Why Does the Color of Immersion Gold on PCBs Vary?

An In-Depth Analysis of ENIG Process and Its Influencing Factors

In modern electronics manufacturing, the surface finish of printed circuit boards (PCBs) plays a critical role in determining the performance and reliability of the final product. Electroless Nickel Immersion Gold (ENIG), a widely used surface finish, is favored for its excellent solderability, oxidation resistance, and electrical conductivity. It is commonly applied in high-reliability electronic products. However, many customers have noticed subtle differences in the color of immersion gold when they receive their PCBs. This raises the question: Why does the color of immersion gold vary? This article delves into the principles of the ENIG process, its influencing factors, and the reasons behind color variations, using specific PCB examples to illustrate these points.

The Fundamentals of the ENIG Process

The ENIG process is a chemical plating technique that involves two main steps: electroless nickel plating and immersion gold plating. First, a uniform layer of nickel, typically 3-6 microns thick, is chemically deposited on the PCB surface. The nickel layer serves as a reliable soldering surface and prevents oxidation of the underlying copper. Next, a thin layer of gold, usually 0.05-0.1 microns thick, is chemically deposited on top of the nickel layer. The gold layer protects the nickel from oxidation and ensures excellent contact performance.

The ENIG process is advantageous because it provides a flat surface, making it suitable forhigh-density interconnect (HDI) PCB designs and fine-pitch component soldering. Additionally, the ENIG surface offers superior oxidation resistance, maintaining its solderability even after prolonged storage.

Reasons for Color Variations in Immersion Gold

Although the ENIG process is theoretically expected to produce a consistent golden-yellow surface, in practice, the color of immersion gold can vary. These color differences are primarily caused by the following factors:

1. Variations in Gold Thickness

The thickness of the gold layer is one of the main factors influencing the color of immersion gold. While the gold layer typically ranges from 0.05 to 0.1 microns, even minor variations within this range can lead to noticeable color differences. A thicker gold layer tends to appear deeper and richer in color, while a thinner layer may look slightly lighter. These variations can result from slight fluctuations in process parameters, such as immersion time, temperature, or solution concentration.

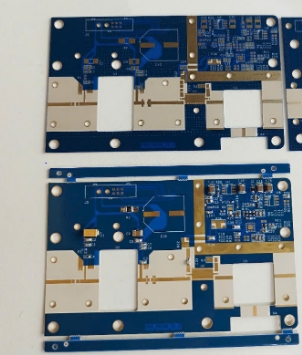

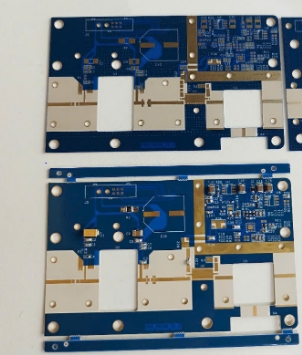

For example, consider two different PCB specifications:

2-layer, RF-35, 20mil material, ENIG

2-layer, RO4350B, 30mil material, ENIG

In the case of the RF-35 material, which is ahigh-frequency laminate, the gold thickness might be optimized for signal integrity, potentially resulting in a slightly thinner gold layer. On the other hand, the RO4350B material, known for its excellent thermal stability, might require a thicker gold layer to ensure durability under high-temperature conditions. These differences in gold thickness can lead to subtle color variations between the two high frequency PCBs.

2. Influence of Base Material Color

The color of the PCB base material can also affect the final appearance of the immersion gold. Although the gold layer covers the nickel layer, the base material's color can still subtly influence the overall appearance through reflection. For example, a darker base material may make the immersion gold surface appear slightly darker, while a lighter base material may make it appear brighter.

In the case of the 2-layer, RF-35 20mil material, ENIG, theRF-35 laminate has a distinct dark brown color, which might cause the immersion gold to appear slightly darker. Conversely, the 2-layer, RO4350B 30mil material, ENIG uses a lighter-colored laminate, which could make the immersion gold appear brighter and more vibrant.

3. Impact of the Nickel Layer

The nickel layer, as an intermediate layer in the ENIG process, also plays a role in determining the final color. The nickel layer typically ranges from 3 to 6 microns in thickness. However, if the nickel layer is uneven or has defects, it can lead to inconsistent gold deposition, affecting the overall color uniformity. Additionally, the inherent color of the nickel layer (usually silver-white) can influence the final appearance of the immersion gold.

For instance, in the 2-layer, Taconic RF-35, 20mil material, ENIG, the nickel layer might be optimized for high-frequency performance, potentially leading to a more uniform but slightly thinner nickel layer. In contrast, the 2-layer, Rogers RO4350B, 30mil material, ENIG might have a thicker nickel layer to enhance thermal performance, which could result in a slightly different color tone.

4. Variations in Process Parameters

The ENIG process involves multiple chemical steps, and each step's parameters (e.g., temperature, time, solution concentration) can impact the final result. Even minor fluctuations within the controlled range can cause color variations. For instance, a slightly longer immersion time may result in a thicker gold layer, altering the color.

In the case of the 2-layer RF-35 PCB, 20mil material, ENIG, the process parameters might be adjusted to prioritize high-frequency performance, potentially leading to a shorter immersion time and a thinner gold layer. On the other hand, the 2-layer RO4350B PCB, 30mil material, ENIG might undergo a longer immersion time to ensure a thicker gold layer for enhanced durability, resulting in a richer golden color.

5. Lighting and Viewing Angle

The color of the immersion gold surface can also be influenced by lighting conditions and viewing angles. Under different lighting conditions, the surface may exhibit varying tones. For example, natural light may make the surface appear brighter, while artificial lighting may make it appear slightly darker. Additionally, the viewing angle can cause subtle shifts in color perception.

Does Color Variation Affect Performance?

While color variations in immersion gold may raise concerns, they generally do not impact the performance of the PCB. The primary purpose of the ENIG process is to provide a reliable soldering surface and oxidation resistance, which are determined by the thickness and uniformity of the gold and nickel layers, not the color. As long as the thickness of these layers falls within the specified range, color differences will not significantly affect the PCB's electrical performance or solderability.

For example, both the 2-layer, RF-35, 20mil material, ENIG and the 2-layer, RO4350B, 30mil material, ENIG are designed to meet specific performance requirements. The RF-35 PCB is optimized for high-frequency applications, while the RO4350B PCB is designed for high thermal stability. Despite potential color differences, both PCBs will perform reliably in their intended applications.

Conclusion

The ENIG process, as a critical surface finish for PCBs, can exhibit color variations due to factors such as gold thickness, base material color, nickel layer thickness, and process parameters. While these variations may concern customers, they typically do not affect the PCB's performance. By strictly controlling process parameters, optimizing base material selection, and enhancing quality inspection, PCB manufacturers can effectively reduce color variations and ensure product consistency and reliability.

For customers, understanding the reasons behind color variations in immersion gold helps them better appreciate the complexities of PCB manufacturing and maintain realistic expectations regarding appearance. Ultimately, the core value of the ENIG process lies in its ability to provide excellent solderability and oxidation resistance, which are essential for ensuring the long-term reliability of electronic products. Whether it's a 2-layer, RF-35, 20mil material, ENIG for high-frequency applications or a 2-layer, RO4350B, 30mil material, ENIG for high thermal stability, the ENIG process delivers consistent performance, even if the color varies slightly.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com