What Makes IsoClad 917 the Ideal Choice for High-Frequency and Flexible PCB Applications?

In the rapidly advancing world of electronics, the demand for high-frequency printed circuit boards (PCBs) that deliver exceptional performance and reliability is greater than ever. For engineers and designers working on cutting-edge RF and microwave applications, the choice of substrate material is paramount. Enter Rogers Corporation's IsoClad 917 high frequency PCB laminate, a material engineered to provide unmatched electrical characteristics and mechanical versatility. This article delves into the unique properties, extensive manufacturing capabilities, and ideal applications of this superior high-frequency solution.

Unparalleled Material Properties for Peak Performance

Rogers IsoClad 917 laminates are meticulously crafted using a specialized composite that minimizes non-woven fiberglass and polytetrafluoroethylene (PTFE) content. This sophisticated formulation is specifically designed to achieve the lowest dielectric constant (Dk) and dissipation factor (Df) within its class, establishing a new benchmark for high-speed, low-loss signal transmission.

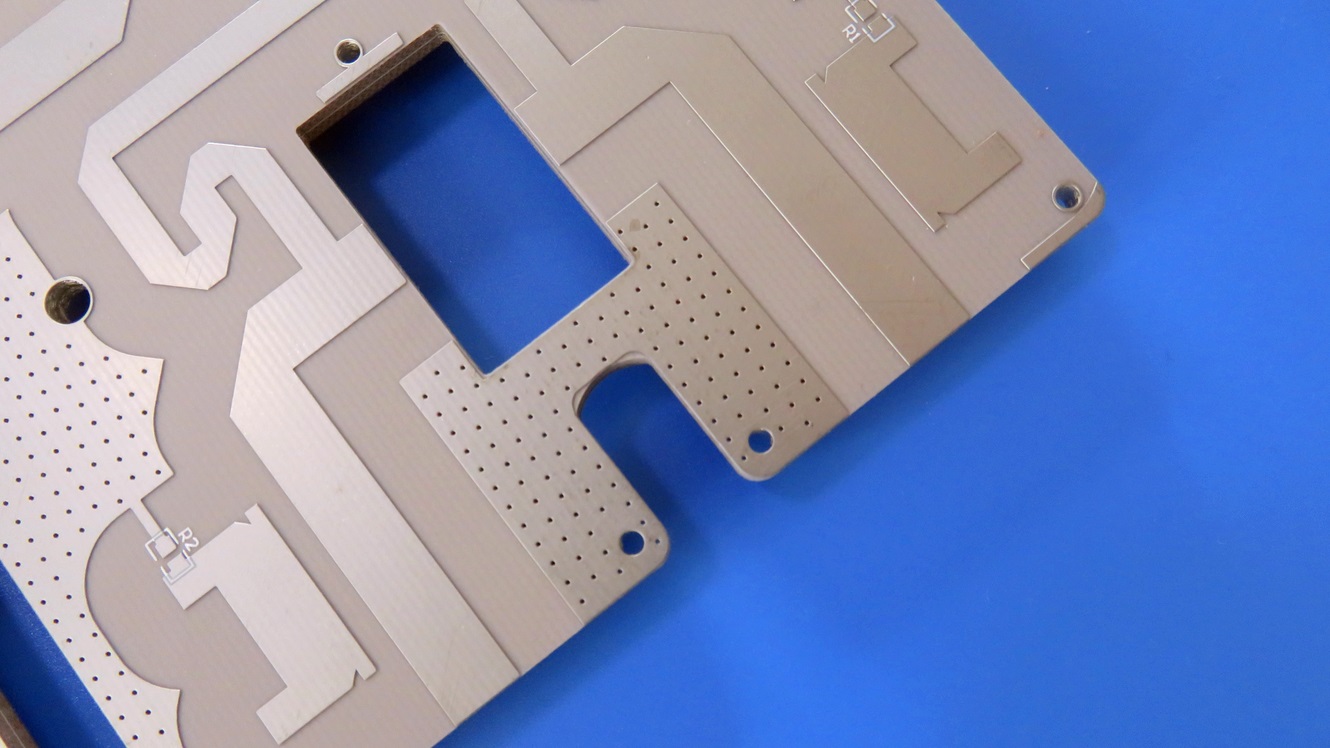

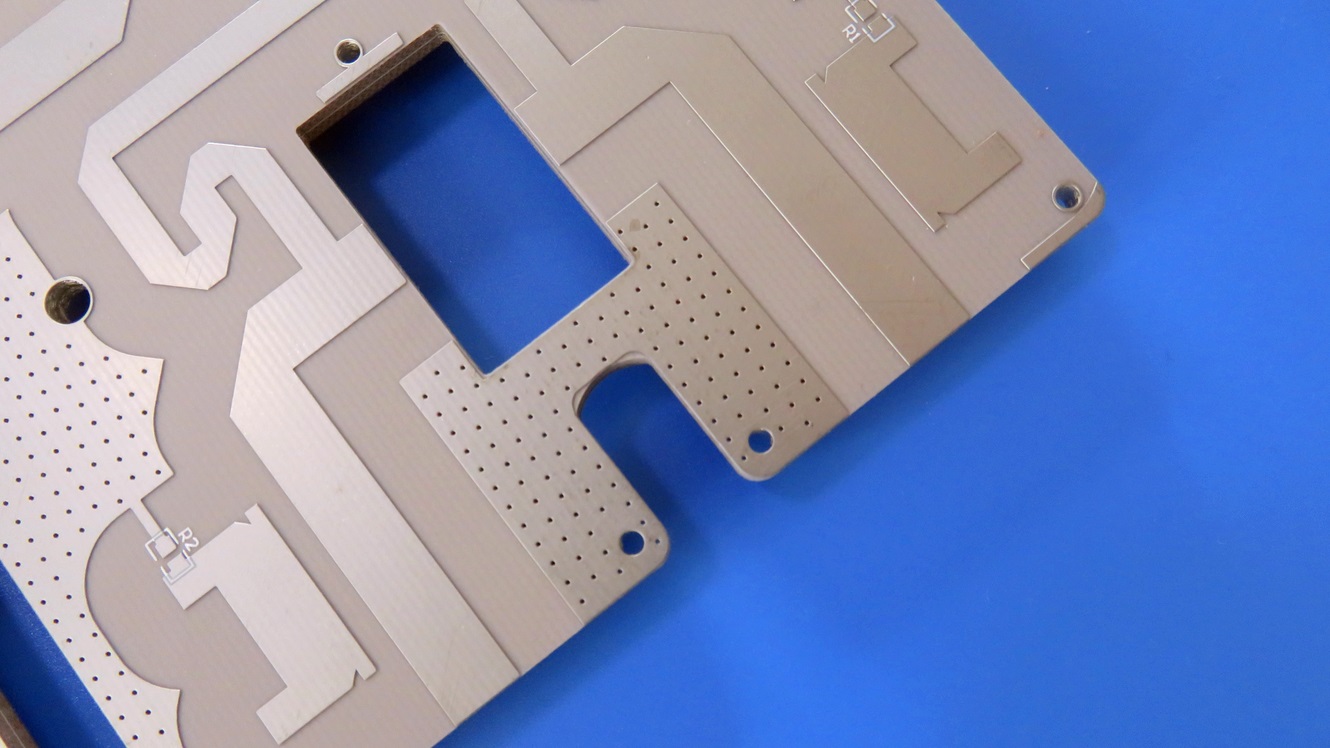

A defining feature of the IsoClad 917 material is its innovative non-woven reinforcement structure. Unlike traditional woven glass substrates, this unique architecture, comprised of longer random fibers and created through a proprietary manufacturing process, grants the laminate remarkable dimensional stability and unparalleled uniformity of dielectric constant across the board. This consistency is critical for maintaining impedance control and preventing signal degradation in sensitive high-frequency designs. Furthermore, this construction makes the final PCB assemblies surprisingly pliable, suitable for applications where the board must be bent or formed, such as in conformal or wrap-around antenna systems.

Detailed Electrical Characteristic

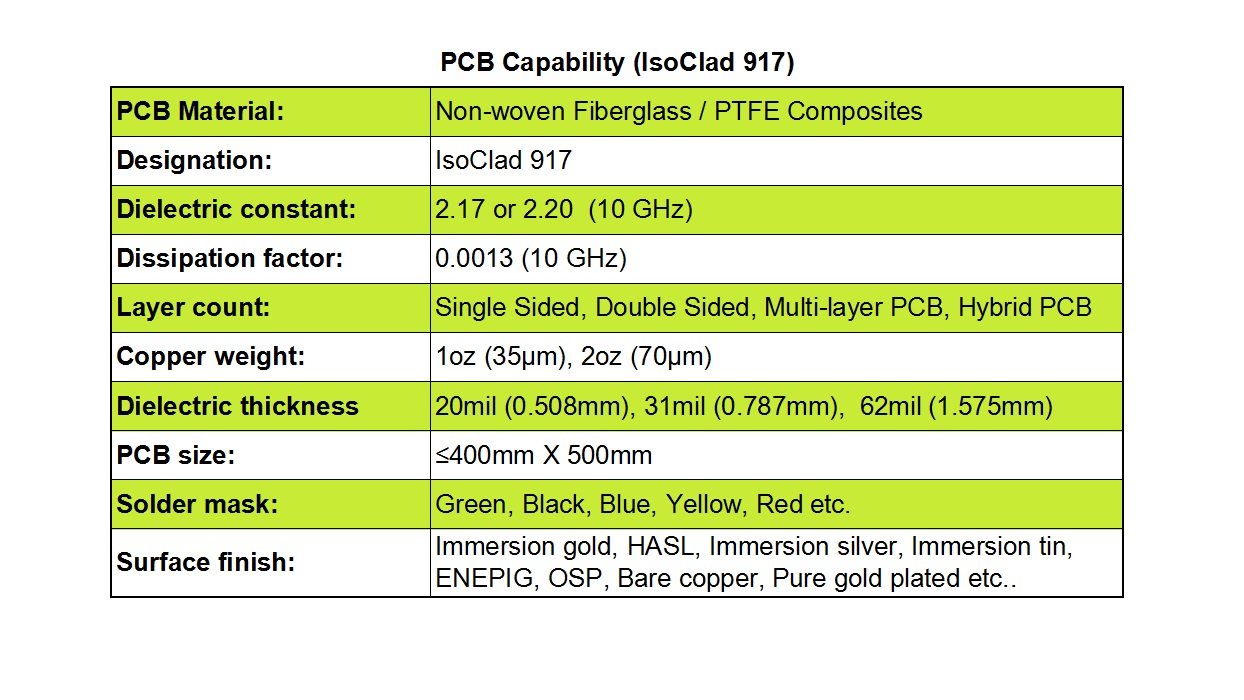

The IsoClad 917 PCB exhibits a exceptionally stable dielectric constant of either 2.17 or 2.20, with an impressively tight tolerance of±0.03 when measured at 10 GHz. This precision allows designers to achieve accurate impedance matching and predictable circuit behavior.

Complementing its stable Dk is an ultralow dissipation factor of just 0.0013 at the same 10 GHz benchmark. This remarkably low loss tangent ensures minimal signal attenuation, preserving signal integrity and enhancing overall system efficiency, which is crucial for power-sensitive applications like radar and communications infrastructure.

Adding to its reliability, IsoClad 917 demonstrates highly isotropic behavior across its X, Y, and Z axes. This means its electrical properties remain consistent regardless of signal direction, guaranteeing uniform performance and bolstering the reliability of complex, multi-layered designs. The material further protects its electrical integrity with a very low moisture absorption rate of only 0.04%, mitigating performance shifts in humid operating environments.

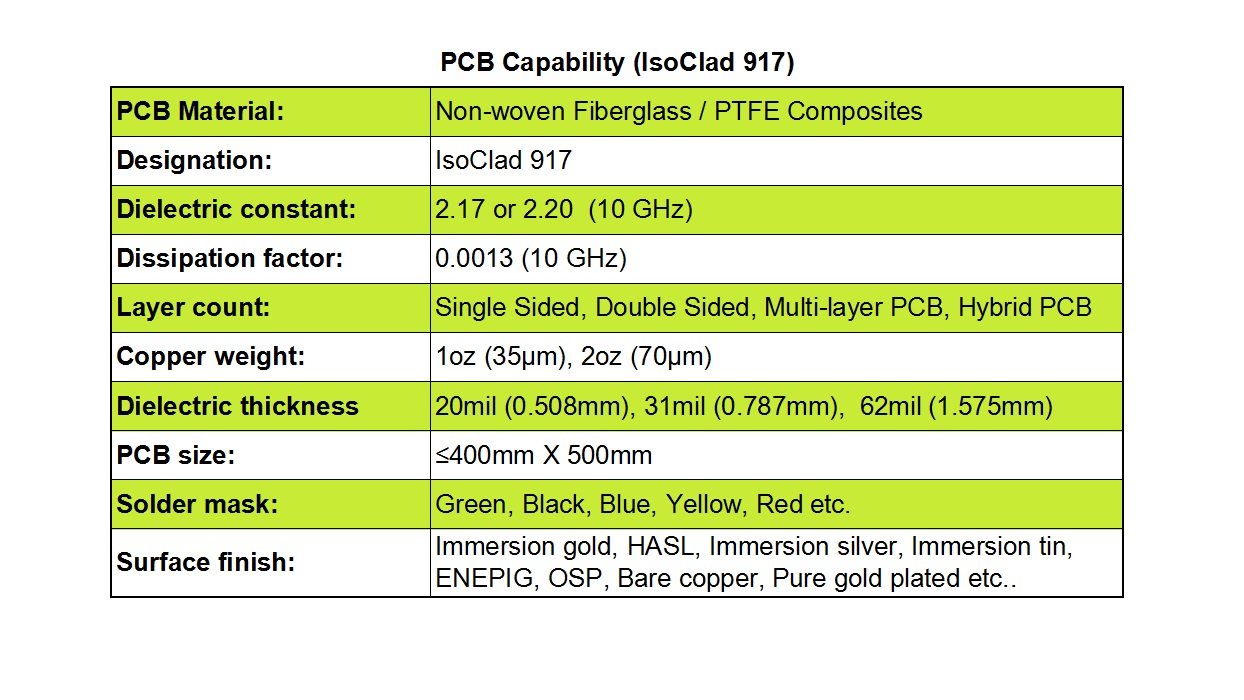

Comprehensive PCB Manufacturing Capabilities

To fully leverage the advantages of this advanced material, partnering with a supplier possessing the right technical expertise is essential. We offer extensive manufacturing services tailored forIsoClad 917 high frequency PCB production, ensuring your designs are realized to the highest standards.

1) Layer Configurations: We support a broad spectrum of project needs, from simple Single Sided and Double Sided boards to complex Multi-layer and Hybrid PCB constructions, which combine IsoClad 917 with other materials.

2) Copper Weight Options: To meet diverse electrical current and conductivity requirements, we provide standard options for 1 oz (35 µm) and 2 oz (70 µm) copper weights.

3) Dielectric Thickness: Multiple dielectric thicknesses are available, including 20 mil (0.508 mm), 31 mil (0.787 mm), and 62 mil (1.575 mm), allowing for precise controlled impedance stack-up design.

4) Board Dimensions: Our fabrication capabilities can accommodate PCB sizes up to 400 mm x 500 mm, whether for a single large board or a panelized array of multiple designs.

5) Aesthetic and Protective Finishes: A variety of solder mask colors, including Green, Black, Blue, Yellow, and Red, are available. We also offer a full range of surface finishes such as Immersion Gold (ENIG), HASL, Immersion Silver, Immersion Tin, ENEPIG, OSP, Bare Copper, and Pure Gold Plating to suit specific assembly and performance needs.

Target Applications

The combination of low loss, stable electrical properties, and unique flexibility makes the IsoClad 917 high frequency PCB an excellent solution for a wide array of demanding applications. It is perfectly suited for:

1) Conformal and Wrap-Around Antennas: Its bendable nature allows it to fit into non-traditional form factors.

2) Stripline and Microstrip Circuits: Provides consistent performance for various transmission line designs.

3) Aerospace and Defense Guidance Systems: Offers the reliability and signal integrity required in critical systems.

4) Radar and Satellite Communication Systems: Its low dissipation factor ensures efficient signal strength over long distances.

Conclusion

In conclusion, Rogers IsoClad 917 PCB stands as a top-tier material for high-frequency designs where minimal signal loss, consistent performance, and mechanical adaptability are non-negotiable. By understanding its properties and leveraging our full suite of manufacturing capabilities, you can push the boundaries of your next innovative project.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com