What Are the Benefits of Using RO4360G2 PCB?

Introduction

With the ever-growing demand for high-speed and high-frequency electronic devices, the need for reliable and efficient printed circuit boards (PCBs) has become paramount. To meet these demands, we are proud to present the RO4360G2 24mil PCB, a cutting-edge solution that combines exceptional performance with enhanced processing capability. In this comprehensive blog post, we will delve deep into the features, benefits, construction details, statistics, and applications of the Rogers RO4360G2 PCB.

1. RO4360G2 Introduction

RO4360G2 laminates mark a significant milestone in the evolution of PCB technology. These Rogers laminates are the first high dielectric constant (Dk) thermoset materials that can be processed similarly to FR-4, opening up a world of possibilities for high-performance applications. With better rigidity for improved processability in multi-layer board constructions, RO4360G2 laminates also reduce material and fabrication costs. They can be seamlessly integrated with the RO440 series prepreg and the lower-Dk RO4000 laminate for highly efficient multi-layer designs.

2. Features

The RO4360G2 24mil Rogers substrate PCB boasts a host of impressive features that make it a standout choice among engineers and designers:

a) Dielectric Constant:At 6.15+/- 0.15 (10 GHz/23°C), the RO4360G2 laminate exhibits excellent electrical performance, providing a stable and reliable signal transmission platform.

b) Dissipation Factor: With a dissipation factor of 0.0038 (10 GHz/23°C), this PCB ensures minimal signal loss, enabling enhanced signal integrity and high-frequency performance.

c) Thermal Performance: The RO4360G2 laminate's thermal properties are truly remarkable. With a Td> 407°C and a high glass transition temperature (Tg) greater than 280°C TMA, it excels in demanding high-temperature environments.

d) Thermal Conductivity:Offering a thermal conductivity of 0.75 W/mK, this PCB effectively dissipates heat, contributing to superior thermal management and reliability, especially in power electronics applications.

e) Coefficient of Thermal Expansion: The PCB exhibits a low Z-axis coefficient of thermal expansion at 28 ppm/°C, ensuring dimensional stability and minimizing the risk of failure caused by thermal stress.

f) Copper Matched Coefficient of Thermal Expansion: The RO4360G2 laminate is designed for compatibility with copper, providing a closely matched coefficient of thermal expansion (-55 to 288°C): 13 ppm/°C along the X-axis and 14 ppm/°C along the Y-axis. This compatibility ensures reliability and minimizes the potential for delamination or mechanical stress.

g) Lead-Free Process Compatibility & Flammability: The RO4360G2 PCB is lead-free process compatible, aligning with environmental regulations. It possesses a 94V-0 flammability rating, ensuring safety and reliability.

3. Benefits

The RO4360G2 high frequencyPCB empowers engineers and designers with a wide range of benefits:

a) Design Flexibility: Unleash your creativity with the RO4360G2 PCB's design flexibility. It enables complex routing, high-density designs, and diverse layer stackups, allowing you to push the boundaries of innovation.

b) Plated Through-Hole Reliability: With exceptional mechanical strength and high reliability, the RO4360G2 PCB ensures robust plated through-hole connections, minimizing failures and improving overall product performance.

c) Automated Assembly Compatibility: Seamlessly integrate the RO4360G2 PCB into your automated assembly processes. This PCB's excellent dimensional stability and reliability simplify manufacturing, reducing errors and enhancing production efficiency.

d) Environmentally Friendly: The RO4360G2 PCB aligns with the global transition towards sustainability. Its lead-free process compatibility promotes environmental responsibility while maintaining the highest quality standards.

e) Efficient Supply Chain & Short Lead Times: Count on the RO4360G2 PCB for its efficient supply chain and short lead times. Streamlined logistics and reliable availability make it a cost-effective material option for your projects.

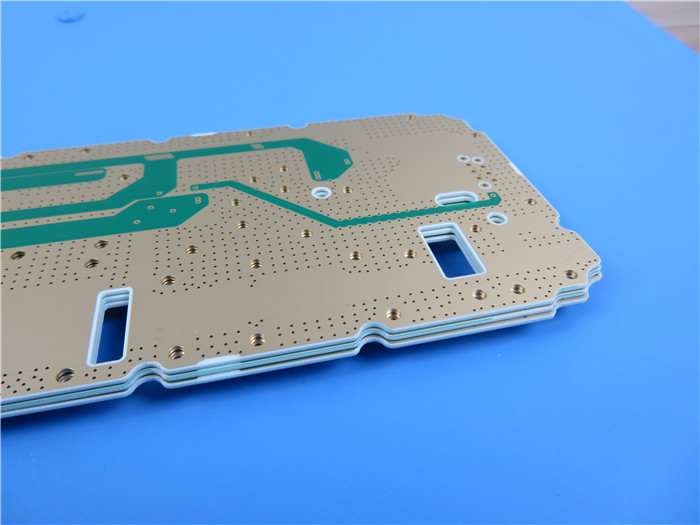

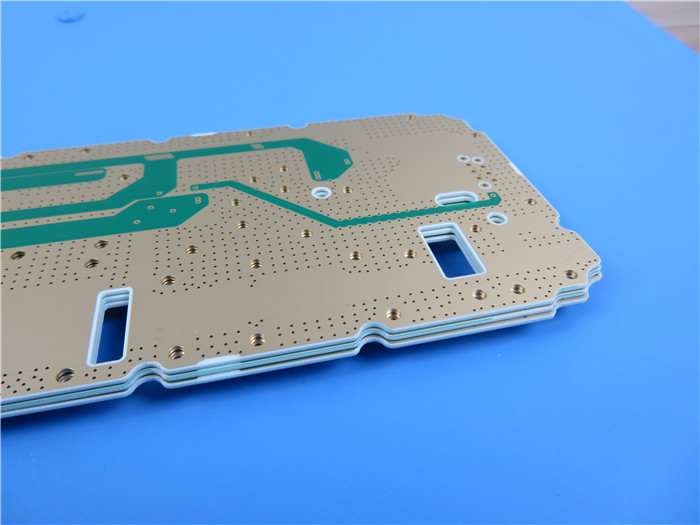

4. PCB Construction Details

To help you grasp the physical aspects of the RO4360G2 Rogers PCB, let's explore its construction details:

Board Dimensions: The RO4360G2 PCB measures 76.48mm x 43.52 mm, providing ample space for your circuit design.

Minimum Trace/Space: Achieve fine routing with minimum trace/space requirements of 5/5 mils, allowing for intricate designs and optimizing circuit density.

Minimum Hole Size: The PCB supports a minimum hole size of 0.30mm, enabling versatile component placement and ensuring compatibility with a wide range of electronic components.

Finished Board Thickness: The RO4360G2 PCB has a finished thickness of 0.73mm, striking an optimal balance between structural integrity and space constraints.

Finished Cu Weight: The outer layers of the PCB feature a finished copper weight of 1 oz (1.4 mils), providing excellent electrical conductivity.

Via Plating Thickness: The PCB's via plating thickness measures 20μm, ensuring reliable electrical connections and reducing signal losses.

Surface Finish: With an immersion tin surface finish, the RO4360G2 PCB offers excellent solderability and corrosion resistance, contributing to long-term reliability.

Silkscreen and Solder Mask: The top silkscreen is white, facilitating component identification during assembly. The top solder mask is green, providing insulation and protection for the copper traces.

Electrical Testing: Each RO4360G2 PCB undergoes a 100% electrical test to ensure the highest levels of quality and functionality prior to shipment.

Via Filling: The PCB features 0.3mm vias filled by resin and capped, increasing the reliability of interconnections and enhancing signal transmission.

5. PCB Statistics

Understanding the specific statistics of the Rogers 4360G2 PCB gives you a comprehensive overview of its capabilities:

Components: The PCB accommodates up to 15 components, providing ample capacity for various circuit requirements.

Total Pads: With a total of 56 pads, the RO4360G2 PCB offers versatile connectivity options for your circuit design.

Thru Hole Pads: The PCB provides 37 thru-hole pads, ensuring secure and reliable connections for your through-hole components.

Top SMT Pads: Featuring 19 top surface mount technology (SMT) pads, this PCB facilitates the integration of surface-mounted components.

Bottom SMT Pads: The RO4360G2 PCB does not feature bottom SMT pads, allowing for versatile design options and minimizing interference.

Vias: With 41 vias, this PCB offers versatile interconnection options, allowing for efficient routing between different layers of the circuit.

Nets: The PCB supports connectivity across 2 nets, ensuring efficient signal propagation and providing flexibility in designing complex circuits.

6. Accepted Standard, Availability, and Applications

The RO4360G2 PCB adheres to the IPC-Class-2 standard, guaranteeing high-quality manufacturing and meeting industry-wide benchmarks. With worldwide availability, this PCB is accessible to engineers and designers globally.

7.Application

The diverse applications of the RO4360G2 Rogers material PCB include:

Base Station Power Amplifiers:

The high-performance characteristics of the RO4360G2 PCB make it an ideal choice for base station power amplifiers, ensuring superior signal quality and robust performance.

Small Cell Transceivers:

Leveraging the excellent signal integrity and thermal management capabilities of the RO4360G2 PCB, small cell transceivers benefit from its ability to handle high-frequency signals and dissipate heat effectively.

The above applications highlight just a fraction of the potential uses for the RO4360G2 PCB. Its versatility extends to industries such as telecommunications, automotive, aerospace, and more.

8.Conclusion

In conclusion, the RO4360G2 wholesale high frequency PCB from Rogers Corporation represents an exceptional solution for engineers and designers striving to push the boundaries of performance, reliability, and processability. With its unmatched features, versatile construction, and compatibility with lead-free processes, it empowers designers to unlock new possibilities in high-frequency applications. From base station power amplifiers to small cell transceivers, the RO4360G2 PCB sets a new standard in performance and cost-effectiveness. Embrace the future of electronics with the RO4360G2 PCB andupdate your designs today.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com