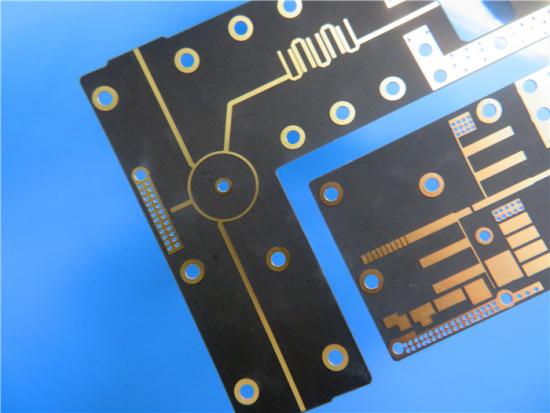

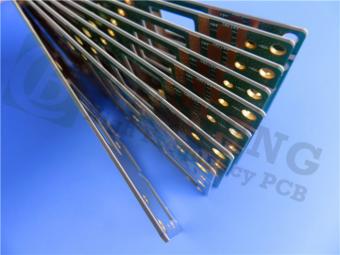

Rogers 4360High Frequency PCB 16mil Double Sided

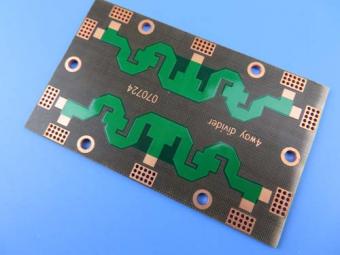

RF PCB with Green Mask and Immersion Gold for Small Cell Transceivers

(PCB's are custom-made products, the picture

and parameters shown are just for reference)

RO4360G2

laminates of Rogers Corporation are 6.15 Dk, low loss, glass-reinforced,

hydrocarbon ceramic-filled thermoset materials that provide the ideal balance

of performance and processing ease. RO4360G2 laminates extend Rogers' portfolio

of high performance materials by providing customers with a product that is

lead-free process capable and offers better rigidity for improved

processability in multi-layer board constructions, while reducing material and

fabrication costs.

RO4360G2

laminates process similar to FR-4 and are automated assembly compatible. They

have a low Z-axis CTE for design flexibility and have the same high Tg as all

of the RO4000 product line. RO4360G2 laminates can be paired with RO4450F

prepreg and lower-Dk RO4000 laminate in multi-layer designs.

Things

that make up the RO4360 PCB Material:

Below

are the components used by the manufacturers in making rogers ro4360.

Copper

foil: These are traces found on the RO4360 PCB. They are conductive in nature.

Prepreg:

The prepreg is a sticky B stage material and ensures the bonding of different

foils or laminates.

Copper

Laminates (Core): This core is made up of copper coils and prepregs, which you

must cure and laminate.

Features

of the RO4360 PCB Material:

Features

of this material include:

-

6.15 Dk and a +/- 0.15

variation

-

It resists CAF

-

With low loss, it integrates

a high thermal conductivity

-

It provides a high Tg, which

is higher than 280 degrees centigrade TMA

-

Z-axis CTE is low and its

glass transition temperature is high

Some

Typical Applications:

1.

Base Station Power Amplifiers

2.

Small Cell Transceivers

3.

Patch antennas

4. Ground-based

Radar

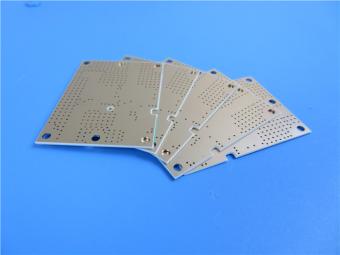

PCB

Capability (RO4360G2)

|

PCB Capability (RO4360G2)

|

|

PCB Material:

|

Hydrocarbon Ceramic-filled Thermoset

Materials

|

|

Designation:

|

RO4360G2

|

|

Dielectric constant:

|

6.15 ±0.15

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

8mil (0.203mm), 12mil (0.705mm), 16mil

(0.406mm), 20mil(0.508mm), 24mil (0.610mm), 32mil (0.813mm), 60mil(1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG, OSP etc..

|

Data

Sheet of RO4360G2:

|

RO4360G2

Typical Value

|

|

Property

|

RO4360G2

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

6.15±0.15

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5

|

|

2.5 GHz/23℃

|

|

Dissipation Factor,tanδ

|

0.0038

|

Z

|

|

10

GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal

Conductivity

|

0.75

|

|

W/mK

|

50℃

|

ASTM D-5470

|

|

Volume Resistivity

|

4.0 X 1013

|

|

Ω.cm

|

Elevated T

|

IPC-TM-650 2.5.17.1

|

|

Surface Resistivity

|

9.0 X 1012

|

|

Ω

|

Elevated T

|

IPC-TM-650 2.5.17.1

|

|

Electrical Strength

|

784

|

Z

|

V/mil

|

|

IPC-TM-650 2.5.6.2

|

|

Tensile Strength

|

131

(19) 97(14)

|

X Y

|

MPa (kpsi)

|

40 hrs 50%RH/23

|

ASTM D638

|

|

Flexural Strength

|

213(31) 145(21)

|

X Y

|

Mpa (kpsi)

|

40 hrs 50%RH/23

|

IPC-TM-650, 2.4.4

|

Coefficient of Thermal Expansion

|

13 14 28

|

X Y Z

|

ppm/℃

|

-50℃to 288℃

After Replicated Heat Cycle

|

IPC-TM-650, 2.1.41

|

|

Tg

|

>280

|

|

℃ TMA

|

|

IPC-TM-650 2.4.24.3

|

|

Td

|

407

|

|

℃

|

|

ASTM D3850 using TGA

|

|

T288

|

>30

|

Z

|

min

|

30

min / 125℃Prebake

|

IPC-TM-650 2.2.24.1

|

|

Moisure Absorption

|

0.08

|

|

%

|

50℃/48hr

|

IPC-TM-650 2.6.2.1

ASTM D570

|

|

Thermal Coefficient of er

|

-131 @10 GHz

|

Z

|

ppm/℃

|

-50℃to 150℃

|

IPC-TM-650, 2.5.5.5

|

|

Density

|

2.16

|

|

gm/cm3

|

RT

|

ASTM D792

|

|

Copper Peel Stength

|

5.2 (0.91)

|

|

pli (N/mm)

|

Condtion B

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94 File QMTS2.

E102765

|

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com