What Makes AD300D PCB the Premier Choice for High-Performance RF and Antenna Applications?

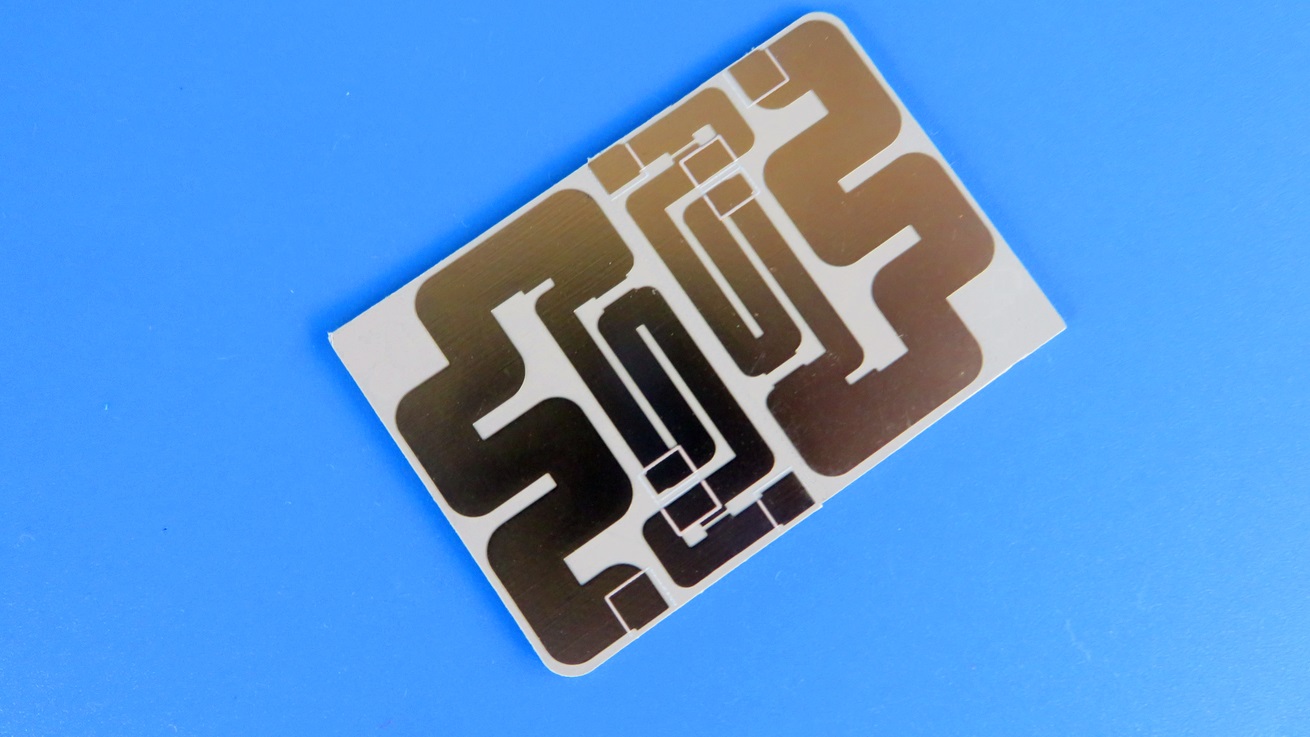

In the rapidly evolving world of wireless communication, the demand for high-frequency, high-reliability printed circuit boards (PCBs) is greater than ever. For engineers and designers seeking a robust foundation for advanced RF systems, AD300D laminates emerge as a superior material solution. This ceramic-filled, glass-reinforced PTFE (Polytetrafluoroethylene) composite is specifically engineered to deliver exceptional electrical and mechanical performance, meeting the stringent requirements of modern wireless antenna markets and beyond. Its compatibility with standard PTFE fabrication processes also makes it a cost-effective option for enhancing product performance without compromising on quality.

Unmatched Electrical Characteristics for Superior Signal Integrity

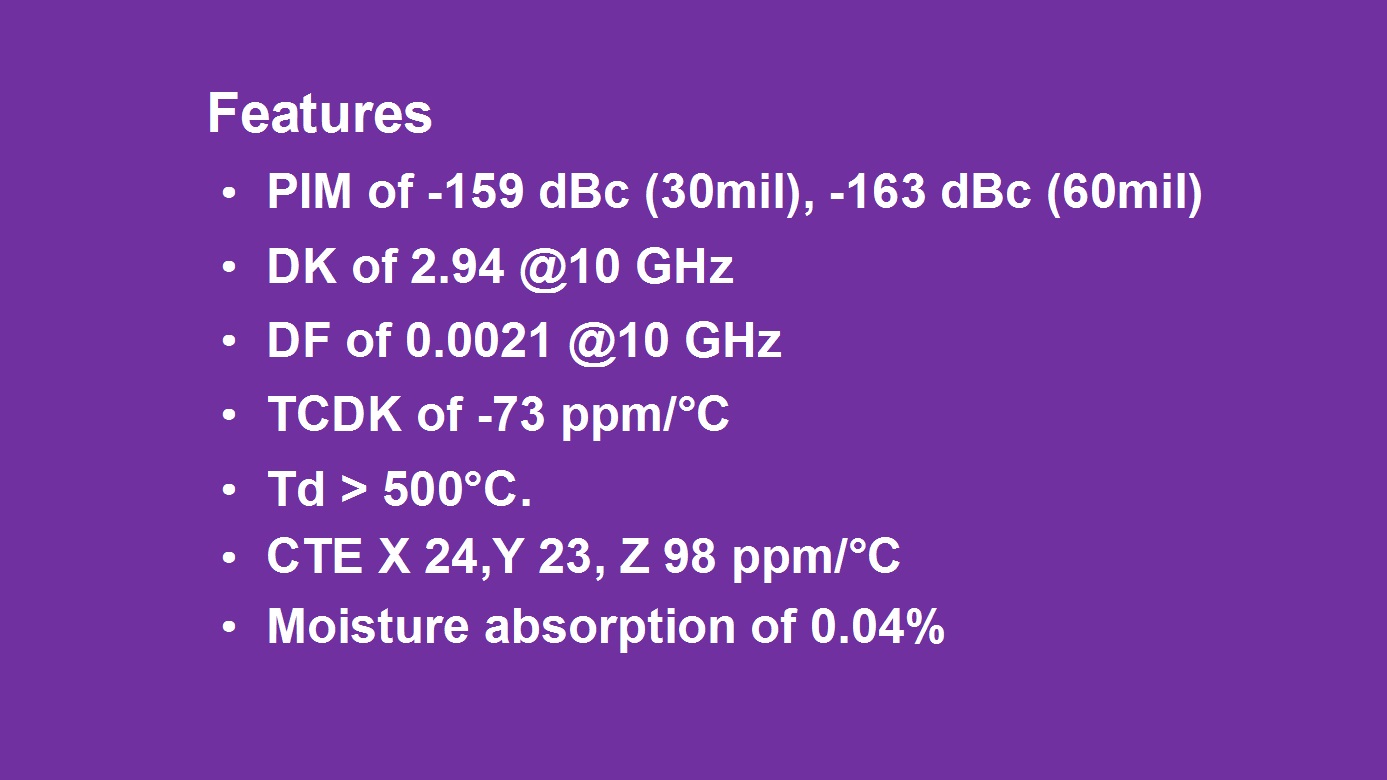

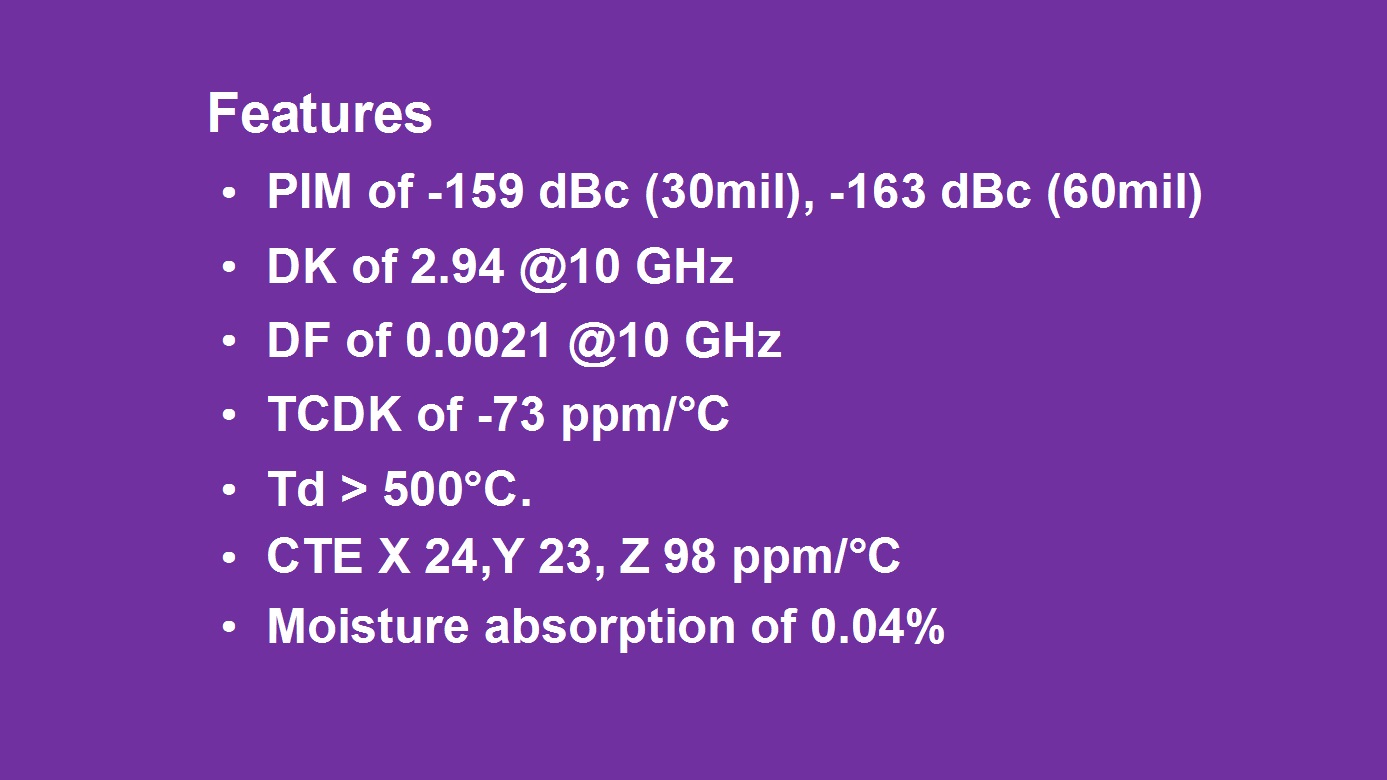

The core of AD300D's value proposition lies in its outstanding electrical properties, which are critical for high-frequency applications. The laminate boasts a tightly controlled dielectric constant (Dk) of 2.94 at 10 GHz, ensuring consistent signal propagation speeds and impedance control. Coupled with an exceptionally low dissipation factor (Df) of 0.0021 at the same frequency, AD300D PCB minimizes signal loss, thereby preserving the integrity and strength of transmissions. This combination is essential for applications where signal clarity and power efficiency are paramount.

A standout feature of Rogers AD300D is its exceptional Passive Intermodulation (PIM) performance. PIM, a common source of interference and noise in multi-frequency systems, is significantly reduced with this material. Tests demonstrate remarkably low PIM values of -159 dBc for 30 mil thickness and -163 dBc for 60 mil thickness, measured with 43 dBm swept tones at 1900 MHz. This ultra-low PIM directly translates to enhanced antenna efficiency, reduced dropped calls, and higher data throughput, while minimizing yield loss associated with PIM-related failures during production.

Exceptional Thermal Stability and Reliability

Performance under varying environmental conditions is a critical benchmark for PCB materials. AD300D excels in thermal stability, characterized by a remarkably low thermal coefficient of dielectric constant (-73 ppm/°C from 0°C to 100°C at 10 GHz). This ensures that its electrical properties remain stable across a wide operational temperature range, preventing performance drift in outdoor or thermally challenging environments.

The material’s thermal resilience is further proven by its decomposition temperature (Td), which exceeds 500°C, indicating superb resistance to high-temperature processing and operation. Its coefficient of thermal expansion (CTE) is carefully engineered at 24 ppm/°C (X-axis), 23 ppm/°C (Y-axis), and 98 ppm/°C (Z-axis) from -55°C to 288°C, ensuring excellent dimensional stability and reliability of plated through-holes. Furthermore, AD300D offers robust adhesion and durability, successfully resisting delamination for over 60 minutes at 288°C, a testament to its longevity. Its minimal moisture absorption rate of 0.04% further guarantees performance stability in humid conditions.

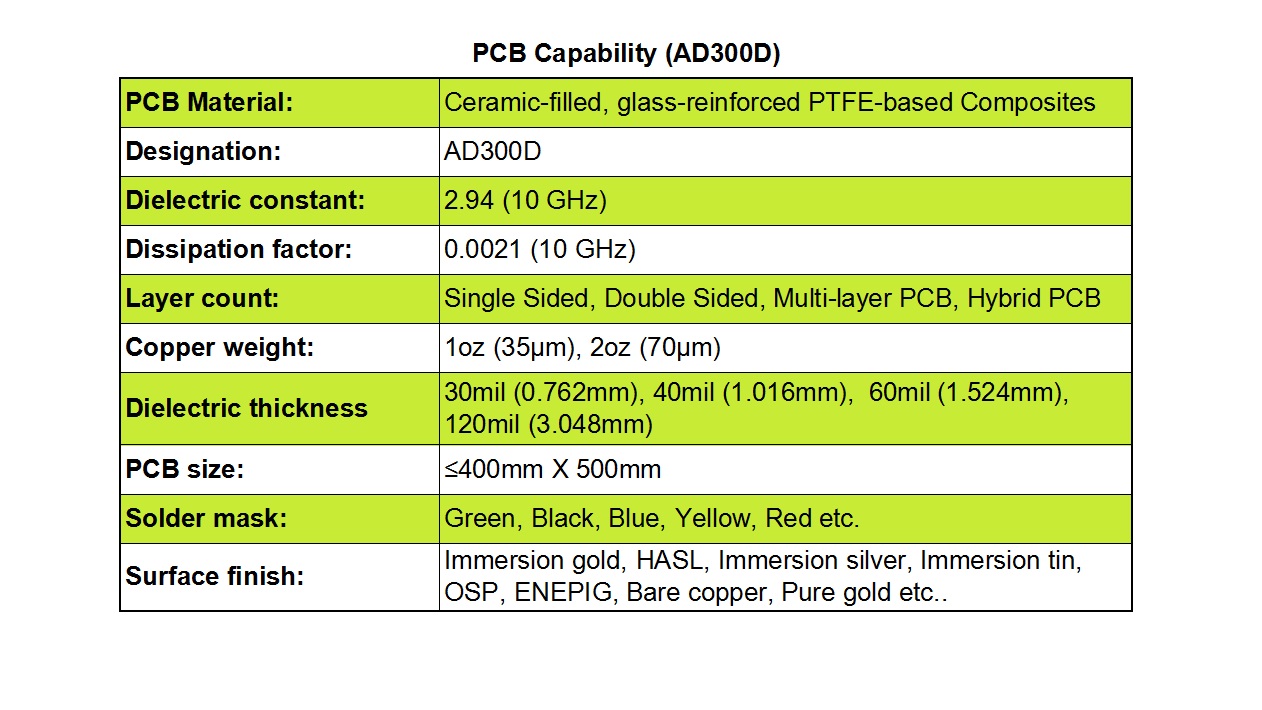

Advanced PCB Manufacturing Capabilities for AD300D

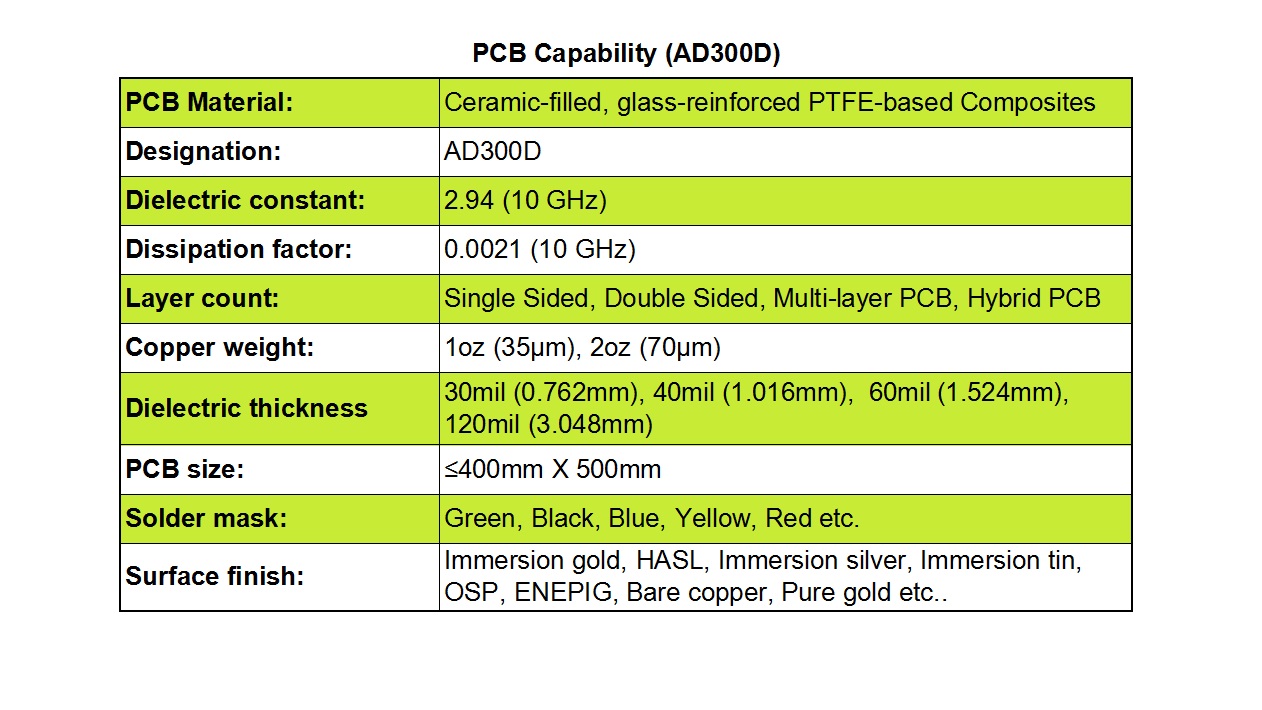

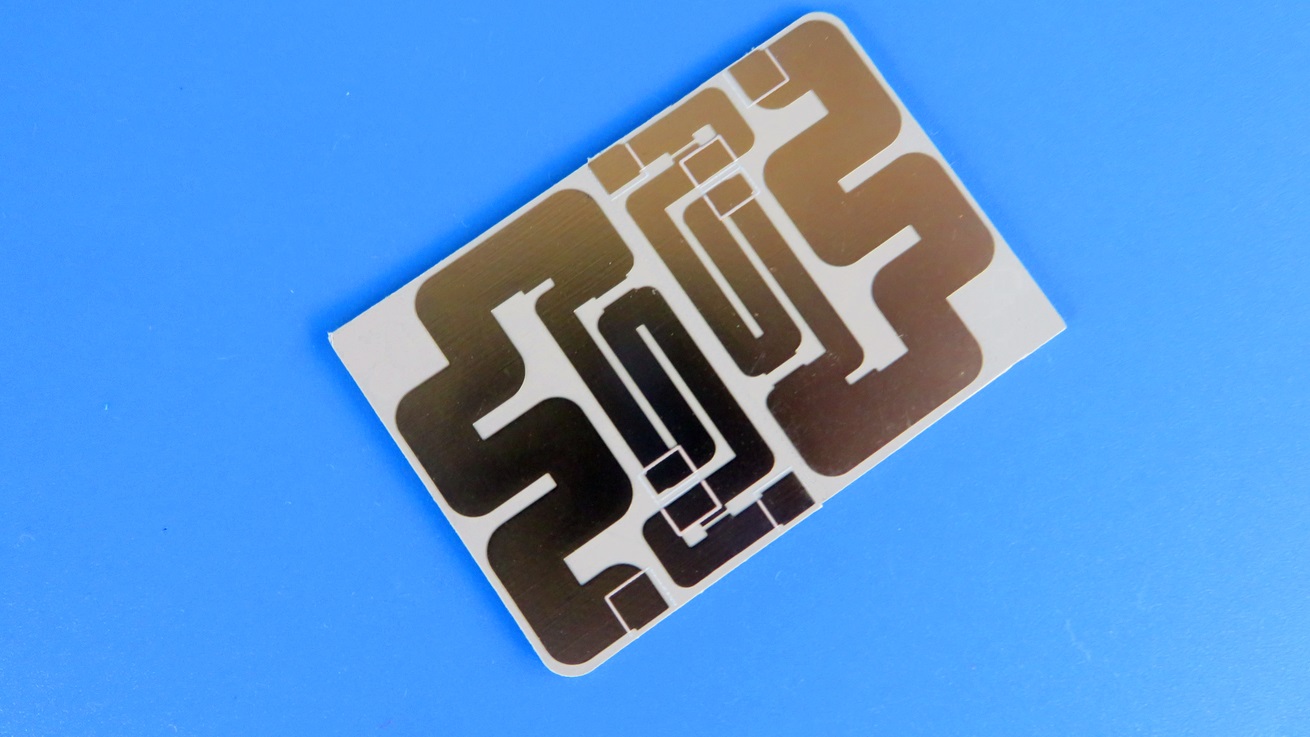

To fully leverage the advantages of this advanced material, partnering with a manufacturer with proven expertise is essential. Our fabrication facilities are fully equipped to process AD300D Rogers substrates into a comprehensive range of PCB types, including single-sided, double-sided, complex multi-layer, and hybrid boards.

We provide designers with flexible options to meet precise application needs:

1) Copper Weights: A choice between 1 oz (35 µm) or 2 oz (70 µm).

2) Dielectric Thickness: Available in 30 mil (0.762mm), 40 mil (1.016mm), 60 mil (1.524mm), and 120 mil (3.048mm).

3) Panel Size: We support a maximum panel size of 400 mm x 500 mm, accommodating either a single large board or multiple arrays for optimized production.

4) Solder Mask: A variety of colors including Green, Black, Blue, Yellow, and Red is available.

5) Surface Finishes: A full spectrum of finishes is offered to suit various assembly and performance requirements, including Immersion Gold (ENIG), HASL, Immersion Silver, Immersion Tin, OSP, ENEPIG, Bare Copper, and Pure Gold.

Diverse Application Fields

The unique property set of AD300D high frequency PCBs makes them an ideal solution for a wide array of high-frequency applications. They are particularly well-suited for:

1) Cellular Infrastructure Base Station Antennas: Where low loss and minimal PIM are critical for 4G/LTE and 5G network performance.

2) Automotive Telematics Antenna Systems: Demanding reliability and stable performance under harsh environmental conditions.

3) Commercial Satellite Radio Antennas: Requiring stable electrical properties over temperature fluctuations for consistent signal reception.

In conclusion,AD300D PCB material represents a pinnacle of high-frequency circuit board technology, offering a blend of electrical excellence, thermal resilience, and manufacturing versatility. By selecting AD300D and an experienced supplier, engineers can significantly enhance the performance, reliability, and yield of their most demanding RF and wireless products.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com