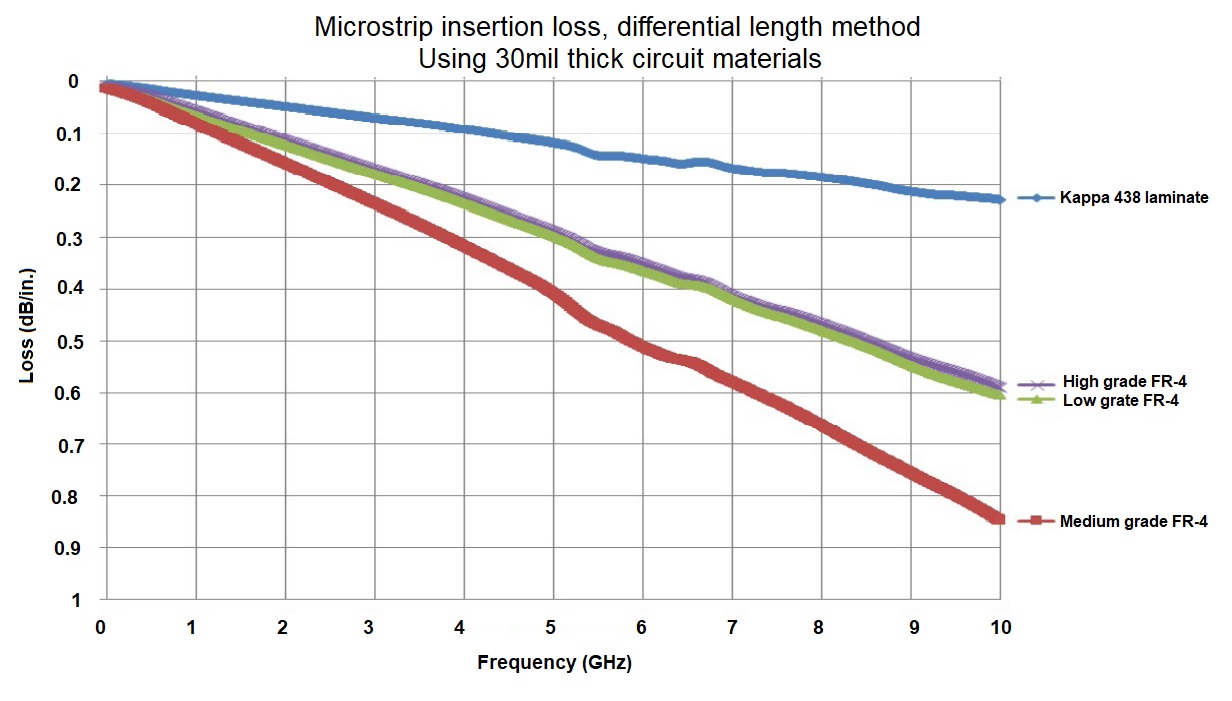

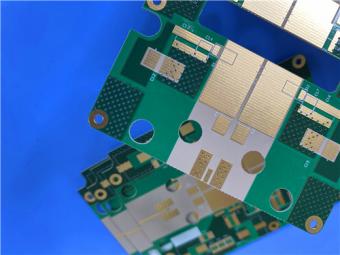

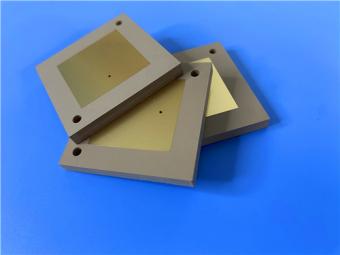

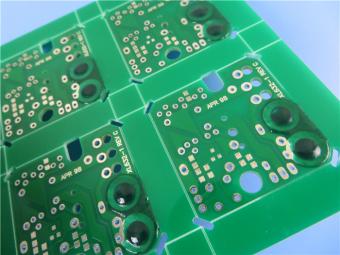

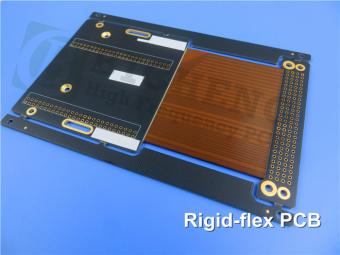

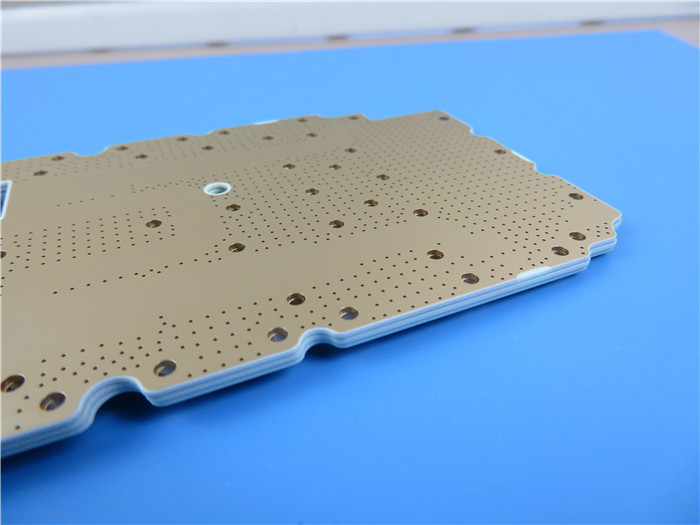

Kappa 438 High Frequency Printed Circuit

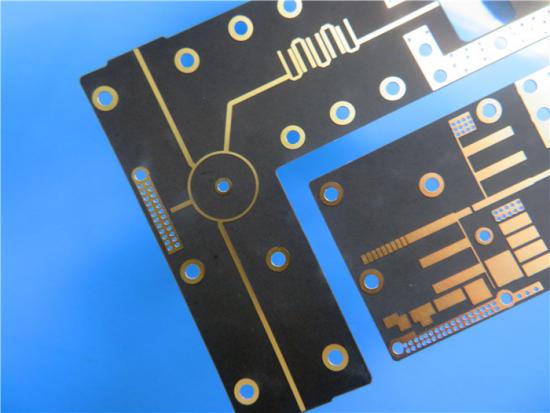

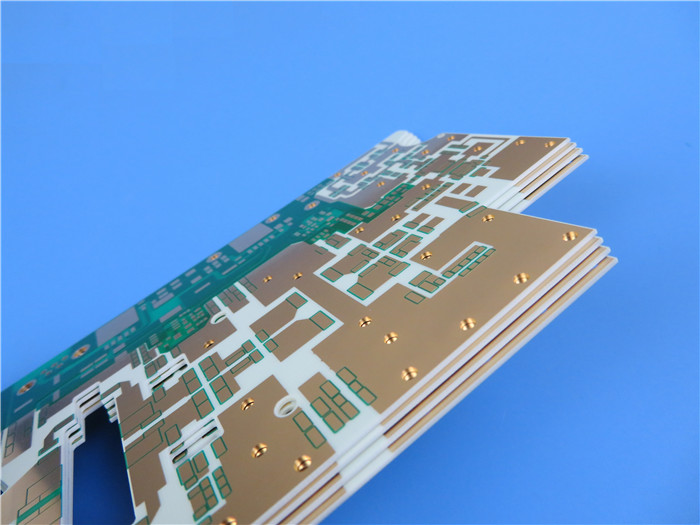

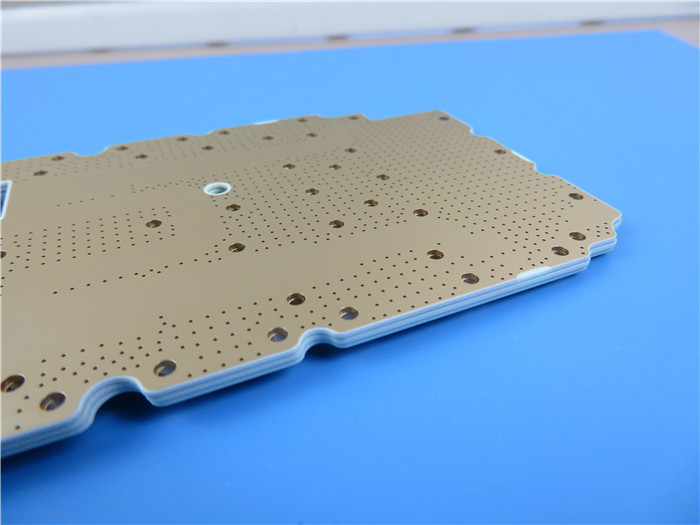

Board Rogers 20mil 0.508mm DK 4.38 PCB with Immersion Gold

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

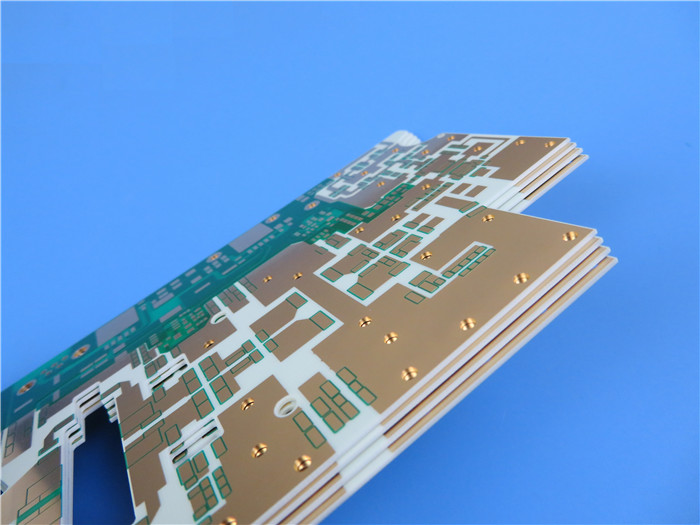

Kappa 438 laminates also have the UL 94

V-0 flame retardant rating and are lead free solder process compatible.

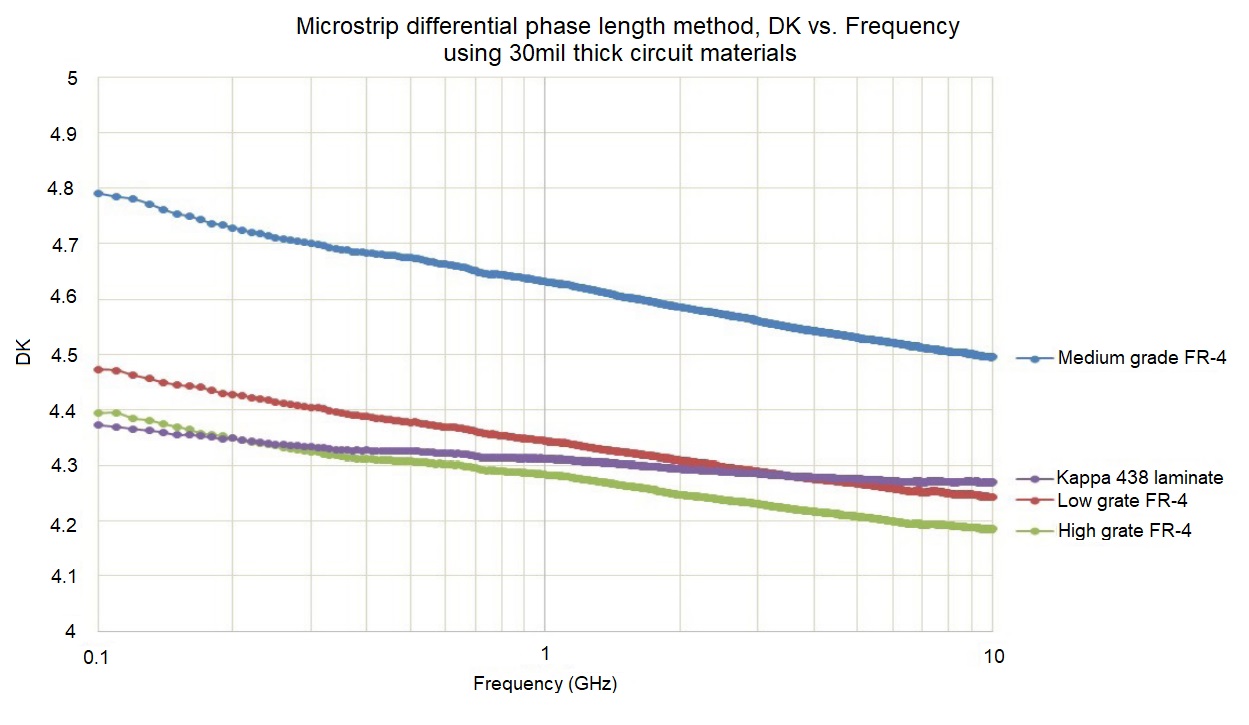

Kappa

438 laminates offer dielectric constants (Dk) tailored to FR-4 industry

standard norms which facilities ease of converting existing FR-4 designs where

better electrical performance is needed.

Features:

1.

Glass reinforced hydrocarbon thermoset platform

2.

Dk of 4.38 is tailored to FR-4 industry standard norms

3.

Tighter Dk and thickness tolerance than FR-4

4.

Low Z Axis CTE of 42 ppm/°C

5.

High Tg of > 280°C TMA

6.

Meets UL 94-V0 requirements

Benefits:

1.

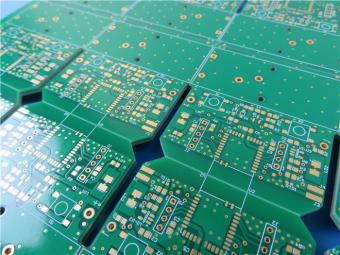

Ease of PCB manufacturing and assembly in Line with FR-4

2.

Design Dk enables ease of converting existing FR-4 designs needing better

electrical performance

3.

Consistent circuit performance

4.

Improved design flexibility and plated through-hole reliability

5.

Automated assembly compatible

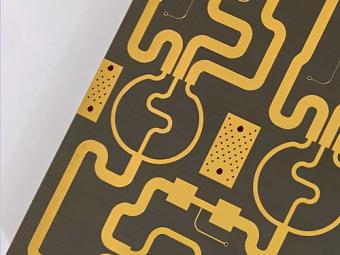

Typical Applications:

1.

Carrier Grade WiFi/Licensed Assisted Access (LAA)

2.

Small Cell and Distributed Antenna Systems (DAS)

3.

Vehicle to Vehicle/Vehicle to Infrastructure Communications (V2X)

4.

Internet of Things (IoT)

Segments:

Smart Home and Wireless Meters

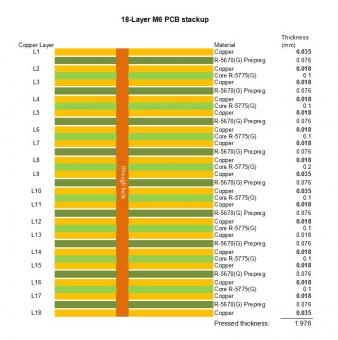

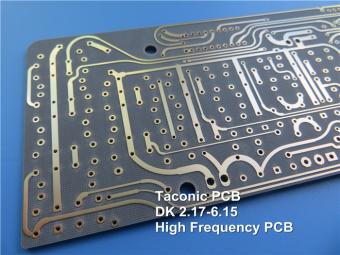

Our PCB Capability (Kappa 438):

|

PCB

Material:

|

Glass

Reinforced Hydrocarbon Ceramic

|

|

Designation:

|

Kappa 438

|

|

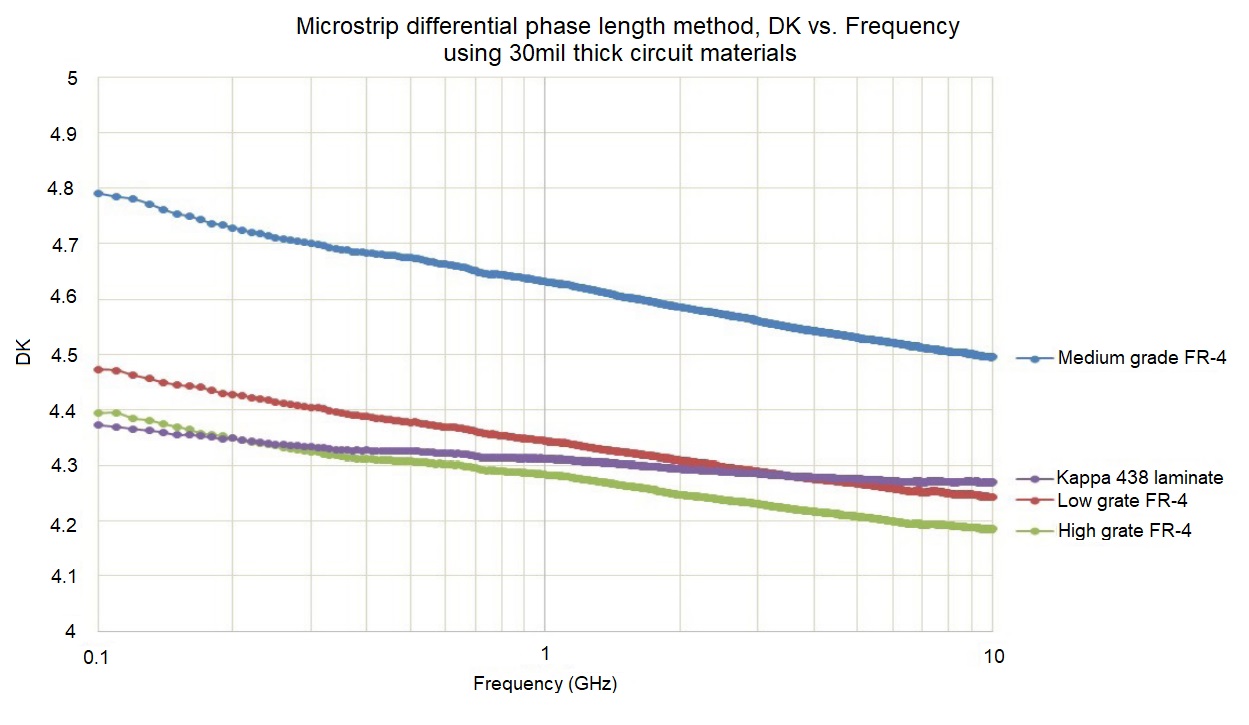

Dielectric constant:

|

4.38

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm)

|

|

PCB thickness:

|

20mil (0.508mm), 30mil (0.762mm), 40mil

(1.016mm), 60mil (1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG, OSP etc..

|

Data Sheet of Kappa 438 Laminate:

|

Property

|

Typical Value

Kappa 438

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant, er Design

|

4.38

|

Z

|

-

|

2.5 GHz

|

Differential Phase

Length Method

|

|

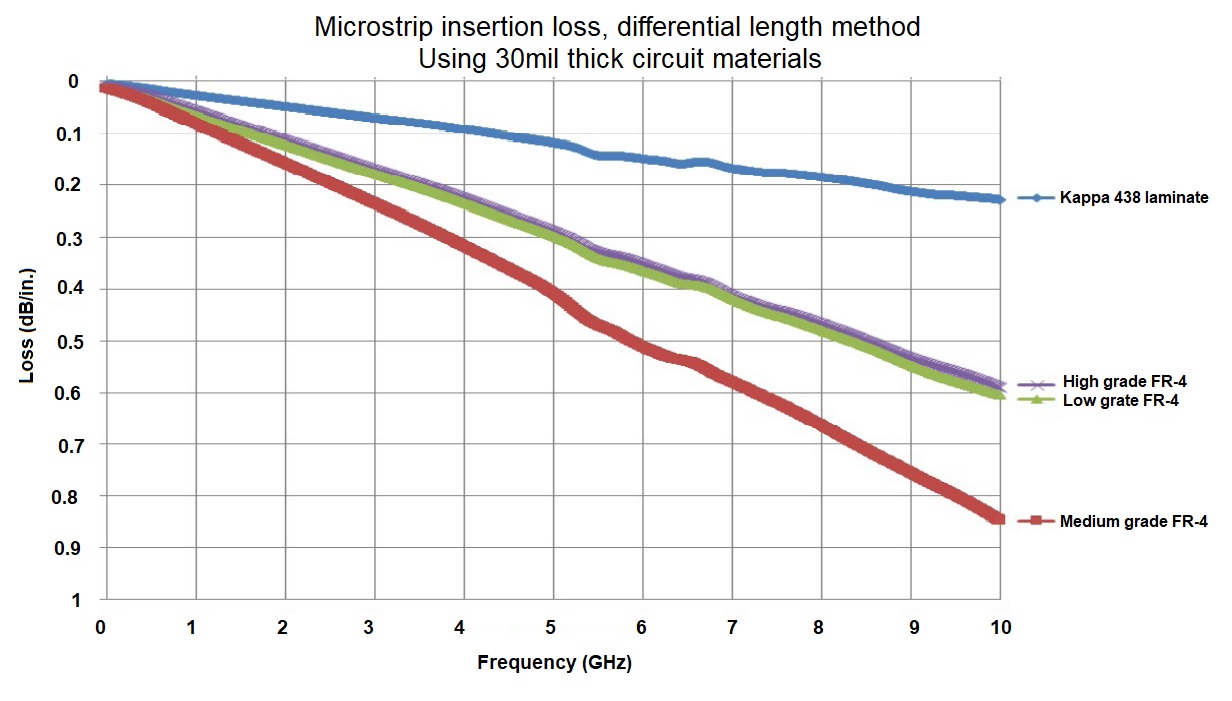

Dissipation Factor tan, d

|

0.005

|

Z

|

-

|

10 GHz/23°C

|

IPC-TM-650 2.5.5.5

|

|

Thermal Coefficient of Dielectric Constant e

|

-21

|

-

|

ppm/°C

|

10

GHz (-50 to 150°C)

|

Modified IPC-TM-650

2.5.5.5

|

|

Volume Resistivity

|

2.9

x 109

|

-

|

MΩ•cm

|

COND A

|

IPC-TM-650 2.5.17.1

|

|

Surface

Resistivity

|

6.2

x 107

|

-

|

MΩ

|

COND A

|

IPC-TM-650 2.5.17.1

|

|

Electrical

Strength

|

675

|

Z

|

V/mil

|

-

|

IPC-TM-650 2.5.6.2

|

|

Tensile

Strength

|

16 12

|

MD CMD

|

kpsi

|

-

|

ASTM D3039/D3039-14

|

|

Flexural

Strength

|

25 19

|

MD CMD

|

kpsi

|

-

|

IPC-TM-650 2.4.4

|

|

Dimensional

Stability

|

-0.48-0.59

|

MD CMD

|

mm/m

|

-

|

IPC-TM-650 2.4.39a

|

|

Coefficient of Thermal Expansion

|

13

|

X

|

ppm/°C

|

-55 to 288°C

|

IPC-TM-650 2.4.41

|

|

16

|

Y

|

|

42

|

Z

|

|

Thermal

Conductivity

|

0.64

|

Z

|

W/(m.K)

|

80°C

|

ASTM D5470

|

|

Time to Delamination (T288)

|

>60

|

-

|

minutes

|

288°C

|

IPC-TM-650 2.4.24.1

|

|

Tg

|

>280

|

-

|

°C TMA

|

-

|

IPC-TM-650 2.4.24.3

|

|

Td

|

414

|

-

|

°C

|

-

|

IPC-TM-650 2.3.40

|

|

Moisture

Absorption

|

0.07

|

-

|

%

|

24/23

|

IPC-TM-650 2.6.2.1

|

|

Young’s

Modulus

|

2264

2098

|

MD CMD

|

kpsi

|

-

|

ASTM D3039/D3039-14

|

|

Flex Modulus

|

2337

2123

|

MD CMD

|

kpsi

|

-

|

IPC-TM-650 2.4.4

|

|

Bow

|

0.03

|

-

|

%

|

-

|

IPC-TM-650 2.4.22C

|

|

Twist

|

0.08

|

-

|

%

|

-

|

IPC-TM-650 2.4.22C

|

Copper Peel Strength After Thermal Stress

|

5.8

|

-

|

lbs/in

|

1

oz (35 µm) foil

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

-

|

-

|

-

|

UL 94

|

|

Specific

Gravity

|

1.99

|

-

|

g/cm3

|

-

|

ASTM D792

|

|

Lead-Free Process Compatible

|

Yes

|

-

|

-

|

-

|

|

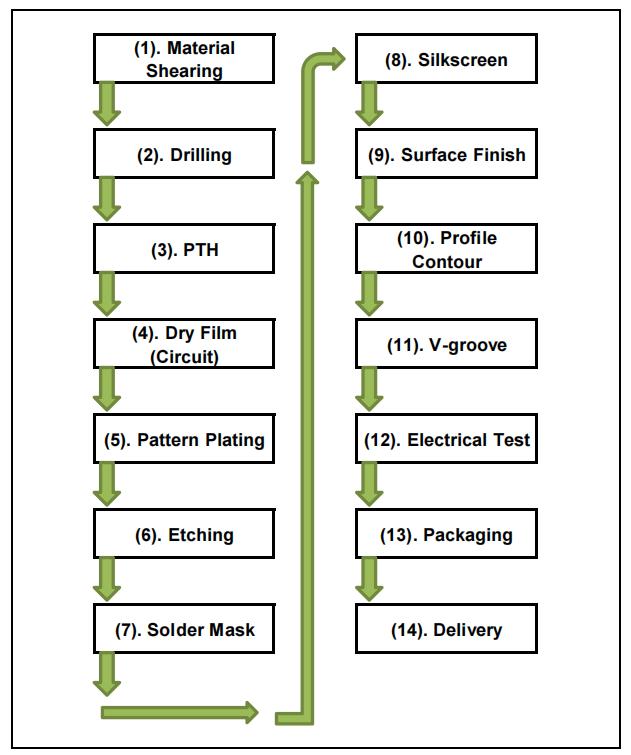

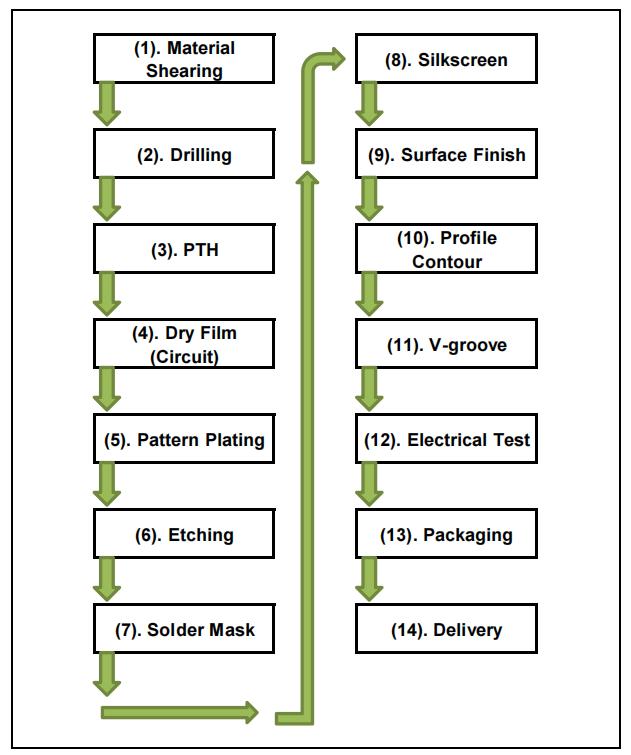

PCB MANUFACTURING PROCESS:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com