Why Choose Rogers RO3210 PCB for High-Frequency and Thermally Demanding Applications?

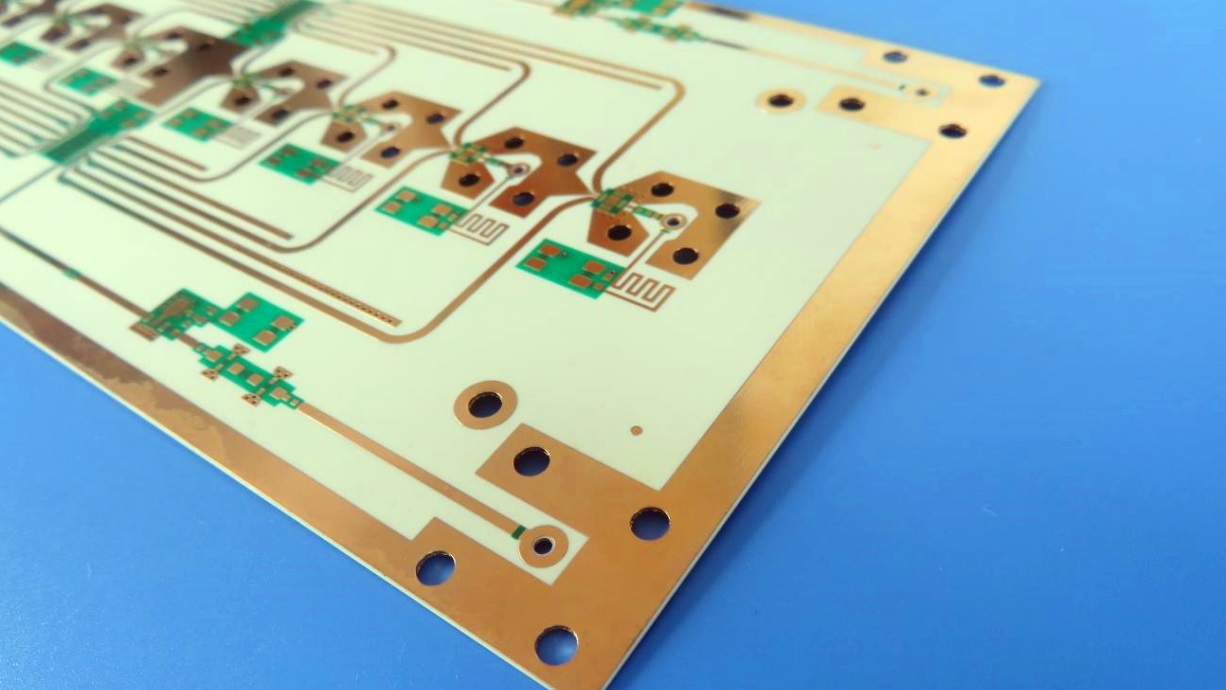

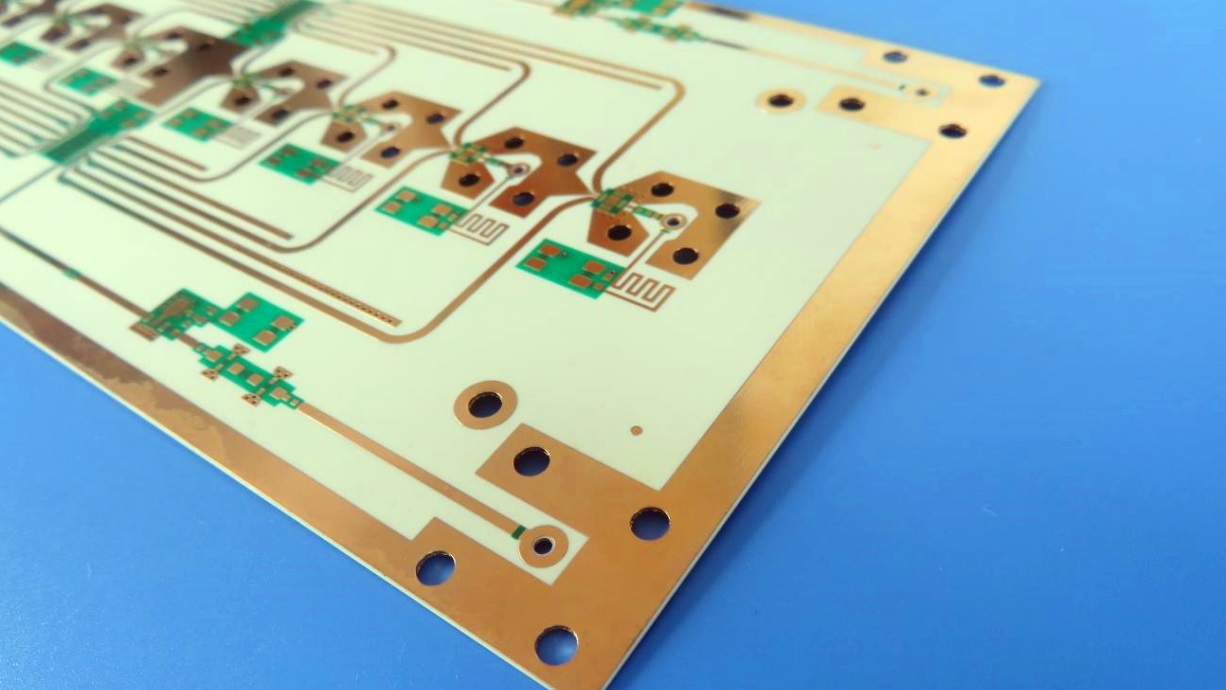

In the world of high-frequency PCB design, selecting the right substrate material is crucial for achieving optimal electrical performance, thermal management, and mechanical reliability. Rogers Corporation’s RO3210 high-frequency circuit materials stand out as an exceptional choice for demanding applications ranging from automotive radar to satellite communications. As an integral member of the renowned RO3000 series, Rogers RO3210 combines ceramic-filled construction with woven fiberglass reinforcement, delivering superior high-frequency characteristics and enhanced mechanical stability at a highly competitive cost.

Superior Electrical and Thermal Properties

One of the most significant advantages of Rogers 3210 is its stable and relatively high dielectric constant (Dk) of 10.2, maintained within a tight tolerance of±0.5. This consistency allows RF designers to develop more compact circuit layouts, supporting the ongoing trend toward miniaturization in electronic devices without compromising electrical integrity. Moreover, its low dissipation factor of 0.0027 at 10 GHz ensures minimal signal loss and reduced distortion, which is essential for maintaining signal quality in high-speed and high-frequency applications.

Thermal management is another critical area where RO3210 excels. With a thermal conductivity of 0.81 W/m/K, this material effectively dissipates heat, reducing the risk of overheating in power-intensive applications. Its low coefficient of thermal expansion (CTE) across the X, Y, and Z axes further enhances reliability by minimizing dimensional changes under thermal stress, thereby supporting solder joint integrity and long-term operational stability.

Enhanced Mechanical Stability and Manufacturing Precision

RO3210 is engineered for exceptional dimensional stability, which significantly improves manufacturing yield and product consistency. This stability is particularly beneficial in multi-layer and hybrid PCB constructions, where alignment accuracy is paramount. The material’s smooth surface finish allows for finer and more precise etching of conductor traces, enabling the production of intricate circuit patterns with high accuracy. This capability is indispensable for advanced designs such as microstrip patch antennas and high-density interconnect (HDI) boards.

Additionally, RO3210 laminates are compatible with epoxy-based multi-layer hybrid designs, providing designers with greater flexibility in creating complex, high-performance systems that integrate both RF and digital sections. This versatility makes it an ideal substrate for sophisticated applications that demand a blend of high frequency operation and robust mechanical properties.

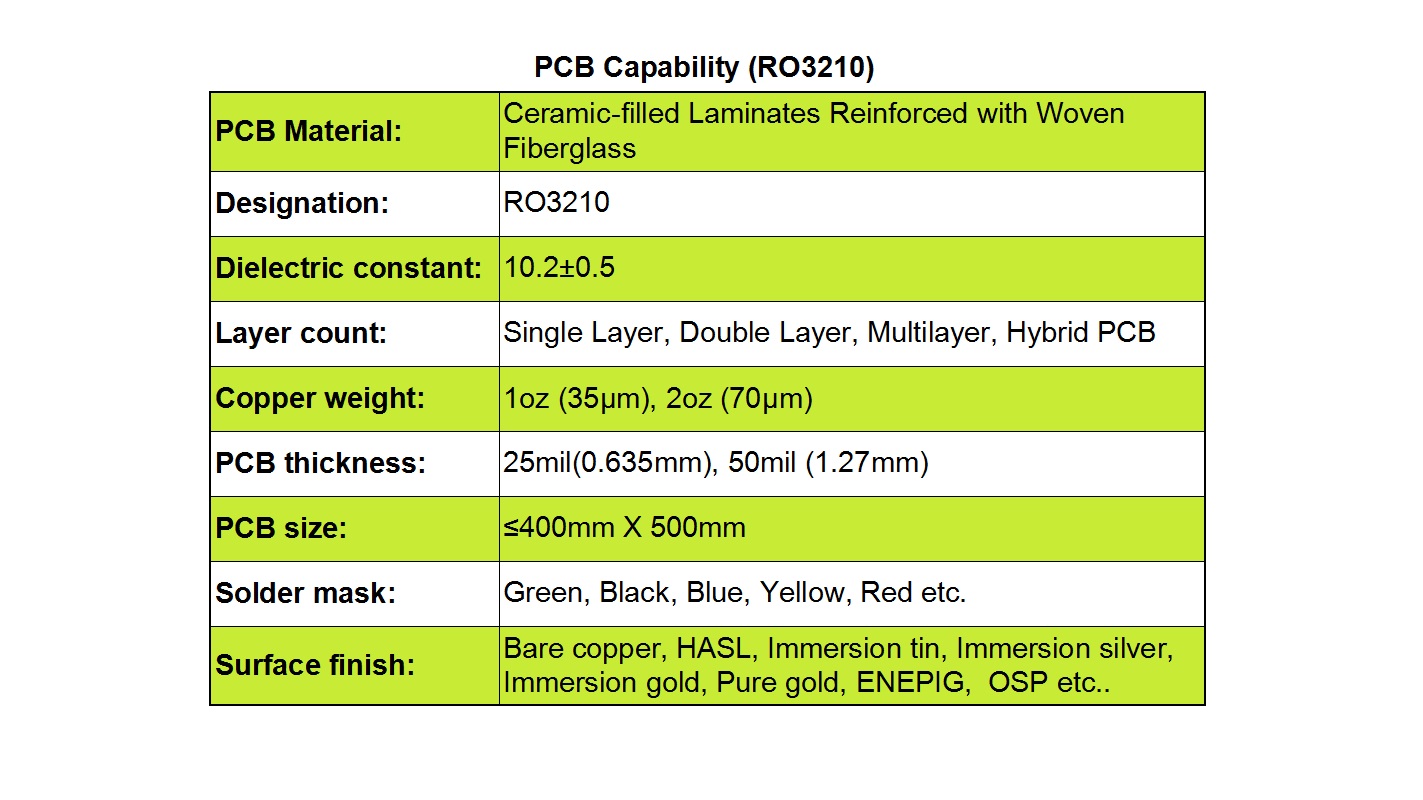

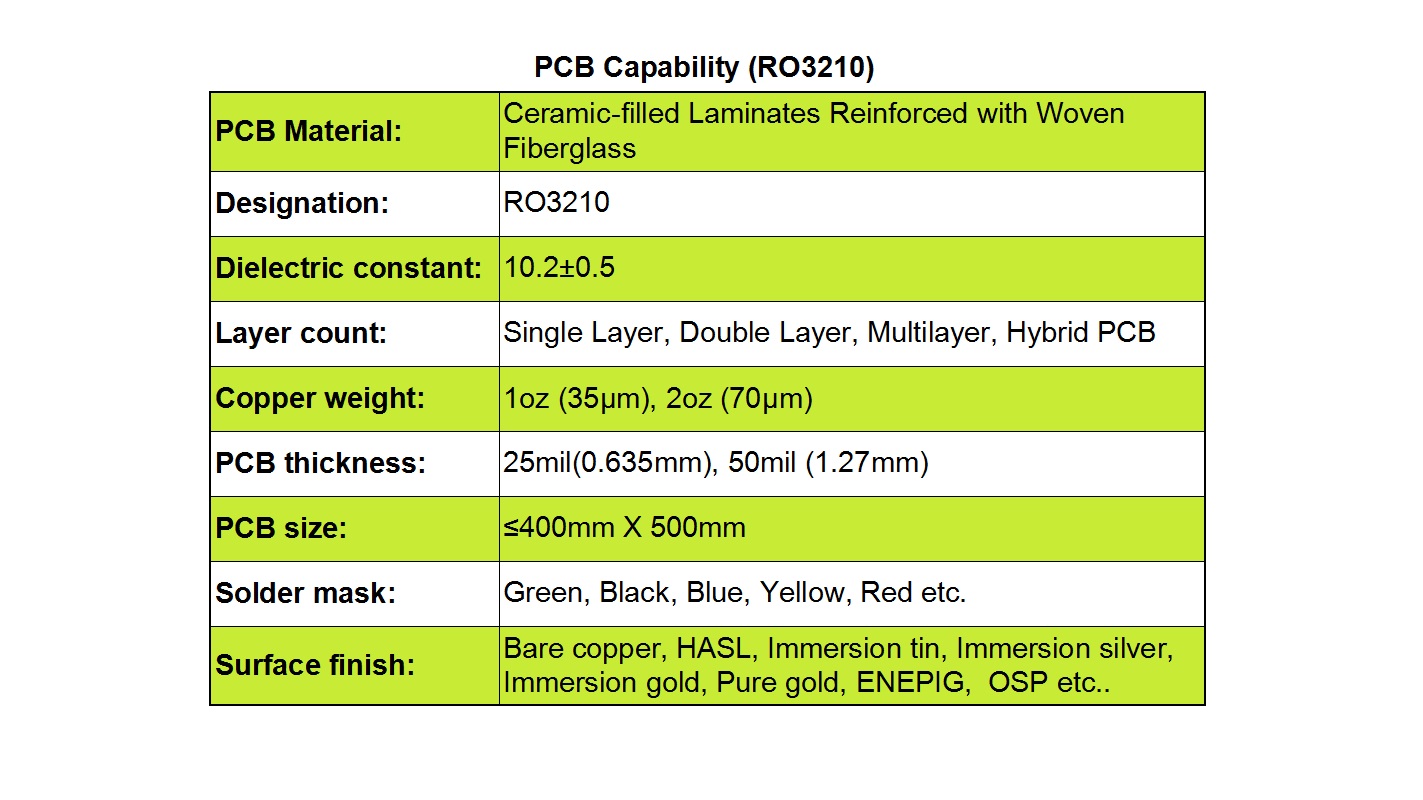

Customized PCB Capabilities with RO3210 Material

Our manufacturing services fully leverage the benefits ofRogers RO3210 to produce high-frequency PCBs tailored to your specific requirements. We support a broad spectrum of design complexities—from simple single-layer boards to advanced multi-layer and hybrid assemblies. With two standard copper weight options—1 oz (35 µm) and 2 oz (70 µm)—we help you balance current carrying capacity and signal loss based on your application needs.

We also offer two standard thicknesses: 25 mils (0.635 mm) and 50 mils (1.27 mm), providing further flexibility in impedance control and mechanical design. Our production facilities can accommodate boards up to 400 mm×500 mm in size, making us well-equipped for both compact modules and larger form-factor designs.

To enhance assembly compatibility and end-use performance, we provide a wide selection of solder mask colors (including green, black, blue, yellow, and red) and a comprehensive range of surface finishes such as HASL, immersion silver, immersion gold, ENEPIG, OSP, and bare copper.

Key Application Areas

Rogers RO3210 PCBs are widely employed in industries where high frequency, thermal stability, and signal integrity are non-negotiable. Common applications include:

-

Automotive radar and collision avoidance systems

-

GPS antennas and telematics modules

-

Wireless infrastructure including 5G base stations

-

Microstrip and patch antennas for communication systems

-

Direct broadcast satellite (DBS) receivers

Other RF and microwave circuits requiring stable performance under varying operating conditions

Partner with a Specialist

If you are looking for a reliable PCB supplier with expertise in high-frequency materials like Rogers RO3210, we invite you to collaborate with us. We provide end-to-end support—from material selection and design advice to manufacturing and testing—ensuring that your boards meet the highest standards of performance and reliability.

Contact us today to discuss your project requirements and discover how RO3210 can enhance your next high-frequency PCB design.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com