, and the final component assembly.

Unfluctuating electrical criteria

This is one of the primary characteristics of this specific PCB. The electrical parts of it are solid. It's highly sturdy and long-lasting as a result. Because of this, designers and engineers can use this PCB for electrical equipment to its full potential.

Its dielectric resistance and dropping are quite flat

In a way, it starts to make sense for uses that need for enormous frequency conduct. For massive tech equipment that employ high frequency automatically, this PCB can function flawlessly.

Using some common fiber brushes, one may remove the RO4003 PCB component.

In the absence of electricity, you often don't need to do any special steps prior to copper lamination or coating. This PCB performs several tasks. Typically, Microstrip can be done using it. It works well for power amps and cellular radix terminal antennas as well.

Ideal for high-frequency applications

Rogers 4003 has excellent characteristics that make it suitable for high-frequency applications. Engineers working on RF microwave circuits favor it for this reason among others. Additionally, it is essential to the defense, automotive, and telecommunications sectors.

More information about RO4003

The Rogers 4003 has a few extra characteristics that consumers should be aware of. First, the production of this PCB must be under the supervision of a skilled electronic designer. Its design development was easy, and its features were straightforward. It has some unusual electromagnetic predominance. It's interesting to note that the Rogers 4003 can be used for applications that need frequencies greater than 300MHz.

PCBs with high frequencies were first useful in military operations. They become progressively easier to reach in medical procedures as technology advances. It is also available in modern industrial settings. This may be observed in many modern communication applications worldwide.

Not only are HF applications a good fit for this PCB. As long as it can function properly, it could be used in any application. The RO4003 PCB has an overly strong dislike of heat. A low power or current sound is also included. Additionally, it exhibits low water receptivity, near effusiveness to copper carts, and low dissolution agent.

This PCB's high fiber conversion febricity or condition is one of its other standout characteristics. Additionally, it has outstanding magnitude stability. Above all, mass production is not that difficult. This explains why engineers use it so frequently.

It is crucial to understand this PCB's Rogers 4003 dielectric constant. Any component that encloses a PCB's covering is the dielectric material for that PCB. This can have a weak electric field or voltage. These elements are unique. They could be certain ductile materials, fiber, phlogopite, porcelain, or particular alloy oxides.

Rogers 4003 Limitations

There are some limitations to the Rogers 4003. This is because of the materials employed in its manufacturing process. The parts are anchored to hydrocarbons. The hydrocarbon element is particularly susceptible to specific alterations as a result of the impact.

This relates to the possibility of prolonged exposure to oxidative conditions. Avoid subjecting the RO 4003 to extreme heat expansion. In such a case, its dielectric properties begin to progressively change.

The terse circuits in the Rogers 4003 PCB are essentially stopped by the solder mask. However, the Roger 4003 PCB does not require the usage of a solder mask. The solder mask can adversely alter the conduct of the PCB regardless of how much shielding is applied to the PCB.That is the reason one may consider using the liquid form of a solder mask.

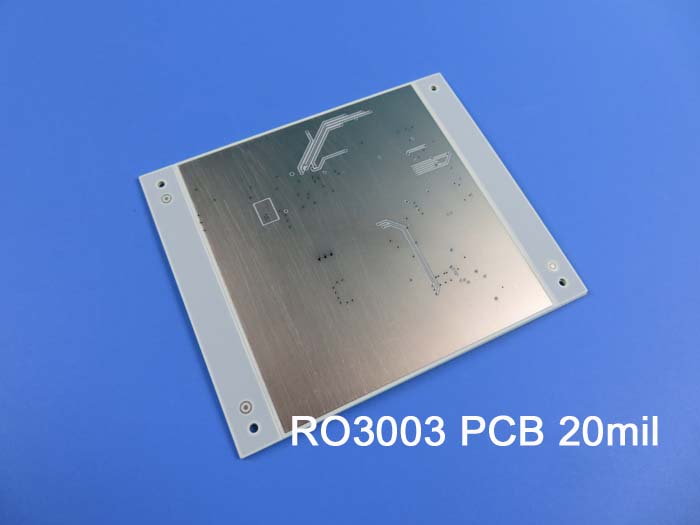

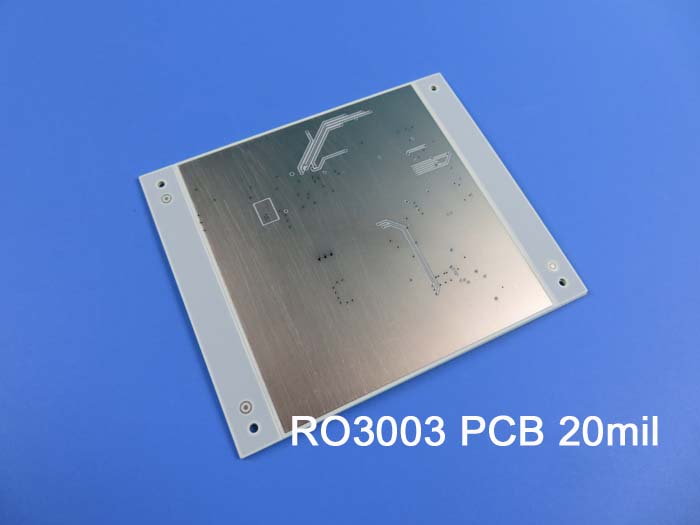

What is Rogers 3003?

Additionally a high-frequency PCB is the Rogers 3003. A materialism microwave with an RF operation is intended to use its components, which are PTFE compounds. The Rogers 3003 is a frequently used design. This is as a result of its affordability and durability.

It provides good solidity with a dielectric constant that ranges from 3 to 40 GHz in a temperature-controlled environment. The dissolving component of the element ranges from 0.0013 to 10 GHz. Additionally, it is ideal for electron-regulated oscillators, microstrip antennas, and band pass filters.

A high-frequency, ceramic-filled PTFE laminate suitable for RF and microwave applications is the Rogers 3003. A member of the RO3000 series is this laminate. Because of this, it has consistent mechanical properties regardless of the required dielectric constant.

The RO3003 has some distinctive qualities, including a 3.00 dielectric constant. Others include a loss agent with a substrate diameter of approximately 0.02 and 0.0013 loss agent. Its copper has a density at about 0.5 ounces.

Its extension measurement is the same as copper's enlargement measurement. This further enhances the components' excellent proportionate stiffness. Notably, its normal plate reduction does not exceed 0.5 inches. About 24 ppm make up its Z center line CTE. This makes this PCB significantly distinctive. Thus, while being in a harsh thermal domain, it provides excellent coating via hole reliability.

Rogers 3003's features and advantages

It's interesting how much there is to know about this PCB. Let's look at several scenarios where you could make good use of this. Sonar systems for locomotives can be used with it. Additionally, it can be used for mobile telecommunication operations that need both antennas and power amplifiers. It can also be applied to satellites intended for direct transfer. It uses corded approaches for its data connection.

The automatic functions on this PCB are excellent for fighting the cold. It has confidence in the fabrication of several plates using tape cords or bars. It has a number of benefits for designs. Engineers and designers will find it simpler to develop without difficulty because to these advantages. It has a few aerospace systems that are cost-effective.

It features mechanical parts that are constant and unchanging for a wide range of dielectric constants. Additionally, it works best when used with blended and crossed patterns of a multidimensional binding of fiber plates.

One of the best PCBs for electrical circuits is this one. The unrestricted movement of electrons is possible. It may also control the temperature in a specific setting. This is possibly one of the most typical forms of Rogers PCBs.

Engineers favor it for a variety of reasons, including its low dielectric loss. Withstanding high temperatures is this board. It can operate in a band of at least 10GHz. This layout also provides strong mechanical support. It contains some polytetrafluoroethylene components.

What Is The Difference Between Rogers 4003 and Rogers 3003?

Rogers 4003 PCB board

Sometimes people believe that the Rogers PCBs in both classes are identical. Despite the fact that they may not have many things in common, they do differ greatly. We'll concentrate on these contrasts in this section of the article.

Fabrication

The Rogers 4003 is distinct from the Rogers 3003 in terms of fabrication. You already know that you can use standard polyester brushes to strip off the Rogers 4003 PCB. This is due to the lack of a specific analysis required prior to copper lamination. The RO4003 component can be built using a few tools. Additionally, this PCB is affected by several steely foil techniques typically used for designs, sealant, or glass.

The fabrication procedure requires varying techniques. This is the same way the selection of materials for fabrication is different. Both PCBs do not follow the same production or construction process. The materials used for both are separate components. You can fabricate the Rogers 3003 into the PCB utilizing the processing techniques of the PTFE circuit board.

Temperature Management

Both PCBs have different temperature management systems. Despite the possibility of some high dissolving components, the two PCBs' approaches to temperature management are distinct. One varies from roughly 6.15 to 11.6. The two don't move along at the same speed.

Even under extreme environmental conditions, the Rogers PCB may function. Despite the fact that both may function in any environment, the RO4003 operates differently from the R0 3003 as a result of environmental conditions. When comparing the Rogers 4003 to some PTFT-constructed PCBs, the high thermal voltage or gravity results in a superior thermal management.

Cost of production

Additionally, the two PCBs' production costs are different. The Rogers 3003 costs less than the Rogers 4003, even though they are both expensive because they both require the use of technological tools in production. They cost differently. Some businesses prioritize the latter over the former. Designers must pay attention to both PCBs, though.

Installation

Strict supervision is needed during installation. It is important for designers to keep in mind that the Rogers 4003 should never be installed recklessly. With strict management, this PCB has some low loss potential. Both PCB installations are done differently. They might not share much in common. The same instructions should not be , though.

Both PCBs' glass composites are made of different materials. People have attempted to compare the composites made from each foil and fiber throughout time. Both of them have unique qualities.

The majority of electrical gadgets contain both. You need these PCBs for everything from power amplifiers to direct transmitters to military applications. For their voltage, you must utilize them in various ratios, nevertheless. It is interesting to note that the Rogers 4003 PCB uses the pattern related to the 1080 glass.

Datasheets

Different data sheets are included with each model of the two PCBs. Sometimes people believe they have the same PCB sheet. They do, however, have various datasheets because of their various patterns.

The thermal, electrical, and mechanical properties of these PCBs are described in their datasheets. You will see that these attributes are different between the two PCBs when you read their datasheets.

Composite

A ceramic laminate with glass reinforcement is called Rogers 4003. This laminate is distinct from Rogers 3003 since it is not PTFE. A laminate with PTFE as its foundation, Rogers 3003, is used in microwave and radio frequency applications. This laminate can be applied to applications operating at 77 GHz.

Properties

There are differences in the mechanical, thermal, and electrical characteristics of these two Rogers laminates. For instance, the thickness of Rogers 3003 varies from 0.13 to 1.52 mm. Thermal conductivity for RO3003 is 0.50 W/m/K, whereas it is 0.71 W/m/K for RO4003.

At 10GHz, the RO3003's dissipation factor is 0.0010. Rogers 4003's can be measured at 0.0027 at 10GHz. This demonstrates how these laminates' constituents are different.

Storage

The Rogers 3003 laminates should be kept at ambient temperatures. Just leave it out in the open.

Testing

Testing is done on all Rogers laminates to make sure they adhere to the necessary standards. Some of the IPC standards for Rogers 4003 laminate include IPC-6013, MIL-P-50884, and IPC-6018. These tests aid in identifying mechanical strength, electrical conductivity, and lamination-peel strength.

For Rogers 3003, cutting-edge testing technology is used to assess the laminate's quality. E-test, impedance control, and X-ray are some of these tests. The surface of Rogers 3003 laminates is treated.

Frequently Asked Questions

How long is a Rogers PCB good for?

Engineers are constantly looking for the ideal materials to build PCBs. This is due to the fact that durability is a major worry for many people.

This high-frequency board has an exceptionally extended lifespan. Whether you don't subject it to dangerous environmental circumstances will determine this. Electrical equipment really depend on this board. Your devices' lifespan is improved by it. You may be guaranteed of its long lifespan using Rogers PCB.

The glass fiber is the most well-liked part of this board. Due to the fact that the PCB's whole structure depends on this material, it is crucial. This PCB can have an infinite lifespan in some electrical circuits. It has exceptional dimensional rigidity at this point.

Everything begins with the building and ends with the use of it. An experienced engineer can construct a sturdy PCB. So far, you adhere to the correct fabrication techniques.

In what industries may I use Rogers PCB?

People frequently believe that this PCB can only be used in particular businesses. The fact is that technology has advanced PCB production more than any other industry. The military, the medical field, technology, the media, and many other fields may use the Rogers PCB more frequently.

However, any business or individual who is interested in building a robust PCB may make sure they do so. The most important thing is to follow the fabrication procedures. Installation should always be assisted by a qualified engineer for this reason.

Conclusion

The Rogers PCB is suitable for usage in a variety of sectors. One of the most common sectors that employ this material is the telecommunications sector. It is essential for all microwave and telecom systems.

The advantages of the Rogers 4003 PCB and the Rogers 3003 PCB have been the main emphasis of this study. Even though each has its own distinctive qualities, they are all different. This article's primary goal is to give specific information about something.

RO4003's fabrication process is different from RO3003's. They occur frequently. They are durable. Construction projects may use a variety of Rogers PCBs depending on the industry. The media and the aviation industry have promoted the usage of PCBs.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com