What Should You Know About Manufacturing PCBs with Rogers DiClad 880 Material?

In the demanding world of high-frequency electronics, the choice of printed circuit board (PCB) substrate is a critical determinant of performance, reliability, and signal integrity. For engineers and designers working on cutting-edge RF and microwave applications, Rogers Corporation’s DiClad 880 high frequency laminate stands out as a superior PTFE-based composite solution. This blog delves into the unique properties, manufacturing capabilities, and diverse applications of DiClad 880, illustrating why it is an ideal material for your most challenging projects.

An Overview of DiClad 880 High Frequency Laminates

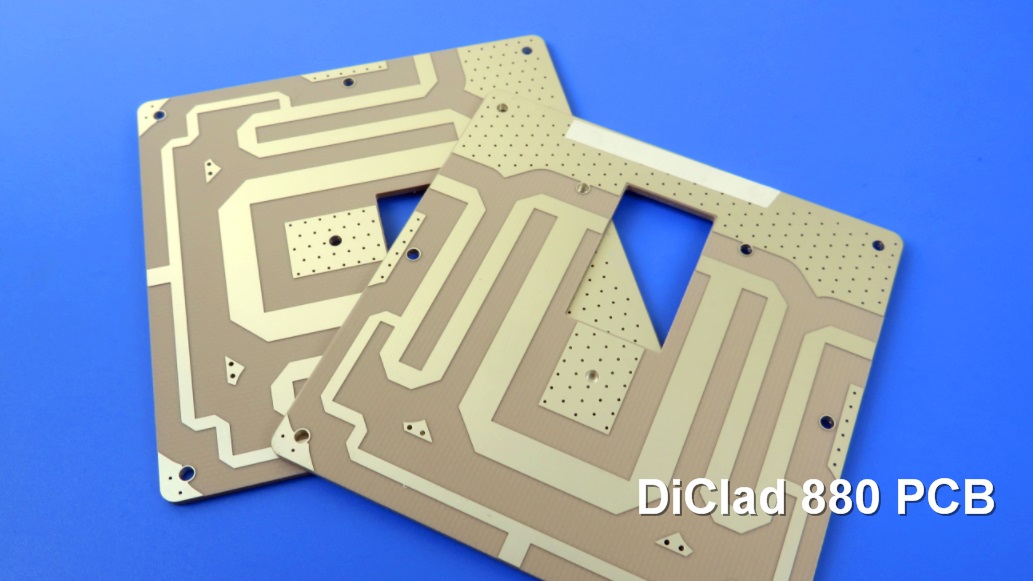

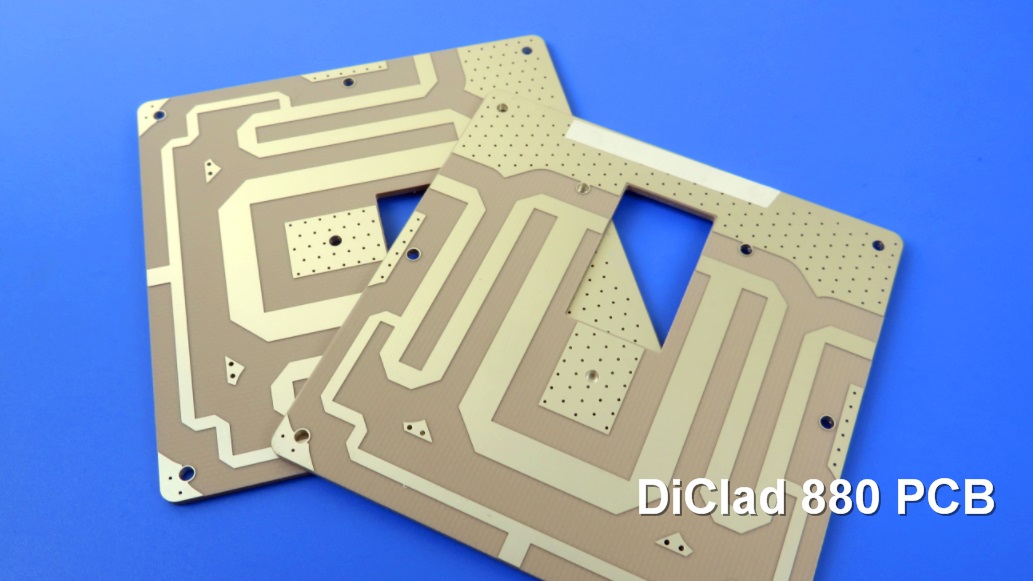

Rogers DiClad 880 PCB is engineered as a polytetrafluoroethylene (PTFE) composite system reinforced with woven fiberglass. What distinguishes it from other laminates is its strategic material composition: by incorporating fewer plies of glass weave and a higher proportion of PTFE, DiClad 880 PCB achieves a reduced dielectric profile even at comparable thickness levels. This design yields two major electrical benefits—a consistently low dielectric constant (Dk) and exceptionally minimal signal loss, making it especially suitable for high-precision, high-speed circuits.

Typical applications include filters, couplers, and low-noise amplifiers where uniform Dk is essential. Moreover, its low-loss characteristics make it highly desirable in power dividers and combiners, among other RF components.

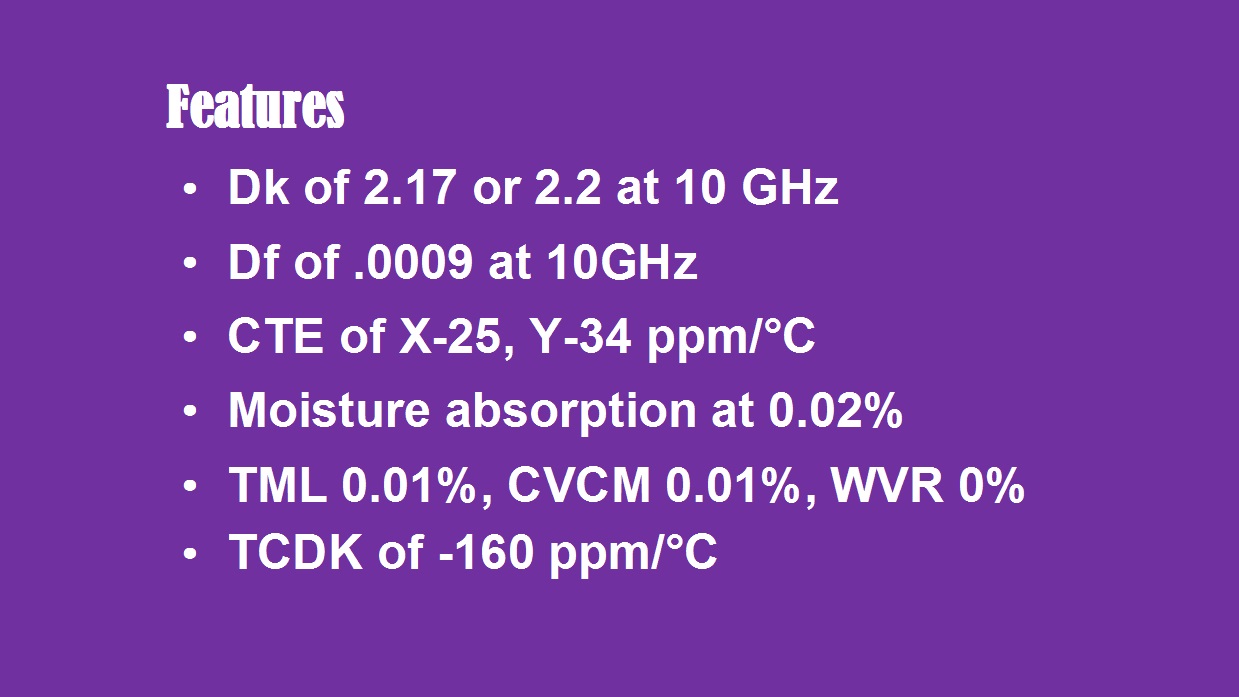

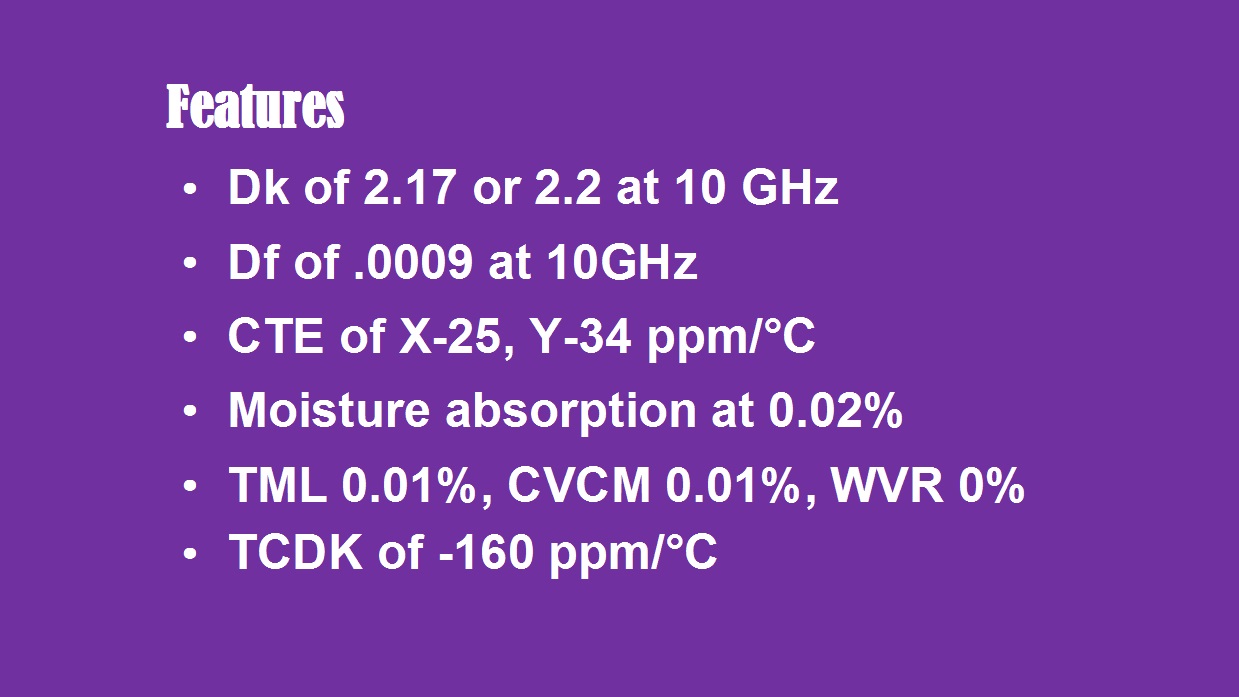

Key Features and Performance Advantages

One of the most defining attributes of DiClad 880 is its stable dielectric constant, available at either 2.17 or 2.20. This low Dk is paired with an ultra-low dissipation factor (loss tangent) of just 0.0009 at 10 GHz—a remarkable achievement for a PTFE-glass hybrid laminate, ensuring high signal fidelity and minimal energy waste in operation.

Beyond electrical performance, DiClad 880 offers outstanding mechanical stability. The woven fiberglass reinforcement significantly improves dimensional stability, outperforming non-woven alternatives with similar Dk values. Its thermal expansion characteristics are well controlled, with a Coefficient of Thermal Expansion (CTE) of 25 ppm/°C in the X-axis and 34 ppm/°C in the Y-axis.

The material also excels in environmental resilience. It absorbs only 0.02% moisture, safeguarding electrical properties in humid conditions, and complies with the UL 94-V0 flammability rating, enhancing end-product safety. Furthermore, DiClad 880 demonstrates exceptional outgassing performance, with a Total Mass Loss of 0.01% and Collected Volatiles of 0.01%, with no water vapor recovery—making it a reliable candidate for aerospace and other high-reliability fields.

It is important, however, to consider certain limitations during the design phase. DiClad 880 has a thermal conductivity of 0.25 W/m/K and a thermal coefficient of dielectric constant (TCDk) of -160 ppm/°C. These values necessitate thoughtful thermal management strategies in high-power or wide-temperature-range applications.

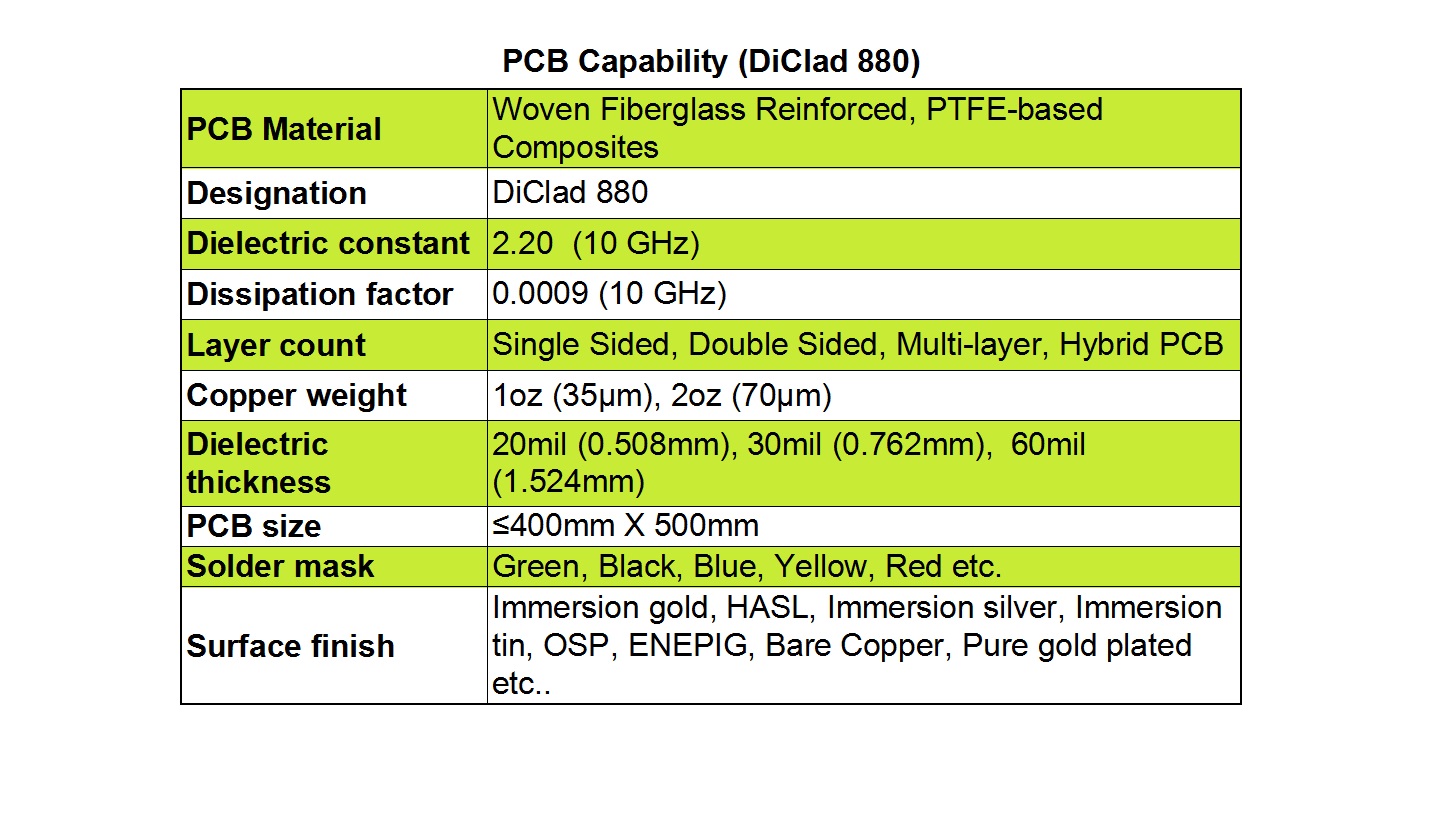

PCB Manufacturing Capabilities with DiClad 880

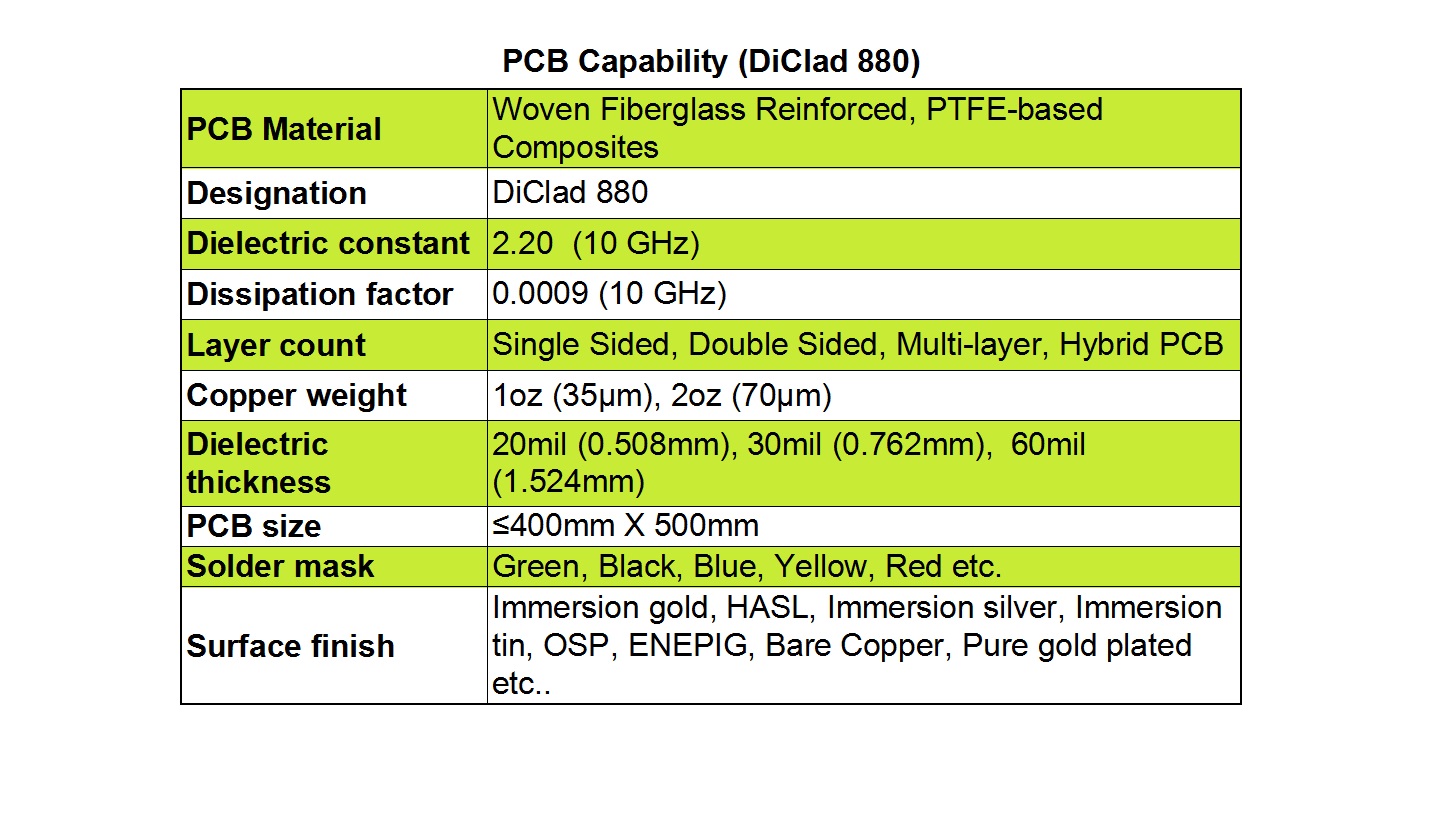

Our manufacturing facilities are fully equipped to produce high-performance PCBs using DiClad 880 laminates, catering to both prototype and volume production needs.

1)Layer Count: We support single-sided, double-sided, multilayer, and hybrid PCB structures.

2)Copper Weights: Standard options include 1 oz (35 µm) and 2 oz (70 µm) to balance current carrying capacity and fine-line etching requirements.

3)Dielectric Thickness: Available in 20 mil (0.508 mm), 30 mil (0.762 mm), and 60 mil (1.524 mm) to meet impedance control and mechanical design specs.

4)Board Dimensions: We can process panels up to 400 mm x 500 mm.

5)Solder Mask: Multiple color options are offered including green, black, blue, yellow, and red for both identification and aesthetic purposes.

6)Surface Finishes: A broad selection is available such as ENIG (Immersion Gold), HASL, Immersion Silver, Immersion Tin, OSP, ENEPIG, bare copper, and gold plating—each providing distinct advantages for solderability, durability, and performance.

Applications of DiClad 880 High Frequency PCBs

Thanks to its outstanding high-frequency characteristics,Rogers DiClad 880 is widely employed across industries where signal loss and stability are non-negotiable. In addition to the uses mentioned earlier, it is often specified in military radar feed networks, commercial phased array antenna systems, low-loss base station antennas, and digital radio antennas. Its blend of electrical excellence and mechanical robustness makes it a future-proof selection for next-generation communication and sensing technologies.

Conclusion

Rogers DiClad 880 high frequency PCBs provide an optimal combination of low dielectric loss, stable mechanical properties, and excellent reliability—enabling advanced electronic systems to perform with precision. Whether you are developing RF communication modules, aerospace radar, or advanced antenna systems, DiClad 800 delivers the performance and quality your application demands.

As an experienced PCB supplier, we offer end-to-end manufacturing support for DiClad 880-based circuits, ensuring that your designs are realized with the highest standards of accuracy and repeatability.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com