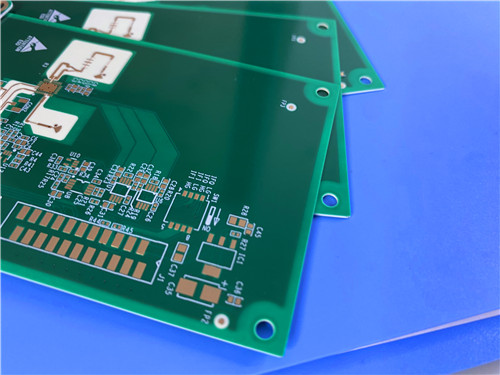

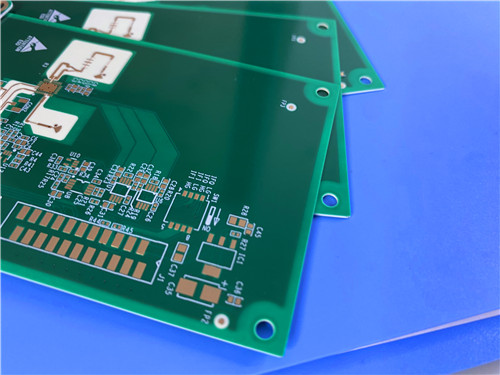

What Are the Performance Advantages of a Hybrid 6-Layer PCB Combining RO4350B and High Tg FR-4?

For engineers designing cutting-edge RF, microwave, and high-speed digital systems, the choice of PCB materials is a critical determinant of performance, reliability, and cost. A homogeneous board made from a single material often forces a compromise. However, a 6-Layer Hybrid PCB that strategically combines Rogers RO4350B on the outer layers with High Tg FR-4 (S1000-2M) on the inner layers breaks this compromise, offering a suite of distinct performance advantages.

This Hybrid PCB Material approach is not a simple cost-cutting measure; it is a performance-optimized architecture that places the right material in the right place to achieve superior results. Here’s a breakdown of its key advantages:

1. Superior High-Frequency Signal Integrity and Low Loss

This is the most significant advantage driven by the RO4350B laminate.

Low Dissipation Factor (Df): RO4350B has an exceptionally low loss tangent of 0.0037 at 10 GHz. When used for the critical outer layers where high-frequency signals are typically routed (e.g., microstrip lines), it minimizes signal attenuation. This means more power reaches the antenna or IC, leading to higher efficiency, better signal-to-noise ratio, and longer range for communication systems.

Stable Dielectric Constant (Dk): With a tight Dk of 3.48±0.05,Rogers4350B ensures consistent characteristic impedance across the entire board and over a range of frequencies and temperatures. This stability is paramount for preventing signal reflections, jitter, and distortion in sensitive RF and high-speed digital circuits.

Performance Impact: Your designs will experience lower insertion loss and more predictable impedance, which is critical for applications like millimeter-wave circuits, point-to-point radio antennas, and radar systems.

2. Excellent Thermal Management and Dimensional Stability

The Hybrid PCB Board construction leverages the thermal properties of both materials to create a robust board.

High Tg of Both Materials: RO4350B has a glass transition temperature (Tg) exceeding 280°C, while the S1000-2M FR-4 has a Tg of 180°C. This high Tg ensures that the board remains mechanically stable and does not soften or deform during the high-temperature stresses of lead-free (RoHS) soldering processes.

Matched CTE with Copper: RO4350B has a X/Y-axis CTE very similar to copper. This means the laminate and the copper traces expand and contract at nearly the same rate during thermal cycling, resulting in excellent dimensional stability. This prevents warping and reduces stress on plated through-holes.

Low Z-Axis CTE of FR-4 Core: The S1000-2M inner core contributes a lower Z-axis CTE, which further enhances the reliability of the plated through-holes that connect the different layers, preventing barrel cracking in severe thermal environments.

Performance Impact: The board offers exceptional reliability through multiple soldering cycles and stable performance in applications with significant thermal swings, such as power amplifiers or outdoor telecommunications equipment.

3. Optimized Cost-Performance Ratio without Compromise

This is the strategic genius of the hybrid approach.

Performance where it Counts: The expensive, high-performance RO4350B material is used exclusively for the outer layers (L1 and L6), which carry the most critical high-frequency signals.

Economy where it Matters: The more cost-effective, yet highly reliable, High Tg FR-4 is used for the inner signal and power planes (L2-L5). These layers are typically shielded by adjacent ground planes, making the ultra-low loss properties of Rogers material less critical, while the FR-4 provides excellent mechanical structure and electrical insulation.

Performance Impact: You achieve 90% of the electrical performance of an all-Rogers board at a fraction of the cost, freeing up budget for other components while still meeting stringent technical requirements.

4. Enhanced Manufacturing Reliability and Plated Through-Hole Integrity

The combination of materials is chosen for manufacturability and long-term reliability.

Ease of Processing: Unlike pure PTFE microwave materials, RO4350B can be processed using standard epoxy/glass (FR-4) manufacturing protocols. It does not require specialized plasma etching for via activation, simplifying the fabrication process and improving yield.

Anti-CAF Performance: The S1000-2M FR-4 material is specifically formulated with excellent Anti-CAF (Conductive Anodic Filamentation) performance. This prevents the growth of copper salts along the glass fibers, a failure mode that can cause short circuits between vias and traces under high humidity and voltage bias, ensuring long-term field reliability.

Robust Vias: The complementary CTE properties of both materials work together to minimize stress on the plated through-holes, ensuring the 20µm via plating remains intact even under thermal shock.

Performance Impact: You get a highly reliable board that is less prone to field failures due to CAF or thermal cycling, which is essential for mission-critical systems in aerospace, defense, and automotive radar.

5. Design Flexibility for Complex, Dense Layouts

The specified construction parameters enable sophisticated designs.

4/4 mil Trace/Space: This fine-line capability allows for denser component placement and more complex routing, enabling more functionality in a compact footprint (like the specified 30.55mm x 37.7mm board).

Blind Vias (L1-L2): These vias connect the outer layer to the adjacent inner layer without going through the entire board. This frees up valuable routing space on the inner layers, simplifies breakout from fine-pitch components like BGAs, and improves signal integrity by reducing via stubs.

Performance Impact: Designers can create more compact and complex boards for advanced systems like commercial airline antennas and guidance systems, where space and weight are at a premium.

Conclusion: A Synergistic Solution

The performance advantages of this 6-Layer Hybrid PCB 4mil RO4350B and High Tg FR-4 are not merely additive; they are synergistic. The RO4350B Frequency PCB delivers the high-frequency speed and signal fidelity, while the High Tg FR-4 provides the mechanical backbone, internal layer functionality, and cost efficiency. Together, they create a platform that is greater than the sum of its parts—offering an optimal balance of electrical performance, thermal reliability, manufacturability, and cost for the most demanding modern electronic applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com