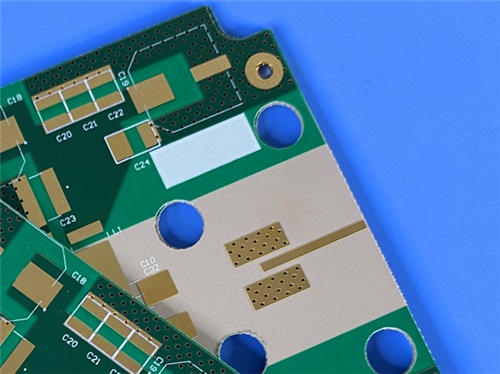

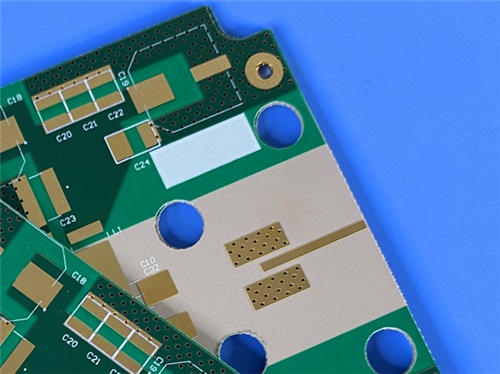

What Makes MT77 a Cost-Effective and FR-4 Compatible RF PCB Material?

1. The Foundation of Cost-Effectiveness: FR-4 Process Compatibility

This is the single most significant factor driving down the total cost of ownership for MT77. Unlike traditional high-performance materials like PTFE (Teflon), which require specialized and expensive processing steps, Astra MT77 integrates seamlessly into existing PCB manufacturing lines.

Here’s a breakdown of what this compatibility means in practice:

-

No Exotic Lamination Cycles: PTFE materials often require very high-pressure and long lamination cycles with special prepregs. MT77, however, can be processed using standard FR-4 lamination pressures and temperatures with common multi-functional epoxy prepregs. This leads to shorter production times, higher throughput, and less energy consumption.

-

Reduced Drill Wear: PTFE is soft and abrasive, causing rapid wear and tear on drilling machines, which requires more frequent drill bit changes and downtime. MT77's glass-reinforced hydrocarbon ceramic composition is much less abrasive, resulting in significantly reduced drill wear and lower tooling costs.

-

Elimination of Plasma Desmear: A critical and costly step for PTFE is plasma desmear, which is necessary to clean and etch the via holes to ensure proper plating adhesion. MT77 does not require this step. Standard chemical desmear processes used for FR-4 are sufficient, removing a capital-intensive and time-consuming process from the workflow.

-

Excellent Flow and Fill: The material demonstrates good resin flow during lamination, ensuring reliable filling of internal copper patterns and voids. This improves yield and reliability without needing special techniques.

-

Robust PTH Reliability: MT77 exhibits a low Coefficient of Thermal Expansion (CTE) in the X and Y axes (12 ppm/°C), similar to FR-4. This prevents excessive stress on Plated Through-Holes (PTHs) during thermal cycles (like soldering), ensuring high reliability and reducing the risk of failure.

2. Superior Electrical Performance at a Competitive Price

While Isola Astra MT77 is process-compatible with FR-4, its electrical performance is in a completely different league, offering a compelling alternative to more expensive materials.

-

Ultra-Low Loss: With a Dissipation Factor (Df) of 0.0017, MT77 exhibits minimal signal loss (insertion loss). This makes it a direct, cost-effective alternative to PTFE (which can have a Df as low as 0.0009 but at a much higher cost) and far superior to standard FR-4 (which has a Df around 0.020).

-

Stable Dielectric Constant (Dk): The Dk of 3.0 remains stable across a wide frequency range (up to W-band) and temperature range (-40°C to +140°C). This stability is crucial for designing predictable, high-performance circuits that won't drift in operation. The cost of achieving this stability with other materials is typically much higher.

The Cost-Performance Spectrum:

Imagine a spectrum where on one end you have Low-Cost FR-4 (with high signal loss), and on the other end you have High-Performance PTFE (with high cost and processing challenges). Astra MT77 positions itself perfectly in the middle, offering ~80% of the electrical performance of PTFE at a fraction of the total cost (both material and fabrication).

3. Enhanced Yield and Scalability

Cost isn't just about the price per panel; it's about how many good boards you get out of the process (yield). MT77's characteristics directly contribute to higher yields:

-

Dimensional Stability: The material has excellent dimensional stability, meaning it shrinks and moves less during processing. This is vital for maintaining registration between layers, especially for designs with 4/4 mil trace/space rules. Better registration means fewer scrapped boards.

-

Multiple Lamination Cycle Capability: For complex multi-layer boards, the material can withstand the heat and pressure of multiple lamination cycles without degrading, providing design flexibility without compromising reliability.

-

Lead-Free Process Compatible: With a high Tg of 200°C, MT77 can easily withstand the higher temperatures required for lead-free soldering without delamination or degradation, which is a mandatory requirement for most modern electronic products.

Conclusion: The Best of Both Worlds

In summary, MT77 Low-loss Dielectric PCB is a cost-effective and FR-4 compatible RF material because it deliberately breaks the traditional trade-off between performance and manufacturability.

-

It is cost-effective not because the raw laminate is the cheapest available, but because the Total Cost of Production is lower. Savings from faster lamination, reduced drill wear, eliminated plasma desmear, and higher overall yields dramatically reduce the final cost per functional board.

-

It is FR-4 compatible by design, allowing PCB manufacturers to use their existing equipment, chemistry, and process knowledge. This eliminates the need for costly capital investment and specialized operator training, making advanced RF technology accessible to a much wider range of projects and companies.

For designers working on automotive radar, advanced driver-assistance systems (ADAS), or 5G connectivity, Isola Astra MT77 offers a pragmatic path to market: achieving the necessary radio frequency performance without incurring the prohibitive costs and complexities of traditional microwave materials.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com