How Does Rogers TMM10 PCB Material Enhance Thermal and Electrical Performance?

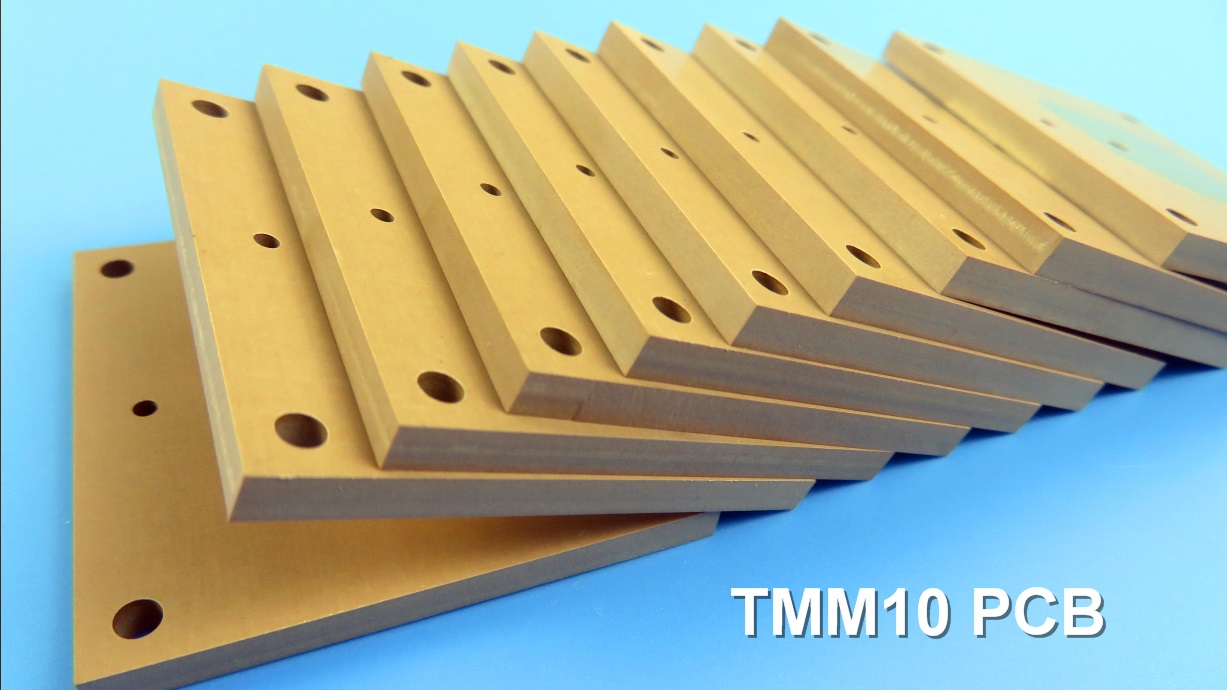

In the demanding world of high-frequency electronics, the choice of printed circuit board (PCB) substrate is paramount to the success of any application. Rogers Corporation's TMM10 microwave materials stand out as a superior solution, engineered to meet the rigorous requirements of modern RF and microwave circuits. This ceramic thermoset polymer composite is specifically designed for high plated-through-hole (PTH) reliability in both stripline and microstrip configurations, offering a unique blend of electrical and mechanical properties that bridge the gap between traditional materials.

Superior Material Properties for Enhanced Performance

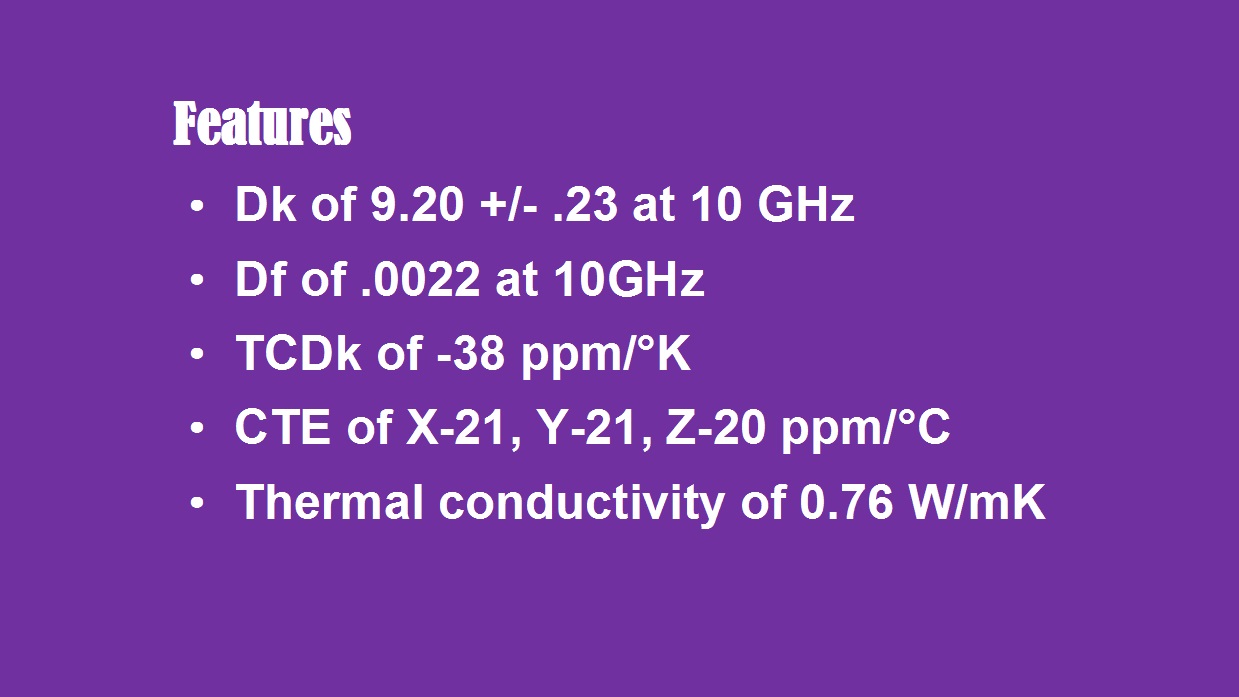

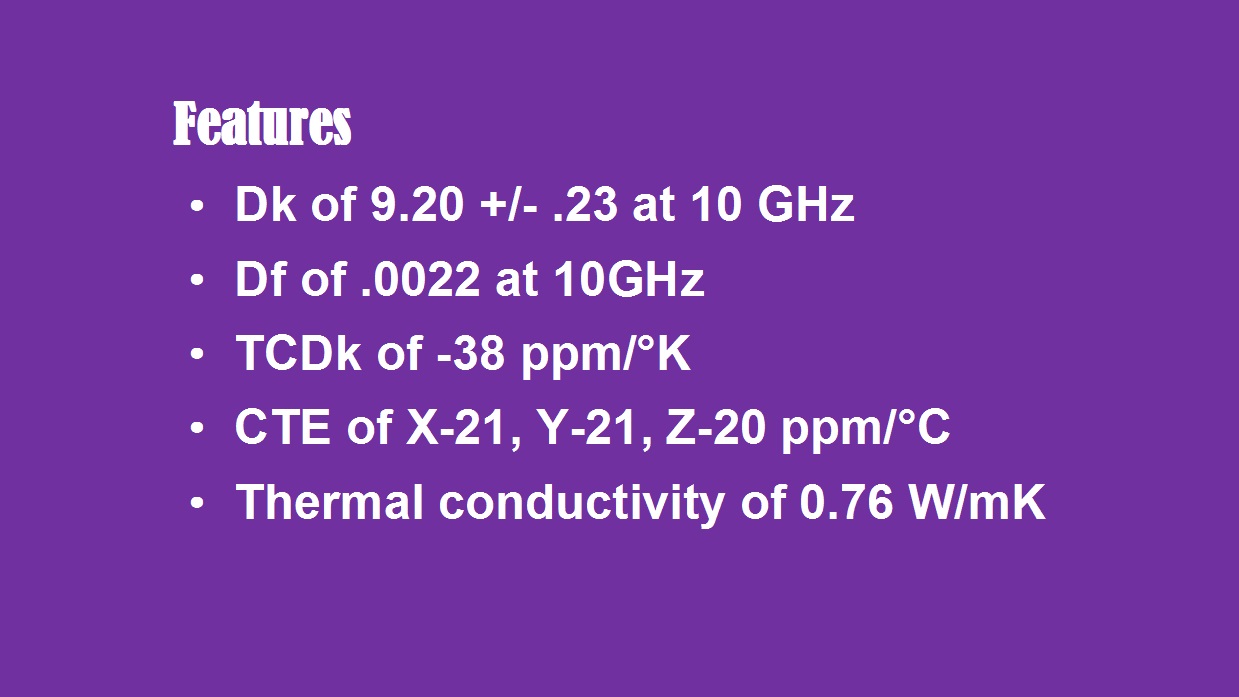

The TMM10 substrate is celebrated for its exceptional electrical characteristics, which directly contribute to more efficient and compact circuit designs. It boasts a stable dielectric constant (Dk) of 9.20 with a tight tolerance of±0.23. This high and consistent Dk is a significant advantage for designers aiming to minimize the physical size of components like antennas and filters, enabling substantial miniaturization without compromising performance.

A critical factor in high-frequency applications is signal integrity, which is safeguarded by TMM10's remarkably low dissipation factor of 0.0022 at 10 GHz. This minimal loss tangent ensures that signal loss is drastically reduced, leading to enhanced efficiency and superior performance in power-sensitive applications. Furthermore, the thermal coefficient of dielectric constant (-38 ppm/°K) guarantees outstanding electrical stability across a wide range of operating temperatures, making it reliable in environments subject to thermal fluctuations.

TheTMM10 PCBmaterial’s mechanical and thermal properties are equally impressive. With a coefficient of thermal expansion (CTE) of 21 ppm/°K on the X and Y axes and 20 ppm/°K on the Z-axis, TMM10 closely matches the CTE of copper. This compatibility is crucial for producing highly reliable plated through-holes, preventing barrel cracking and ensuring long-term structural integrity. Additionally, its thermal conductivity of 0.76 W/m/K is approximately double that of standard PTFE/ceramic laminates, significantly improving heat dissipation and helping to manage thermal loads in power-amplifier and other heat-sensitive applications. The robust mechanical properties also effectively resist creep and cold flow, ensuring dimensional stability and durability under stress.

Advanced PCB Manufacturing Capabilities with TMM10

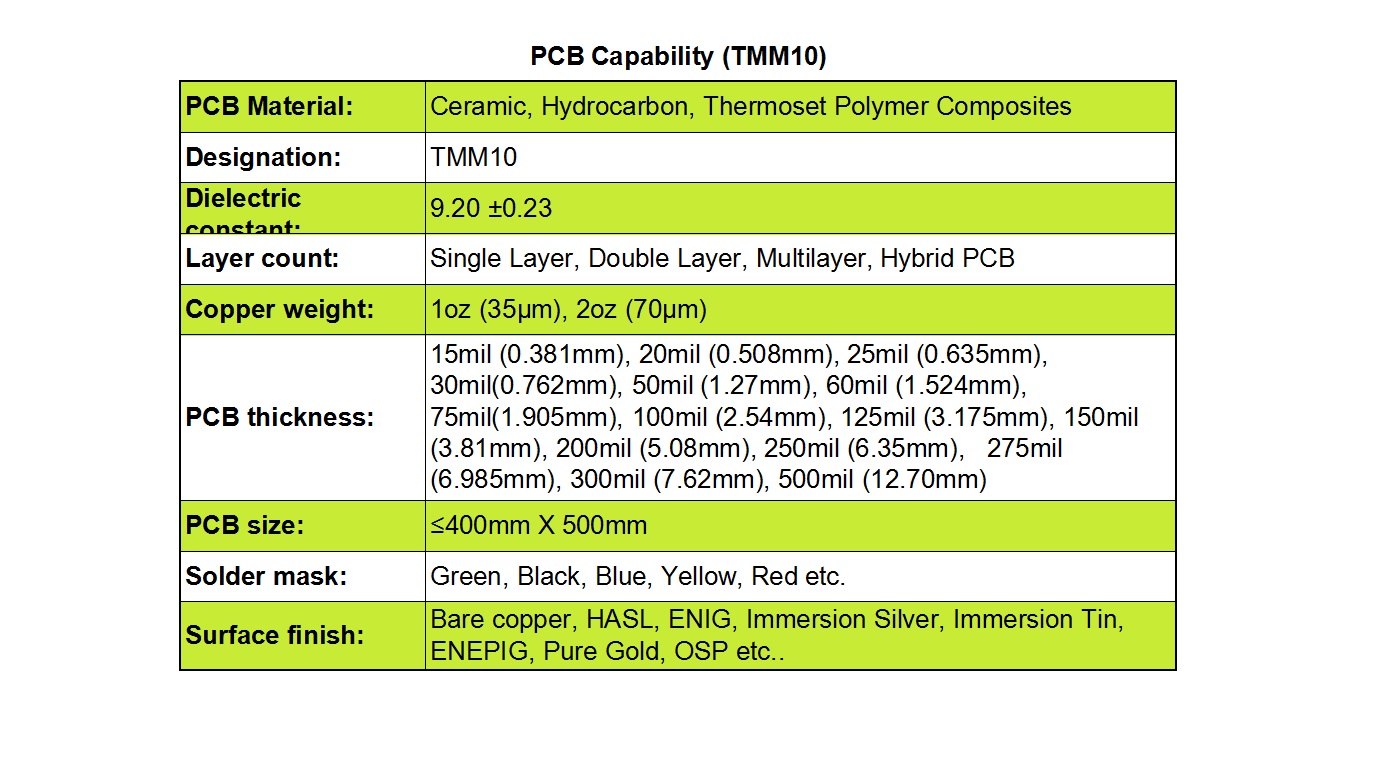

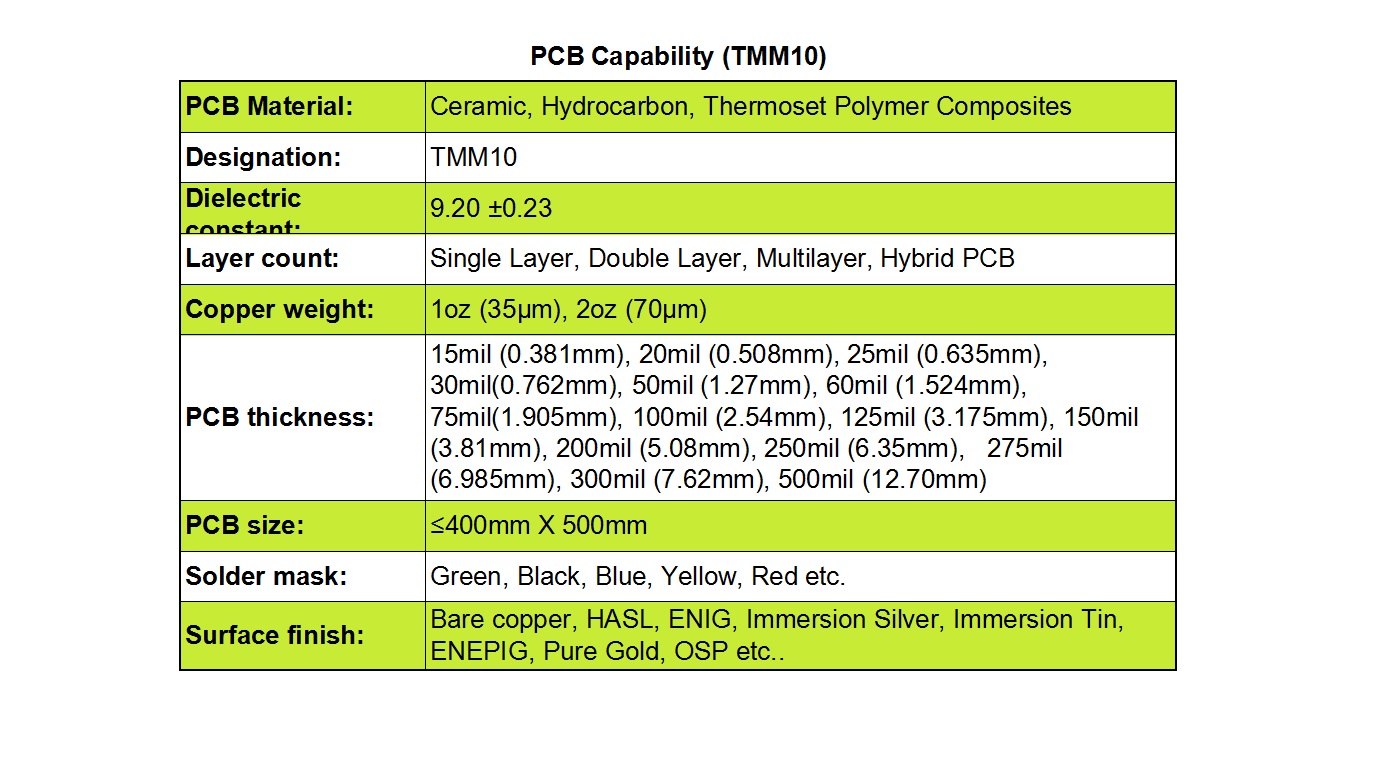

At Bicheng, we leverage our advanced manufacturing expertise to fully harness the potential of Rogers TMM10 laminates. We provide comprehensive PCB solutions tailored to diverse and complex project requirements. Our capabilities include the production of:

1)Layer Variations: Single-layer, double-layer, multilayer, and hybrid PCB constructions, offering design flexibility for various circuit complexities.

2)Copper Weights: Standard options of 1oz (35µm) and 2oz (70µm) to cater to different current-carrying and thermal management needs.

3)Board Thickness: A wide range from a slender 15mil (0.381mm) to a substantial 500mil (12.70mm), supporting everything from ultra-compact to extremely robust and durable designs.

4)Panel Size: Capable of handling large formats up to 400mm x 500mm, ideal for sizable projects and efficient panelization.

5)Aesthetics and Finish: A selection of solder mask colors (green, black, blue, yellow, red) and a variety of surface finishes including Bare Copper, HASL, ENIG, Immersion Silver, Immersion Tin, ENEPIG, Pure Gold, and OSP to meet both technical and aesthetic specifications.

Diverse Application Spectrum

The exceptional properties of TMM10 PCBs make them the material of choice for a wide array of high-performance applications. They are commonly deployed in:

1)Chip Testers: Where signal integrity and thermal stability are critical for accurate testing.

2)Dielectric Polarizers and Patch Antennas: Benefiting from the stable high Dk for compact, efficient design.

3)Satellite Communication Systems and GPS Antennas: Where low signal loss and reliability under varying environmental conditions are non-negotiable.

Conclusion

Rogers TMM10 represents a paradigm shift in high-frequency PCB materials, combining the best attributes of ceramics and polymers without their inherent limitations. For engineers designing next-generation RF and microwave products, TMM10 offers a path to miniaturization, enhanced reliability, and superior electrical performance. As a trusted PCB supplier, Bicheng possesses the technical proficiency to transform this advanced material into high-quality, reliable circuit boards that meet your most challenging application demands.

Contact us today to discuss how we can support your specific project needs with our TMM10 high frequency PCB capabilities.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com