What Is Your Minimum Drill Hole Size?

A Comprehensive Guide to PCB Drilling Capabilities

When designing a printed circuit board (PCB), one critical specification engineers must consider is the minimum drill hole size. This parameter determines the feasibility of vias, through-holes, and microvias, directly impacting the board’s functionality, density, and cost.

In this article, we’ll explore:

- Standard vs. laser drill hole sizes (0.2mm mechanical vs. 0.1mm laser for HDI)

- How material selection affects drilling precision (e.g., F4BM220 laminates)

- Key considerations for high-frequency and RF applications

- Real-world PCB examples with drilling constraints

Understanding Minimum Drill Hole Sizes: Mechanical vs. Laser Drilling

1. Standard Mechanical Drilling (≥0.2mm)

Mechanical drilling is the most common method for creating through-holes in PCBs. The standard minimum drill size is 0.2mm (8 mils), though some manufacturers can achieve 0.15mm (6 mils) with high-precision equipment.

Limitations:

- Aspect ratio constraints (drill depth vs. diameter)

- Potential for drill breakage with ultra-small holes

- Material-dependent performance (e.g., fiberglass-reinforced laminates vs. PTFE-based materials)

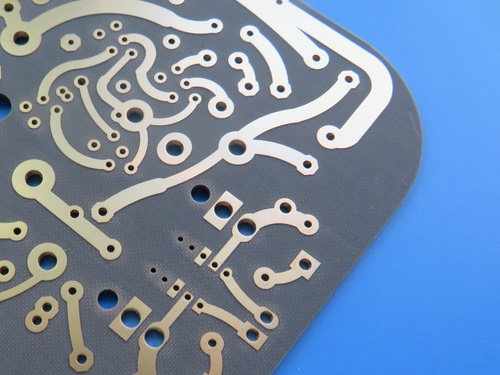

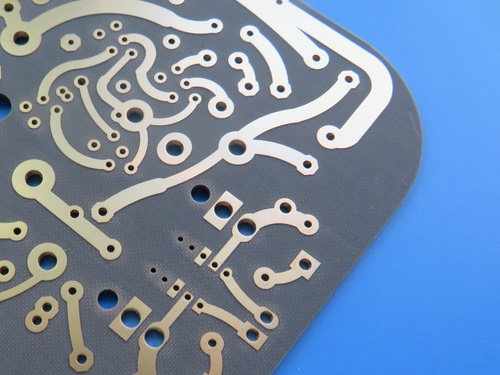

Example PCB with Mechanical Drilling:

- Minimum Hole Size: 0.3mm (12 mils)

- Layer Count: 2

- Base Material: F4BM220 (PTFE-based, low-loss)

- Finished Thickness: 1.7mm

- Plating Thickness: 20µm

This design suits RF/microwave applications where larger vias are acceptable, and signal integrity is prioritized over ultra-high density.

2. Laser Drilling for HDI PCBs (≥0.1mm)

High-Density Interconnect (HDI) PCBs require laser drilling to achieve microvias as small as 0.1mm (4 mils). This method is essential for:

- Smartphones, wearables, and compact electronics

- High-speed digital circuits (e.g., 5G modules)

- RF systems needing buried/blind vias

Advantages of Laser Drilling:

- No physical drill wear (longer tool life)

- Tighter tolerances (±0.025mm)

- Suitable for flexible andrigid-flex PCBs

However, laser drilling is more expensive and may require specialized materials (e.g., low-Dk laminates like F4BM220 for minimal signal loss).

How PCB Material Affects Drill Hole Size & Performance

The choice of substrate plays a crucial role in determining achievable hole sizes and signal performance.

Case Study: F4BM220 PTFE Laminate

Our F4BM220 material is engineered for high-frequency applications with:

- Dielectric Constant (Dk): 2.2±0.04 @ 10GHz

- Dissipation Factor (Df): 0.001 @ 10GHz

- Low Moisture Absorption (≤0.08%)

Why This Matters for Drilling:

✔Thermal Stability (CTE: 25 ppm/°C in X/Y-axis) reduces hole wall deformation during drilling.

✔Low Dk/Df ensures minimal signal loss in high-speed/RF designs.

✔Compatibility with both mechanical and laser drilling (unlike some ceramics).

Comparison with FR-4:

|

Parameter

|

F4BM220 (PTFE)

|

Standard FR-4

|

|

Min Hole Size

|

0.1mm (laser)

|

0.2mm (mech.)

|

|

Dk @ 10GHz

|

2.2

|

4.3-4.8

|

|

Df @ 10GHz

|

0.001

|

0.02

|

|

Thermal Stability

|

Excellent

|

Moderate

|

For microwave antennas, satellite comms, and radar systems, F4BM220 PCB ensures better signal integrity than FR-4, even with smaller vias.

Design Considerations for Optimal Drill Hole Sizes

1. Aspect Ratio & Reliability

- Standard PCBs: Max aspect ratio of 10:1 (e.g., 1.7mm board thickness→min hole size ~0.17mm).

- HDI PCBs: Can exceed 1:1 ratio with stacked microvias.

2. Plating Quality (Critical for High-Frequency PCBs)

- Via plating thickness≥20µm (ensures conductivity in RF circuits).

- ENIG surface finish (prevents oxidation in harsh environments).

3. Cost vs. Performance Trade-offs

- Laser drilling adds ~20-30% cost but enables smaller form factors.

- Mechanical drilling is economical for larger boards (e.g., our 130.5mm x 103mm example).

Conclusion: Choosing the Right Drill Size for Your PCB

The minimum drill hole size depends on:

✅Manufacturing method (mechanical: 0.2mm; laser: 0.1mm)

✅Material properties (PTFE vs. FR-4)

✅Application needs (RF vs. digital)

For high-frequency designs, our F4BM220 PCBs offer:

- Low-loss signal transmission

- Stable mechanical drilling down to 0.3mm

- Superior thermal performance

Need a custom solution? Contact us for expert guidance on optimizing your PCB’s drill sizes and stackup!

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com