F4BME Series Laminates High Frequency Aluminum-based PCB F4BME225

Introduction

F4BME series laminates are made by scientifically formulating and strictly pressing a combination of fiberglass cloth, polytetrafluoroethylene resin, and polytetrafluoroethylene film. Its electrical performance is improved compared to F4B, mainly due to a wider range of dielectric constants, lower dielectric loss, increased insulation resistance, and improved stability. It can replace similar foreign products.

F4BME and F4BM have the same dielectric layer but different copper foil combinations: F4BME is paired with reverse-treated foil (RTF) copper foil, offering excellent PIM performance, more precise line control, and lower conductor loss. F4BM is paired with ED copper foil, suitable for applications without PIM requirements.

By adjusting the ratio between polytetrafluoroethylene and fiberglass cloth, F4BM and F4BME achieve precise control of the dielectric constant, providing low loss and enhanced dimensional stability. A higher dielectric constant corresponds to a higher proportion of fiberglass, resulting in better dimensional stability, lower thermal expansion coefficient, improved temperature drift, and a slight increase in dielectric loss.

Features & Benefits

-DK options available: 2.17 to 3.0, customizable DK

-Low loss

-F4BME paired with RTF copper foil, excellent PIM performance

-Diverse sizes, cost-effective

-Radiation resistance, low outgassing

-Commercialized, large-scale production, high cost-effectiveness

Laminate Models and Data Sheet

|

Product Technical Parameters

|

Product Model & Data Sheet

|

|

Product Features

|

Test Conditions

|

Unit

|

F4BME217

|

F4BME220

|

F4BME233

|

F4BME245

|

F4BME255

|

F4BME265

|

F4BME275

|

F4BME294

|

F4BME300

|

|

Dielectric Constant (Typical)

|

10GHz

|

/

|

2.17

|

2.2

|

2.33

|

2.45

|

2.55

|

2.65

|

2.75

|

2.94

|

3.0

|

|

Dielectric Constant Tolerance

|

/

|

/

|

±0.04

|

±0.04

|

±0.04

|

±0.05

|

±0.05

|

±0.05

|

±0.05

|

±0.06

|

±0.06

|

|

Loss Tangent (Typical)

|

10GHz

|

/

|

0.001

|

0.001

|

0.0011

|

0.0012

|

0.0013

|

0.0013

|

0.0015

|

0.0016

|

0.0017

|

|

20GHz

|

/

|

0.0014

|

0.0014

|

0.0015

|

0.0017

|

0.0018

|

0.0019

|

0.0021

|

0.0023

|

0.0025

|

|

Dielectric Constant Temperature Coefficient

|

-55ºC~150ºC

|

PPM/℃

|

-150

|

-142

|

-130

|

-120

|

-110

|

-100

|

-92

|

-85

|

-80

|

|

Peel Strength

|

1 OZ F4BM

|

N/mm

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

|

1 OZ F4BME

|

N/mm

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

|

Volume Resistivity

|

Standard Condition

|

MΩ.cm

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

|

Surface Resistivity

|

Standard Condition

|

MΩ

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

|

Electrical Strength (Z direction)

|

5KW,500V/s

|

KV/mm

|

>23

|

>23

|

>23

|

>25

|

>25

|

>25

|

>28

|

>30

|

>30

|

|

Breakdown Voltage (XY direction)

|

5KW,500V/s

|

KV

|

>30

|

>30

|

>32

|

>32

|

>34

|

>34

|

>35

|

>36

|

>36

|

|

Coefficientof Thermal Expansion

|

XY direction

|

-55 º~288ºC

|

ppm/ºC

|

2,534

|

2,534

|

2,230

|

2,025

|

1,621

|

1,417

|

1,416

|

1,215

|

1,215

|

|

Z direction

|

-55 º~288ºC

|

ppm/ºC

|

240

|

240

|

205

|

187

|

173

|

142

|

112

|

98

|

95

|

|

Thermal Stress

|

260℃, 10s,3 times

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

|

Density

|

Room Temperature

|

g/cm3

|

2.17

|

2.18

|

2.20

|

2.22

|

2.25

|

2.25

|

2.28

|

2.29

|

2.29

|

|

Long-Term Operating Temperature

|

High-Low Temperature Chamber

|

℃

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

|

Thermal Conductivity

|

Z direction

|

W/(M.K)

|

0.24

|

0.24

|

0.28

|

0.30

|

0.33

|

0.36

|

0.38

|

0.41

|

0.42

|

|

PIM

|

Only applicable to F4BME

|

dBc

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

|

Flammability

|

/

|

UL-94

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

|

Material Composition

|

/

|

/

|

PTFE, Fiberglass Cloth

F4BM paired with ED copper foil, F4BME paired with reverse-treated (RTF) copper foil.

|

Our PCB Capability (F4BME )

|

PCB Capability (F4BME)

|

|

PCB Material:

|

PTFE glass fiber cloth copper clad laminates

|

|

Designation (F4BME )

|

F4BME

|

DK (10GHz)

|

DF (10 GHz)

|

|

F4BME217

|

2.17±0.04

|

0.0010

|

|

F4BME220

|

2.20±0.04

|

0.0010

|

|

F4BME233

|

2.33±0.04

|

0.0011

|

|

F4BME245

|

2.45±0.05

|

0.0012

|

|

F4BME255

|

2.55±0.05

|

0.0013

|

|

F4BME265

|

2.65±0.05

|

0.0013

|

|

F4BME275

|

2.75±0.05

|

0.0015

|

|

F4BME294

|

2.94±0.06

|

0.0016

|

|

F4BME300

|

3.00±0.06

|

0.0017

|

|

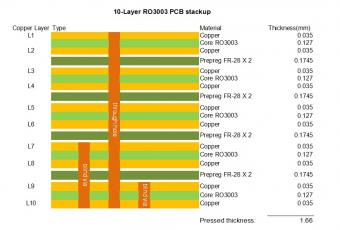

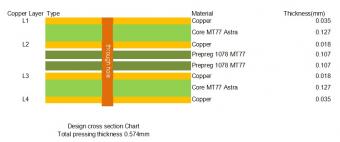

Layer count:

|

Single Sided, Double Sided PCB, Multilayer PCB, Hybrid PCB

|

|

Copper weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

Dielectric thickness (or overall thickness)

|

0.127mm (dielectric), 0.2mm, 0.25mm, 0.5mm, 0.508mm, 0.762mm, 0.8mm, 1.0mm, 1.5mm, 1.524mm, 1.575mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface finish:

|

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold, ENEPIG etc..

|

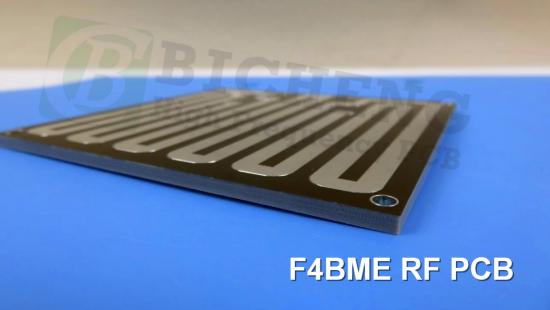

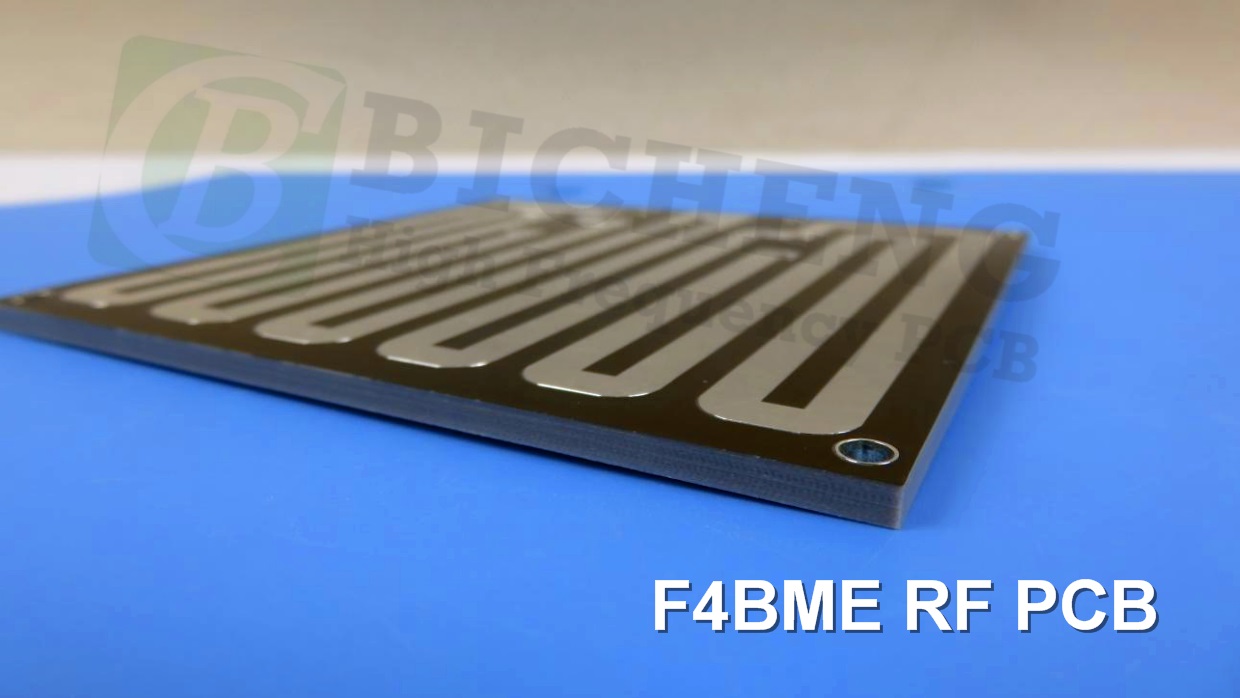

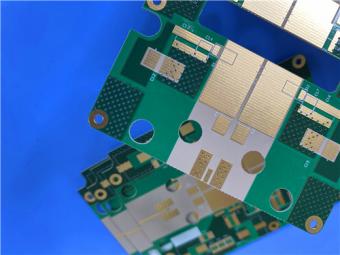

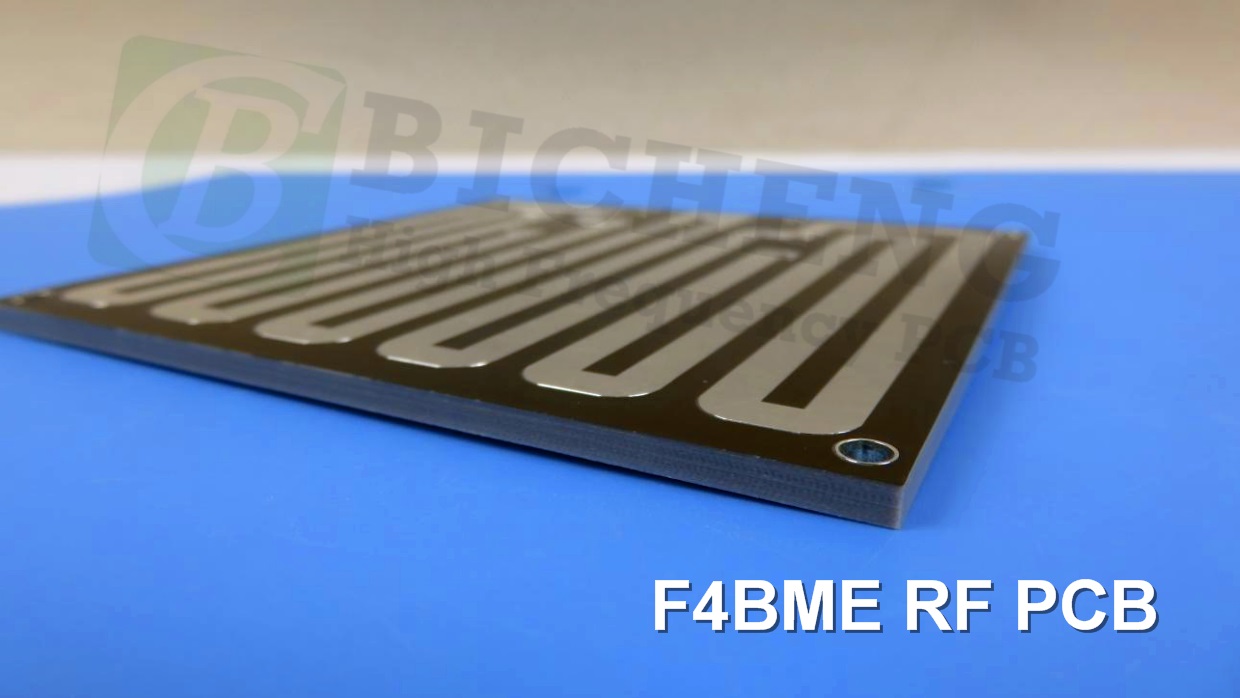

A PCB and Typical Applications

Displayed on the screen is a 2-layer copper F4BME PCB with a low DK of 2.2, utilizing F4BME material and HASL surface finish on a F4BME 3.0mm substrate.

F4BME high-frequency PCB finds applications in microwave, RF, and radar systems, as well as in phase shifters, passive components, power dividers, couplers, combiners, feed networks, phased array antennas, satellite communications, and base station antennas.

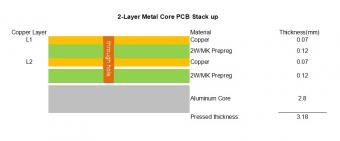

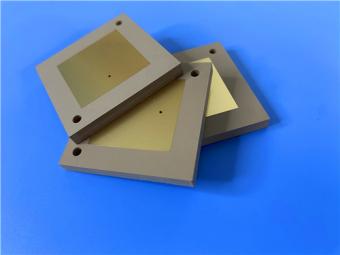

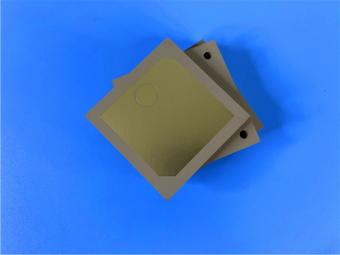

Final -F4BME series aluminum-based/copper-based boards

These F4BME series laminates can provide aluminum-based or copper-based materials, where one side of the dielectric layer is covered with copper foil, and the other side is covered with either aluminum-based material orcopper-based , serving as shielding or heat dissipation purposes.

Model examples

F4BME225-CU represents F4BME225 with ancopper-based substrate.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com