What's the Features & Bebefits for TC600 PCB?

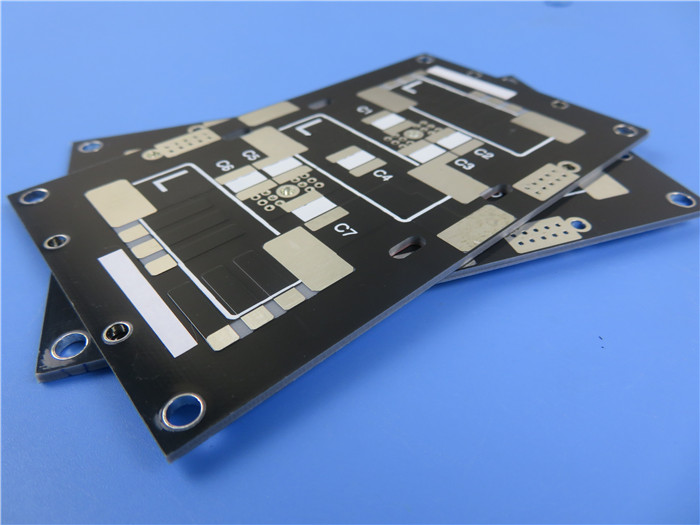

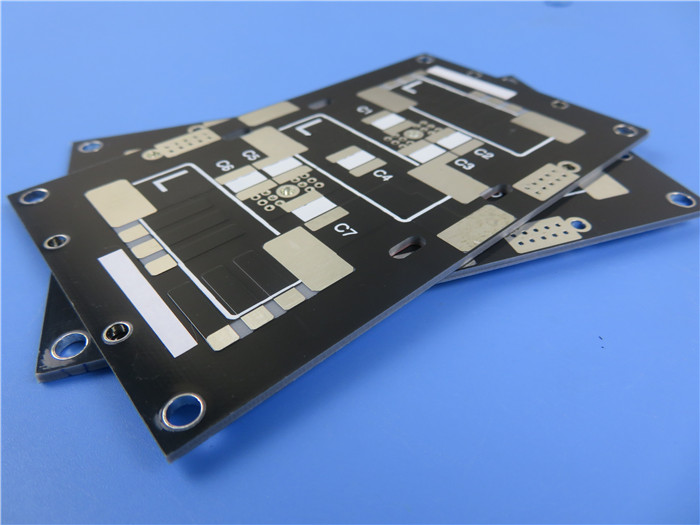

For use as a printed circuit board substrate, the "Best-In-Class" thermal conductivity of the TC600 woven fiberglass reinforced, ceramic filled, PTFE-based composite is intended to improve heat transmission while lowering insertion and dielectric loss. Greater amplifier and antenna gains/efficiencies are produced via lower losses. For the 6.15 dielectric constant market, mechanical robustness has also significantly increased.

Higher power handling, fewer hotspots, and enhanced device dependability are all benefits of the TC600 laminate's greater thermal conductivity. The increased heat transfer within the substrate works in conjunction with designs that incorporate thermal vias, heat sinks, or coins to give designers more flexibility when managing heat. The

Rogers TC600 PCB laminate greatly enhances heat transmission if the main thermal channel is through the laminate in systems with few thermal management choices. As a result, in junction temperatures are decreased, and the lifespan of active components is increased. These effects are crucial for increasing the dependability of power amplifiers, MTBF, and lowering warranty costs. Furthermore, component attachment that is susceptible to solder fatigue, solder softening, and joint failure is more reliably secured by lower operating temperatures and thermal expansion characteristics that match the chip.

Over a wide temperature range, Arlon TC600 PCB laminate provides "Best-in-class" dielectric constant stability. As a result, gain can be maximized and dead bandwidth lost due to dielectric constant drift as operational temperature changes can be minimized in power amplifier and antenna designs. Dielectric constant stability is especially important for phase-sensitive devices, such as network transformers used in power amplifier circuitry for impedance matching networks.

The Z-Direction CTE of TC600 laminate is low. Through-hole plating dependability is unmatched because to this feature. Because TC600 PCB has a "soft substrate," it is relatively impervious to vibration-induced stress. By suspending micro-dispersed ceramics on a comparatively supple, woven fiberglass reinforced PTFE-based substrate, it overcomes the brittleness of thermoset ceramic loaded hydrocarbons or ceramics (such as alumina or LTCC) by the robustness of its design. As a result, RF designers can benefit from minimal loss without sacrificing the mechanical robustness needed to meet the criteria of shock, drop, and impact testing for electronics. Manufacturers of boards choose it because it can be easily cut, drilled, and routed without being susceptible to breaking.

Features:

-

"Best in Class"Thermal Conductivity(1.1W/m-K) and Dielectric Constant Stability across Wide Temperatures (-75 ppm/C)

-

Very Low Loss Tangent provides Higher Amplifier or Antenna Efficiency

-

Mechanically Robust; replaces brittle laminates that cannot withst and processing, impact, or High G forces

-

Priced Affordably for Commercial Applications

-

High Peel Strength for Reliable Narrow Lines

Benefits:

-

Heat Dissipation and Management

-

Replace Ceramic in Some Applications

-

lmproved Processing and Reliability

-

Large Panel Sizes for Multiple Circuit

-

Layout for Lowered Processing Costs

Typical Applications:

-

Power Amplifiers, Filters and Couplers

-

Microwave Combiner and Power Divider Boards in Avionics Applications

-

Small Footprint Antennas

-

Digital Audio Broadcasting(DAB) Antennas(Satellite Radio)

-

GPS & Hand-held RFID Reader Antennas

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com