RO4730G3PCB 60mil Rogers Substrate Antenna Grade High Frequency Circuit Board

Introduction

The RO4730G3 high frequency PCB, which is a type of antenna grade PCB.

Rogers RO4730G3 high frequency materials are reliable laminates designed for antennas. They are compatible with conventional FR-4 and high temperature lead-free solder processes. This material provides a cost-effective alternative to traditional PTFE-based antenna substrates, allowing designers to balance cost and performance.

RO4730G3 Typical Properties

Rogers 4730G3 PCBis a high-performance material with excellent characteristics for various applications. Let's explore its key properties.

RO4730G3 has a dielectric constant of 3.0±0.5 during the manufacturing process and 2.98 in design, making it suitable for high-frequency applications ranging from 1.7 GHz to 5 GHz.

The RO4730G3 material has achieved a flammability rating of V-0, meeting the strict requirements of UL 94. This rating indicates its self-extinguishing properties and high resistance to combustion.

RO4730G3 is compatible with lead-free processes, making it suitable for environmentally-friendly manufacturing and assembly methods.

More RO4730G3 Typical Properties as follows:

|

Property

|

RO4730G3

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

3.0±0.5

|

Z

|

|

10 GHz 23℃

|

IPC-TM-650 2.5.5.5

|

|

Dielectric Constant,εDesign

|

2.98

|

Z

|

|

1.7 GHz to 5 GHz

|

Differential Phase Length Method

|

|

Dissipation Factor,tanδ

|

0.0028

|

Z

|

|

10 GHz 23℃

|

IPC-TM-650 2.5.5.5

|

|

|

2.5 GHz

|

|

Thermal Coefficient of ε

|

+34

|

Z

|

ppm/℃

|

-50℃to 150℃

|

IPC-TM-650 2.5.5.5

|

|

Dimensional Stability

|

<0.4

|

X, Y

|

mm/m

|

after etech +E2/150℃

|

IPC-TM-650 2.4.39A

|

|

Volume Resistivity (0.030")

|

9 X 107

|

|

MΩ.cm

|

COND A

|

IPC-TM-650 2.5.17.1

|

|

Surface Resistivity (0.030")

|

7.2 X 105

|

|

MΩ

|

COND A

|

IPC-TM-650 2.5.17.1

|

|

PIM

|

-165

|

|

dBc

|

50 ohm 0.060"

|

43 dBm 1900 MHz

|

|

Electrical Strength (0.030")

|

730

|

Z

|

V/mil

|

|

IPC-TM-650 2.5.6.2

|

|

Flexural Strength MD

|

181 (26.3)

|

|

Mpa (kpsi)

|

RT

|

ASTM D790

|

|

CMD

|

139 (20.2)

|

|

|

Moisure Absorption

|

0.093

|

-

|

%

|

48/50

|

IPC-TM-650 2.6.2.1 ASTM D570

|

|

Thermal Conductivity

|

0.45

|

Z

|

W/mK

|

50℃

|

ASTM D5470

|

|

Coefficient of Thermal Expansion

|

15.9

14.4

35.2

|

X

Y

Z

|

ppm/℃

|

-50℃to 288℃

|

IPC-TM-650 2.4.4.1

|

|

Tg

|

>280

|

|

℃

|

|

IPC-TM-650 2.4.24

|

|

Td

|

411

|

|

℃

|

|

ASTM D3850

|

|

Density

|

1.58

|

|

gm/cm3

|

|

ASTM D792

|

|

Copper Peel Stength

|

4.1

|

|

pli

|

1oz,LoPro EDC

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-free Process Compatible

|

Yes

|

|

|

|

|

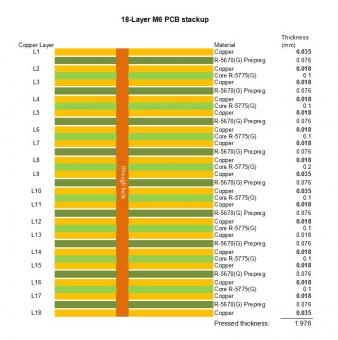

RO4730G3 PCB Capabilities

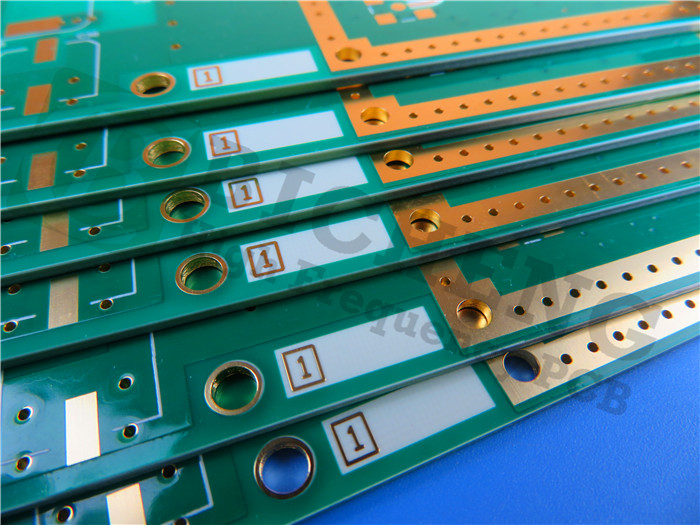

We offer a range of PCB options using RO4730G3, including single layer, double layer, multi-layer, and hybrid types.

|

PCB Material:

|

Hydrocarbon ceramic woven glass

|

|

Designation:

|

RO4730G3

|

|

Dielectric constant:

|

3.0 ±0.05 (process)

|

|

|

2.98 (design)

|

|

Layer count:

|

1-layer, 2-layer, Multi-layer, Hybrid designs

|

|

Laminate thickness (low profile copper):

|

5.7mil(0.145mm), 10.7mil(0.272mm), 20.7mil(0.526mm, 30.7mil(0.780mm), 40.7mil(1.034mm), 60.7mil(1.542mm)

|

|

Laminate thickness (ED Copper):

|

20mil(0.508mm), 30mil(0.762mm), 40mil(1.016mm), 50mil(1.270mm), 60mil(1.524mm)

|

|

Copper weight:

|

1oz (35 µm), 2oz (70µm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, Pure gold, ENEPIG etc.

|

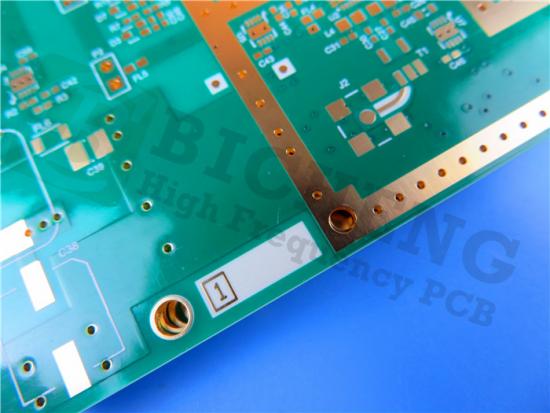

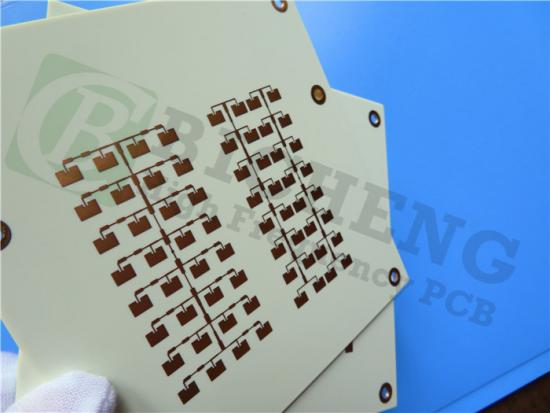

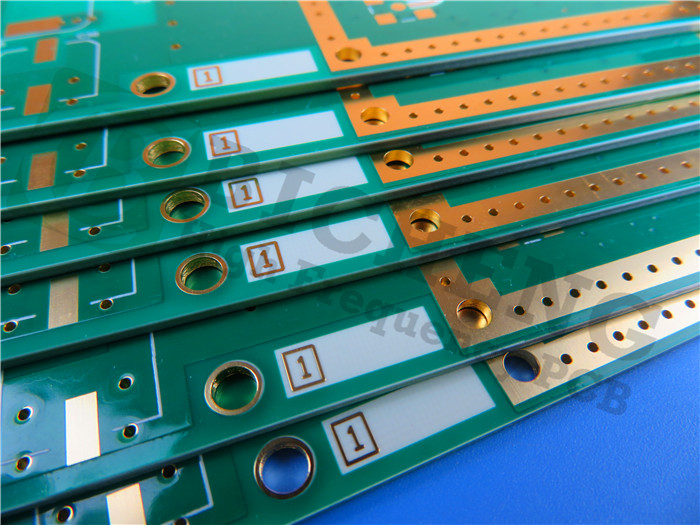

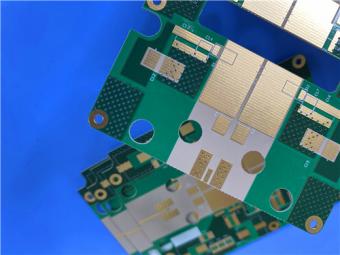

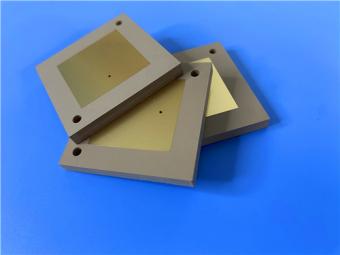

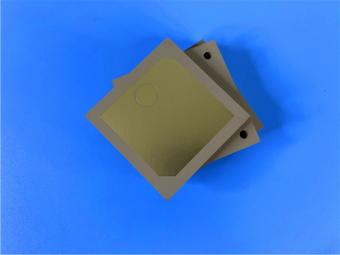

An Example of RO4730G3 PCB

Displayed on the screen is an example of a 60mil RO4730G3 PCB. It is double-sided with immersion gold, specifically designed for base station antennas.

Conclusion

In conclusion, the RO4730G3 60mil substrate PCB is a highly reliable and versatile material with excellent electrical properties, dimensional stability, and thermal performance. Its superior characteristics make it suitable for various applications, including high-frequency circuit boards and electronic components.

Additionally, RO4730G3 PCBs offer low insertion loss and are lightweight, being 30% lighter than PTFE or fiberglass materials.

We explored the impressive features of the Rogers RO4730G3 and our printed circuit boards using this material. If you have any further inquiries or require more information, please feel free to contact our team.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com