What Makes TMM3 the Superior Choice for Stable and Efficient Microwave PCBs?

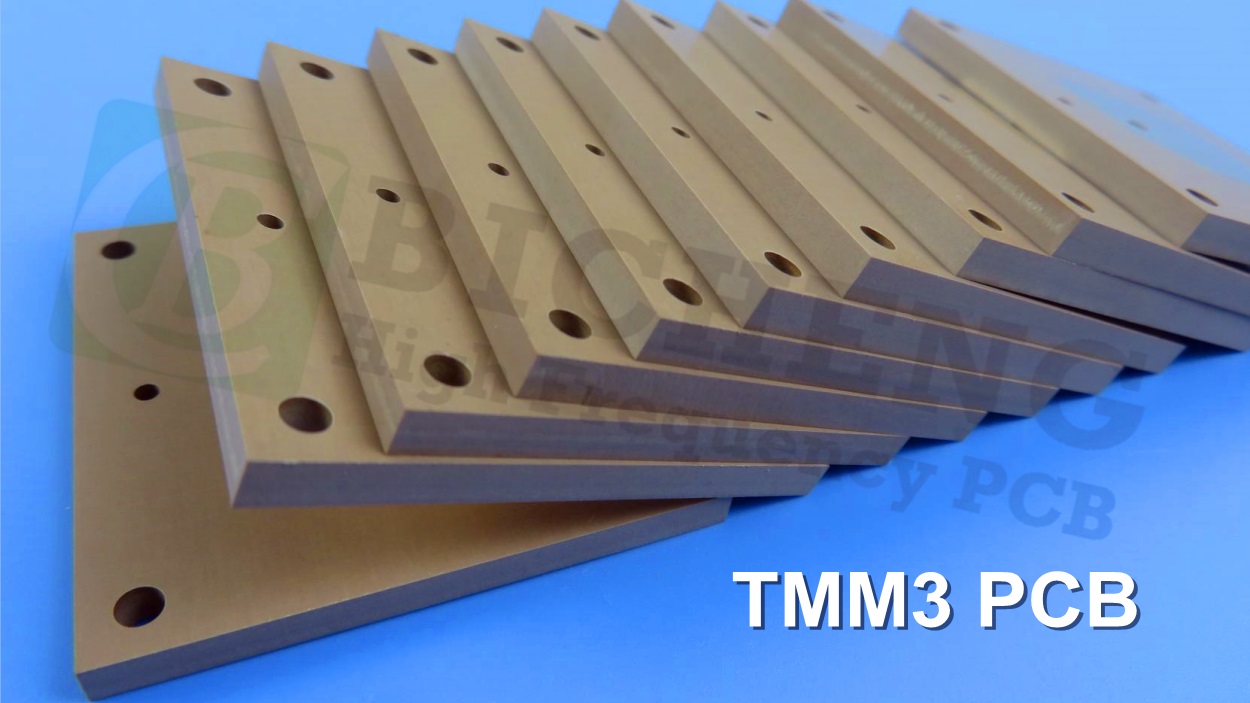

In the high-stakes realm of RF and microwave electronics, the choice of printed circuit board (PCB) substrate is a critical determinant of overall system performance, reliability, and manufacturability. For engineers and designers working on cutting-edge communication and radar systems, selecting a material that delivers consistent electrical properties, robust mechanical integrity, and streamlined processing is paramount. This is where Rogers Corporation's TMM3 thermoset microwave laminate distinguishes itself as an exceptional solution. Specifically engineered for strip-line and micro-strip applications where unparalleled plated through-hole reliability is non-negotiable, TMM3 represents a significant advancement in PCB material technology.

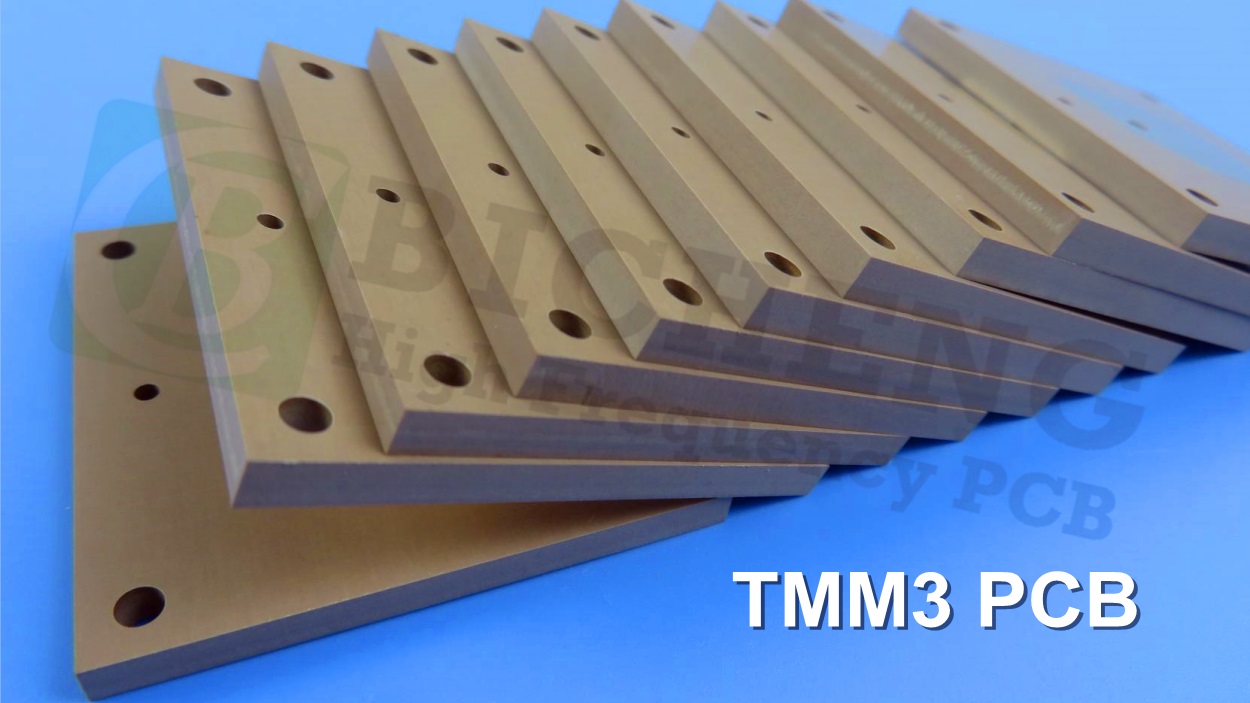

Rogers TMM3 is a ceramic thermoset polymer composite that masterfully combines the most desirable characteristics of both ceramic-based materials and traditional PTFE (Polytetrafluoroethylene) microwave laminates. This unique hybrid formulation effectively eliminates the need for the complex and often challenging production techniques typically associated with these material families. By leveraging a robust thermoset resin system,TMM3PCBlaminates guarantee exceptional reliability for sensitive processes like wire-bonding, effectively mitigating common failure modes such as pad lifting or substrate deformation that can plague other materials. This inherent stability provides designers with greater confidence and extends the operational lifespan of the final product.

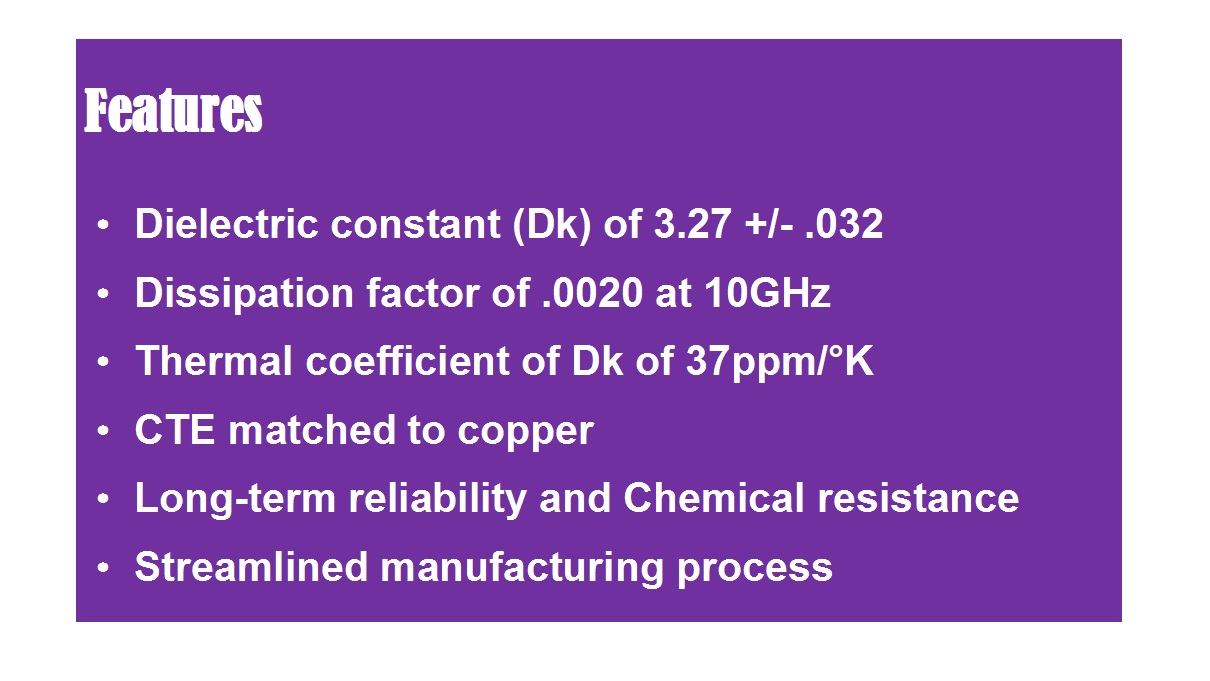

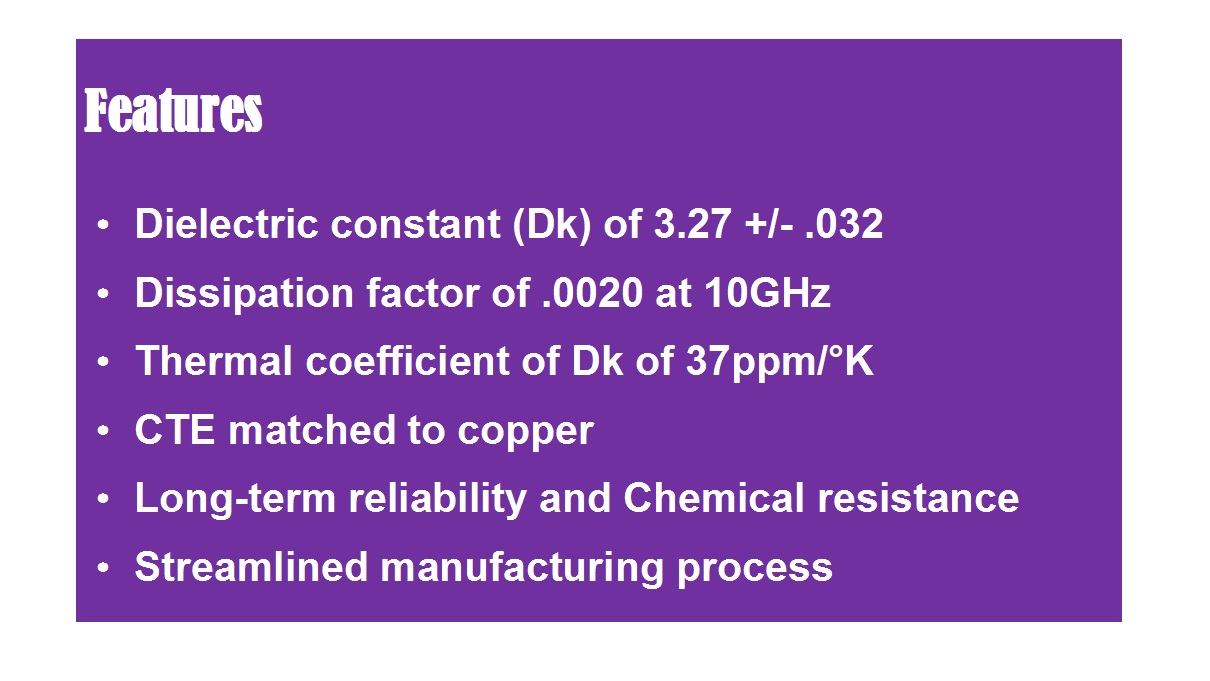

Unmatched Electrical Performance and Thermal Stability

The cornerstone of TMM3's superiority lies in its precisely controlled and stable electrical properties. The laminate possesses a dielectric constant (Dk) of 3.27 with an exceptionally tight tolerance of +/- 0.032. This consistency ensures predictable and precise signal transmission across the board, which is vital for maintaining signal integrity in high-frequency designs. Furthermore, TMM3 exhibits an extremely low dissipation factor (Df) of just 0.0020 at 10 GHz. This minimal signal loss translates into highly efficient and effective communication within the circuitry, maximizing power transfer and minimizing heat generation.

Performance under thermal stress is another area where TMM3 excels. Its thermal coefficient of dielectric constant is a low 37 ppm/°K, meaning the electrical properties remain stable even when operating in environments with fluctuating temperatures. This stability is crucial for applications that cannot tolerate frequency drift. Complementing this, the coefficient of thermal expansion (CTE) of TMM3 is expertly matched to that of copper. This precise matching significantly reduces mechanical stresses at the copper-substrate interface during thermal cycling, thereby preventing delamination and enhancing the long-term reliability of plated through-holes.

Enhanced Mechanical Robustness and Streamlined Fabrication

Beyond its electrical prowess, TMM3 PCB offers outstanding mechanical properties that contribute to its durability. The material is highly resistant to creep and cold flow, ensuring dimensional stability and long-term reliability under mechanical load. It also demonstrates excellent resistance to a wide range of process chemicals used in standard PCB fabrication, reducing the risk of damage during manufacturing and ensuring a higher yield.

A significant advantage for PCB manufacturers is that TMM3 eliminates the need for a sodium napthanate treatment step prior to electroless copper plating. This not only simplifies the production workflow but also reduces processing time and associated costs, making it a more economical choice without compromising on quality or performance.

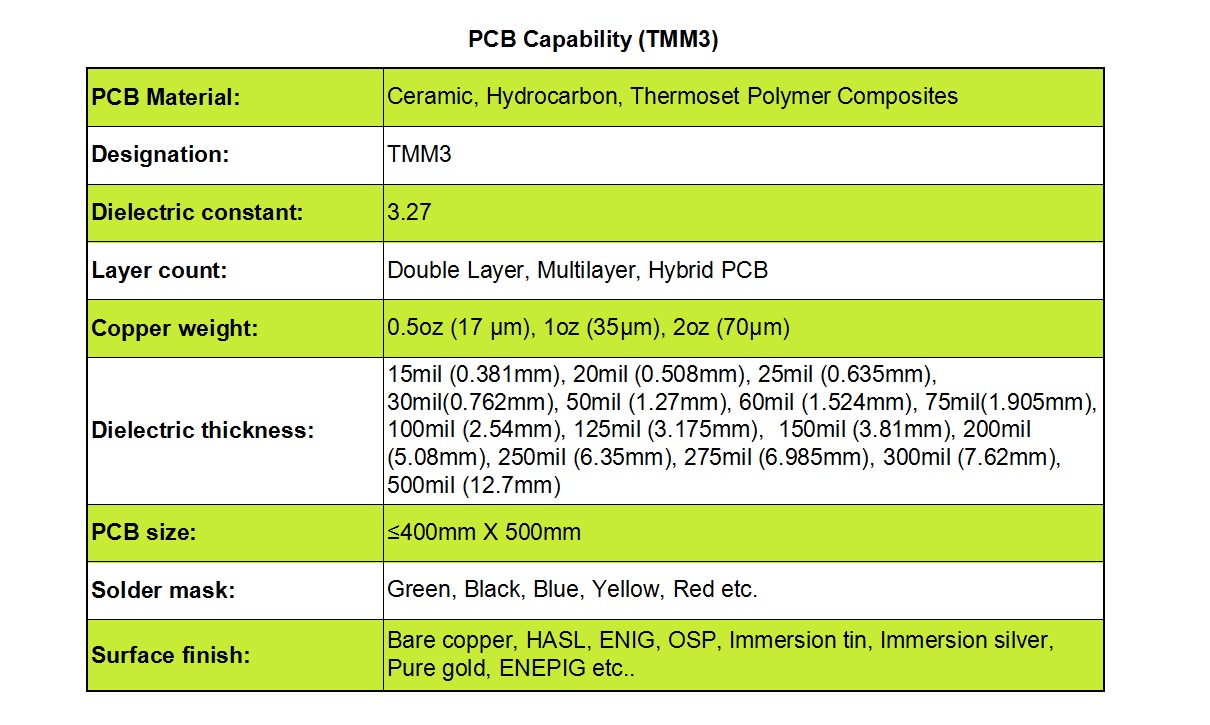

Comprehensive PCB Capabilities to Meet Your Design Needs

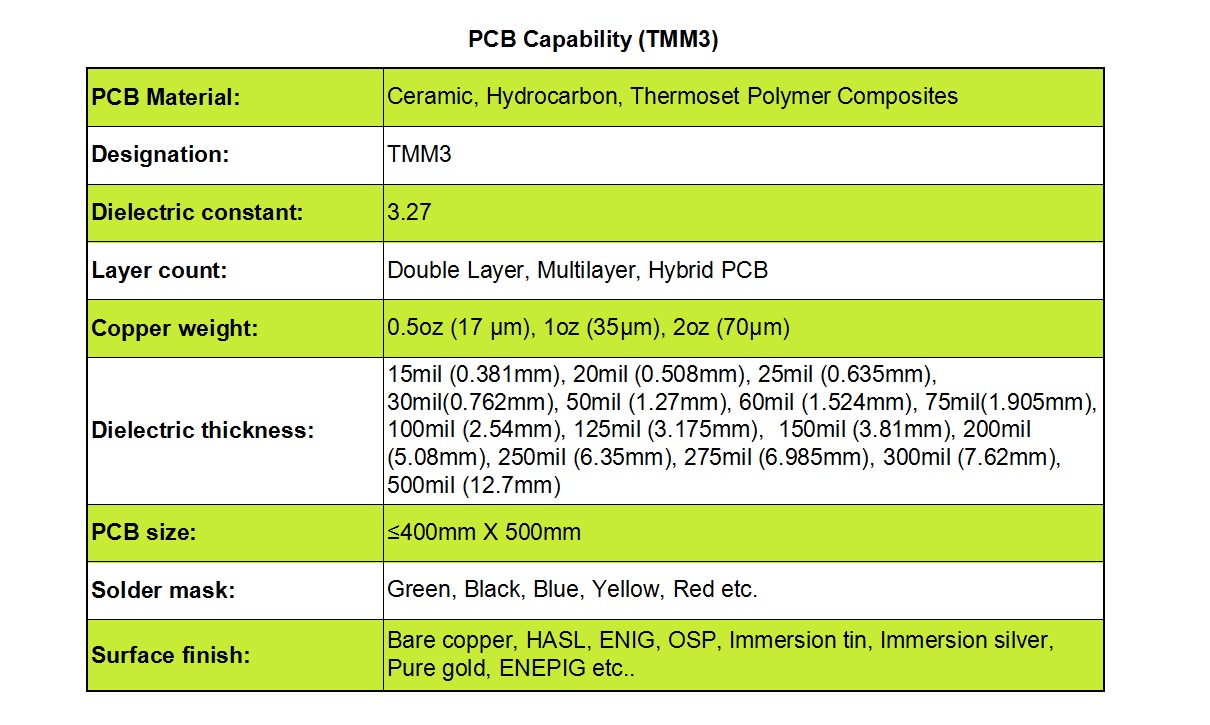

As a leading PCB supplier, we are equipped to fully leverage the benefits ofTMM3PCBmaterial to meet your specific project requirements. Our manufacturing capabilities are designed to offer maximum flexibility:

1) Layer Configurations: We provide double-layer, multilayer, and hybrid PCB constructions.

2) Copper Weights: Choose from 0.5oz (17µm), 1oz (35µm), or 2oz (70µm) to achieve optimal conductivity for your application.

3) Board Thickness: We cater to diverse needs with thickness options ranging from a slender 15mil (0.381mm) to a substantial 500mil (12.7mm).

4) Panel Size: We can accommodate designs up to a maximum size of 400mm x 500mm.

5) Aesthetics and Protection: A variety of solder mask colors (green, black, blue, yellow, red) and surface finishes (HASL, ENIG, OSP, Immersion Tin, Immersion Silver, Pure Gold, ENEPIG) are available.

Diverse Application Spectrum

The unique combination of properties makes TMM3 Microwave PCBs ideally suited for a broad spectrum of high-frequency applications. These include:

-

RF and Microwave Circuitry

-

Power Amplifiers and Combiners

-

Filters and Couplers

-

Satellite Communication Systems

-

Global Positioning System (GPS) Antennas

-

Patch Antennas

-

Dielectric Polarizers and Lenses

-

Chip and Circuit Testers

In conclusion,TMM3 high frequency PCBs stands as a superior microwave PCB material that successfully bridges the gap between high performance, exceptional reliability, and manufacturability. Its stable electrical characteristics, thermal resilience, and mechanical durability make it an intelligent choice for demanding applications across the telecommunications, aerospace, and defense industries.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com