Exploring the Advanced Capabilities and Benefits of RF-10 High Frequency PCB Manufacturing

In the rapidly evolving world of electronics, the demand for high-frequency printed circuit boards (PCBs) that deliver exceptional performance and reliability is greater than ever. For engineers and designers working on cutting-edge RF applications, selecting the right laminate material is a critical decision that directly impacts the success of a project. This is where RF-10 High Frequency PCBs excel, offering a superior combination of electrical, thermal, and mechanical properties tailored for high-performance needs.

Superior Material Composition for Optimal Electrical Performance

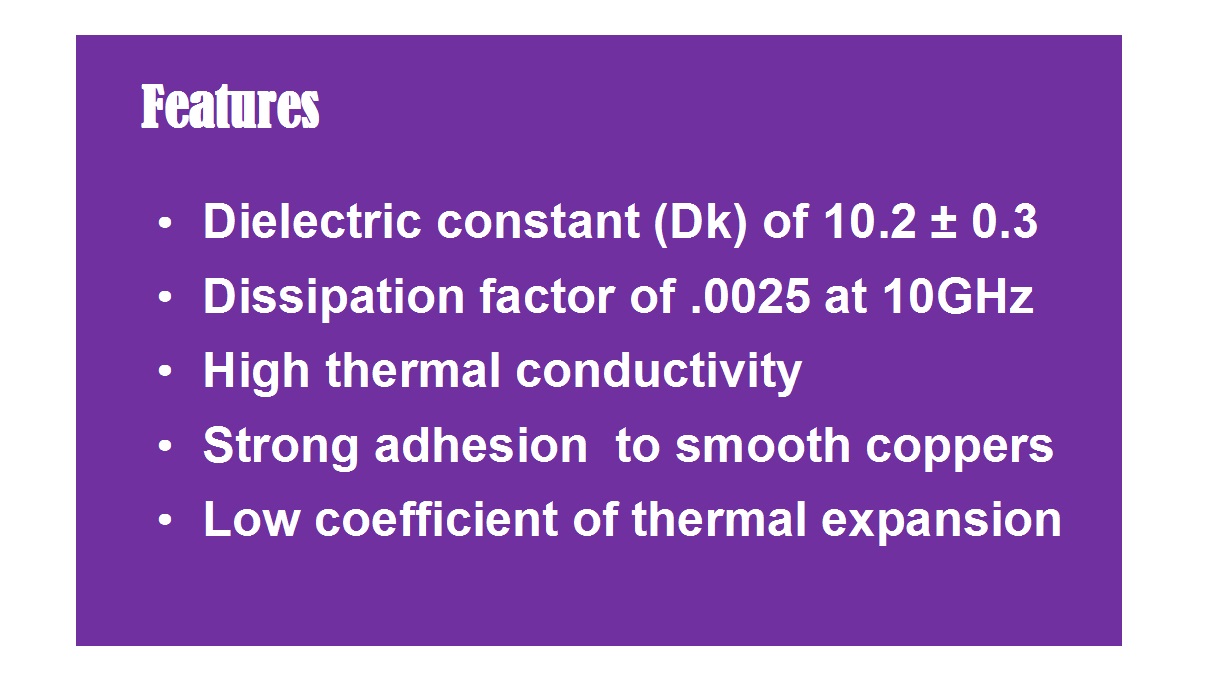

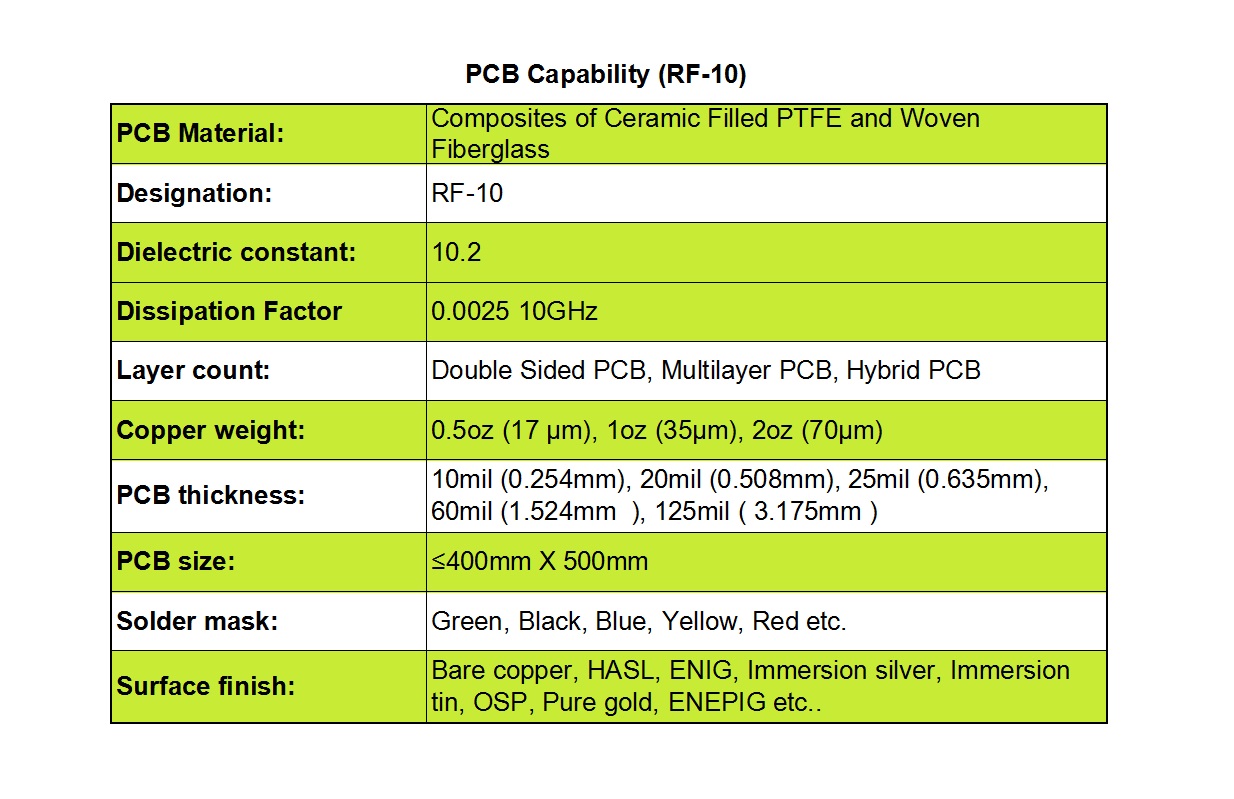

Taconic RF-10 laminates are engineered from an advanced composite material that integrates ceramic-filled Polytetrafluoroethylene (PTFE) with a fine woven fiberglass reinforcement. This specific formulation is pivotal to achieving outstanding high-frequency characteristics. The primary advantage lies in its high dielectric constant (Dk) of 10.2±0.3, coupled with an exceptionally low dissipation factor (Df) of 0.0025 at 10 GHz. This high Dk value PCB is a significant benefit for RF circuit design, as it allows for a substantial reduction in the physical size of the circuits without compromising performance. Simultaneously, the ultra-low loss tangent ensures minimal signal attenuation, preserving signal integrity and quality even at high frequencies, which is paramount for sensitive RF and microwave systems.

The inclusion of thin woven fiberglass does more than just minimize dielectric loss; it significantly enhances the laminate's rigidity and dimensional stability. This improved handling strength is particularly advantageous during the fabrication of complex multilayer circuits, where material stability is crucial for maintaining precise layer-to-layer registration and overall structural integrity.

Exceptional Thermal Management and Dimensional Stability

Effective heat dissipation is a cornerstone of reliable high-frequency operation. RF-10 PCB laminates possess a thermal conductivity of 0.85 W/m·K when unclad, facilitating the efficient transfer of heat away from active components. This inherent thermal management capability helps prevent overheating, ensuring consistent circuit performance and long-term reliability under demanding thermal conditions.

Furthermore,Taconic RF-10 PCB exhibits remarkably low coefficients of thermal expansion (CTE) across all axes: 16 ppm/°C in the X-axis, 20 ppm/°C in the Y-axis, and 25 ppm/°C in the Z-axis. This dimensional stability is a critical factor for the longevity of the PCB. It ensures exceptional reliability for plated through-hole (PTH) connections by minimizing the stress caused by thermal cycling, thereby reducing the risk of barrel cracking. This low CTE also simplifies the design process by reducing the scaling factors typically required for artwork compensation.

Robust Manufacturing Capabilities for Diverse Applications

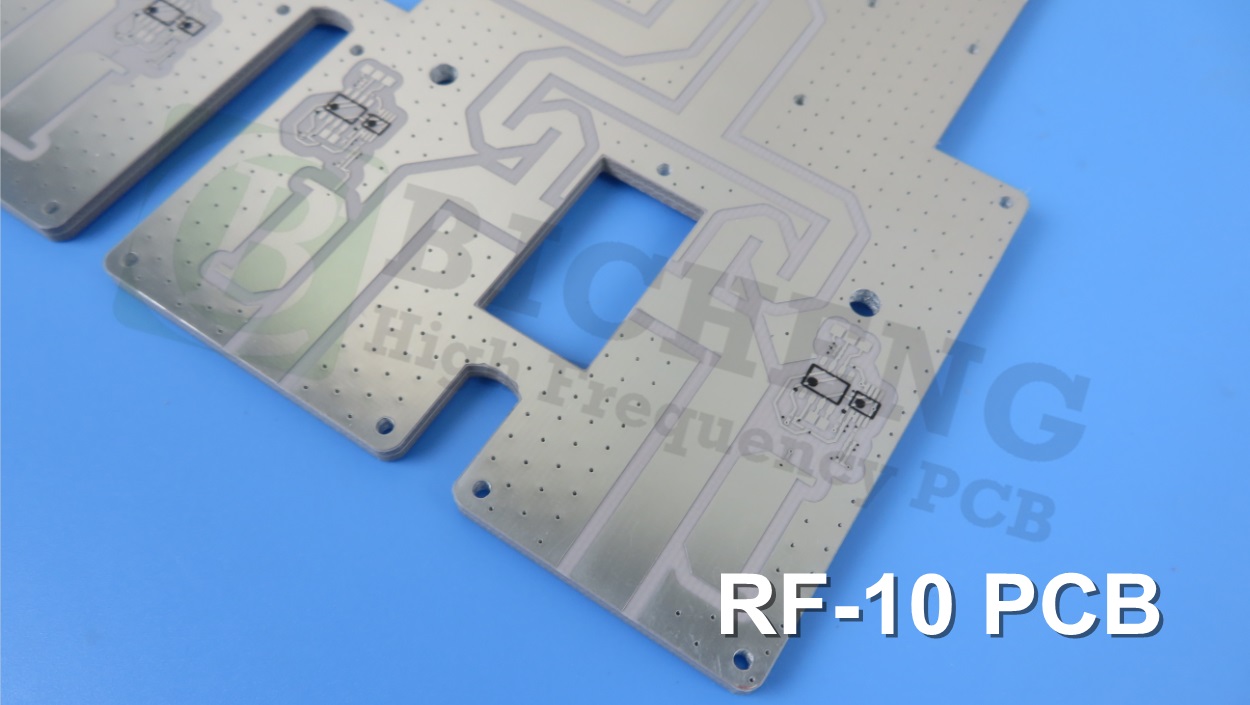

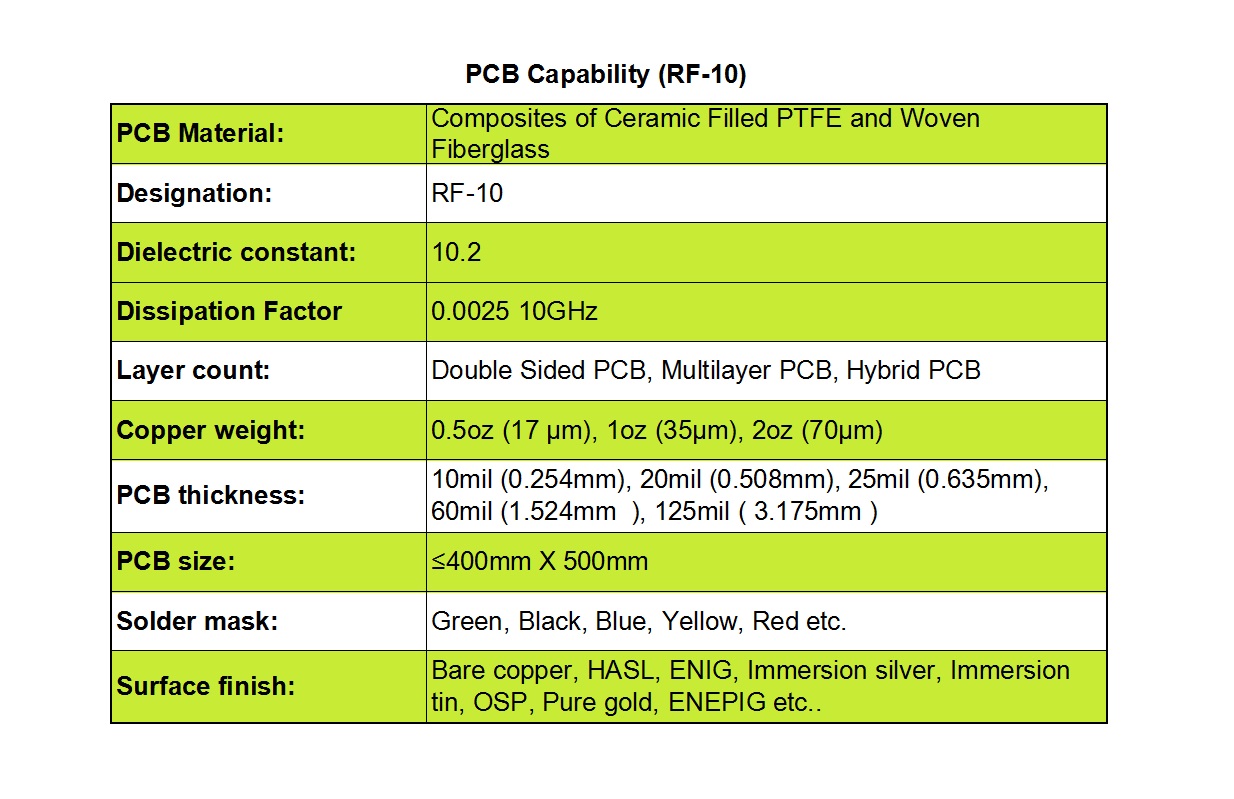

Our manufacturing expertise ensures that RF-10 Taconic RF PCB are produced to the highest standards, catering to a wide range of design complexities. We support the production of double-sided, multilayer, and hybrid PCBs, providing flexibility for various project requirements. Designers can select from a range of copper weights, including 0.5oz (17 µm), 1oz (35µm), and 2oz (70µm), to suit specific current-carrying and thermal needs.

We accommodate diverse PCB thicknesses, such as 10mil, 20mil, 25mil, 60mil, and 125mil, with a maximum board size capability of 400mm x 500mm. To meet both technical and aesthetic requirements, a variety of solder mask colors—including green, black, blue, yellow, and red—are available. The selection of surface finishes is comprehensive, encompassing options like Bare Copper, HASL, ENIG, Immersion Silver, Immersion Tin, OSP, Pure Gold, and ENEPIG, ensuring compatibility with different assembly processes and end-use environments.

Proven Applications in Critical Industries

The unique properties of RF-10 PCBs make them the material of choice for a host of advanced electronic applications. They are extensively used in:

1) Microstrip Patch Antennas and GPS Antennas: Where stable electrical performance and minimal signal loss are non-negotiable.

2) Passive Components: Such as filters and couplers, requiring precise impedance control.

3) Aerospace and Defense Systems:Including aircraft collision avoidance systems, where reliability under extreme conditions is paramount.

4) Satellite Communication Components: Demanding materials that can withstand the rigors of space while maintaining high performance.

In conclusion, RF-10 High Frequency PCBs represent a top-tier solution for engineers pushing the boundaries of RF technology. Their blend of a high dielectric constant, low loss, excellent thermal properties, and outstanding dimensional stability provides a solid foundation for creating robust, high-performance electronic devices. By leveraging our advanced manufacturing capabilities, you can harness the full potential of RF-10 Taconic RF PCB Circuit Board for your most demanding applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com