How Can a Laminate with a Dk of 2.33 and 0.0016 Loss Tangent Enhance Your RF Design?

In the demanding world of high-frequency electronics, the choice of printed circuit board (PCB) substrate is a critical determinant of performance, reliability, and overall system success. Rogers Corporation's IsoClad 933 high frequency PCB emerges as a premier material engineered to meet these rigorous challenges. This composite material, crafted from a unique blend of polytetrafluoroethylene (PTFE) and a non-woven fiberglass reinforcement, is specifically designed to deliver an exceptional balance of electrical performance, mechanical robustness, and dimensional stability for advanced RF and microwave applications.

Introduction: A Reinforced Material for Superior Stability

Rogers IsoClad 933 substrates distinguish themselves through their innovative composite structure. Unlike standard substrates that use woven fiberglass, IsoClad 933 PCB is manufactured with a higher proportion of non-woven fiberglass within a PTFE matrix. This specific formulation results in a significantly more reinforced material substrate. The key benefit of this unique non-woven reinforcement architecture is twofold: it provides remarkable dimensional stability, minimizing board movement during fabrication and operation, and it imparts enhanced mechanical strength. Furthermore, this structure introduces a degree of flexibility, making IsoClad 933 an ideal candidate for applications where circuit conformability—the ability to bend or fit into non-planar spaces—is essential. The utilization of longer, randomly oriented fibers combined with a proprietary manufacturing process ensures consistent and predictable performance, setting a new benchmark compared to traditional woven fiberglass laminates.

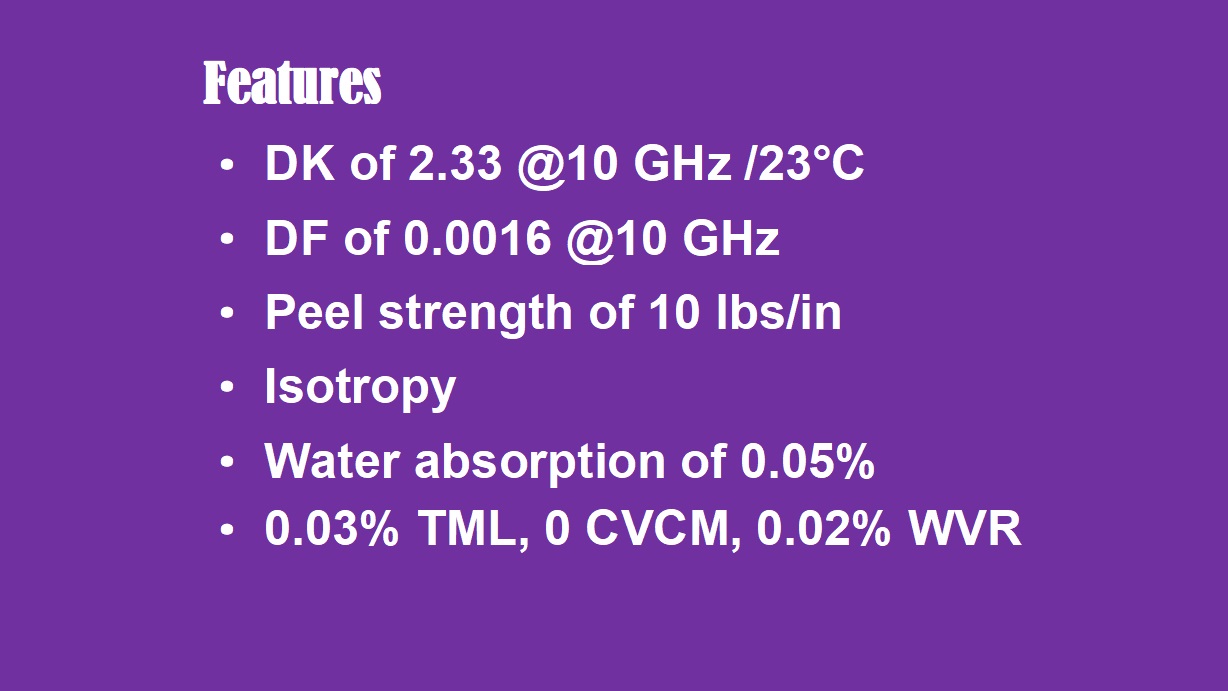

Unmatched Features for Optimal Electrical Performance

The electrical characteristics of IsoClad 933 are precisely tailored for high-frequency operation, ensuring signal integrity is maintained even in the most sensitive applications.

1) Low Dielectric Constant (Dk): The laminate boasts a stable dielectric constant of 2.33, measured at 10 GHz and 23°C. This low Dk is crucial for minimizing signal propagation delays and allowing for the design of finer circuit features, which is vital for high-speed digital and high-frequency analog circuits.

2) Exceptionally Low Dissipation Factor (Df): With an ultra-low dissipation factor of just 0.0016 at the same test conditions, IsoClad 933 ensures minimal dielectric loss. This translates to significantly reduced energy loss and higher efficiency, which is paramount for power-sensitive applications like amplifiers and antennas.

3) Robust Mechanical Properties: The material exhibits an impressive peel strength of 10 pounds per inch, guaranteeing strong mechanical adhesion between the copper foil and the dielectric substrate. This prevents delamination and ensures long-term reliability under thermal and mechanical stress.

4) Isotropic Consistency: A standout feature of IsoClad 933 is its highly isotropic nature. It performs uniformly across the X, Y, and Z axes, providing reliable and predictable electrical behavior in all directions. This eliminates performance variations based on circuit orientation, simplifying the design process.

5) Environmental Resilience: Additional features include very low water absorption (0.05%), which protects electrical properties in humid environments, and minimal outgassing (0.03% TML, 0.00% CVCM), making it suitable for vacuum and aerospace environments. Excellent Dk uniformity across the entire panel guarantees consistent performance from board to board.

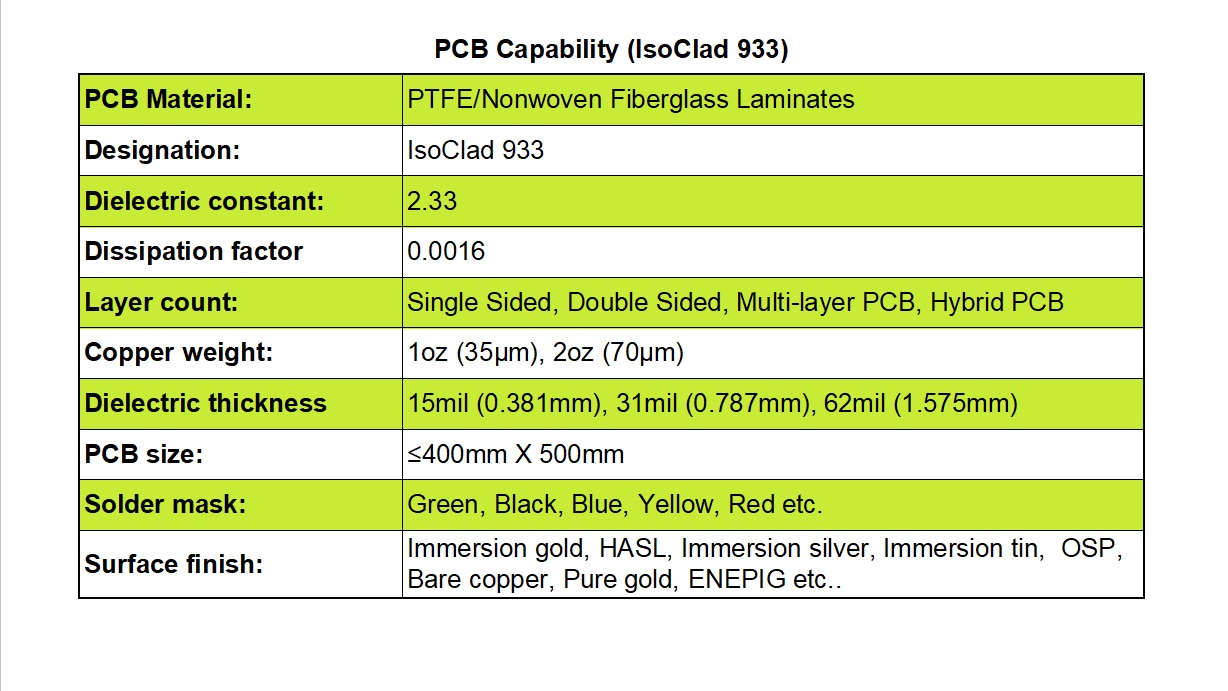

Comprehensive PCB Capabilities for Customized Designs

To fully leverage the superior properties of the IsoClad 933 laminate, we offer extensive PCB fabrication capabilities that provide designers with unparalleled flexibility.

1) Configuration Versatility: We support a wide array of PCB configurations, including double-sided, complex multilayer, and hybrid constructions, allowing for sophisticated circuit integration.

2) Material Customization: Designers can select from various copper weights, such as 1oz (35µm) and 2oz (70µm), to optimize current-carrying capacity and thermal management. Multiple dielectric thickness options, including 15 mils (0.381mm), 31 mils (0.787mm), and 62 mils (1.575mm), enable precise control over impedance and overall board profile.

3) Physical Dimensions: Our manufacturing process can accommodate boards up to 400mm x 500mm, providing ample real estate for large or complex designs.

4) Aesthetic and Surface Finish Options: A selection of solder mask colors (green, black, blue, yellow, red) is available for identification and protection. Furthermore, a comprehensive range of surface finishes—including Immersion Gold (ENIG), HASL, Immersion Silver, Immersion Tin, OSP, Bare Copper, Pure Gold, and ENEPIG—ensures optimal solderability and compatibility with various assembly processes.

Diverse High-Performance Applications

The combination of its electrical and mechanical properties makes Rogers IsoClad 933 the material of choice for a spectrum of high-reliability applications. It is exceptionally well-suited for:

1) Conformal Antennas: Its flexibility and stable electrical properties are critical for antennas that must conform to the shape of a vehicle or aircraft.

2) Stripline and Microstrip Circuits: The material's consistent Dk and low loss are ideal for these transmission line structures, which require precise control over impedance and signal integrity.

3) Advanced Aerospace and Defense Systems: This includes radar systems, electronic warfare (EW) platforms, and advanced guidance systems, where unwavering performance and reliability under extreme conditions are non-negotiable.

In conclusion, IsoClad 933 Rogers PCB represents a top-tier solution for engineers pushing the boundaries of high-frequency technology. Its unique reinforced composition, exceptional electrical properties, and our extensive fabrication capabilities make it an indispensable asset for creating reliable, high-performance electronics for the most demanding applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com