What Makes Rogers RO4730G3 PCB a Superior High-Frequency Circuit Board Material?

In the realm of high-frequency electronics, the choice of printed circuit board (PCB) material is paramount to the performance, reliability, and cost-effectiveness of the final product. For engineers and designers seeking a robust solution for demanding RF applications, Rogers RO4730G3 antenna-grade laminates present a compelling alternative to traditional PTFE-based materials. This article delves into the key attributes, capabilities, and applications of RO4730G3 high-frequency PCBs, illustrating why they are an optimal choice for next-generation designs.

Introduction: A High-Performance, Cost-Effective Alternative

Rogers RO4730G3 antenna-grade laminates are engineered to deliver exceptional mechanical and electrical properties essential for superior antenna performance, while simultaneously offering a reliable and lower-cost substitute to conventional polytetrafluoroethylene (PTFE) laminates. The advanced resin system formulated for RO4730G3 dielectric materials ensures optimal functionality in high-frequency circuits, making it an ideal selection for a wide array of wireless applications.

A significant advantage of RO4730G3 laminates is their full compatibility with standard FR-4 manufacturing processes and high-temperature, lead-free solder assembly. Unlike traditional PTFE-based materials, which often necessitate special treatments and handling procedures for plated through-hole (PTH) preparation, RO4730G3 streamlines the production process. This compatibility reduces manufacturing complexity and associated costs, enabling designers to achieve an optimal balance between performance objectives and budget constraints without compromising on quality.

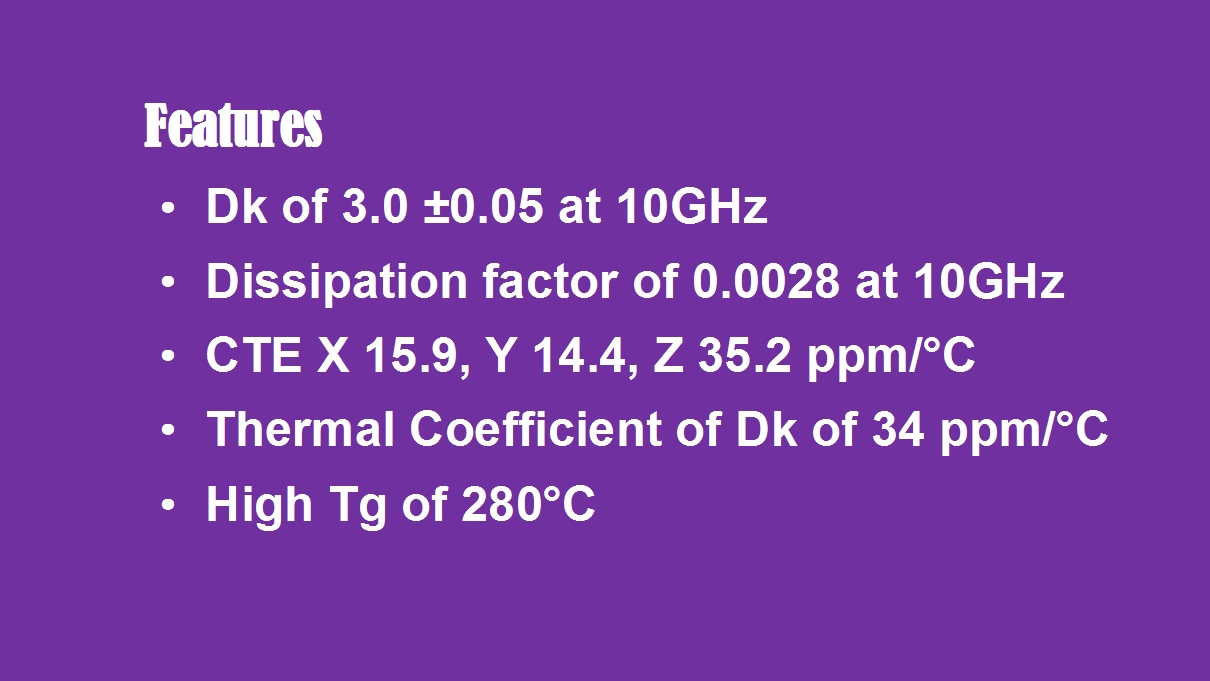

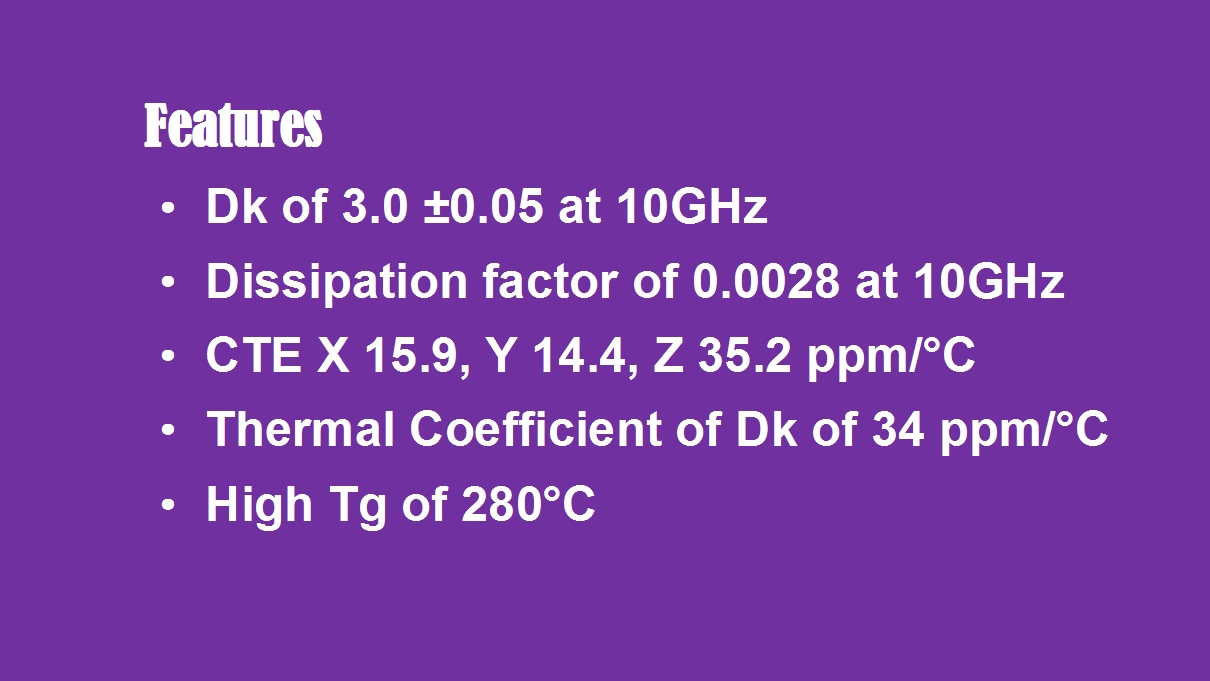

Outstanding Material Properties for Enhanced Signal Integrity

The performance of high-frequency PCBs is critically dependent on stable and precise electrical properties. RO4730G3 substrates excel in this regard with a dielectric constant (Dk) of 3.0, maintained within an exceptionally tight tolerance of±0.05. This uniformity guarantees consistent signal integrity and predictable impedance control across the entire board, which is vital for minimizing signal reflection and loss in sophisticated RF designs.

Furthermore, RO4730G3 high frequency PCB exhibits an impressively low dissipation factor (Df) of 0.0028. This property translates to minimal signal attenuation and highly efficient energy transmission, ensuring that high-frequency signals pass through the circuit with reduced loss, which is crucial for maintaining the strength and clarity of signals in communication systems.

Thermal management is another area where RO4730G3 demonstrates superior performance. The material features a remarkably low Z-axis coefficient of thermal expansion (CTE) of 35.2 ppm/°C. This low CTE significantly diminishes the risks of via cracking and layer delamination, especially during thermal cycling, thereby enhancing the long-term durability and reliability of the assembly under strenuous operating conditions.

Complementing its thermal stability, RO4730G3 also offers a low temperature coefficient of dielectric constant (TCDk) of 34 ppm/°C. This ensures that the electrical properties of the material remain stable across a wide temperature range, providing consistent performance even as environmental conditions fluctuate.

Finally, the laminate boasts an exceptionally high glass transition temperature (Tg) exceeding 280°C. This high Tg allows the material to withstand the elevated temperatures encountered during both assembly processes and operational life, further bolstering the mechanical and electrical reliability of the end product.

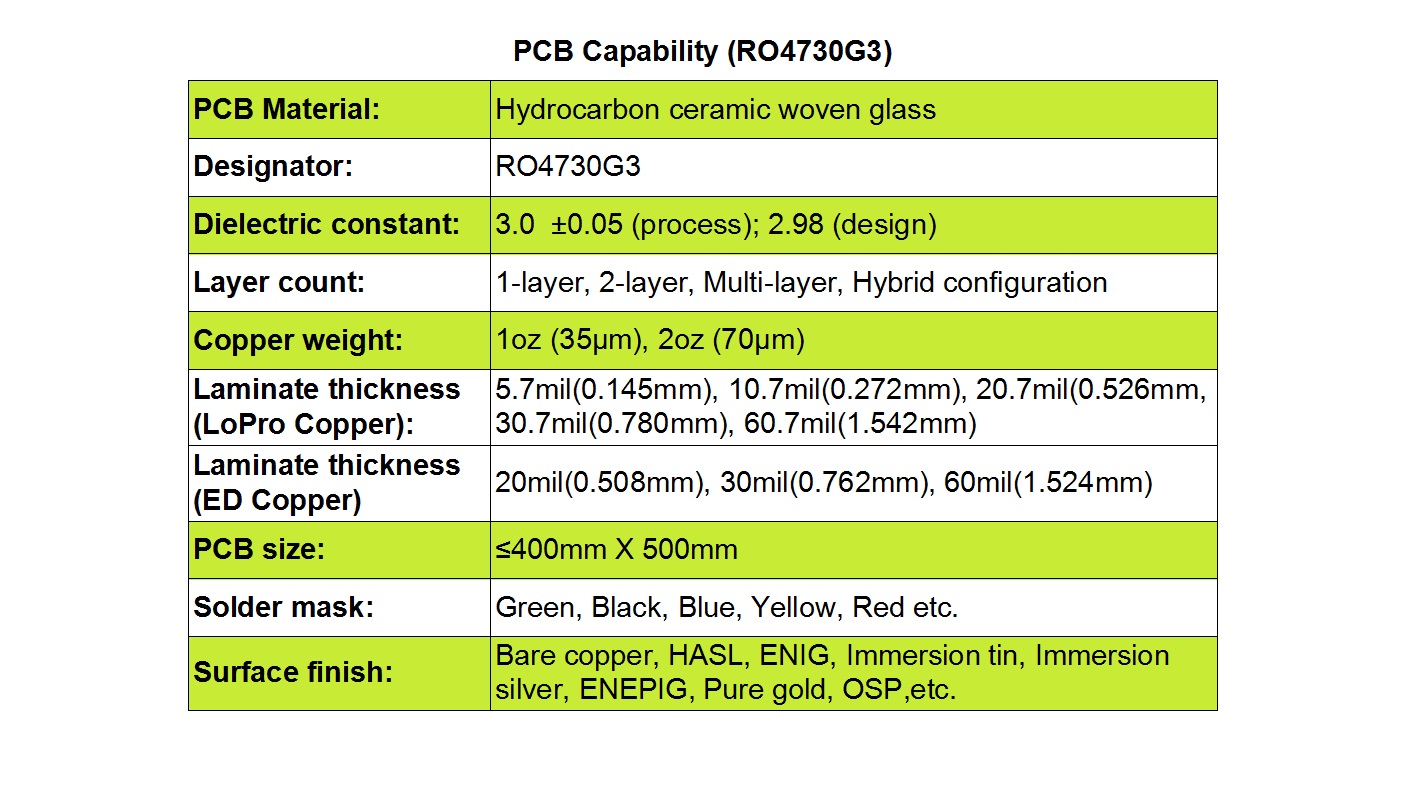

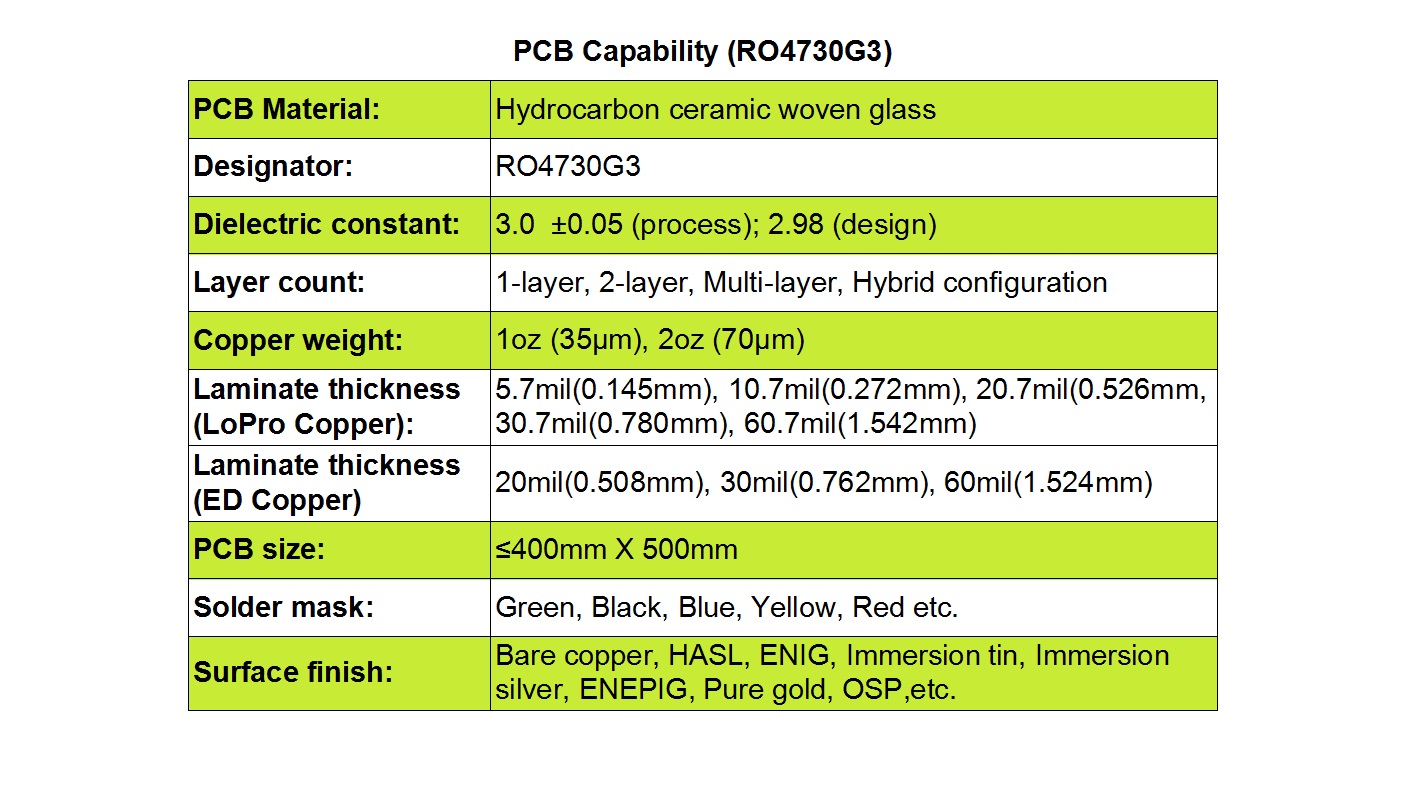

Comprehensive PCB Capabilities with RO4730G3

We provide fullycustomized RO4730G3 PCBs tailored to meet the specific requirements of your project. Our manufacturing services support a broad spectrum of configurations, including single-layer, double-layer, multi-layer, and hybrid stack-ups. You can select from standard copper weights such as 1oz (35µm) and 2oz (70µm), and choose from a range of laminate thickness options, including LoPro Copper (5.7mil to 60.7mil) and ED Copper (20mil to 60mil), offering unparalleled flexibility for diverse design applications.

Our production facilities can accommodate PCBs with maximum dimensions of 400mm x 500mm. To suit your aesthetic and functional preferences, we offer solder mask in various colors, including green, black, blue, yellow, and red. Additionally, a wide selection of surface finishes is available, such as bare copper, HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), immersion tin, immersion silver, ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold), pure gold, and OSP (Organic Solderability Preservative).

Primary Applications

The combination of stable electrical properties, thermal resilience, and cost-effectiveness makes Rogers RO4730G3 PCB particularly well-suited for radio frequency applications. Its most common application is in Cellular Base Station Antennas, where consistent high-performance signal transmission and durability are critical. However, its benefits also extend to other wireless infrastructure components, automotive radar systems, and various aerospace and defense communication modules.

By choosing Rogers RO4730G3 for your PCB needs, you are opting for a material that delivers outstanding high-frequency performance, manufacturing convenience, and long-term reliability, all at a competitive price point.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com