What Makes the Rogers

RO4003C PCB Stand Out from the Crowd?

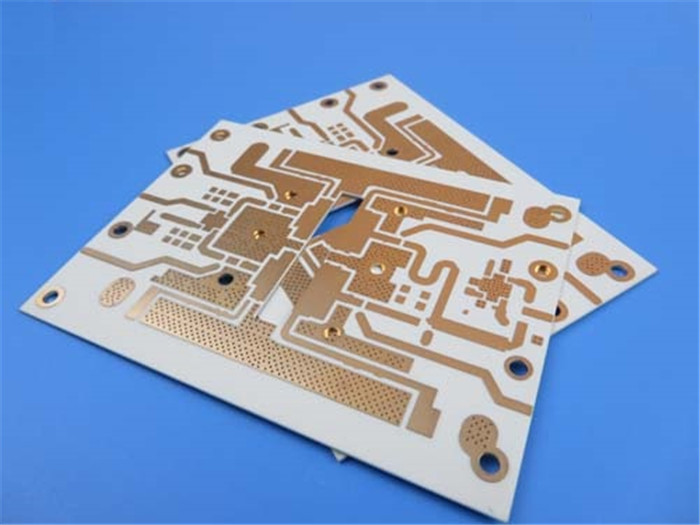

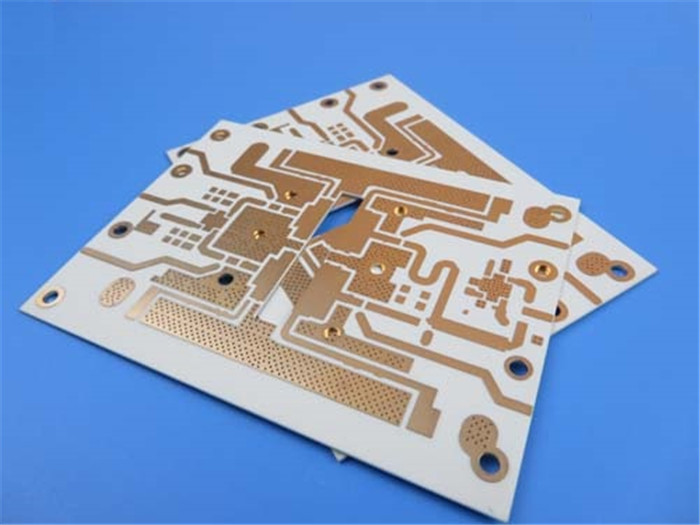

When

it comes to finding a reliable and high-quality PCB material, the 32 mil Rogers

RO4003C material PCB stands out as an exceptional choice. This article will

explore this advanced PCB material and provide insight into its features,

benefits, and technical specifications.

Features and Benefits of the Rogers RO4003C PCB

The

Rogers RO4003C PCB has a minimum trace/space of 6/7 mils, a finished board

thickness of 0.98 mm, and a finished Cu weight of 1 oz (1.4 mils) for all

layers. Its surface finish is ENIG (Electroless Nickel and Immersion Gold), and

it has no silkscreen on solder pads. This PCB has undergone a 100% electrical

test, and slotted holes are plated through according to Gerber. The panelized

solder paste stencil is supplied for the top side, and there are no blind or

buried vias. Additionally, the Rogers RO4003C PCB has impressive component and

pad counts, with 97 components, 163 total pads, 15 thru-hole pads, 67 top SMT

pads, and 81 bottom SMT pads. It also has 100 vias and 70 nets, making it a

versatile and efficient board for a wide range of applications.

Technical Specifications of the Rogers RO4003C PCB

The Rogers RO4003C substrate has a dielectric constant of 3.38±0.05 and a

dissipation factor tan, δ of "0.0027/0.0021" at 10 GHz/23℃and 2.5

GHz/23℃,

respectively. Its thermal coefficient of ε is +40 ppm/℃within the

range of -50℃ to 150℃,

and its volume resistivity is 1.7 x 1010 MΩ.cm (COND A). The surface

resistivity is 4.2 x 109 MΩ (COND A), and the electrical strength is 31.2(780)

Kv/mm (v/mil) at 0.51mm (0.020") thickness. The PCB has a Tg of >280℃TMA (A) and

a Td of 425℃TGA, making it suitable for high-temperature applications. Its thermal

conductivity is 0.71 W/M/K at 80℃, and its moisture

absorption is 0.06% after 48hrs immersion at 50℃. The density is 1.79

gm/cm3 at 23℃,

and the copper peel strength is "1.05 (6.0)" N/mm (pli) after solder

float with 1 oz. EDC Foil.

Impedance Matching and Design Guidelines for the Rogers

RO4003C PCB

While

the Rogers RO4003C PCB does not come with impedance matching, it can support a

range of design features, including blind and buried vias, controlled

impedance, and fine pitch components. Designers should follow design guidelines

to ensure optimal performance and reliability. The PCB is compatible with

lead-free processes and can be manufactured using standard PCB fabrication

techniques.

Applications of the Rogers RO4003C PCB

The

Rogers RO4003C PCB is suitable for a wide range of applications, including

wireless infrastructure, aerospace and defense, automotive, and industrial

automation. Its high-temperature range and excellent electrical properties make

it ideal for high-frequency applications and harsh environments.

Manufacturing Process and Lead-Free Compatibility of the

Rogers RO4003C PCB

The

Rogers RO4003C PCB is manufactured using a lead-free process, making it

environmentally friendly and compliant with ROHS and WEEE regulations. Standard

PCB fabrication techniques can be used to manufacture and assemble this PCB.

In

conclusion, the high-performance Rogers RO4003C PCB is a versatile and can provide superior results for a wide range of applications. Its

advanced features, excellent electrical properties, and lead-free compatibility

make it an ideal choice for designers and manufacturers looking for reliable

and high-quality PCB material. Choose the Rogers RO4003C PCB for your next

project and experience the difference it can make.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com