What Makes CER-10 High Frequency PCB the Ideal Choice for Demanding RF Applications?

In the rapidly advancing world of wireless communication, radar systems, and aerospace technology, the demand for high-frequency printed circuit boards (PCBs) that deliver uncompromising performance and unwavering reliability is greater than ever. Selecting the right substrate material is a foundational decision that directly impacts the efficiency, signal integrity, and longevity of your electronic designs. Among the top-tier materials available,Taconic CER-10 High Frequency PCB laminate emerges as a premier solution. But what specific attributes position CER-10 PCB as the ideal choice for the most demanding RF and microwave applications? This article explores the advanced material properties, robust manufacturing capabilities, and critical application strengths that define the CER-10 advantage.

Superior Material Properties for Peak High-Frequency Performance

Taconic CER-10 belongs to Taconic's esteemedORCER product family, which represents a sophisticated fusion of organic compounds and ceramic elements. This unique organic-ceramic composition is engineered to excel where standard FR-4 materials fall short.

1) Exceptional Dielectric Properties: At the heart of its performance is a stable dielectric constant (Dk) of 10 and an exceptionally low dissipation factor (Df) of just 0.0035 at 10 GHz. This combination is critical for high-frequency circuits, as it enables effective miniaturization (a higher Dk allows for smaller wavelengths) while minimizing signal loss and heat generation, thereby preserving signal strength and clarity.

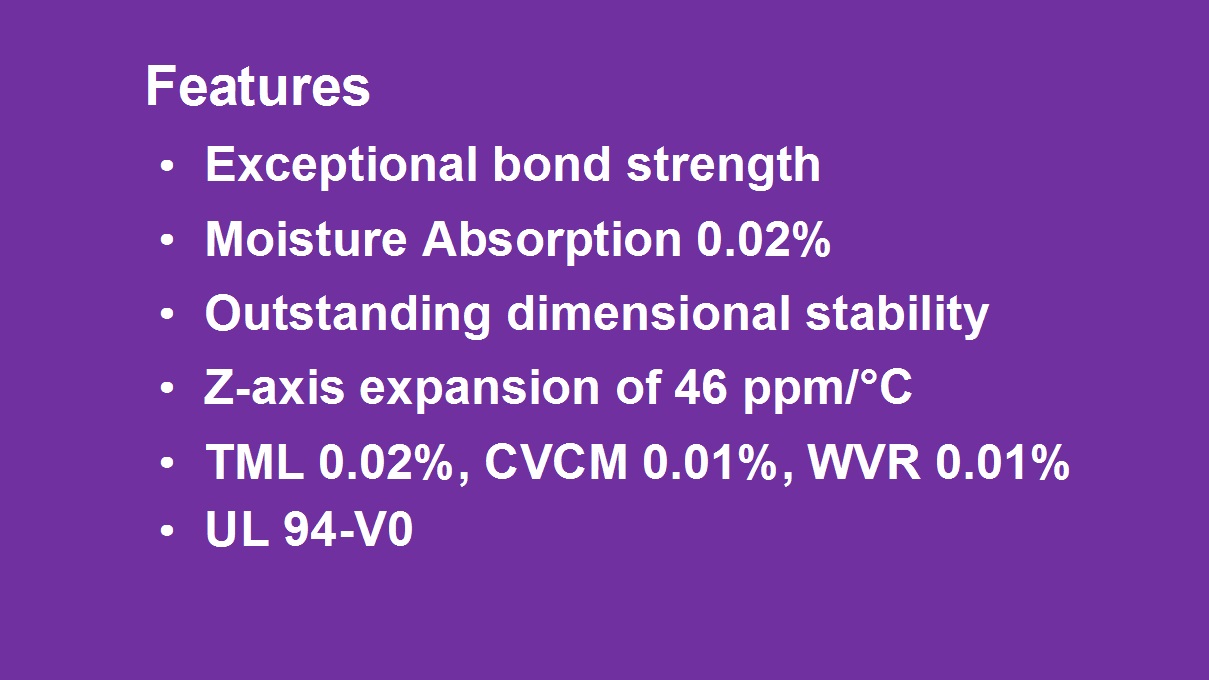

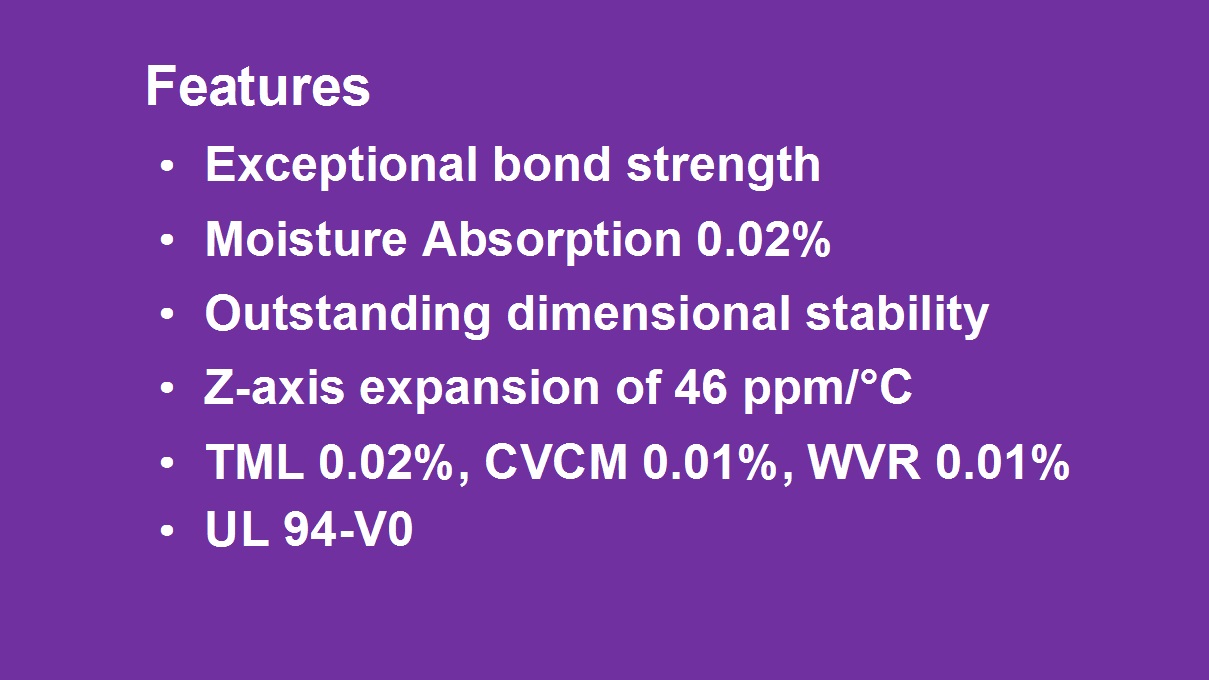

2) Enhanced Mechanical and Thermal Reliability: CER-10 is reinforced with a woven glass fabric, a feature that grants it outstanding dimensional stability and improved flexural strength, preventing warping during fabrication and operation. A key reliability feature is its optimized Z-axis coefficient of thermal expansion (CTE) of 46 ppm/°C. This low and controlled expansion is vital for protecting plated through-holes (PTHs) from stress and cracking during extreme temperature cycling, a common challenge in harsh environments.

3) Resilience in Challenging Conditions: The laminate exhibits ultra-low moisture absorption of only 0.02%, ensuring that its electrical properties remain stable even in humid conditions. Furthermore, CER-10 demonstrates low outgassing characteristics, with a Total Mass Loss (TML) of 0.02%, Collected Volatile Condensable Materials (CVCM) of 0.01%, and Water Vapor Regain (WVR) of 0.01% as per ASTM E 595. This makes it suitable for vacuum and space-related applications where contamination from outgassing is a major concern. Its UL 94 V-0 flammability rating confirms its compliance with stringent safety standards.

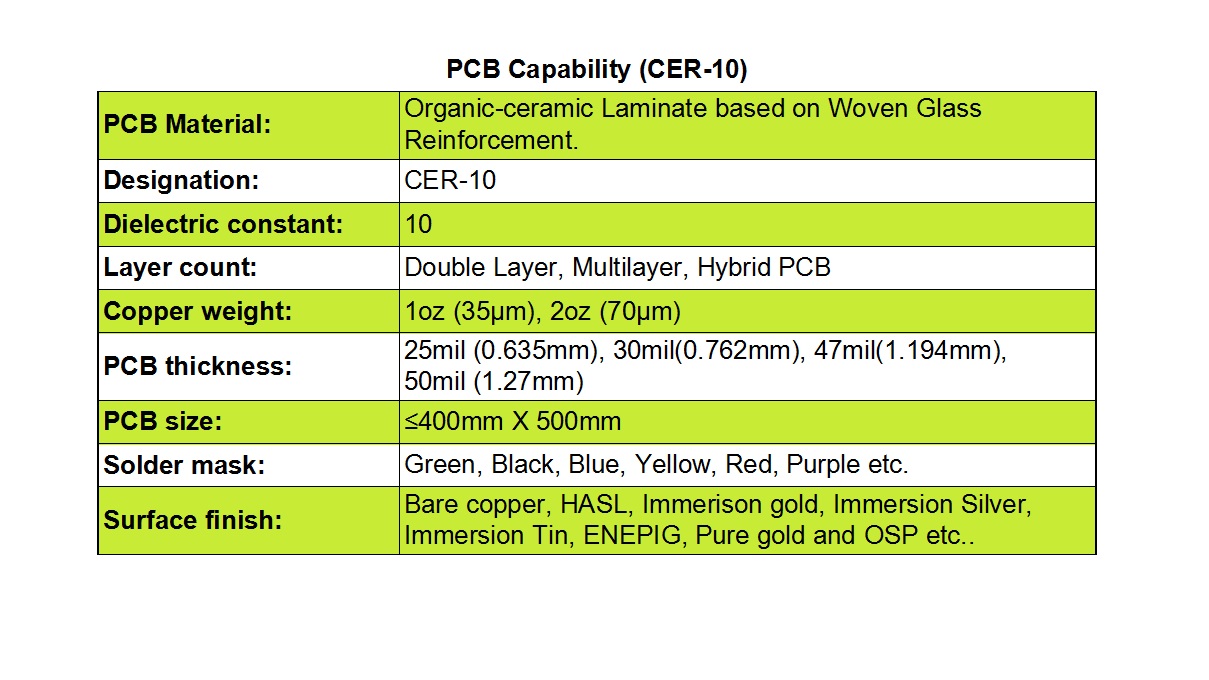

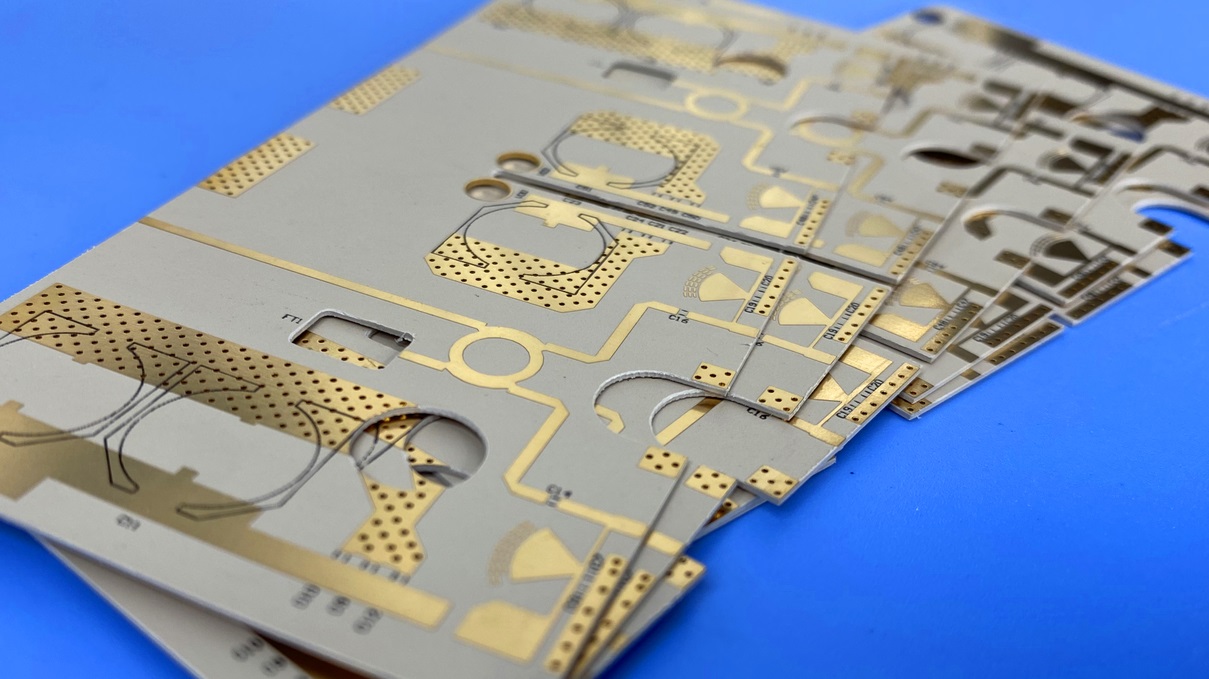

Comprehensive PCB Fabrication Capabilities with CER-10

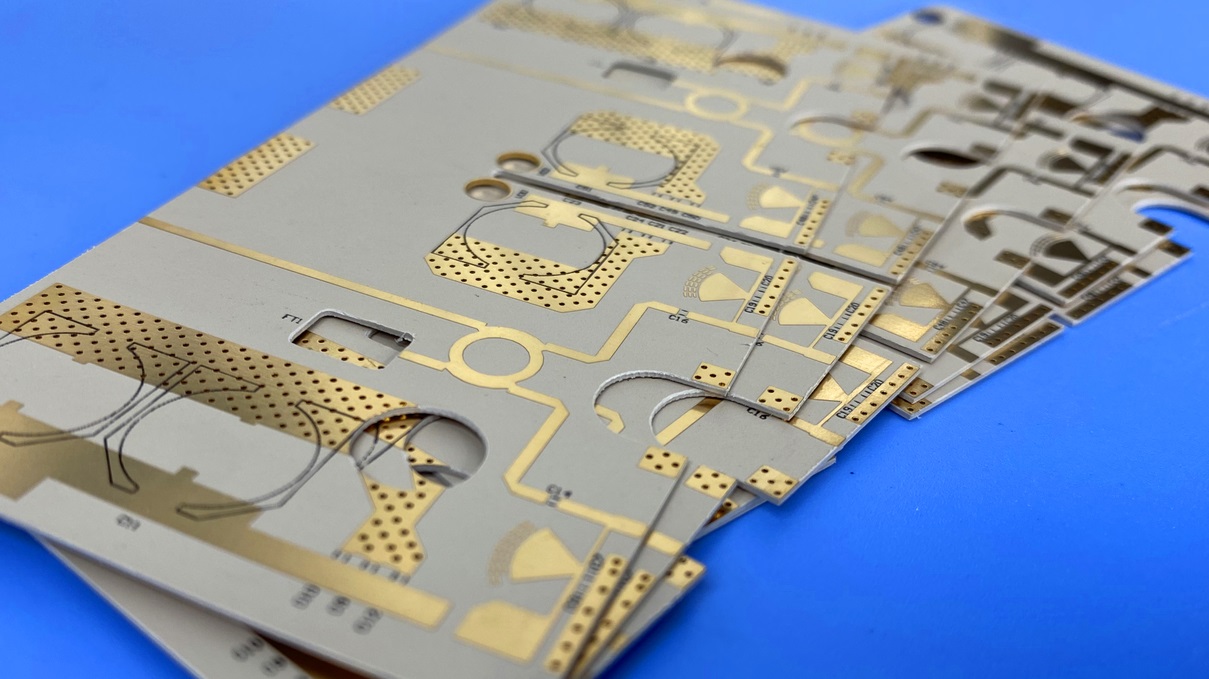

Possessing a superior laminate is only half the equation; it must be paired with expert fabrication to unlock its full potential. We provide comprehensive PCB manufacturing services tailored to harness the benefits of CER-10 Taconic RF PCB for your specific projects.

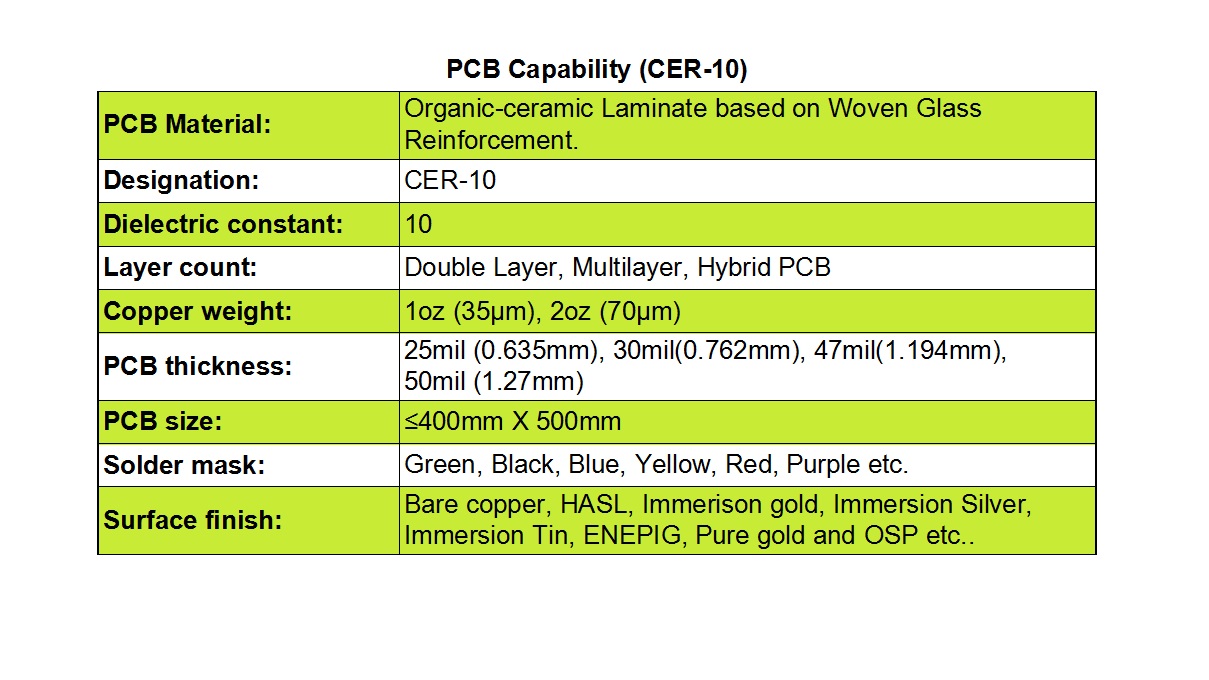

1) Flexible Configurations: We produce CER-10 PCBs in various structures, including standard double-layer, complex multilayer builds for intricate circuits, and hybrid constructions where CER-10 can be combined with other materials to optimize cost and performance.

2) Precision Engineering: To meet diverse design requirements, we offer a range of dielectric thicknesses from 25 mil (0.635 mm) up to 50 mil (1.27 mm). Copper weights are available from standard 1oz (35µm) to heavy 2oz (70µm) for enhanced current-carrying capacity. We can accommodate large-format designs with PCB sizes up to 400mm x 500mm.

3) Customization Options: Your boards can be customized with a variety of solder mask colors, including green, black, blue, yellow, red, and purple. We also offer a full spectrum of surface finishes to match your application needs, such as Bare Copper, HASL, Electroless Nickel Immersion Gold (ENIG), Immersion Silver, Immersion Tin, ENEPIG, Pure Gold, and OSP (Organic Solderability Preservative).

Ideal Applications for CER-10 High Frequency PCB

The unique property set of CER-10 Printed Circuit Board makes it the material of choice for high-performance applications where signal integrity and thermal reliability are non-negotiable. It is exceptionally well-suited for:

1) Power Amplifiers: Its low loss tangent ensures efficient power transmission.

2) Waveguide Filters and Directional Couplers: The stable Dk is crucial for maintaining precise electrical parameters.

3) Other Microwave Passive Components: Such as antennas and multiplexers, particularly in telecommunications infrastructure, aerospace, and defense systems.

Conclusion

When performance and reliability cannot be compromised, CER-10 High Frequency PCB stands out as a robust and high-performing solution. Its blend of stable electrical properties, exceptional thermal and mechanical resilience, and adaptability to advanced manufacturing processes makes it an ideal substrate for pushing the boundaries of high-frequency electronic design. For your next project that demands the best, consider CER-10 Double Layer PCB as the foundation for success.

Contact us today to discuss how we can supply high-quality CER-10 PCBs tailored to your exact specifications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com